Seikom Electronic NLSW2aS3 User manual

This manual suits for next models

2

Table of contents

Languages:

Other Seikom Electronic Measuring Instrument manuals

Seikom Electronic

Seikom Electronic RLSW 5A User manual

Seikom Electronic

Seikom Electronic RLSW 8 LCD User manual

Seikom Electronic

Seikom Electronic NLSW45-5 User manual

Seikom Electronic

Seikom Electronic F3.xEx Series User manual

Seikom Electronic

Seikom Electronic NLSW 2a User manual

Seikom Electronic

Seikom Electronic NLSW45-3Ex User manual

Seikom Electronic

Seikom Electronic NLSW 45-4 User manual

Seikom Electronic

Seikom Electronic NLSW 45-3 Ex SIL2 User manual

Seikom Electronic

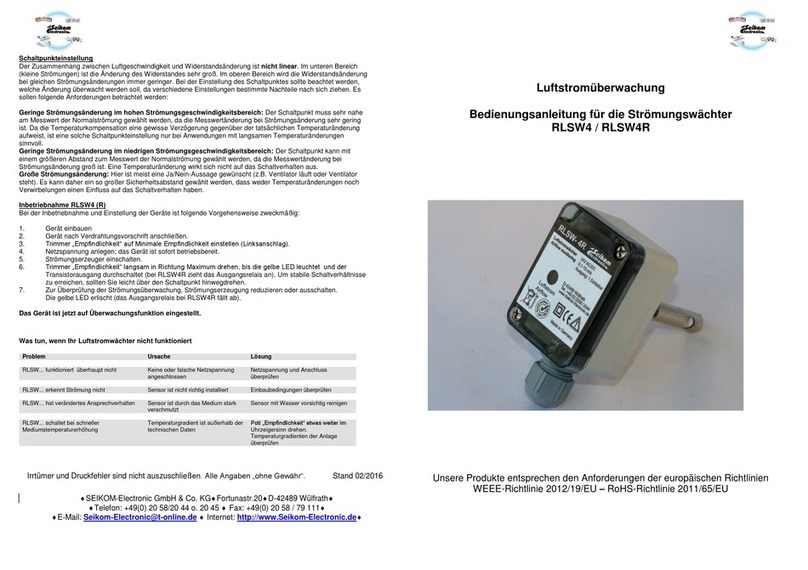

Seikom Electronic RLSW4 User manual

Seikom Electronic

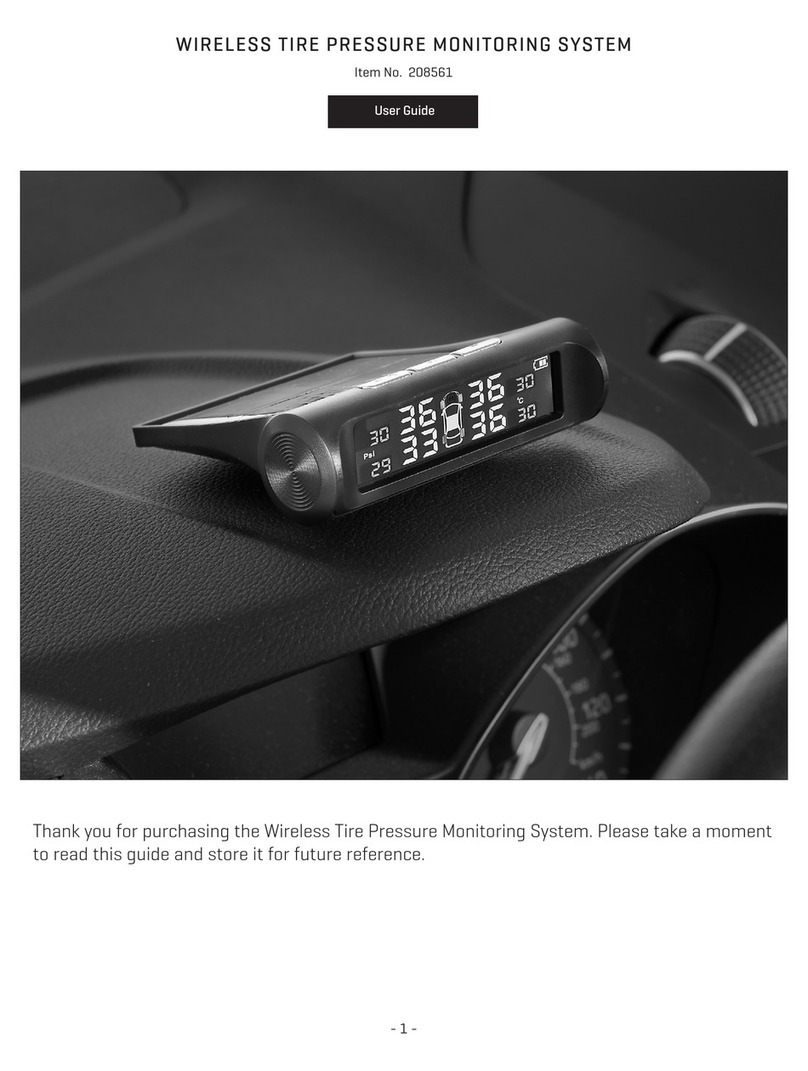

Seikom Electronic 77029 User guide

Seikom Electronic

Seikom Electronic NLSW45-6 User guide

Seikom Electronic

Seikom Electronic NLSW 45-3 SIL2 User manual

Seikom Electronic

Seikom Electronic NLSW45-4 User guide

Seikom Electronic

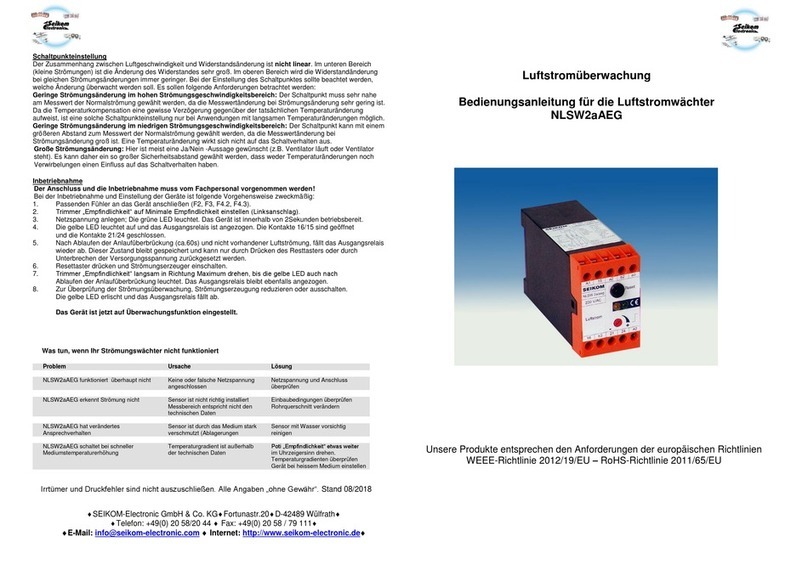

Seikom Electronic NLSW2aAEG User manual

Seikom Electronic

Seikom Electronic RLSW 7 User manual

Seikom Electronic

Seikom Electronic NLSW75-AEx (Gg) User manual

Seikom Electronic

Seikom Electronic NLSW45-3Ex User guide

Seikom Electronic

Seikom Electronic RLSW4 User manual

Seikom Electronic

Seikom Electronic NLSW 45-3 SIL1 User manual

Seikom Electronic

Seikom Electronic NLSW45-6 User manual

Popular Measuring Instrument manuals by other brands

Riken Keiki

Riken Keiki GW-3 Technical manual

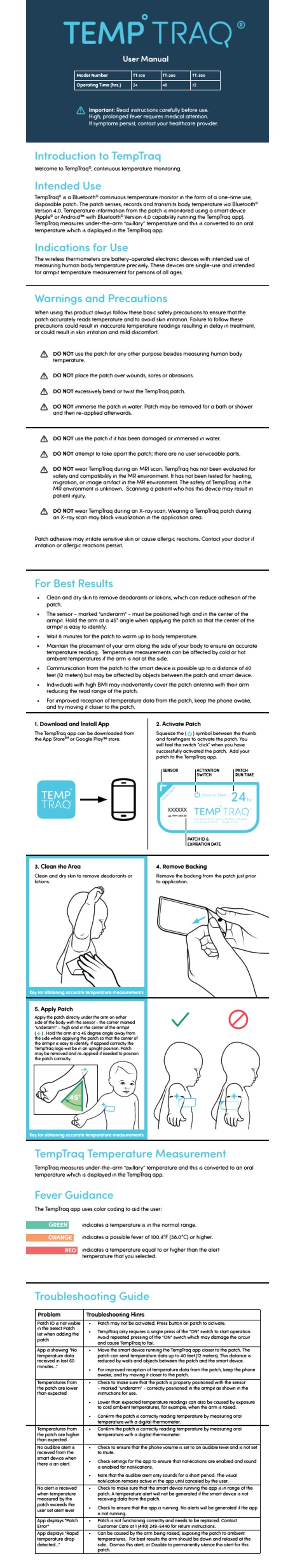

TEMP TRAQ

TEMP TRAQ TT-100 user manual

PCB Piezotronics

PCB Piezotronics Platinum Swiveler 607A11/020AD Installation and operating manual

Teledyne

Teledyne 212R instruction manual

Dini Argeo

Dini Argeo DFWIECEX user manual

Elcometer

Elcometer SG80 operating instructions

Camille Bauer

Camille Bauer SINEAX DME 400 Series operating instructions

PCB Piezotronics

PCB Piezotronics 353B77 Installation and operating manual

Leader

Leader LT 4446 instruction manual

Kroeplin

Kroeplin G P3 Series user manual

Hubbell

Hubbell CHANCE PSC4033955 operating instructions

Rion

Rion PV-91C instruction manual