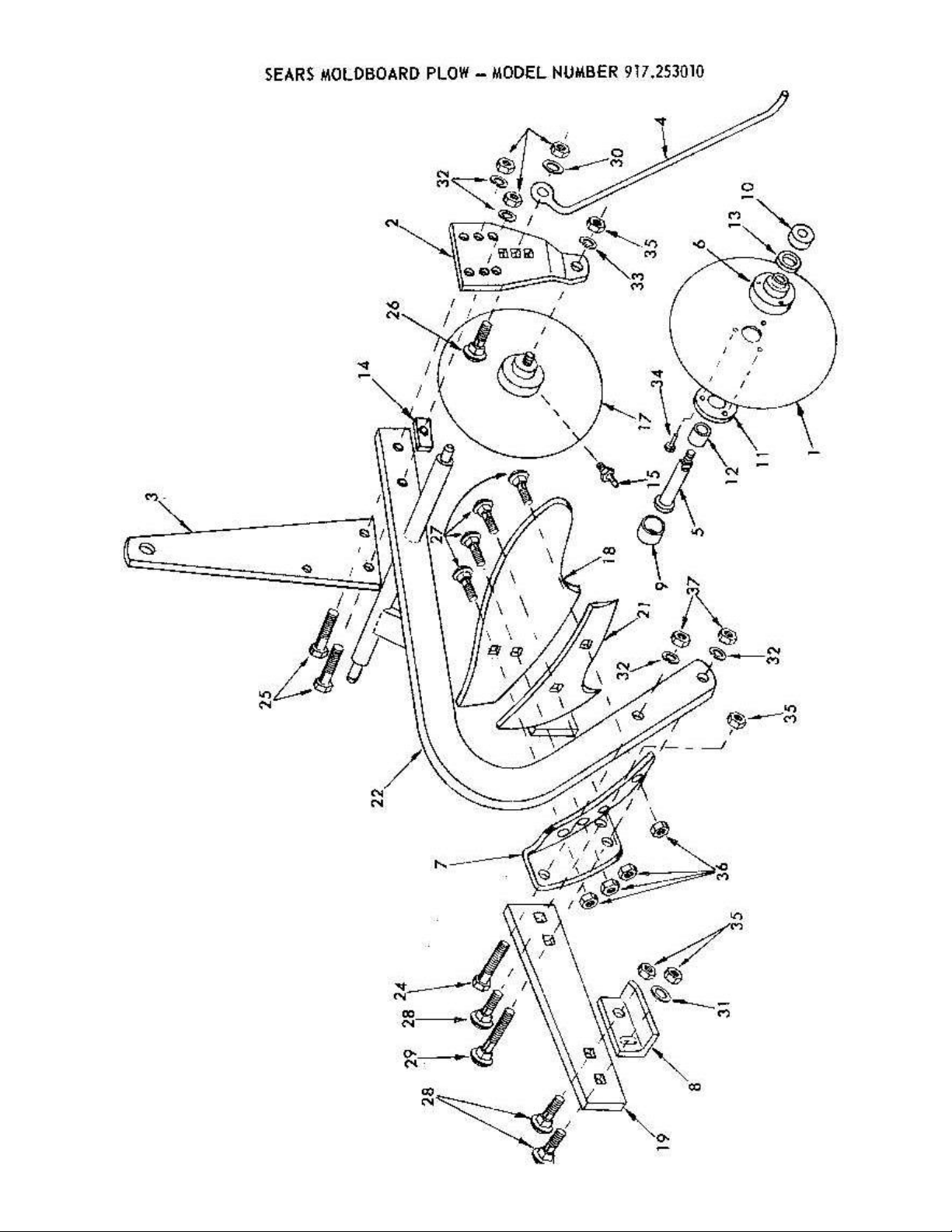

OPERATING INSTRUCTIONS – Continued

In laying out a land, the plot should be measured and staked out so that the furrows will come out even when the ploot is

finished. Stakes at each end, will enable the operator to drive the tractor straight across the field so that the furrows will

make a neat appearance. Set the plow so that the first furrow is plowed about one half the depth you would normally

plow; beam must be vertical. This half depth is required so that first furrows are turned properly. Drive the tractor across

the plot in as straight a line as possible. Turn tractor and plow back across the plot, running the R.H. wheel of the tractor

as close to the previously plowed ground as possible, o if desired directly on the first plowed ground.

The tractor can now be driven with the R.H. front wheel next to the furrow wall of the first furrow made and plow

immediately returned to the ground. The top linkage (adjusting screw and clevises), must be shortened so that plow will

penetrate (or plow), to the desired depth. Adjust R.H. lift links to keep beam vertical. Upon arriving at the opposite end,

lift the plow from the ground and turn tractor around driving with R.H. front wheel next to the furrow wall. Proceed by

following in each successive furrow until the plot has been completely plowed.

If you decide to fall plow, your gardening should be planned so that your plowing can be done as early as possible;

especially before the ground becomes dry and hard. Ground which is dry and hard will cause the plow to be unstable and

you will be unable to penetrate the ground to an even depth. Also, these conditions will cause the plow to pull hard and

overload the tractor.

It is undesirable to plow when the ground is too wet. This condition is most likely to occur when attempting to spring plow.

If the ground is too wet, the soil will slide from the moldboard in an almost solid mass, slick and shiny. After the ground

has been exposed to the sun and starts to dry it will become hard and you will be unable to work it into a suitable seed

bed. A good test to determine if the soil is too wet is to take a handful of soil and try to compress it into a ball, if it

crumples as soon as released from the hand, it probably is suitable to plow.

PLOW ADJUSTMENTS

DEPTH

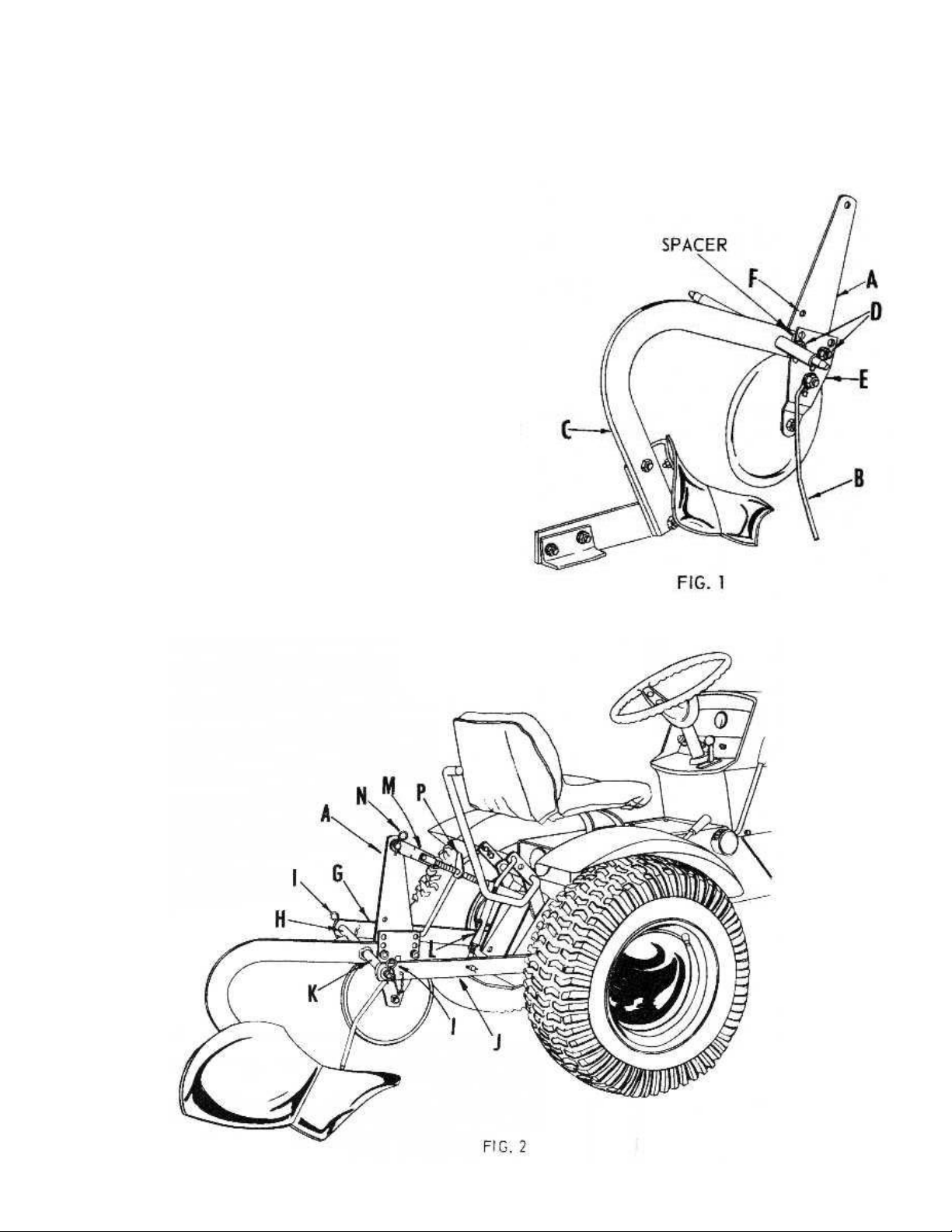

To increase the plowing depth, adjust the top linkage by turning adjusting screw (P, Fig. 2), to shorten the linkage. The

plow will go deeper until plow levels, and under normal conditions will hold that depth. This levels the plow and will leave

a level furrow bottom. Adjustment can be varied to give a better furrow turning.

Actually measure the width of the cut with a ruler to determine width of cut. This should be done where the furrow is

straight to get an accurate measurement. A depth of more than 6 inches is not recommended.

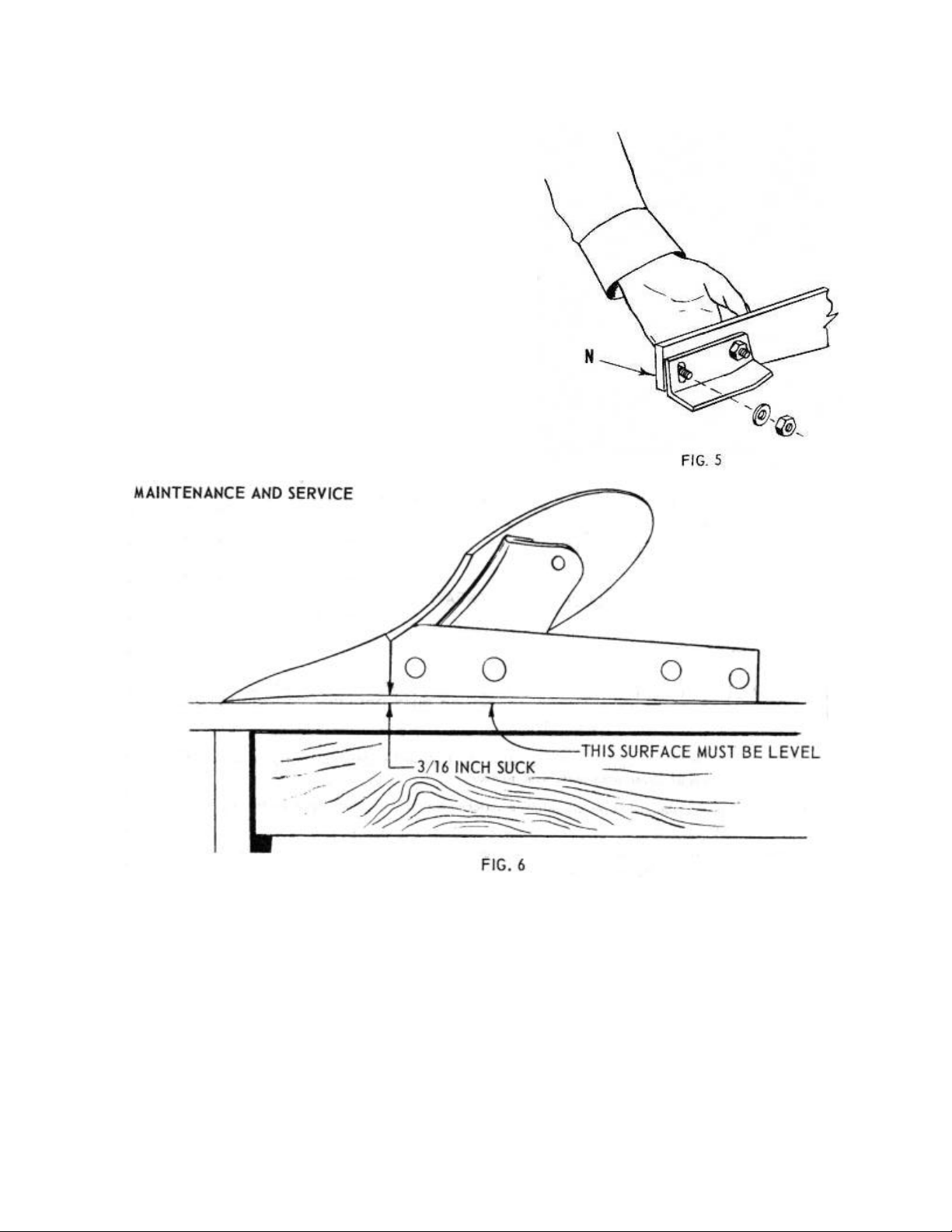

COULTER

The depth to which the coulter cuts is adjusted by raising or lowering the counter bracket with respect to the beam by the

three sets of holes provided.

When the ground is very hard, the coulter should be raised so that it will not interfere with depth of plowing. The blade

should run just deep enough to cut through all trash and leave a smooth furrow wall. When operating in soil where large

stones are prevalent, the coulter and bracket should be removed as a complete unit from the beam, to prevent the coulter

from holding or raising the plow bottom from the ground.

A grease fitting is provided in the coulter hub and should be greased before first operation and after every four hours of

operation. CAUTION: Care should be taken to avoid excessive pressure when greasing so as not to force hub cap off the

hub.

The cutting edge should be kept sharp at all times and can be sharpened by filing or grinding on an emery wheel. If the

coulter blade becomes rusty it should be repolished with 00 sandpaper and crocus cloth.

WEED ROD

The purpose of the weed rod is to aid in tuning under all weeds, grass, etc. It is adjustable by means of its attaching biolt.

It should be set according to the depth of plowing and material being turned under.

COUNTERWEIGHT

A front end counterweight should be attached to tractor if front end of tractor becomes too light and is difficult to steer in a

heavy pull.

TRACTION

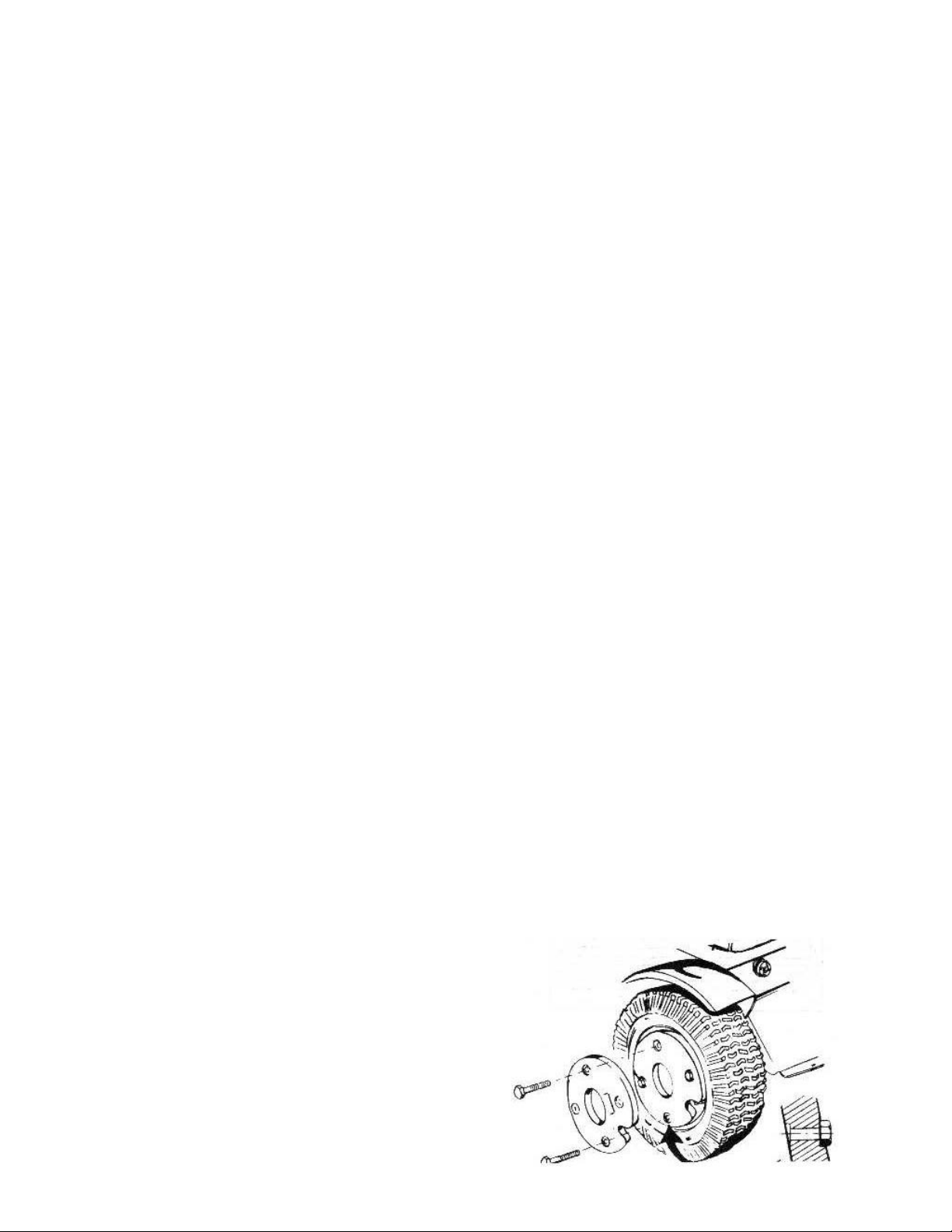

Two wheel weights assembled to L.H. rear wheel is

necessary for satisfactory plowing. The L.H. rear wheel

runs on top of the unplowed ground. Most of the weight

of the tractor is shifted to the R.H. rear wheel. This is

the reason for assembling the two wheel weights to the

L.H. rear wheel to prevent it from slipping.

If wheels still slip, another weight can be added to R.H.

rear wheel, and a calcium chloride solution can be

added to both rear tires. This added weight will increase

the traction to about half the weight added. Refer to

wheel weight manual for assembly instructions.

another free manual from www.searstractormanuals.com