SEFRAM CDM User manual

CDM-Sensor –Dust Emission

Incident Detector

Notice Technique

FI 72.0401.0819E

Page 1 / 12 - 1 -Page 1 sur 12 - 1 - - 1 - - 1 - - 1 -

PLACE GUTENBERG - 59175 TEMPLEMARS (France)

Tel: +33(0)3 20 60 49 49 - Fax: +33(0)3 20 95 59 62

Email: contact@sefram.eu Web: www.sefram.eu

Electronics dedicated to dedusting

and air quality

CDM-Sensor –Dust Emission

Incident Detector

Notice Technique

FI 72.0401.0819E

Page 2 / 12 - 2 -Page 2 sur 12 - 2 - - 2 - - 2 - - 2 -

GENERAL

The CDM is a controller of dust emission based on

triboelectricity principle. It is directly installed on the pipe

and the sensor is in direct contact with the air flow and

particles.

The CDM controls in real time the dust emission rate and

warns if this rate becomes higher than the ALARM and

ALERT level, adjusted by the operator on site.

The CDM reports the status of ALARM and ALERT level on

contact toggle switch.

An interface of visualization allows the user to check the

efficient running of the CDM.

The display also shows the trend of dust emission in %

compared to the threshold ALARM.

No material is needed to adjust the probe CDM. All the

adjustments are done thanks to the user interface

integrated in the CDM.

When we install the probe, it is necessary to start a self-

learning of the mean dust emission rate (PR) in normal

running conditions, and we must adjust several thresholds

necessary to have a good running of the CDM:

-Value X: Value in minutes: during this time, the

CDM defines a mean value of the dust

emission rate, in Measure mode or in PR self-

learning mode. This mean rate is recalculated

every second.

-Value n1: this value concerns the adjustment of

the ALERT threshold.

Threshold ALERT= n1 x PR

-Value n2 : this value concerns the adjustment

of the ALARM threshold.

Threshold ALARM = n2 x PR

SUMMARY

GENERAL Page 2

MECHANICAL ASSEMBLY Page 3

ELECTRICAL CONNECTIONS Page 4

ADJUSTMENTS Page 5

THE DEVICE Page 7

DYSFUNCTION Page 9

CHARACTERISTICS Page 10

GENERAL INSTRUCTIONS Page 11

FOR SAFETY, ASSEMBLY,

COMMISSIONING AND

MAINTENANCE

WARRANTY Page 12

CERTIFICATE Page 12

CDM-Sensor –Dust Emission

Incident Detector

Notice Technique

FI 72.0401.0819E

Page 3 / 12 - 3 -Page 3 sur 12 - 3 - - 3 - - 3 - - 3 -

MECHANICAL ASSEMBLY

The sensor is directly fixed on the pipe to monitor, in the following conditions:

- Thread G1/2"

-placed on the straight part of the pipe, following the drawing underneath,

-on a metallic pipe linked to earth, we must have a continuity of earth between the sensor and the pipe,

-standard length of the probe: 220 mm for 250mm < pipe diameter < 1000mm

After consult if pipe diameter > 1000mm

On request if 100mm < pipe diameter < 250mm

Figure 1 : mechanical assembly

Figure 2: mechanical dimensions

ELECTRICAL CONNECTIONS

Version ATEX

Version ATEX

CDM-Sensor –Dust Emission

Incident Detector

Notice Technique

FI 72.0401.0819E

Page 4 / 12 - 4 -Page 4 sur 12 - 4 - - 4 - - 4 - - 4 -

ELECTRICAL CONNECTIONS

Use the cable supplied with the sensor CDM (cable length=3.5m)

Cable PVC Gray, 8x0.25mm² (AWG24), Diam. Ext 6.2mm

Connect the contacts (naked part) of the cable with the external process.

Warning:

- Connect the sensor to earth by the terminal which is on the body of the sensor.

- Check the electrical characteristics of the CDM before any connection to the process, to prevent any

damage to the CDM.

- We recommend shielded cables between the sensor and the COM RS485.

Figure 3 : list of contacts Gland Version

Contact

Couleur

Signal

1

Yellow

ALARM Contact 1

2

Green

ALARM Contact 2

3

Brown

ALERT Contact 1

4

White

ALERT Contact 2

5

Gray

RS485/B (-)

6

Pink

RS485/A (+)

7

Blue

GND

8

Red

VCC

Please isolate unused contacts individually in order to avoid short circuit,

may cause damage or malfunction of the equipment.

CDM-Sensor –Dust Emission

Incident Detector

Notice Technique

FI 72.0401.0819E

Page 5 / 12 - 5 -Page 5 sur 12 - 5 - - 5 - - 5 - - 5 -

ADJUSTMENTS

Self-learning of reference point (PR):

Value of the mean dust rate, in normal conditions of exploitation.

1/ Sensor in MEASURE mode

2/ Open the cover of the sensor, after taking off the screw –Cover opening

3/ Maintain « F » key until the bargraph starts to turn on as a chase.

4/ Close quickly the cover with the screw, in order not to disturb the measure by external environment (electromagnetic

wave). The self-learning will really start only start 10 seconds when the sensor is in self-learning mode.

5/ At the end of the self-learning, automatic transition to MEASURE MODE of the CDM.

Time of the self-learning: X threshold.

During the whole self-learning phase, we recommend that the installation is in normal running conditions.

Adjustment of the Value X (from 1 to 33 min):

Value in minutes. During this time the CDM defines a mean value of the dust rate, in MEASURE mode and

AUTOLEARNING mode of the PR. This mean value is recalculated each second.

1/ Sensor in MEASURE mode.

2/ Open the cap of the sensor by taking off the screw –cap opening.

3/ push the key « F » several times until the led X flashes.

Visualization of the adjustment value with the bargraph (see Board 2).

4/ Adjust the value X by pressing the button « + » until you get the expected value.

The adjusted value can only be increased. When the max value is reached, we go back to mini value.

5/ Automatic transition to MEASURE mode when no key is pressed during more than 5 seconds.

Adjustment of threshold n1 (from x2 to x33):

This value is used to adjust the value of the threshold ALERT: threshold ALERT= n1 x PR

1/ Sensor in MEASURE mode.

2/ Open the cap of the sensor by taking off the screw –cap opening.

3/ push the key « F » several times until the led n1 flashes.

Visualization of the adjustment value with the bargraph (see Board 2).

4/ Adjust the value n1 by pressing the key « + » until you get the expected value.

The adjusted value can only be increased. When the max value is reached, we go back to mini value.

5/ Automatic transition to MEASURE mode when no key is pressed during more than 5 seconds.

Adjustment of threshold n2 (from x2 to x33):

This value is used to adjust the value of the threshold ALARM: threshold ALARM= n2 x PR

1/ Sensor in MEASURE mode.

2/ Open the cap of the sensor by taking off the screw –cap opening.

3/ push the key « F » several times until the led n2 flashes.

Visualization of the adjustment value with the bargraph (see Board 2).

4/ Adjust the value n2 by pressing the key « + » until you get the expected value.

The adjusted value can only be increased. When the max value is reached, we go back to mini value.

5/ Automatic transition to MEASURE mode when no key is pressed during more than 5 seconds.

CDM-Sensor –Dust Emission

Incident Detector

Notice Technique

FI 72.0401.0819E

Page 6 / 12 - 6 -Page 6 sur 12 - 6 - - 6 - - 6 - - 6 -

Configuration of the running of signals ALARM and ALERT

Depending on the position of switches SEL1 and SEL2 (see drawing 4), the running of the signals ALARM and ALERT

present 4 modes:

Table 1 :

Mode

Switch

SEL1

Switch

SEL2

ALERT (contact open)

ALARM (contact open)

1*

Off

Off

If mean dust rate during X min. > n1 x PR

If mean dust rate during X min. > n2 x PR

2

Off

On

If instantaneous dust rate > n1 x PR

If mean dust rate during X min. > n2 x PR

3

On

Off

If instantaneous dust rate < n1 x PR

If mean dust rate during X min. > n2 x PR

4

On

On

if failure

If mean dust rate during X min. > n2 x PR

*: Value defined in our workshop.

Remarks:

In case of supply shutdown, the CDM doesn’t need to be adjusted again.

All the adjusted parameters are recorded.

The adjustments, which need the opening of the cover, must be done quickly. Don’t let the cover open when not

needed.

During the self-learning phase of the reference point, the top of the sensor must be closed.

Be sure that the cover is correctly closed after every opening of it.

To limit the electrostatic impact during the use of user interface, we recommend to the operator to wear an

electrostatic bracelet.

CDM-Sensor –Dust Emission

Incident Detector

Notice Technique

FI 72.0401.0819E

Page 7 / 12 - 7 -Page 7 sur 12 - 7 - - 7 - - 7 - - 7 -

THE DEVICE

User Interface

Figure 4 : user interface

Supply Led

Key F

Key +

ALERT Led

ALARM Led

PR/x LED

TST/n1 Led

MES/n2 Led

11 parts BARGRAPH (0 to 100%)

SEL1, SEL2

CDM-Sensor –Dust Emission

Incident Detector

Notice Technique

FI 72.0401.0819E

Page 8 / 12 - 8 -Page 8 sur 12 - 8 - - 8 - - 8 - - 8 -

Table 2 : Signification of Leds

Leds

Mode

State

Signification

ALERT

(Orange)

Measure

on

Contact ALERT opened (1)

off

Contact ALERT closed (1)

ALARM

(Red)

Measure

on

Contact ALARM opened (1)

off

Contact ALARM closed (1)

flashing

Failure (2)

BARGRAPH

(Blue)

Measure

on

Shows the trend of the dust emissions (mean value for each minute) in % of the adjusted

ALARM threshold : 100% = ALARM= PR x n2

If only the part 0% flashes => Measure < Value PR

If parts 0% to 90% are on and the part 100% flashes => Measure > Threshold ALARM

Adjustment PR

Daisy chain

If parts 0% to 100% on => PR< Measure < Threshold ALARM

Adjustment Value

x,thresholds n1, n2

Always on

Value1 = 3xNb parts always on

Slow flashing

Value = Value1 +1

Fast flashing

Value = Value1 +2

MES/ n2 (Vert)

Measure

on

CDM mode MEASURE

Adjustment n2

flashing

CDM mode ADJUSTMENT Threshold n2

TST/n1 (Vert)

Measure

on

CDM mode AUTOTEST

Adjustment n1

flashing

CDM mode ADJUSTMENT Threshold n1

PR/x (Vert)

Adjustment PR

on

CDM mode AUTOLEARNING PR

Adjustment x

flashing

CDM mode ADJUTMENT Value x

(1) : See conditions Board 1

(2) : See conditions Board 3

Examples :

Case n°1 :

Adjustments : n1=2 => Threshold ALERT = 2*PR

n2=5 => Threshold ALARM = 5*PR

x =5 => Average of measured dust rate during the last 5 minuts

If mean value of dust rate = 2.5*PR

Then Visu Bargraph = 2.5 / 5(n2) x100 = 50% : Relay ALARM Off

And Threshold ALERT < mean dust rate measure : Relay ALERT On

Case n°2 :

Adjustments : n1=2 => Threshold ALERT = 2*PR

n2=5 => Threshold ALARM = 5*PR

x =5 => Average of measured dust rate during the last 5 minuts

If mean value of dust rate = 1.5*PR

Then Visu Bargraph = 1.5 / 5(n2) x100 = 30% : Relay ALARM Off

And Threshold ALERT > mean dust rate measure : Relay ALERT Off

CDM-Sensor –Dust Emission

Incident Detector

Notice Technique

FI 72.0401.0819E

Page 9 / 12 - 9 -Page 9 sur 12 - 9 - - 9 - - 9 - - 9 -

FAILURE

The CDM regularly runs an AUTOTEST of its electronics, to check its efficiency.

If an internal failure is detected by the CDM, this one informs the user by the ALARM Led and the ALARM Relay.

Table 3 :

ALARME LED

Failure

Priority

Remark

Flashing 1x +

Pause

Internal T°C

5

Contact the supplier

Flashing 2x +

Pause

Electronics

4

Contact the supplier

Flashing 3x +

Pause

Saturation

3

Contact the supplier

Flashing 4x +

Pause

Threshold ALARM out of limits

Threshold ALERT out of limits

Threshold ALARM > Threshold ALERT

2

Modify the value n2

Modify the value n1

Modify the value n2 and/or n1

On

Dust Measure > Threshold ALARM

1

If several faults appear at the same time, it is the failure with the highest priority, which will be indicated by the ALARM Led

and Relay.

CDM-Sensor –Dust Emission

Incident Detector

Notice Technique

FI 72.0401.0819E

Page 10 / 12 - 10 -Page 10 sur 12 - 10 - - 10 - - 10 - - 10 -

CHARACTERISTICS

Supply 24VDC +/- 10%

Consumption 80mA max.

Relay ALERT / ALARM inverter contact 1A 30VDC / 0.3A 125VAC

Network type RS 485 maxi length < 1,2 km (depends on cable)

Link MODBUS Mode RTU

Speed 115200 Bauds / 8Bits / 1 Bit Start / 1 Bit Stop / No parity

MODBUS Table available on request

Adjustments parameters via User Interface Sensor CDM or via Com. MODBUS RS485

Device Protection via resettable fuse

Protection Level IP 65

Weight 600g

Measure interval From 0.1 mg/m3

Diameter Pipe Standard : from 250 to 1000mm

If Ø < 250mm : on request

If Ø > 1000mm : consult us

Running Temperature

- external part to the pipe, body of the CDM : -20°C to +60°C

- internal part to the pipe : flow < 150° (CDM standard)

Storage Temperature -20°C to +85°C

Material Body of the sensor : aluminium

Transparent window of the sensor: Polycarbonate

Body of the probe : Inox

PTFE for isolator

Version non ATEX : Polyamid gland

Version ATEX : Brass Nickel-plated gland

Cable Link Process Length 3.5m (8*AWG24)

Version ATEX see document TRIB’ATEX-CDM FI 72.0419.xxxx

CDM-Sensor –Dust Emission

Incident Detector

Notice Technique

FI 72.0401.0819E

Page 11 / 12 - 11 -Page 11 sur 12 - 11 - - 11 - - 11 - - 11 -

General instructions for safety, assembly, commissioning, usage and maintenance

to be read before working on the device

I. GENERAL

These instructions must be read jointly with:

+the standard NFC15-100

+the technical data sheet specific to the device

The Sefram devices are designed to be assembled,

commissioned and used in compliance with the

characteristics/data given in the technical data sheet.

Always adhere to all of directives, legislation, orders and

most recent standards in force for the stated field of

application.

The assembly, commissioning, usage and maintenance

operations must always be carried out by qualified and

authorised personnel.

Personnel working on the devices must be familiar with

the safety rules and requirements in force regarding the

components, devices, machines and electrical

installations.

II. RECEPTION - STORAGE

After unpacking the device, check that this latter has not

been damaged during transport; for certain devices,

remove the protective film from the cover. The material

must be stored inside in a dry place.

In the event of a problem, please contact Sefram.

III. ASSEMBLY

The assembly operations must be carried out by

qualified, skilled and authorised personnel. Personnel

working on these devices must be familiar with the

safety rules and requirements in force.

The box must be mounted vertically.

For material connected permanently to the network, a

quickly accessible cut-off device must be incorporated

into the cabling installation of the building.

The device supply must be equipped with a device for

protection against risks of over-current and fault

isolation. The number of poles protected must be

appropriate to the neutral regime of the building and to

the regulations in force.

The equipment must be connected to the PE protection

mass by green/yellow wires (NFC15-100).

The device is compatible with the neutral regimes TT,

TN or IT;

Nevertheless, we recommend that the device is

supplied through the intermediary of an insulation

transformer for which the primary is supplied between

phases and not between phase and neutral, so as to

avoid any accidental over-voltage caused when the

neutral is cut before the phases.

If question or problem during these operations,

please contact Sefram.

IV. COMMISSIONING AND USAGE

Commissioning is authorised only after duly establishing

that the device, the machine or the installation in which

the device has been integrated in a compliant manner,

satisfies all of the directives, legislation, orders and

most recent standards in force.

Commissioning operations must be carried out by

qualified, skilled and authorised personnel. Personnel

working on these devices must be familiar with the

safety rules and requirements in force.

Note: correct operational functioning does not in itself

constitute an indication of conformity to the

recommendations for the use of the material in

complete safety.

Also read the maintenance recommendations which

equally apply during commissioning and use.

In the event of a problem, please contact Sefram.

V. MAINTENANCE

The device does not require any special maintenance.

The following operations are recommended; they

constitute a minimum:

- Before any work intervention, we recommend

that the dust is removed before opening the

cover,

- The device must not be opened in an

excessively dusty environment,

- The settings must be carried out in the shortest

lapse of time so as not to engender any risks,

- The integrity of the joints must be checked:

remove any trace of dust or other deposit,

- Remove any trace of dust which could have

penetrated during the setting operation,

- Always ensure that the cover is correctly

closed.

- For high concentrations of "sticky / caking"

products, periodically clean the sensor which is

immersed in the flow.

- In the event of a major change appears on the

operating conditions may affect the baseline

rate of dust, make learning a new reference

point PR.

Maintenance operations must be carried out by

qualified, skilled and authorised personnel. Personnel

working on these devices must be familiar with the

safety rules and requirements in force.

N.B : Version ATEX →see instruction FI 72.0419

CDM-Sensor –Dust Emission

Incident Detector

Notice Technique

FI 72.0401.0819E

Page 12 / 12 - 12 -Page 12 sur 12 - 12 - - 12 - - 12 - - 12 -

WARRANTY:

The warranty does not apply in the following cases:

-Breakage through dropping or knocks to non-packaged products

-Damage caused by abnormal use of the device, connecting error, surges/overvoltages, etc.

-Any intervention on the device apart from the connections

Warranty and homologation of ATEX devices :

No intervention can be done on the deveice : this one must be sent back to our workshop. Otherwise, it may

loose its homologation and warranty.

In case of failure, no action is permitted and the unit must be returned to the following address:

CERTIFICATE

The CDM respects the European directives ( CEM and ATEX ), which concerns it.

However, it must be used correctly in applications for which it is intended, and should be linked or near CE approved

products.

Certificate available on request.

SEFRAM

PLACE GUTENBERG

59175 TEMPLEMARS

Table of contents

Other SEFRAM Measuring Instrument manuals

SEFRAM

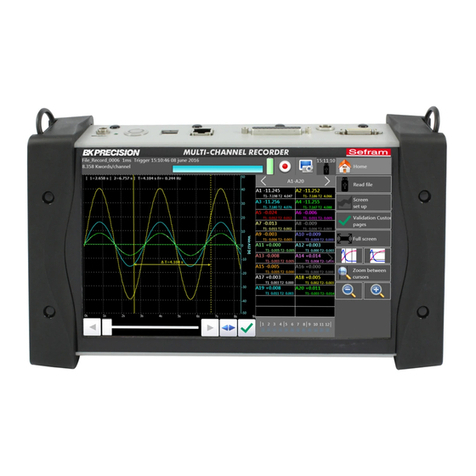

SEFRAM BK Precision DAS30 User manual

SEFRAM

SEFRAM 87 User manual

SEFRAM

SEFRAM DAS240 User manual

SEFRAM

SEFRAM M9885A00 User manual

SEFRAM

SEFRAM MW 3950 User manual

SEFRAM

SEFRAM 7880 User manual

SEFRAM

SEFRAM MW3366 User manual

SEFRAM

SEFRAM 52 User manual

SEFRAM

SEFRAM 7859 User manual

SEFRAM

SEFRAM MW 3352 User manual

SEFRAM

SEFRAM 7940 Series User manual

SEFRAM

SEFRAM 3526BF User manual

SEFRAM

SEFRAM DAS220BAT User manual

SEFRAM

SEFRAM DAS240BAT User manual

SEFRAM

SEFRAM 9836 User manual

SEFRAM

SEFRAM 3515F User manual

SEFRAM

SEFRAM MW3518 User manual

SEFRAM

SEFRAM MW3036 User manual

SEFRAM

SEFRAM MW3027 User manual

SEFRAM

SEFRAM 7805B User manual