10 K000000000S9 036113 130121

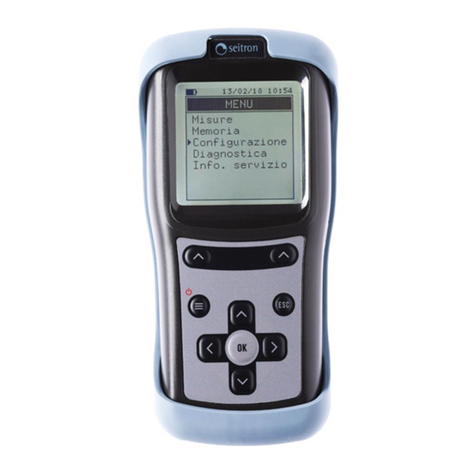

4.1 General Description of the Combustion Analyzer

The design of the handheld combustion analyzer "S1500/S4500" is clean and ergonomic with an extremely clear

and user-friendly keypad.

"S1500/S4500" immediately suggests just how even the most sophisticated engineering can give life to an

incredibly comfortable and easy to use work instrument.

Devised to analyze flue gases, monitor the pollutants emitted and measure environmental parameters, "S1500/

S4500" uses two electrochemical sensors that provide the oxygen and carbon monoxide values while a third

sensor is used to measure the pollutants NO and NOx.

The most complete version can house a fourth sensor for measuring NO2, SO2 and CxHy. CO,NO,NO2 and SO2

measuring sensors are also available with a reduced measuring range, with a resolution of 0.1 ppm and better

accuracy.

Two external sensors measure the environmental parameters; it is also possible to measure flue draft and carbon

black and, with the measuring range of up to 200mbar, system pressure and pressure in the combustion

chamber can be measured and the pressure switches checked.

Intended for eleven main types of combustibles amongst which natural gas, LPG, diesel and fuel oil, it is also

possible to insert into the memory of "S1500/S4500" another 16 combustibles of which the chemical composition

is known. The functions of "S1500/S4500" include the storage and the average of the data acquired, the printing

(on a roll of thermal polyester paper) of the results and the possibility of connecting the device to a computer to

store to data via USB connection.

Its memory is able to store 1000 complete analyses and using the dedicated SW and mini-USB serial

communication cable it is possible to download the data to a PC. It is also interesting to know that "S1500/S4500"

is equipped with a single "Li-Ion" rechargeable battery pack used both to power the unit and for the printer: it also

has a bright and wide (2,17 x 3,74 inches) TFT color display that has an excellent readability also thanks to the

zoom function and the backlight.

Another characteristic that distinguishes it from other similar products in the market is the fact the power supply

that comes with the product can carry out the dual function of battery charger and power supply for the

instrument which means the user can carry out analyses even if the batteries are completely flat.

Another important function is the possibility of carrying out an autozero cycle with the probe inside the stack,

exploiting a sophisticated flow deviation system.

As for maintenance, it is useful to know that the sensors can be replaced by the user himself without having to

send the device to a service center because the sensors are pre-calibrated; it will however be necessary to get

the device calibrated at least once a year.

Also:

Operator interface: user-friendly - so much so that it can be used without the instruction manual.

Wide and bright TFT color display: great readability thanks to the Zoom function and to an efficient

backlight.

Integrated thermal printer: with thermal polyester paper or thermal paper you get maximum readability and

durability and heat resistance.

One battery pack: rechargeable for powering the instrument and the printer, indicating the charge level and is

accessible from outside.

Pneumatic input connectors (gas and pressure/draft) staying inside the profile of the instrument: for

greater resistance to knocks.

Precalibrated sensors, directly replaceable by the user.

4.2 General features of the Flue Gas Analyzer

The portable analyzer S1500/S4500 has been carefully designed in accordance with regulatory requirements and

the specific needs of the customers.

The device contains a single board with all the basic operating circuits, pre-calibrated measuring sensors, a gas

extraction pump, a solenoid valve, a dilution pump, a membrane keyboard, a TFT backlit graphic display, a high-

capacity "Li-Ion" rechargeable battery pack and an integrated thermal printer. The two halves of the casing are

securely fastened together with seven screws on the back of the device.

The pneumatic circuit and the measuring sensors with electronic module are positioned in the back of the casing

and they are accessible, for rapid maintenance and replacement, by removing the magnet cover in the lower part

of the device. The roll of paper is located at the top, above the display, and it can be replaced easily by removing

the pressure-locked door. On the bottom part of the analyzer are the pneumatic connectors for gas sampling and

for the measurement of the pressure/draft: the T1 connector to connect the gas probe thermocouple plug and the

T2 connector to connect the combustion air probe thermocouple plug. On the right side of the device are the B-

type USB connector for the connection of the external power source or of the PC and the 8-pole mini DIN

connector for the serial interface or for an external probe (optional).

The user interface includes a TFT graphic display with back light always active and a membrane keyboard. The

menu screens and all the operator messages can be set in the desired language.

The use of the analyzer is simplified by the symbol keys with direct access to the most important functions.

Navigation through the various menu screens is easy and intuitive.

4.0 DESCRIPTION OF THE PRODUCT