SEMIKRON SKiiP 4 F L5066401 User manual

Technical

Explanation

© by SEMIKRON

PROMGT.1026 / Rev. 1 / Template Technical

Explanation

2017-08-30 - Rev02

1 / 21

This document is valid for the following part numbers:

- L5066401 SKiiP®4 F-Option with D-Sub connector, no plastic case

- L5066402 SKiiP®4 F-Option with D-Sub connector

- L5066403 SKiiP®4 F-Option without D-Sub connector

Technical Explanation SKiiP®4 F-Option Board

Revision:

02

Issue Date:

2017-08-30

Prepared by:

Schiller Anastasia

Approved by:

AG E-KAZ

SKiiP®4 F-Option Board

Please note:

Unless otherwise specified, all values in this technical explanation are typical values. Typical values are the average values

expected in large quantities and are provided for information purposes only. These values can and do vary in different applications.

All operating parameters should be validated by user’s technical experts for each application.

The document remains effective until replaced by subsequent revision of this document.

Technical Explanation

SKiiP®4 F-Option Board

© by SEMIKRON

2017-08-30 - Rev02

2 / 21

Table of content:

1Related documents .........................................................................................................................................3

2Application and handling instructions..............................................................................................................4

3General description .........................................................................................................................................5

4Block diagram..................................................................................................................................................6

5Dimensions......................................................................................................................................................7

6Mounting Instruction......................................................................................................................................10

6.1 Mounting Instruction for F-Option Board Variants 2 and 3.....................................................................10

6.2 Mounting Instruction for F-Option Board Variant 1.................................................................................12

7Description of D-Sub connector X2...............................................................................................................12

7.1 Pin Description........................................................................................................................................12

7.2 Not used Signals.....................................................................................................................................13

8Pin Description of optical connectors X4, X5, X6..........................................................................................13

9Power Supply ................................................................................................................................................13

10 Optical Input/Output Signals..........................................................................................................................14

10.1 PWM TOP/BOT Signals .........................................................................................................................14

10.2 ERROR_OUT Signal ..............................................................................................................................15

11 D-Sub Connector signals ..............................................................................................................................16

11.1 HALT Signal............................................................................................................................................16

11.2 GPIO Signal............................................................................................................................................17

11.3 Analogue Signals....................................................................................................................................17

11.4 CAN Signals............................................................................................................................................17

12 Logistics.........................................................................................................................................................18

13 Provisions and handling after use.................................................................................................................19

Technical Explanation

SKiiP®4 F-Option Board

© by SEMIKRON

2017-08-30 - Rev02

3 / 21

1 Related documents

Technical Explanation SKiiP®4, Rev. 3

CANopen User Manual Rev.6

Data sheets SKiiP®4

Data sheets SKiiP®4 F-Option

Data sheets SKHBP SKiiP®4

Technical Explanation SKiiP®4 Parallel Board

Technical Explanation

SKiiP®4 F-Option Board

© by SEMIKRON

2017-08-30 - Rev02

4 / 21

2 Application and handling instructions

Please provide static discharge protection during handling. As long as the board is not completely

assembled, the input terminals have to be short-circuited. Persons working with devices have to wear a

grounded bracelet. Any synthetic floor coverings must not be statically chargeable. Even during

transportation the input terminals have to be short-circuited using, for example, conductive rubber.

Worktables have to be grounded.

When first operating a newly developed circuit, SEMIKRON recommends to apply low collector voltage

and load current in the beginning and to increase these values gradually, observing the turn-off

behavior of the free-wheeling diode and the turn-off voltage spikes generated across the IGBT. An

oscillographic control will be necessary. Additionally, the case temperature of the module has to be

monitored. When the circuit works correctly under rated operation conditions, short-circuit testing may

be done, starting again with low collector voltage.

It is important to feed any errors back to the control circuit and to switch off the device immediately in

failure events. Repeated turn-on of the IGBT into a short circuit with a high frequency may destroy the

device.

Technical Explanation

SKiiP®4 F-Option Board

© by SEMIKRON

2017-08-30 - Rev02

5 / 21

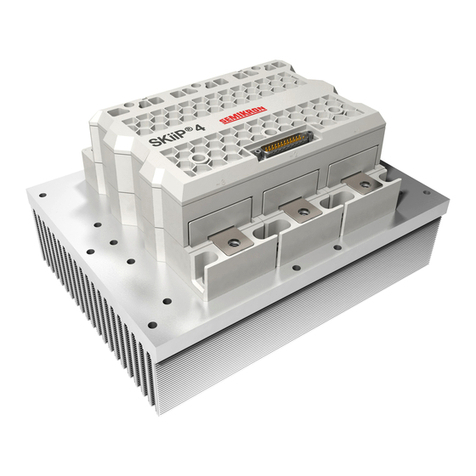

3 General description

The SKiiP®4 F-Option Board allows the controlling of SKiiP®4 system by means of fiber optics. There are three

variants of SKiiP®4 F-Option available:

- Variant 1: L5066401 SKiiP®4 F-Option with D-Sub connector, no plastic case

- Variant 2: L5066402 SKiiP®4 F-Option with D-Sub connector

- Variant 3: L5066403 SKiiP®4 F-Option without D-Sub connector

In case of using SKiiP®4 F-Option the two switching signals (TOP/BOT) and the GPIO error signal are

transferred via optical connection. In addition the analogue signals as well as the CAN-Bus signals are

available on the D-Sub connector X2 for Variants 1 and 2 of F-option boards described above.

The electrical connection between SKiiP®4 F-Option board and SKiiP®4 driver must be realized by 25-wired

ribbon cable. The built-in connector of the SKiiP®4 F-Option board can be directly plugged in case of mounting

SKiiP®4 F-Option on the SKiiP®4 top cover (Variants 2 and 3) or on SKiiP®4 Paralleling Board (Variant 1). In

other cases the usage of cable extention up to 1,5m is allowed. On the other side it must always be connected

to the SEMIKRON “SKiFace Standard” interface of SKiiP®4 driver by a 25-pin D-Sub female connector. Please

refer to the Technical Explanation SKiiP®4 for pin assignment of connector X1.

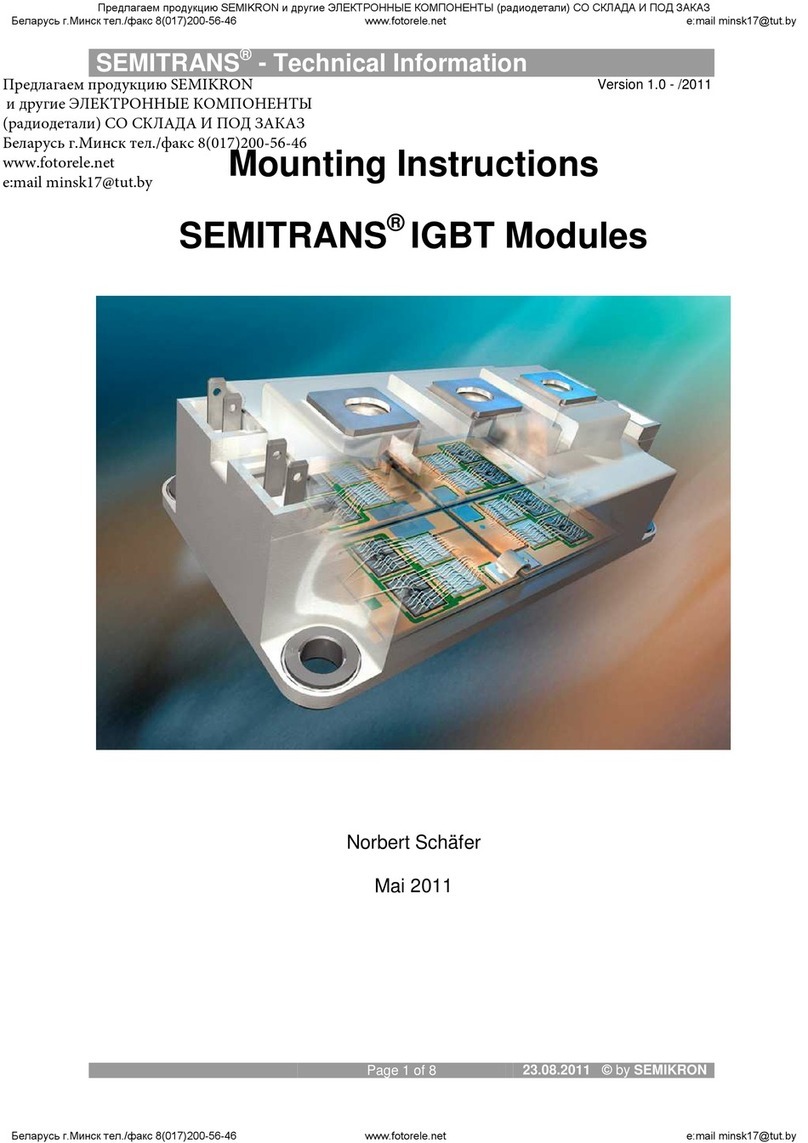

The example of SKiiP®4 F-Option board application for Variant 1 is shown in the Figure 3.1.

Figure 3.1: SKiiP4 F-Option board (Variant 1) application example with connected SKiiP®4 system

Please note that in case of mounting SKiiP®4 F-Option board (Variant 1) on the SKiiP®4 Parallel board the

SKiiP®4 Parallel board variant compatible to the F-Option board should be chosen. The following SKiiP®4

Parallel boards are compatible to the F-Option Board (Variant 1):

L5064204 (paralleling of 4 SKiiP®4 systems),

L5064205 (paralleling of 3 SKiiP®4 systems),

L5064206 (paralleling of 2 SKiiP®4 systems).

Pollution degree class 2 and IP00 shall be considered for all SKiiP®4 F-Option boards.

Technical Explanation

SKiiP®4 F-Option Board

© by SEMIKRON

2017-08-30 - Rev02

6 / 21

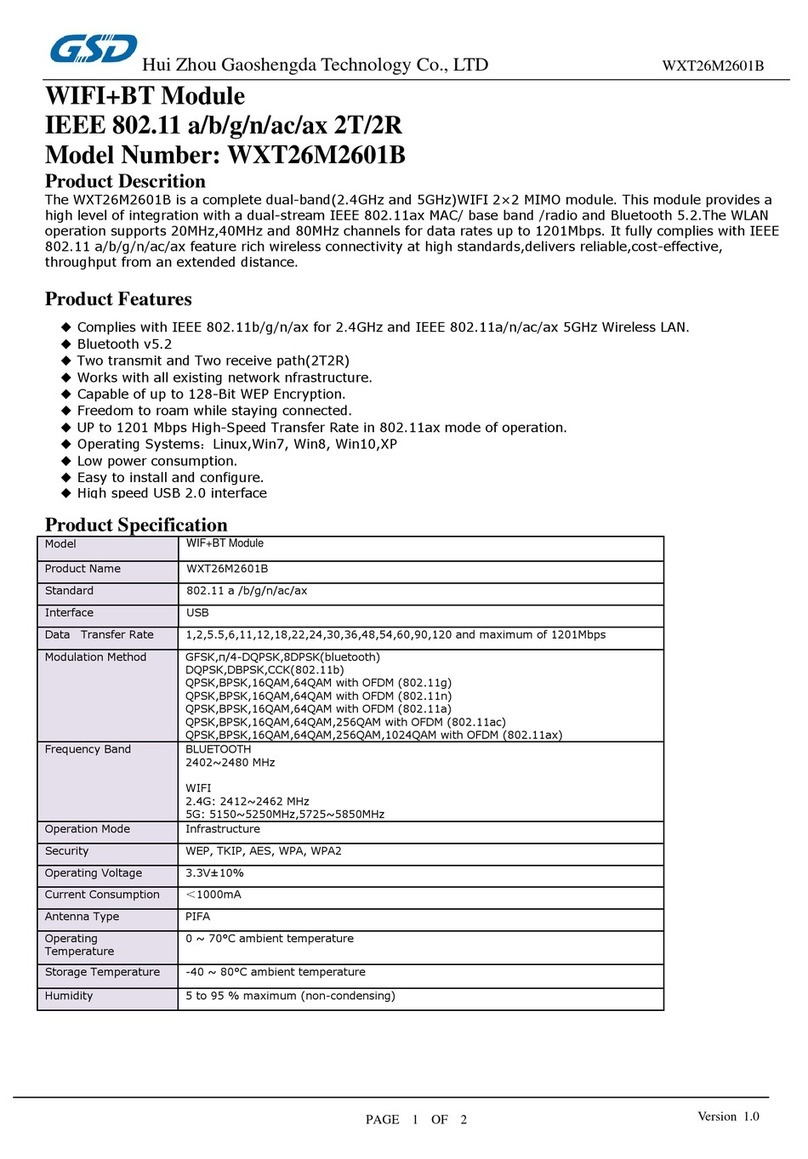

4 Block diagram

Figure 4.1: Block diagram of SKiiP®4 F-Option board main functions

TOP/BOT

optical signals

CMN_DCL

CMN_TEMP

HB_I

PWR_VS

HB_TOP/

HB_BOT

ERROR_OUT

optical signal

X4/X6 X1 (SKiFace)

SKiiP4 F-Option

CAN-Bus

Current

measurement

Temperature

measurement

DC-Link

measurement

CAN-Bus

X2

+24V

X5

X3 Power supply

F-BLOCK 1

F-BLOCK 2

F-BLOCK 3

CMN_GPIO

HALT

GPIO

+24V

Converting of GPIO

signal from SKiiP4 to

optical signal

CMN_HALT

or

F-BLOCK 4

F-BLOCK 5

Converting of optical TOP/BOT signals

to SKiFace Standard Signals

Only available for

Variants 1 and 2

The main functions of the SKiiP®4 F-Option board are shown in the Figure 4.1. They are:

F-Block 1: Converting the optical TOP/BOT switching signals from the connectors X4/X6 to the SKiiP®4

connector X1

F-Block 2: Converting the GPIO signal from SKiiP®4 connector X1 to optical error signal ERROR_OUT

at connector X5

F-Block 3: +24V power supply

The F-Blocks 4 and 5 as well as +24V routing from controller connector X2 to SKiiP®4 connector X1 (please

see Chapter 9 for details) are available only for F-Option Variants 1 and 2:

F-Block 4: Forwarding of analogue signals from SKiiP®4 connector X1 to F-Option D-Sub connector X2

F-Block 5: Forwarding of CAN-Bus signals from SKiiP®4 connector X1 to F-Option D-Sub connector X2

HALT and GPIO Signals are available on the F-Option D-Sub connector X2 as well.

Technical Explanation

SKiiP®4 F-Option Board

© by SEMIKRON

2017-08-30 - Rev02

7 / 21

5 Dimensions

The mechanical dimensions of SKiiP®4 F-Option board Variant 1, top view are shown in the Figure 5.1.

Figure 5.1: Mechanical dimensions of SKiiP®4 F-option board Variant 1, top view

The mechanical dimensions of SKiiP®4 F-Option board Variant 1, side view are shown in the Figure 5.6.

Figure 5.2: Mechanical dimensions of SKiiP®4 F-option board Variant 1, side view

Technical Explanation

SKiiP®4 F-Option Board

© by SEMIKRON

2017-08-30 - Rev02

8 / 21

The mechanical dimensions of SKiiP®4 F-Option board Variant 2, top view are shown in the Figure 5.3.

Figure 5.3: Mechanical dimensions of SKiiP®4 F-option board Variant 2, top view

The mechanical dimensions of SKiiP®4 F-Option board Variant 2, side view are shown in the Figure 5.4.

Figure 5.4: Mechanical dimensions of SKiiP®4 F-option board Variant 2, side view

Technical Explanation

SKiiP®4 F-Option Board

© by SEMIKRON

2017-08-30 - Rev02

9 / 21

The mechanical dimensions of SKiiP®4 F-Option board Variant 3, top view are shown in the Figure 5.5.

Figure 5.5: Mechanical dimensions of SKiiP®4 F-option board Variant 3, top view

The mechanical dimensions of SKiiP®4 F-Option board Variant 3, side view are shown in the Figure 5.6.

Figure 5.6: Mechanical dimensions of SKiiP®4 F-option board Variant 3, side view

Technical Explanation

SKiiP®4 F-Option Board

© by SEMIKRON

2017-08-30 - Rev02

10 / 21

6 Mounting Instruction

6.1 Mounting Instruction for F-Option Board Variants 2 and 3

The mounting process for both Variants 2 and 3 is identic, the description below is shown on example of F-

Option board Variants 2.

The F-Option plastic housing consists of two parts: bottom part (Figure 6.1, left) and top cover (Figure 6.3, left).

1. The bottom part should be placed on the SKiiP®4 top cover so that the snap-fits with larger distance (see

green arrows Figure 6.1) match to the slots of SKiiP®4 top cover. Afterwards the other side should be

pressed inside applying slight pressure (see red arrows Figure 6.1) till the click is audible.

Figure 6.1: Mounting of bottom part of plastic cover SKiiP4 F-option board

2. The PCB can now be inserted in the bottom part of the F-Option housing (Figure 6.2), where it will be fixed

by pressure parts at the sides (see blue arrows Figure 6.2). One edge of the PCB and housing is cut off

(see red arrow Figure 6.2) to avoid the reversed placing of PCB. It is recommended to insert the PCB into

the housing at the beginning on one side and then to press it inside on the other side applying slight

pressure. Please check the screw holes on PCB match to the holes of bottom part of plastic cover.

Technical Explanation

SKiiP®4 F-Option Board

© by SEMIKRON

2017-08-30 - Rev02

11 / 21

Figure 6.2: Inserting of the PCB inside the plastic cover

3. The next step is mounting of the top part of the plastic housing SKiiP®4 F-Option. Please take care that the

snap-fits of bottom part match to the snap-fits of the top cover of the housing (see red arrows Figure 6.3,

the cable connection between F-option Board and SKiiP®4 is not shown).

Figure 6.3: Mounting of the top part of the plastic cover SKiiP®4 F-option board

Technical Explanation

SKiiP®4 F-Option Board

© by SEMIKRON

2017-08-30 - Rev02

12 / 21

Figure 6.4: Mounting of the top part of the plastic cover SKiiP®4 F-option board, final view

4. The PCB should now be fixed with 4 screws Ejot Delta PT 40x18 T20, order number: 4230435809, in the

bottom part of the F-Option housing (please see Figure 6.4, blue arrows). Please use the screws included

in delivery. The screwing parameters should be set up as follows:

Screwer to be used (Bit): T20 Torx

Rpm: 500 –600 U\min

Torque for the first time screwing: 1,8 Nm

Torque for the next screwing (manually, without rpm control): 1,2 - 1,4 Nm

By inadequate setting of screwing parameters mounting problems can occur, e.g. loosing of top cover or

thread damage.

6.2 Mounting Instruction for F-Option Board Variant 1

Please refer to the Technical Explanation SKiiP®4 Parallel Board for information about mounting of F-Option

SKiiP®4 Variant 1 on the SKiiP®4 Parallel Board.

It is also possible to use F-Option SKiiP®4 Variant 1 as a spare part replacement for Varant 2. In this case it

must be inserted into the plastic housing as decribed in the chapter 6.1.

7 Description of D-Sub connector X2

7.1 Pin Description

Please refer to SKiiP®4 Technical Explanation Rev.3 Chapter 5.2 “Gate driver interface SkiFace” for further

information and pin out of connector X2.

Please note: Pin 8 HB_TOP and pin 21 HB_BOT are not connected!

Technical Explanation

SKiiP®4 F-Option Board

© by SEMIKRON

2017-08-30 - Rev02

13 / 21

7.2 Not used Signals

For more details please see Technical Explanation SKiiP®4 Rev.3 Chapter 5.2.11 ”Reserved or not used

signals”.

8 Pin Description of optical connectors X4, X5, X6

Table 1: Description of optical connectors X4, X5, X6

Connector

Type

Signal description

X4

Optical Receiver

Type: HFBR-2521ETZ, horizontal

Receives the PWM control signal for TOP-

IGBT from the controller

X5

Optical Transmitter

Type: HFBR-1521ETZ, horizontal

Transmits the GPIO error signal from SKiiP4

driver to controller

X6

Optical Receiver

Type: HFBR-2521ETZ, horizontal

Receives the PWM control signal for BOT-

IGBT from the controller

The following fiber optical cable type was used for the qualification: Leoni KHPS-HPS11005m. This fiber optic

cable consists of:

2 optical connectors SXHP-SSO-19-0040 (incl. crimp barrel)

5m long optical fiber cable V2Y 1P980/1000.

9 Power Supply

Please refer to SKiiP®4 Technical Explanation Rev.3 Chapter 5.2 “Gate driver interface SkiFace” for further

information and pin out of connector X2.

The pin assignment of power supply connector X3 is shown in the Table 2.

Table 2: Power supply connector X3 pin assignment

Pin

Signal name

Function

01

n.c.

02

GND

Ground

03

+24V

Supply voltage input for F-Option Board and SKiiP®4

Table 3 shows the required features of an appropriate power supply for a SKiiP®4 system.

Table 3: Requirements of the power supply

Power supply

Supply voltage should be +24V (+/- 20%). The supply is defined at the F-Option

Board input.

Maximum rise time of 24V

< 2s

Rated current

1.5 times of the maximum SKiiP driver input current

Minimum peak

2 times of the maximum SKiiP driver input current (at least 1,5A)

For further information please refer to the Technical Explanation SKiiP®4.

Please note: The supply voltage for SKiiP®4 F-Option Board and SKiiP®4 system can be provided over

power supply connector X2 if the voltage drop over the ribbon cable will not be too high due to the supply

current (please see data sheet SKiiP®4 for supply current formula). Otherwise supply connector X3

should be used.

Please note: Power supply cable should be twisted or shielded to enhance the EMI robustness.

Technical Explanation

SKiiP®4 F-Option Board

© by SEMIKRON

2017-08-30 - Rev02

14 / 21

10 Optical Input/Output Signals

10.1 PWM TOP/BOT Signals

The PWM TOP/BOT optical signals could be described as follow: by recognised incoming light the IGBT will be

switched on, by no light the IGBTwill be switched off. Please see Table 4.

Table 4: PWM TOP/BOT optical signals

Optical Receiver receives light

Optical Receiver receives no light

IGBT ON

IGBT OFF

Please note: A non-connected optical link will be considered as LOW signal (IGBT OFF).

If the light intensity is not sufficient the IGBT might stay off and an ERROR_OUT signal might be set. To avoid

this the minimal transmitter current IFdc at the controller side should be at least 50 mA. Please see Figure 10.1

for example of the circuit for transmitter LED at the controller side.

Figure 10.1:Transmitter current controller side

Technical Explanation

SKiiP®4 F-Option Board

© by SEMIKRON

2017-08-30 - Rev02

15 / 21

10.2 ERROR_OUT Signal

Characteristics and functionality:

Shows the status of the IGBT driver

For ERROR_OUT logic please see Table 5.

Table 5: ERROR_OUT optical signal

Optical Transmitterr emits light

Optical Transmitter emits no light

No error

Error

The connected SKiiP®4 system sets the ERROR-OUT signal (Optical transmitter emits no light) if following

happens:

the unit is not ready to operate

error happened

Please refer to the SKiiP®4 Technical Explanation Rev.3 chapter “GPIO -Signal” for further information.

Technical Explanation

SKiiP®4 F-Option Board

© by SEMIKRON

2017-08-30 - Rev02

16 / 21

Please note: D-Sub connector signals are available only for SKiiP®4 F-Option Board Variants 1 and 2.

Please note: maximal number of devices for paralleling of HALT signal is 6 items.

11 D-Sub Connector signals

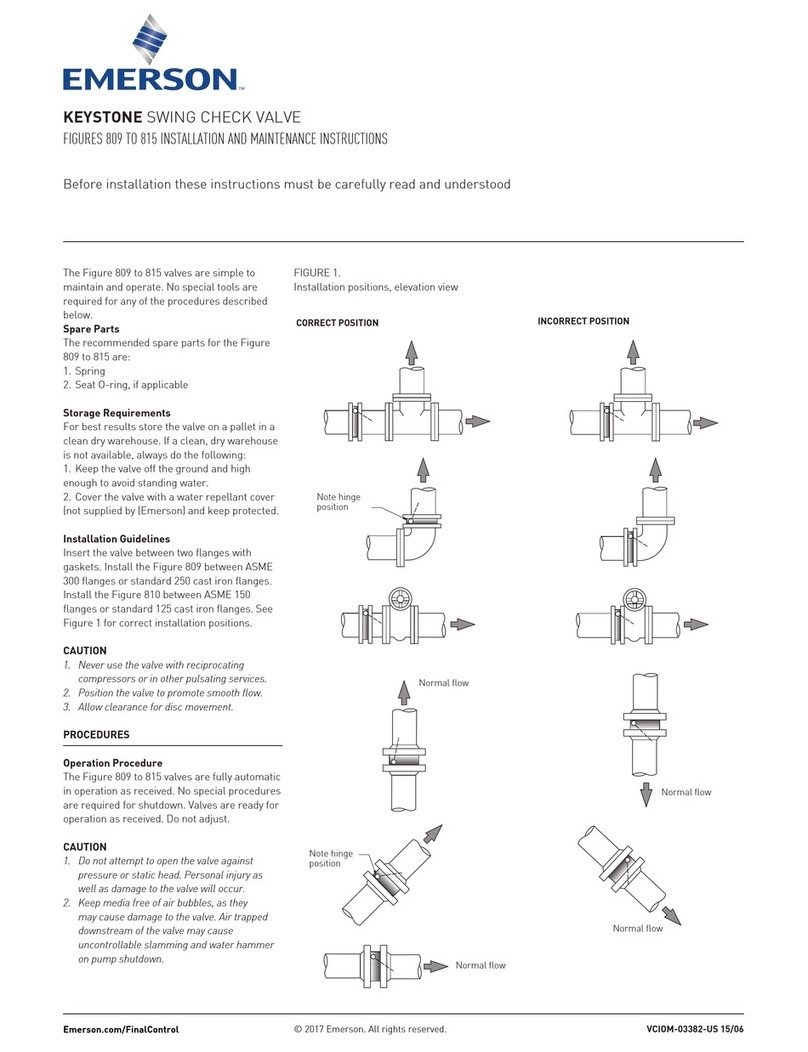

11.1 HALT Signal

Figure 11.1 depicts:

on the left hand side the Input/Output stage of the CMN_HALT signal

on the right hand side an example of the input stage on the user controller board for each CMN_HALT

output of several SKiiP®4 with F-Option Boards.

Figure 11.1: Application example of the HALT signal

1k 20k

Driver Board including F-Option Board 1

to µC

from

µC

VS

Vcc µC

Transmitter

Receiver

10k

12.1k

20k

51k

24.3k

1k

User Controller Board

to µC

from

µC

Vcc µC

Transmitter

Receiver

PWR_VS

VS

to stopp all devices

to send HALT signal

to receive HALT

signal to receive HALT

signal

External

Power Supply

CMN_HALT

CMN_GND

30V 10n

1k

909Ω

(Pin 5)

1k

to µC

from

µC

VS

Vcc µC

Transmitter

Receiver

10k

12.1k

20k

51k

24.3k

1k

to µC

from

µC

Vcc µC

Transmitter

Receiver

PWR_VS

VS

to stopp all devices

to send HALT signal

to receive HALT

signal to receive HALT

signal

CMN_HALT

CMN_GND

30V 10n

1k

909Ω

(Pin 5)

6.19k

30V

30V

20n

20n

6.19k

20k

c

The HALT signals of all SKiiPs in the application and from other hardware components can also be connected

together. That means that the HALT signal is set to LOW state when one of the connected SKiiPs is not ready

to operate. In this case only one receiver circuit on the user controller board is necessary. In case of failure the

switch off time for all such connected susystems will be shorter, than for SKiiPs with separately processed

HALT-signals.

Technical Explanation

SKiiP®4 F-Option Board

© by SEMIKRON

2017-08-30 - Rev02

17 / 21

11.2 GPIO Signal

Figure 11.2 depicts:

on the left hand side the output stage of the CMN_GPIO signal

on the right hand side an example of the input stage on the user controller board for each CMN_GPIO

output of several SKiiP®4 with F-Option Boards.

Figure 11.2: Application example of the CMN_GPIO (inverted HALT signal) as error output signal

Driver Board including

F-Option Board 1

from µC

10k

12.1k

20k

24.3k

1k

User Controller Board

to µC

Vcc µC

PWR_VS

VS

External

Power Supply

CMN_GND

VS

1k

Driver Board including

F-Option Board n

from µC

VS

GPIO

CMN_GND

12.1k

20k

24.3k

1k

to µC

Vcc µC

VS

send GPIO signal

send GPIO signal

51k

10k51k

GPIO

30V 10n

30V 10n

20n

20n

30V

30V

6.19k

6.19k

11.3 Analogue Signals

F-Option Board with D-Sub-Connector forwards analogue signals without any changes. For signal

characteristics and further information please see Technical Explanation SKiiP®4 Rev.3 Chapter 5.3.8.

11.4 CAN Signals

F-Option Board with D-Sub-Connector forwards CAN signals without any changes. For more details please see

Technical Explanation SKiiP®4 Rev.3 Chapter 5.2.8 as well as the CANopen User Manual Rev.6.

Technical Explanation

SKiiP®4 F-Option Board

© by SEMIKRON

2017-08-30 - Rev02

18 / 21

12 Logistics

Figure 12.1: Part Marking Information

Technical Explanation

SKiiP®4 F-Option Board

© by SEMIKRON

2017-08-30 - Rev02

19 / 21

13 Provisions and handling after use

Components which are obsolete or defective must be disposed according to local regulations

Technical Explanation

SKiiP®4 F-Option Board

© by SEMIKRON

2017-08-30 - Rev02

20 / 21

List of figures:

Figure 3.1: SKiiP4 F-Option board application with connected SKiiP4 system......................................................5

Figure 4.1: Block diagram of SKiiP®4 F-Option board main functions ..................................................................6

Figure 5.1: Mechanical dimensions of SKiiP®4 F-option board, top view...............................................................7

Figure 5.2: Mechanical dimensions of SKiiP®4 F-option board, side view.............................................................9

Figure 6.1: Mounting of bottom part of plastic cover SKiiP4 F-option board....................................................... 10

Figure 6.2: Inserting of the PCB inside the plastic cover..................................................................................... 11

Figure 6.3: Mounting of the top part of the plastic cover SKiiP®4 F-option board.............................................. 11

Figure 6.4: Mounting of the top part of the plastic cover SKiiP®4 F-option board, final view.............................. 12

Figure 10.1:Transmitter current controller side.................................................................................................... 14

Figure 11.1: Application example of the HALT signal ......................................................................................... 16

Figure 11.2: Application example of the CMN_GPIO (inverted HALT signal) as error output signal.................. 17

Figure 12.1: Part Marking Information................................................................................................................. 18

List of tables:

Table 1: Description of optical connectors X4, X5, X6 ........................................................................................ 13

Table 2: Power supply connector X3 pin assignment ......................................................................................... 13

Table 3: Requirements of the power supply........................................................................................................ 13

Table 4: PWM TOP/BOT optical signals ............................................................................................................. 14

Table 5: ERROR_OUT optical signal .................................................................................................................. 15

References

[1] www.SEMIKRON.com

[2] A. Wintrich, U. Nicolai, W. Tursky, T. Reimann, “Application Manual Power Semiconductors”,

ISLE Verlag 2011, ISBN 978-3-938843-666

This manual suits for next models

2

Table of contents

Other SEMIKRON Control Unit manuals

Popular Control Unit manuals by other brands

Pentair

Pentair Fleck 4600 MECH user guide

Paso

Paso PM2044-B Instructions for use

STIEBEL ELTRON

STIEBEL ELTRON WPM Commissioning

Baker Hughes

Baker Hughes Consolidated 2700 Series instruction manual

Pfeiffer Vacuum

Pfeiffer Vacuum EVB 063 PA instruction sheet

Bristan

Bristan N2 SHCVO C Installation instructions & user guide

Jung

Jung BT 1001 Series operating instructions

Vega

Vega VEGADIS 81 operating instructions

Beckhoff

Beckhoff KM2002 Documentation

Helo

Helo WE 40 User and installation manual

National Instruments

National Instruments NI 9269 Getting started guide

KOGANEI CORPORATION

KOGANEI CORPORATION HV160E1-2 instruction manual