OPERATING

INSTRUCTIONS

BEFORE

CUTTING

AN

UNFAMILIAR

PLOT

OF

GRASS,

ALWAYS

STOP

TO

ANALYZE

THE

LAWN

OR

FIELD

FOR

BEST

MOWING

PROCE-

DURE.

CONSIDER

ALSO

THE

HEIGHT

OF

GRASS

TO

BE

MOWED.

TYPE

OF

TERRAIN

(LEVEL,

HILLY

OR

PITTED),

AS

WELL

AS

THE

PRESENCE

OF

ROCK

OR

TRASH.

EACH

CONDITION

WILL

REQUIRE

CERTAIN

AD-

JUSTMENTS

OR

PRECAUTIONS

AS

OUT-

LINED

IN

THIS

MANUAL.

I

/

DO

NOT

STOP

OR

START

SUDDENLY

WHEN

GOING

UPHILL

OR

DOWNHILL.

OPERATE

MOWER

UP

AND

DOWN

THE

FACE

OF

SLOPES;

NEVER

ACROSS

THE

FACE.

NEVER

OPERATE

MOWER

ON

SLOPES

WITH

MORE

THAN

A

15

DEGREE

SLOPE.

The

blade

clutch

handle

is

located

at

right

hand

of mower on

cutter

head

or on R.H.

side

of

tractor

frame

depending

on

tractor.

The

blade

clutch

handle

engages

the

mo

wer

bl

ades.

1.

Set

engine

speed

to

about

half

throttle

before

engaging

or

disengaging

mower.

In

either

case,

engage

or

disengage

blade

.clutch

handle

slowly.

After

mower

is

engaged,

set

to

full

throttle.

Caution:

Never

engage

mower

except

when

sit-

ting on

tractor

seat,

and

keep

hands

and

feet

from

beneath

the

housing.

After mower

is

engag-

ed,

advance

throttle

lever

to full

throttle.

2.

Push

down on foot

pedal

and move

gear

shift

lever

to

speed

desired.

Normal

cutting

speed

is

1

st

gear

on a

three

speed

custom

tractor,

2nd

gear

011

a four

speed

custom

tractor,

or 3rd

gear

low

range

on a

eight

speed

custom

tractor.

If

engine

pulls

down,

shift

to

a lower

gear

on four

and

eight

speed

tractors,

and

cut

less

than

a

full width

cut

on a

three

speed

custom.

In

ex-

treme

heavy

cutting

it

may

be

necessary

to

use

the

lowest

gear

and

take

a narrower

cut.

Do

not

operate

the

tractor

in

high

gear

going

down

hill',

and

do

not

turn

sharp corners

while

going

down

hill.

If

it

is

necessary

to

stop tractor

while

going

down

hill,

do

so quickly

to

prevent

tractor

from

picking

up

speed

during

the

de-

clutching

to

braking operation.

NOTE:

The

engine produces considerable

braking

action

when

throttled back

to

idling

speed

without

de-

clutching,

and

this

procedure

is

recommended

before

applying brake.

3. Normal

cutting

height

is

'1-7/8

inches,

height

of

cut

can

be

adjusted

by

means

of

lift

lever.

Mov-

ing

the

lever

forward

lowers

the

mower

wh

iIe

moving

it

backwards

raises

the

mower. '

With

lift

lever

set

to

height

of

cut

desired

and

with

tractor

and mower on

level

ground,

adjust

gauge

wheel

s

so

that

they

c

lear

the

ground by

approximately

Y2

inch.

3828R-8.1.73

- 8 -

4. Make

left

hand

turn s when mowing,

this

spreads

the

grass

clippings

evenly

over

the

grass

which

has

been

cut.

Grass

is mowed

regularly

(do

not

let

grass

get

too

high),

there

is

little

or

no

raking

necessary

after

mowing.

WHEN

MOWING

NEXT

TO

BUILDINGS OR

FLOWER

BEDS

THE

TRACTOR

SHOULD

BE

DRIVEN SO

THAT

THE

DISCHARGE

OF

MOWER

WILL

BE

AWAY

FROM BUILDING OR FLOWER

BED.

Do

not

shift gears while

going

up

steep

hi

lis.

Choose a

low

enough

gear

to

cI

imb

h

ill

without

stopping

and

shifting gears. If

it

is necessary

to

stop

while

going

up

hill,

do

so quickly

to

prevent tractor

roll

ing

backward.

When

start

ing

tractor

in

motion

going

up

hill,

use

one

of

the

lowest gears, reduce engine speed

and

engage

clutch gradually

to

prevent tractor

from

"rearing

up".

maintenance

lubrication

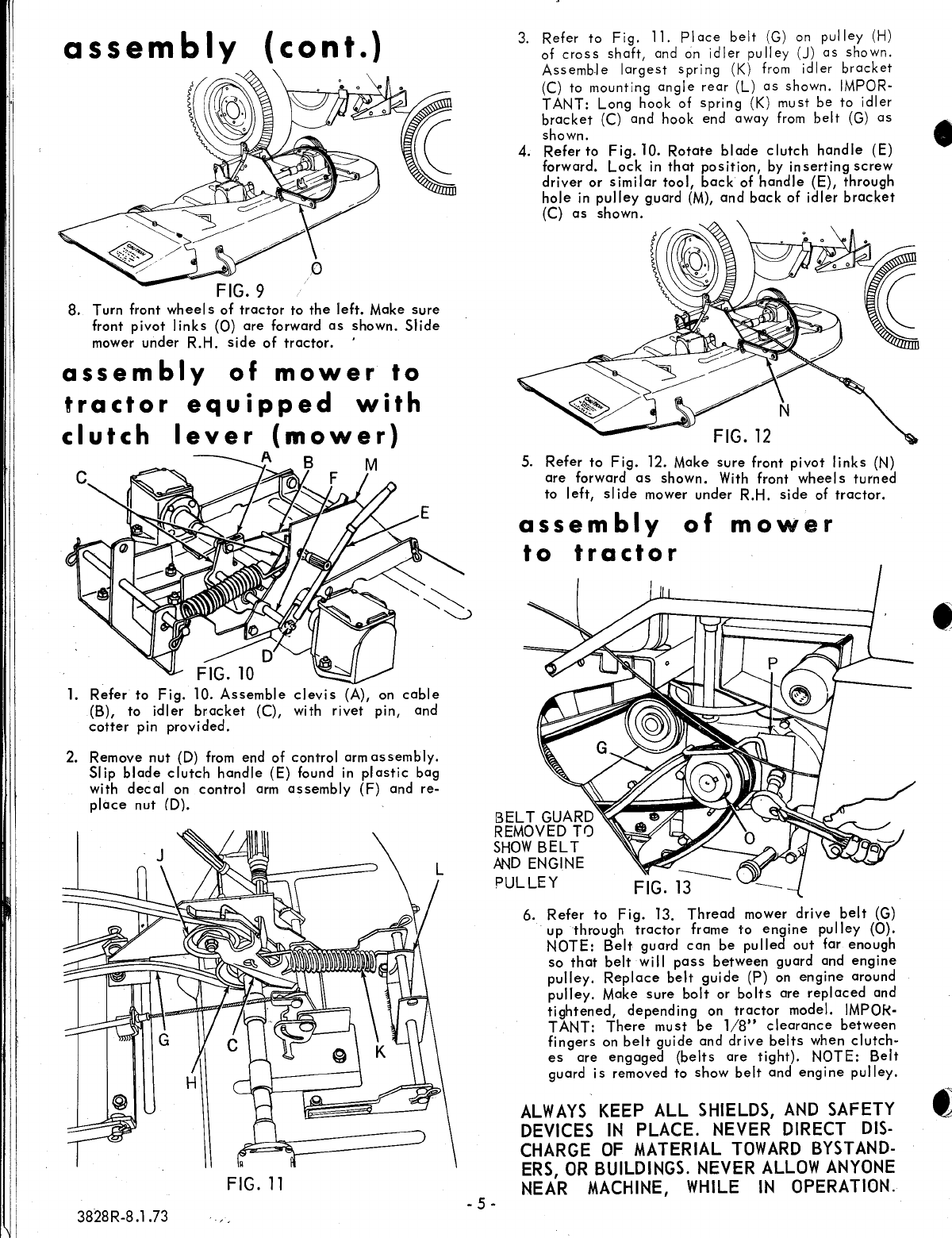

FIG.

23

1.

Check

grease

in

gear

boxes

after

each

fifty

hours

of

operation.

Each

gear

box

shou

Id

be

approximately

Y2

full.

Lubrication

-

Gear

case

moly

E.P.

lithium

grease

4

oz.

required

in

each

gear

box.

Can

be

purchased

from

Sears

automotive

department.

2.

To

check,

remove

gear

box

cover

by

unscrewing

4

screws.

See

Figure

23.

3.

Refer

to

Page

6,

Fig.

16.

Lubricate

cable

with

light

oil,

twice

a

year.

another free manual from www.searstractormanuals.com