Seikom Electronic NLSW 45-3 Ex SIL2 User manual

Table of contents

Other Seikom Electronic Measuring Instrument manuals

Seikom Electronic

Seikom Electronic NLSW 45-3 SIL2 User manual

Seikom Electronic

Seikom Electronic NLSW 45-4 User manual

Seikom Electronic

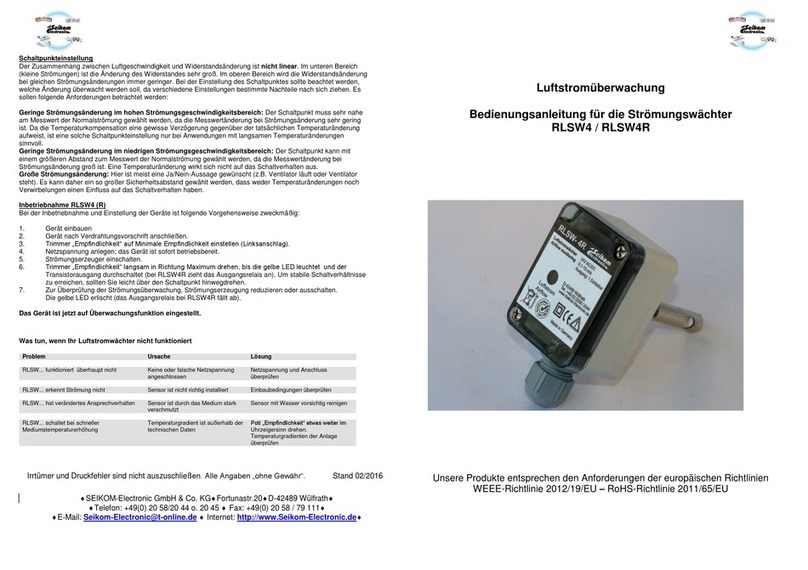

Seikom Electronic RLSW4 User manual

Seikom Electronic

Seikom Electronic 77029 User guide

Seikom Electronic

Seikom Electronic RLSW4 User manual

Seikom Electronic

Seikom Electronic RLSW 7 User manual

Seikom Electronic

Seikom Electronic F3.xEx Series User manual

Seikom Electronic

Seikom Electronic NLSW 45-3 SIL1 User manual

Seikom Electronic

Seikom Electronic NLSW 2a User manual

Seikom Electronic

Seikom Electronic RLSW 5A User manual

Seikom Electronic

Seikom Electronic F3 Ex SIL1 Series User manual

Seikom Electronic

Seikom Electronic NLSW45-6 User manual

Seikom Electronic

Seikom Electronic NLSW45-5 User manual

Seikom Electronic

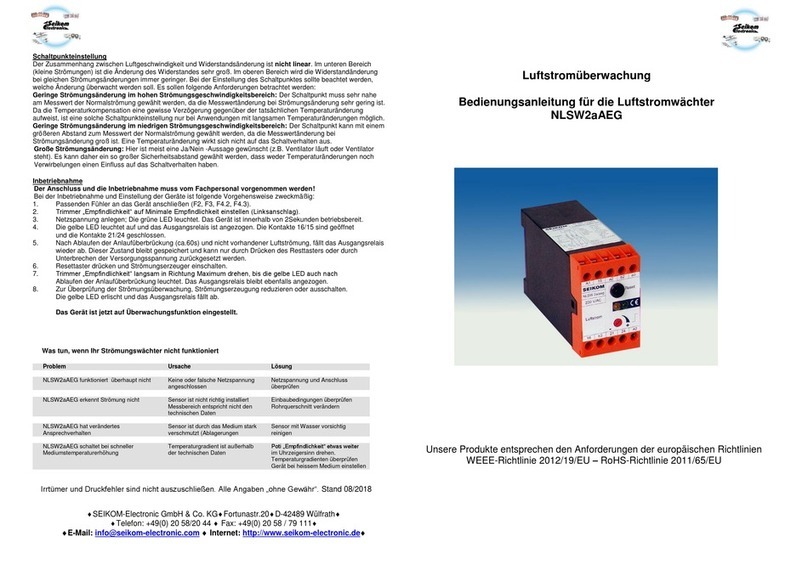

Seikom Electronic NLSW2aAEG User manual

Seikom Electronic

Seikom Electronic NLSW45-6 User guide

Seikom Electronic

Seikom Electronic NLSW75-AEx (Gg) User manual

Seikom Electronic

Seikom Electronic NLSW45-3Ex User manual

Seikom Electronic

Seikom Electronic RLSW 8 LCD User manual

Seikom Electronic

Seikom Electronic NLSW2aS3 User manual

Seikom Electronic

Seikom Electronic NLSW45-3Ex User guide

Popular Measuring Instrument manuals by other brands

Brüel & Kjær

Brüel & Kjær 2239 B manual

CARLO GAVAZZI

CARLO GAVAZZI EM 21 manual

Thermo Scientific

Thermo Scientific Nanodrop Lite Quick reference guide

Spectrum

Spectrum 3445 product manual

Trafox

Trafox SUPERINTEND IM-04DCCT Instructions for installation and use

Keysight Technologies

Keysight Technologies E4981A Service guide