BP 805 246 BE / A (2010-04)

A PASSION

FOR PERFECTION

EVB 063 … 160 PA/X

Angle valve, pneumatically actuated, bellows sealed,

with position indicator and control valve, normally open

Instruction Sheet

Product Identification

In all communications with Pfeiffer Vacuum, please specify

the information on the product nameplate. For convenient

reference copy that information into the space provided

below.

Pfeiffer Vacuum, D-35614 Asslar

Typ:

No:

F-No:

Nominal voltage

Validity

This document applies to products with the following part

numbers:

Aluminum housing:

PF B18 202 (DN 63 ISO-K)

PF B28 202 (DN 100 ISO-K)

PF B38 202 (DN 160 ISO-K)

Stainless steel housing:

PF B18 232 (DN 63 ISO-K)

PF B28 232 (DN 100 ISO-K)

The part number (No) can be taken from the product

nameplate.

If not indicated otherwise in the legends, the illustrations in

this document correspond to valves with the DN 100 ISO-K

vacuum connection. They apply to valves with other vacuum

connection by analogy.

We reserve the right to make technical changes without prior

notice.

All dimensions in mm.

Intended Use

The Angle Valves are used as shut-off and venting devices

for vacuum applications.

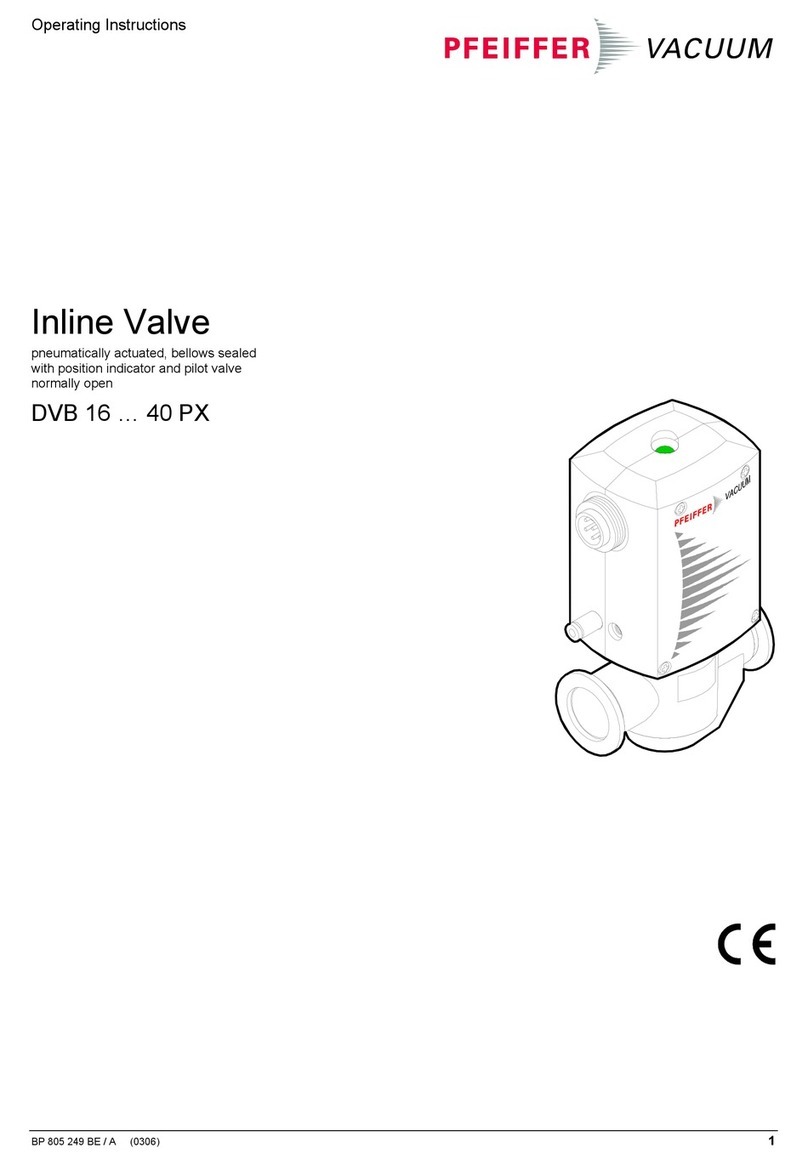

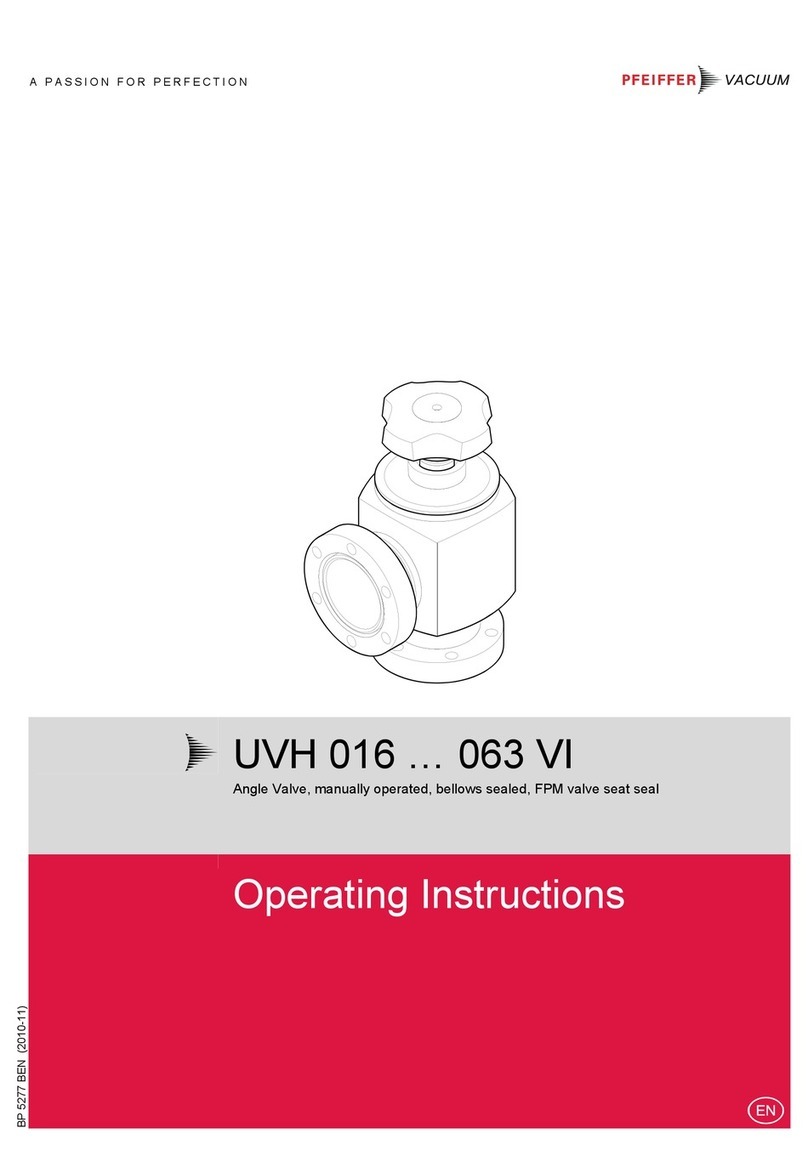

Description

Compressed air

outlet with silencer

Visual position indicator

Vacuum connection

DN 63 ... 160 ISO-K

Compressed air inlet

Connector for electrical

position indicator and

pilot valve (enclosed)

Instant push-in

fitting for educting

the compressed air

(enclosed)

Functional Principle

When the pilot valve is activated, the angle valve is closed by

the pressure spring. The position indicator is invisible.

When the pilot valve is deactivated, the angle valve is

opened by the pneumatic actuator. The green position indi-

cator becomes visible.

The final positions can be polled by the electrical position

indicator.

Safety

Symbols Used

DANGER

Information on preventing any kind of physical injury.

WARNING

Information on preventing extensive equipment and en-

vironmental damage.

Caution

Information on correct handling or use. Disregard can lead

to malfunctions or minor equipment damage.

Personnel Qualifications

Skilled personnel

All work described in this document may only be carried

out by persons who have suitable technical training and

the necessary experience or who have been instructed by

the end-user of the product.

General Safety Instructions

•Adhere to the applicable regulations and take the neces-

sary precautions for the process media used.

Consider possible reactions between the materials and

the process media.

•Adhere to the applicable regulations and take the neces-

sary precautions for all work you are going to do and con-

sider the safety instructions in this document.

•Before beginning to work, find out whether any vacuum

components are contaminated. Adhere to the relevant re-

gulations and take the necessary precautions when hand-

ling contaminated parts.

Communicate the safety instructions to all other users.

Liability and Warranty

Pfeiffer Vacuum assumes no liability and the warranty be-

comes null and void if end-users or third parties

•disregard the information in this document

•use the product in a non-conforming manner

•make any kind of changes (modifications, alterations etc.)

to the product

•use the product with accessories and options not listed in

the corresponding product documentation.

The end-user assumes the responsibility in conjunction with

the process media used.

Failures due to contamination or wear and tear, as well as

expendable parts (e.g. seals), are not covered by the

warranty.