5

POR MDX BI0 0SE 021338A0 171012

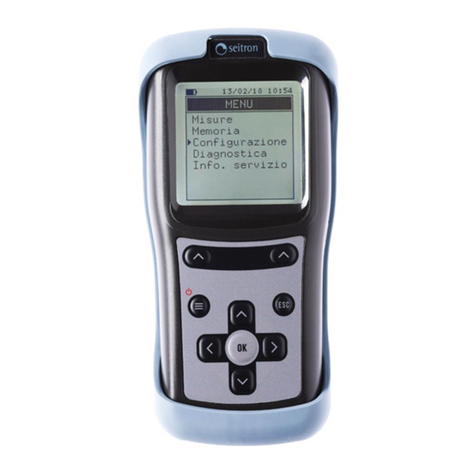

)XQFWLRQVPHQX

Use the ’ )81& ’ key to access functions. Use the arrow keys to select a gas tight test or the Data Logger

function from the menu:

81,Gas tight test for working systems.

81, Gas tight test for new or reconditioned systems.

'DWD/RJJHU Acquires and saves pressure trends.

81,*DVWLJKWWHVWIRUH[LVWLQJV\VWHPV

The UNI 11137: 2012 norm applies to internal systems which are already functioning. To carry out UNI 11137:

2012 gas tight tests with PRESSOTEST input the required parameters for the test (system volume, the gas

type the system runs on, the test gas), adjust the system to the test pressure specified by the instrument,

stabilise the test gas and then wait for one minute for Methane and LPG in air and 2.5 minutes for the LPG fuel

while the manometer evaluates the fall in pressure in the system. From the pressure fall figure and the system

characteristics the instrument calculates the extent of the leak and compares it to the range required by the

norm to generate the result of the test.

Start the UNI 11137: 2012 gas tight test by pressing ’ 6(7 ’ on the 81,function selection screen.

Step by step the instrument requests the operator to insert the parameters detailed below and confirm them

with ’ 6(7 ’. Other details are supplied in the flow diagrams illustrated further on in the manual.

’ XRO’ The system volume is a required parameter for carrying out the UNI 11137: 2012 gas tight test.

With PRESSOTEST it can either be inserted, if known, or measured by a simple procedure. Given

the large number of small systems, the instrument also has a third option for systems of up to

18 dm3(litres); here no specific volume is required because the instrument automatically considers

a volume of 18 dm3.

The first option displayed for setting the gas tight test parameters is the option for systems of up to

18 dm3, shown on the display by ’ -18L ’ (volume of less than 18 litres). This selection can be

confirmed by using ’ 6(7 ’ or the system volume can be input using the horizontal arrow keys.

For manual input the instrument automatically displays the volume used for the last gas tight test

carried out. This value can be edited by using the arrow keys as described in the Select/edit

paragraph on page 3.

On the insert volume screen it is also possible to calculate the volume directly using the syringe

supplied with the pipe kit for gas tight tests. The procedure is summarised in a few simple steps

below:

x

Connect the syringe to its pipe from the gas tight test kit (opposite the pump).

x

Open the tap and extract exactly 100 ml (100 cc) of gas from the plant

x

Wait until the system restabilises. Removing the syringe full of gas disturbs the system’s

pressure and the manometer displays its variability by a flashing volume indication. Wait until it

has stopped flashing before continuing.

x

Inject the contents of the syringe back into the system and close the pipe kit tap.

x

Wait until the system restabilises again. As before the volume indicator will flash until it has

stabilised. Wait until it stops flashing.

x

As soon as the system restabilises and the display stops flashing the measured volume will be

shown.

To carry out the test with the volume shown, whether it has been input or measured, press ’ 6(7 ’.

’ &RPE’ System combustible gas.

Gas tight tests are carried out under different test conditions and according to the type of gas the

system uses. Select combustible gas from the options: natural gas ’ *Q$W’ and LPG. ’ *3/’.

’ J$’Test gas.

Gas tight testing is carried out under different conditions according to the test gas used. Select the

test gas from either the system’s combustible gas ’ &RPE ’ or air ’ $ULD ’.

’ W$E’Stabilisation time.

Set the test gas stabilisation time when added to the system.