SEFRAM SEQUENCER EC8-18 User manual

SEQUENCER

Technical brochure

FI 72.0540.0920E

Page 2 of 12

SUMMARY :

DESCRIPTION :

The EC8-18 is an adjustable device for control and full

automatization of declogging equipment, whose declogging is done

by pressured air injections.

It can perform the function of declogging sequence

It has :

- Up to 18 outputs for connecting solenoid valves depending

on the version.

- There are two versions: 8 outputs or 18 outputs.

- An electrical fault check.

- 1 digital input AON (loop control)

- 1 relay output for fault report.

The device can be configured according to use.

All the operating parameters can be viewed and adjusted on the

front of the device using keys and on a red LED display.

The evolution of the declogging cycle, operating faults are

displayed and detailed.

Page

- DESCRIPTION

2

- CHARACTERISTICS

3

- DIMENSIONS AND FIXATION

4

- PROTECTION AND

CONNECTIONS

5

- FRONT FACE

8

- SETTINGS AND

OPERATION

8

- PRECAUTIONS

11

- WARRANTY

11

- CONFORMITY

11

- GENERAL INSTRUCTIONS OF

SAFETY, ASSEMBLY,

COMMISSIONNING AND

MAINTENANCE

12

SEQUENCER

Technical brochure

FI 72.0540.0920E

Page 3 of 12

CHARACTERISTICS :

- Supply voltage (nominal voltage) :

AC Version: 115V or 230V 10 % 50-60 Hz

DC Version: 24V

- Consumption (nominal current) maxi:

5VA + SV consumption

- Protection:

by fuse 5x20mm

rating according to supply voltage (see table 1)

- Solenoid valve voltage:

According to supply voltage (see table 1)

AC Version : 24V, 115V ou 230V

DC Version : 24V

Pmax :25 VA / 25 W

- AON inputs characteristics:

voltage : 24VDC supplied by the device

Load current +/- 1mA

- Relay contact characteristics :

Dry contact. max: 250V /1A

(to be protected by user)

- operating temperature :

-20° to 60°C

- Storage temperature :

-20° to 70° C

- Case :

Material ABS - IP65

SEQUENCER :

- maxi outputs quantity

According version : 8 or 18

- activation time of an output (T1)

from 3/100th to 255/100th of a second

- idle time between two outputs (T2)

from 1 to 255 seconds

- forced declogging time (T4)

from 0 to 255 hours

- Number of cycles if fan stopped

from 0 to 255 cycles

- Number of cycle in manual operation

from 0 to 255 cycles

Table 1: supply voltage / solenoid valve / fuses

Supply voltage

230VAC

115VAC

24VDC

Solenoid valve voltage Pmax: 25VA / 25W

230VAC

24VAC

24VDC

115VAC

24VAC

24VDC

24VDC

F1 fuse rating

1A

1A

1.6A

F2 fuse rating

1A

1A

1.6A

F3 fuse rating

1A

1A

1A

SEQUENCER

Technical brochure

FI 72.0540.0920E

Page 4 of 12

DIMENSIONS AND FIXATION:

1 2 3 4 5 6

Cable glands

1

ISO16b : supply

2

ISO20 : multi-conductor cable SV outputs

3

ISO20 : multi-conductor cable SV outputs

(only if 18 SV version)

4

ISO20 : multi-conductor cable SV outputs

(only if 18 SV version)

5

ISO20 : AON input

6

ISO20 : relay output

Glands clamping capacity :

ISO 16b

From 5 to 10 mm

ISO 20

From 7.5 to 13 mm

Can be fixed on a rail

(optional kit) RAIL AXIS

→see detail

FIXATION

DEVICE VIEW FROM BEHIND

SEQUENCER

Technical brochure

FI 72.0540.0920E

Page 5 of 12

Three mounting possibilities:

PROTECTION AND CONNECTIONS:

It is possible, depending on the version of the box, to modify the supply voltage and the voltage of the solenoid valves

by positioning jumpers on the electronic board.

The jumpers are set at the factory for a supply voltage and a solenoid valve voltage corresponding to the version

ordered.

Check or position the jumpers according to the desired voltages.

The jumpers are accessible after removing the front panel.

The connection terminal blocks are accessible after removing the connection cover (lower part of the box).

Warning: changes of jumpers and connections must be made with the power off

Version 230VAC/24VAC

Version 230VAC/230VAC

Version 115VAC/24VAC

Version 115VAC/115VAC

Accessible after removing the front panel:

Output protection :

Size 5x20

See table 1 page 3

Choice of output power supply:

Same as general supply: 24V :

General supply

choice :

230V : 115V :

I. With screws through the case.

II. By means of fixings in the corners or in the middle

(optional kit).

III. By DIN-rail mounting (optional kit).

1°) Push the locking stops into place.

2°) Hang the housing on the DIN rail.

3°) Turn the locking stops up behind the DIN rail.

SEQUENCER

Technical brochure

FI 72.0540.0920E

Page 6 of 12

Version 230VAC/24VDC

Version 115VAC/24VDC

Version 24VDC/24VDC

No adjustment possible

CAUTION: A change in the supply voltage and / or solenoid valve voltage requires updating the identification

label placed on the outside of the box.

Output protection :

Size 5x20

See table 1 page 3

General supply

choice :

230V : 115V :

Accessible after removing the front panel:

SEQUENCER

Technical brochure

FI 72.0540.0920E

Page 7 of 12

Connection 18EV version:

Connection 8EV version:

Power supply terminal clamping capacity : 2,5 mm².

Terminal clamping capacity SV and K1 and I1 : 1,5 mm².

General

supply

General protection:

2 fuses

Size 5x20

See table1 page3

SV connection

AON input I1:

"loop control"

Relay output:

"Electrical fault"

General protection:

2 fuses

Size 5x20

See table1 page3

SV connection

AON input I1:

"loop control"

Relay output:

"Electrical fault"

If AC

If DC - +

if AC

if DC -+

General

supply

SEQUENCER

Technical brochure

FI 72.0540.0920E

Page 8 of 12

FRONT FACE :

SETTINGS AND OPERATION:

The various parameters are adjusted as follows:

- Press the "SELECT" key until the yellow "menu" led lights up in front of the parameter to be set and press the "+"

and "-" keys to obtain the desired value.

- Then return to the "CYCLE" position using the "SELECT" key. Each parameter is saved in a memory when going

to the next step or when automatically returning to the "CYCLE" position.

Remarks :

- The return to the "CYCLE" position is automatic after 60 seconds.

- Each parameter can be viewed at any time during the operation of the device.

See the correspondence with the number below.

Signaling

Yellow led

Parameter setting menu

FIXE (1)

FLASHING (2)

FIXE (3)

FLASHING (4)

FIXE (5)

FLASHING (6)

FIXE (7)

FLASHING (8)

Green Led :

On if input « loop

control » present

(=1)

3 digits display

red led

Red led :

On if

presence of a

fault

SEQUENCER

Technical brochure

FI 72.0540.0920E

Page 9 of 12

1) Visu Cycle:

In this position, the CYCLE menu led is on fixe.

If a fault is present, display of the fault (this display has priority).

If the sequencer is stopped: display "0".

If an unclogging pulse is in progress:

- display of "n x" with x = number of the current SV

- rapid flashing of the menu led in front of T1.

If rest time between two shots in progress:

- display of the time count before the next pulse

- rapid flashing of the menu led in front of T2.

Whether it is an unclogging of n cycles in manual operation, or unclogging due to the detection of a

fan stop, rapid flashing of the menu led in front of the fan / manual

At any time, if the + key is pressed: display of "n x" with x = EV which will be engaged on the next shot.

2) Setting the stop mode:

Two stop modes are possible if loss of loop control (input I1):

- « FcY » for end of cycle: the current cycle ends until the last SV.

- « Sto » for cycle stop: the cycle stops at the EV where it arrived. It will resume at the next EV when

reappearance of the run order

3) Setting the number of outputs:

Number of SV in the cleaning cycle: from 1 to 18.

4) T1 setting:

Activation time of an output (in 1 / 100th of a second) : from 3 to 255.

5) T2 setting:

Idle time between two outputs (in seconds) : from 1 to 255.

6) T4 setting:

If there has been no unclogging for the set time (T4), the current cycle ends (if stopped in cycle)

and a full cycle is performed.

If set to 0: this function is disabled.

Note: the T4 time delay is initialized for each pulse on an SV.

7) Setting the number of cycles when the fan is stopped:

If the loop control is lost (input I1), the stopping of the fan is detected.

In this case, the n cleaning cycles set here are carried out one after the other.

If set to 0: this function is disabled.

8) Manual running:

Setting the desired number of cycles in manual running. The cleaning cycles follow one after the other

(regardless of the state of input I1).

SEQUENCER

Technical brochure

FI 72.0540.0920E

Page 10 of 12

- Sequencer operation:

The unclogging cycle consists of driving the EV outputs one after the other with a T1 pulse time and a rest

time T2 between two pulses.

4 orders can initiate unclogging:

oInput « loop control » (I1) :

▪If input=1 (closed input),

▪Unclogging cycles follow one another as long as the entry=1.

oT4 time :

▪If end of time T4 : execution of a cleaning cycle.

oDetection of fan stop (loss of input I1):

▪The n cycles set are executed.

oManual running :

▪The n cycles are executed.

Note: On power-up, a 10-second delay prohibits unclogging.

- Fault check operation:

When activating an EV, the device monitors the current consumed.

If there has been no consumption, an EV electrical fault is generated (for example: EV no or bad

connected, defective EV coil, etc.).

If power consumption is observed while no EV should be piloted, a fault

electrical short-circuit is generated (for example card failure…).

Electrical faults are maintained until reset by the "RESET" key.

Indication of:

"DEF" if electrical fault short-circuit

"Dxx" if electrical fault on EV with xx = number of EV.

Note : All faults are stacked in memory and are displayed in ascending order of the solenoid valves.

To cancel a fault and go to the next display, press the "RESET" button.

- Relay output:

The relay is energized if there is no fault (contact between 13 and 14).

It is no longer powered if there is an electrical fault (no more contact between 13 and 14).

SEQUENCER

Technical brochure

FI 72.0540.0920E

Page 11 of 12

PRECAUTIONS :

-If a fuse needs to be changed, replace it with a fuse of the same rating.

-Take the necessary precautions to meet the characteristics of the device (overvoltage, temperature, etc.).

-For specific operating conditions: contact us

-Interventions must always be done by qualified workforce

WARRANTY :

The warranty does not apply in the following cases:

-Breakage through dropping or knocks to non-packaged products

-Damage caused by abnormal use of the device, connecting error, surges/overvoltages, excessive

temperature condition, etc.

-Any intervention on the device apart from the connections

Address where the device must be returned:

CONFORMITY :

The SET10DP device respects the European directives ( CEM, BT), which concerns it.

However, it must be used correctly in applications for which it is intended, and should be linked or near CE

approved products.

Certificate available on request.

We are free to implement any technical modification on our devices,

as long as we consider it as convenient.

SEFRAM

11 bis, PLACE GUTENBERG

59175 TEMPLEMARS

FRANCE

SEQUENCER

Technical brochure

FI 72.0540.0920E

Page 12 of 12

General instructions for safety, assembly, commissioning, usage and maintenance

to be read before working on the device

I. GENERAL

These instructions must be read jointly with:

+the standard NFC15-100

+the technical data sheet specific to the device

The Sefram devices are designed to be assembled,

commissioned and used in compliance with the

characteristics/data given in the technical data sheet. Always

adhere to all of directives, legislation, orders and most recent

standards in force for the stated field of application.

The assembly, commissioning, usage and maintenance

operations must always be carried out by qualified and

authorized personnel.

Personnel working on the devices must be familiar with the

safety rules and requirements in force regarding the

components, devices, machines and electrical installations.

Before any intervention on the cabinet, the equipment must be

de-energized by cutting off the power source upstream of it.

II. RECEPTION - STORAGE

After unpacking the device, check that this latter has not been

damaged during transport; for certain devices, remove the

protective film from the cover. The material must be stored

inside in a dry place.

In the event of a problem, please contact Sefram.

III. ASSEMBLY

The assembly operations must be carried out by qualified,

skilled and authorized personnel. Personnel working on these

devices must be familiar with the safety rules and requirements

in force.

The box must be mounted vertically.

For material connected permanently to the network, a quickly

accessible cut-off device must be incorporated into the cabling

installation of the building.

The device supply must be equipped with a device for

protection against risks of over-current and fault isolation. The

number of poles protected must be appropriate to the neutral

regime of the building and to the regulations in force.

The equipment must be connected to the PE protection mass

by green/yellow wires (NFC15-100).

The device is compatible with the neutral regimes TT, TN or IT;

Nevertheless, we recommend that the device is supplied

through the intermediary of an insulation transformer for which

the primary is supplied between phases and not between

phase and neutral, so as to avoid any accidental over-voltage

caused when the neutral is cut before the phases.

In the event of a problem, please contact Sefram.

IV. COMMISSIONING AND USAGE

Commissioning is authorized only after duly establishing that

the device, the machine or the installation in which the device

has been integrated in a compliant manner, satisfies all of the

directives, legislation, orders and most recent standards in

force.

Commissioning operations must be carried out by qualified,

skilled and authorized personnel. Personnel working on these

devices must be familiar with the safety rules and requirements

in force.

Note: correct operational functioning does not in itself constitute

an indication of conformity to the recommendations for the use

of the material in complete safety.

Also read the maintenance recommendations which equally

apply during commissioning and use.

In the event of a problem, please contact Sefram.

V. MAINTENANCE

The device does not require any special maintenance.

For devices equipped with the pressure measurement, in order

to retain a precise pressure measurement, an annual

calibration is advised particularly at « zero » (see § calibration

on the technical data sheet)

The following operations are recommended; they constitute a

minimum:

- Before any work intervention, we recommend that the

dust is removed before opening the box,

- The device must not be opened in an excessively

dusty environment,

- The settings must be carried out in the shortest lapse

of time so as not to engender any risks,

- The integrity of the joints must be checked: remove

any trace of dust or other deposit,

- Remove any trace of dust which could have

penetrated during the setting operation,

- Always ensure that the transparent cover is correctly

closed.

Maintenance operations and interventions inside the box must

be carried out by qualified, skilled and authorized personnel.

Personnel working on these devices must be familiar with the

safety rules and requirements in force.

In the event of a problem or any questions during these

operations please contact SEFRAM.

Table of contents

Other SEFRAM Measuring Instrument manuals

SEFRAM

SEFRAM 7951 User manual

SEFRAM

SEFRAM DAS220BAT User manual

SEFRAM

SEFRAM BK Precision DAS30 User manual

SEFRAM

SEFRAM DAS240 User manual

SEFRAM

SEFRAM 7803B User manual

SEFRAM

SEFRAM 9835 User manual

SEFRAM

SEFRAM 7940 Series User manual

SEFRAM

SEFRAM 3515F User manual

SEFRAM

SEFRAM CDM User manual

SEFRAM

SEFRAM MW 3360 User manual

SEFRAM

SEFRAM 7859 User manual

SEFRAM

SEFRAM 9862 User manual

SEFRAM

SEFRAM MW 3015 User manual

SEFRAM

SEFRAM 7849B User manual

SEFRAM

SEFRAM 7805B User manual

SEFRAM

SEFRAM 3526BF User manual

SEFRAM

SEFRAM MW3518 User manual

SEFRAM

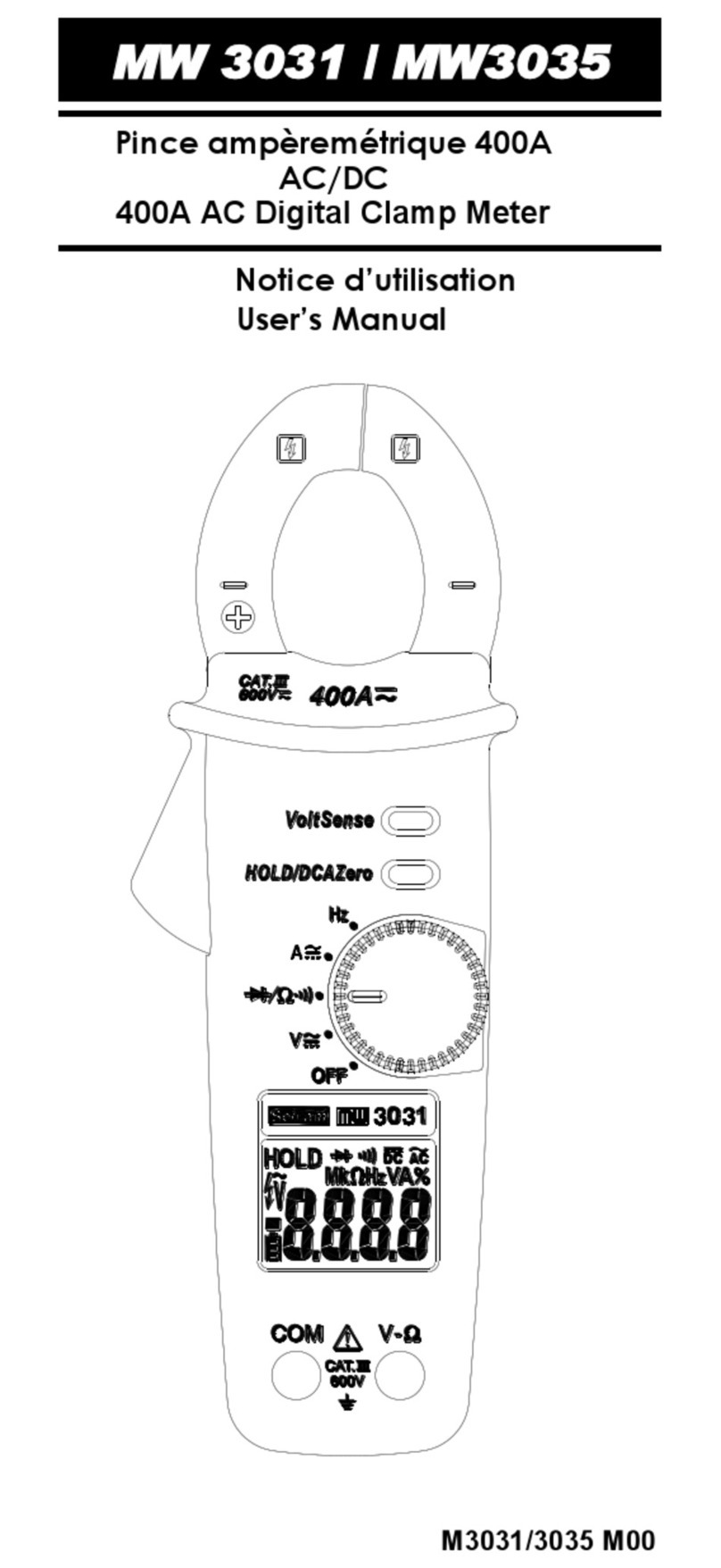

SEFRAM MW 3031 User manual

SEFRAM

SEFRAM MDPP2S V2 User manual

SEFRAM

SEFRAM MW3036 User manual