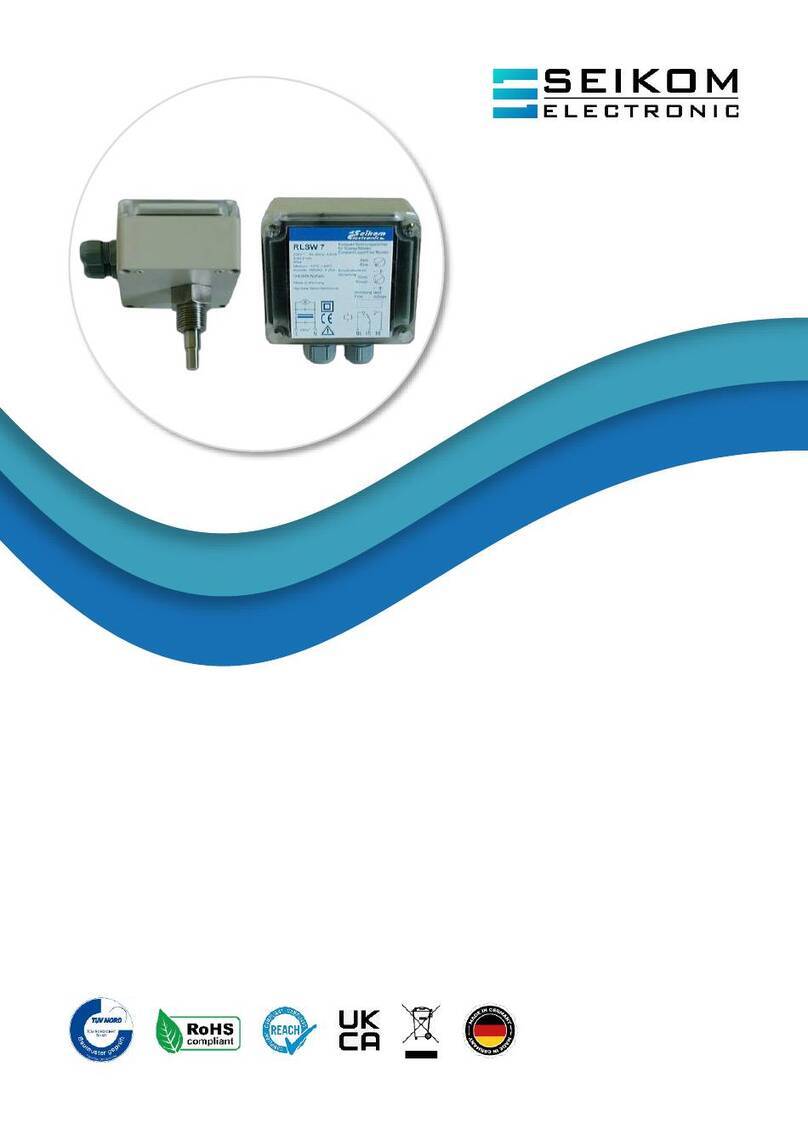

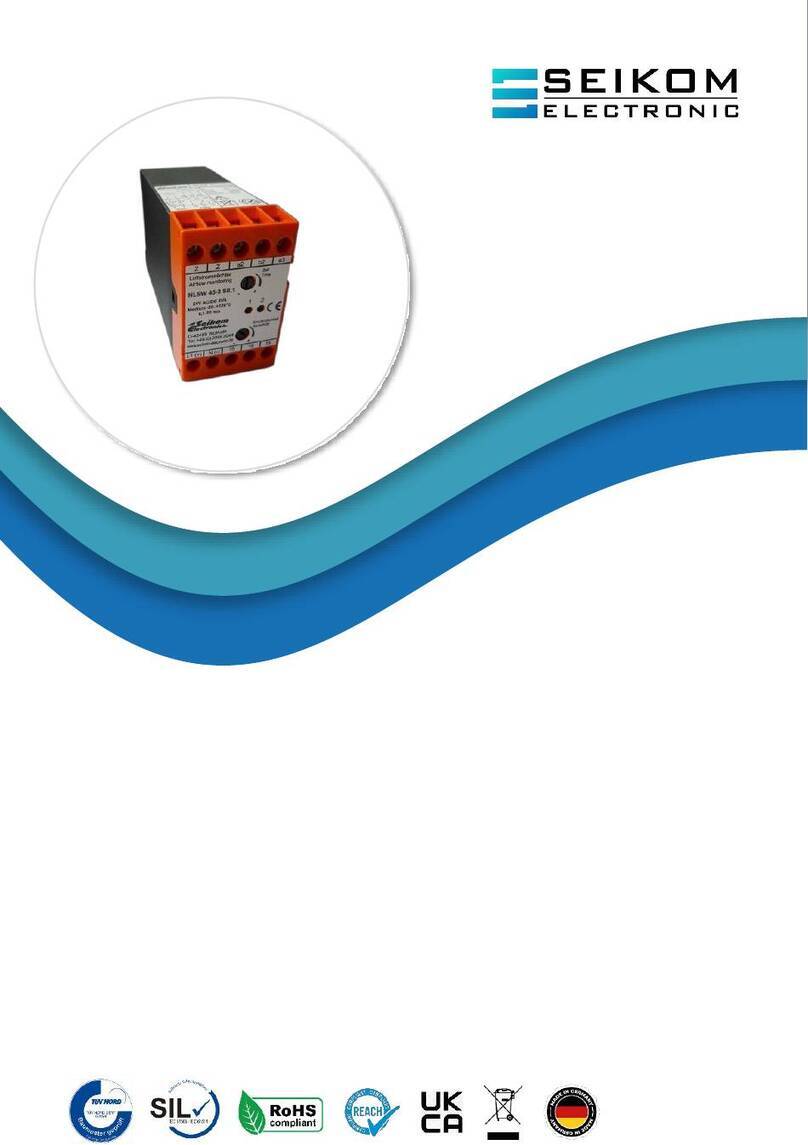

General Information

The NLSW45-6 monitors gaseous media with tamperatures in the range of -20 to 250°C and up to 400°C with F8/400.

The sensor is watched for short-circuit and loss of connection. The start-up delay and the switching point is settable step-

less. The NLSW45-6 is used in combination with the sensor series F8. The compensation of different temperatures

keeps the switching point constant.

Measuring principal

A temperature-sensitive resistor is heated according to the calorimetric measuring principle. The temperature-sensitive resistor is

heated by a second resistor. A flow dissipates heat from the measuring resistor, causing the resistor’s temperature to fall and thus a

change of impedance. This temperature change is evaluated. Since both the velocity and the temperature of the flowing medium

affect the dissipated heat, a relationship must be created between flow and temperature. For this purpose, a second temperature-

sensitive resistor is located next to the first one. The second measuring resistor is not heated and is only used for the temperature

measurement.

Airflow > / = switch point Switching output is energised Yellow LED “Airflow“ switch on

Airflow < switch point Switching output isn’t energised Yellow LED “Airflow“ switch off

Technical Data

Relay, 1 change-over contact

Relay, 1 change-over contact

Relay output

Minimum switching load

250VAC, 8A, 2kVA

10mA / 5V DC

250VAC, 8A, 2kVA

10mA / 5V DC

Signal lamp, start up delay

Media temperature range NLSW45-6

Media temperature range NLSW45-6.1

Switching point adjustment

Airflow range NLSW45-6

Airflow range NLSW45-6.1

Measuring probes NLSW45-6

Measuring probes NLSW45-6.1

F8, F8.1, F8.2, F8.3

F8/400°C, F8.1/400°C,

F8.2/400°C, F8.3/400°C

F8, F8.1, F8.2, F8.3

F8/400°C, F8.1/400°C

F8.2/400°C, F8.3/400°C

protection category, housing

protection category, terminals

Installation Instruction

Before setting up the switching point, the device should have been active for at least 2 minutes in normal conditions. To set up the

switching point please attend the following steps:

-The sensors tip should be placed in the duct’s middle and has to be flowed around completely by the medium.

-The flow in vertical-ducts needs to be upwards.

-To assure maximum reliability the sensor needs a length of the inlet path of 5xD (inside pipe diameter) and 3xD (inside

pipe diameter) of the outlet path.

-The sensor is to be mounted only with its own hex-head screw.

-The sensor must be connected to the evaluation unit as described in its manual. Incorrect connection leads to

malfunctioning and can destroy both!

-If the sensor’s cable is laid in a conduit with other live cables (motor-, solenoid valve-cables, …) we recommend

shielding it.

-If the length of the cable needs to be changed it needed to be done with a.w.g. 16 (1.5mm²) and must not be longer than

20m!

Maintenance information

In order to avoid malfunction the sensor should be maintained in regular distances according to its pollution. Cleaning the sensor pay

attention to following steps:

-Dismantle the sensor.

-Insert the sensor in slightly warm and soaped water carefully for about 10 minutes.

-Carefully rinse off the airflow sensor with lukewarm water.

-Assemble the airflow sensor.

Attention: Do not use screwdrivers or equal to clean the sensor!

Attention!!

Connection and commissioning must be performed by properly authorized and qualified personnel!

Connection to mains supply (L, N) must be made by means of a protected isolating switch with the usual fuses.

As a matter of principle, the General VDE Regulations must be complied with (VDE 0100, VDE 0113, VDE 0160). If

the potential-free contact is connected to an extra-low safety voltage, sufficient insulation must be provided for

the connecting cables up to the terminal, since otherwise the double insulation to the mains voltage side may be

impaired. The current load capacity of the potential-free contact is limited to 10 A. Therefore, the electrical

circuit of the potential-free contact must be protected by a 10.3 a fuse.

Electrical connection

Core colours: BN=brown BK=black BU=blue