5.2. PULLING OUT THE WIRE ROPE

5.2.1. The wire rope has been installed on the winch under minimal load at the factory. It must be re-spooled onto the drum so the outer

layers will not draw down into the inner layers, causing damage to the rope.

5.2.2. Pullandrotatetheclutchlevertothe,“disengaged”positionasshowning.10.Ifthereisaloadonthewirerope,theclutchlever

may not turn easily. DO NOT force the clutch lever. Release the tension on the wire rope by paying out some of the wire rope, then try

releasing the clutch.

5.2.3. Pull out the wire rope and secure it to an anchor or a load.

5.2.4. Checkthatthereareatleastveturnsofwireropeleftonthedrum.

5.2.5. Re-engagethedrumbyrotatingtheclutchlevertothe“engaged”position,seeg.10.

WARNING! The lever must be in the engaged position and locked before winching.

5.2.6. Your winch incorporates a proportional friction-type brake. After winching in a load, this mechanism holds the load, up to the rated

capacity of the winch. While powering out the load, the winch controls the rate of speed by applying the brake in proportion to the

amount of load on the wire rope. This results in heavier loads powering-out more slowly than lighter loads. Similar to the friction-type

brakes in your car which can generate heat if used for a long time, the winch brake can generate heat if used to power-out a load

for a long period of time. To ensure optimum winch performance, always limit powering-out a load to one minute and allow the brake

tocoolforfteenminutesbeforecontinuingtowinch.Undernormalusethebrakemechanismshouldnotrequireanyadjustment.

Should the brake fail to hold a load or maintain a constant rate of speed during a powering-out operation, the brake pad may be worn

and require replacement.

5.2.7. Keep a tightly wound wire rope drum. DO NOT allow the windings on the drum to become loosely wound. A loosely wound drum allows

wire rope under load to work its way down into the layers of wire rope on the drum. When this occurs, wire rope may become wedged

within the body of the windings causing damage to the wire rope. To prevent this keep the wire rope tightly and evenly wound on the

drum at all times. Rewind the rope under tension after each use. One method is to attach the hook to a stationary object at the top of a

small hill or incline and winch your vehicle up the incline.

8DO NOT allow the motor to overheat. The winch is designed for intermittent use only. During long or heavy pulls the motor will get hot,

with its internal parts hotter than the case. To check motor temperature, stop winching and carefully touch the end of the motor. If

uncomfortably warm, allow the motor to cool before continuing. Keep engine running to recharge battery during this break.

5.2.8. The pull required to start a load moving is often much greater than the pull to keep it moving. Avoid stopping and starting during a pull

except when required by motor temperature.

5.2.9. Prevent kinks in the cable before they occur, by keeping an even tension on the cable when paying in. (Refer to 5.2.6).

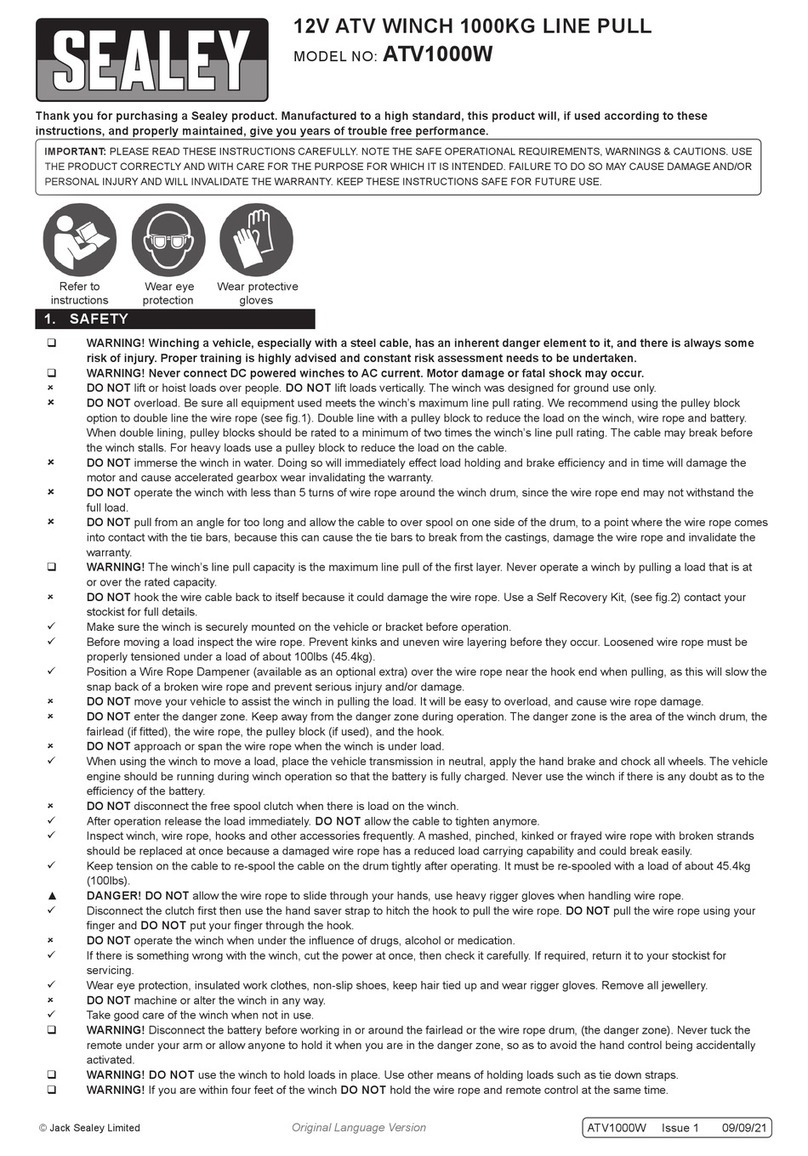

5.2.10. Equipping the winch with a roller fairlead (supplied) will substantially reduce wear on the wire rope during angle pulls, because rollers

eliminateheavyrubbingandabrasiontothewirerope,seeg.11.

NOTE: Never winch your vehicle in gear or in park, which would damage your vehicle’s transmission.

Never wrap the wire rope around an object and hook the cable back onto itself, this can cause damage to the object being pulled and

kink or fray the wire rope.

Keep hands, clothing, hair and jewellery clear of the drum and cable when winching.

Never use the winch if the cable is frayed, kinked or damaged.

Never allow anyone to stand near the cable, or in line with the cable or behind the winch while it is under power. If the cable should slip

or break it can suddenly whip back towards the winch, causing great danger for anyone in the area. Always stand well to the side while

winding and use a wire rope dampener.

8DO NOT leave the switch plugged in when the winch is not in use.

CHECK THE WINCH THOROUGHLY AND CAREFULLY BEFORE OPERATING!

6. MAINTENANCE

6.1. It is strongly recommended that the winch is used regularly (once a month). Simply power out 15mtr

of cable, free spool 5mtr then power back in. This will keep all the components in good working

condition so that the winch can be relied on when needed.

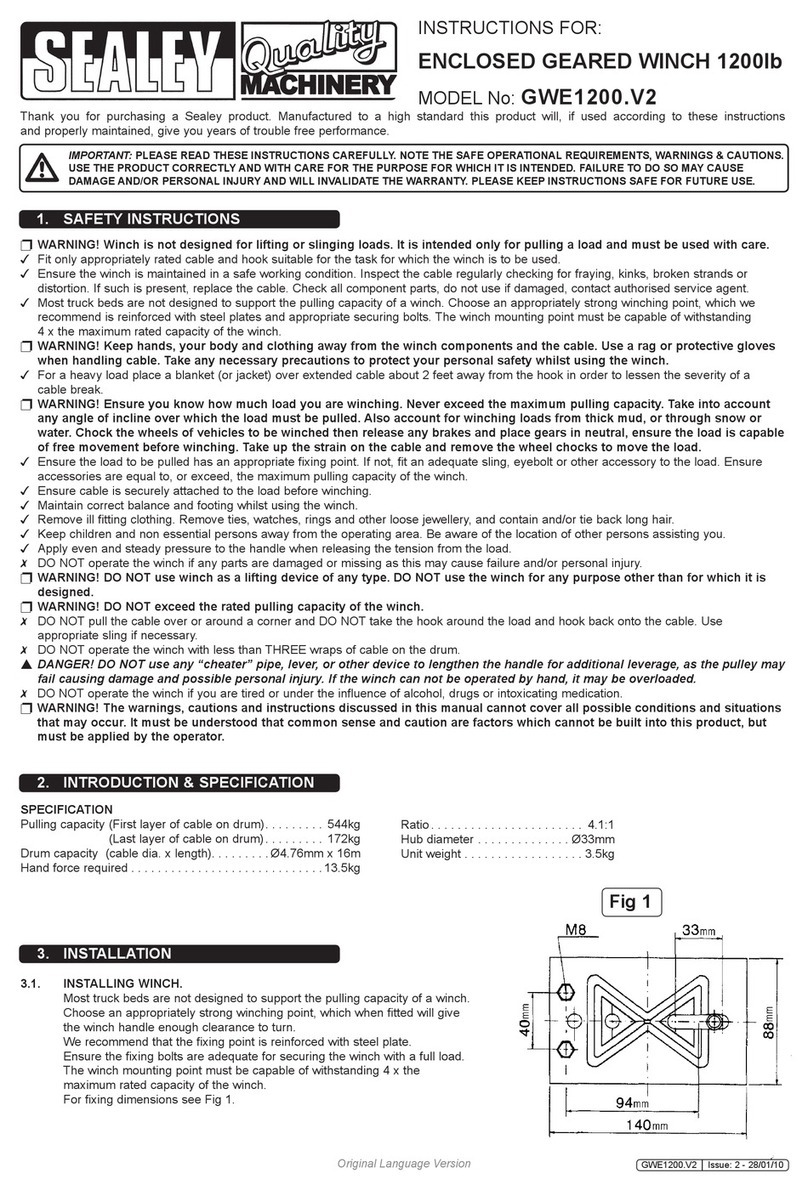

Fig.11

Sealey Group, Kempson Way, Suffolk Business Park, Bury St Edmunds, Suffolk. IP32 7AR

01284 757500 01284 703534 sales@sealey.co.uk www.sealey.co.uk

Note: It is our policy to continually improve products and as such we reserve the right to alter data, specifications and component parts without prior

notice.

Important: No Liability is accepted for incorrect use of this product.

Warranty: Guarantee is 12 months from purchase date, proof of which is required for any claim.

ENVIRONMENT PROTECTION

Recycle unwanted materials instead of disposing of them as waste. All tools, accessories and packaging should be sorted, taken to

a recycling centre and disposed of in a manner which is compatible with the environment. When the product becomes completely

unserviceable and requires disposal, drain any fluids (if applicable) into approved containers and dispose of the product and fluids

according to local regulations.

WEEE REGULATIONS

Dispose of this product at the end of its working life in compliance with the EU Directive on Waste Electrical and Electronic Equipment

(WEEE). When the product is no longer required, it must be disposed of in an environmentally protective way. Contact your local solid

waste authority for recycling information.

RW5675.V2 Issue:2(S) 02/05/18

Original Language Version

© Jack Sealey Limited