Series EC-8 — 8.0 K-factor

Extended Coverage (Light Hazard)

Pendent and Recessed Pendent Sprinklers

Page 1 of 6 DECEMBER 2014 TFP223

IMPORTANT

Always refer to Technical Data

Sheet TFP700 for the “INSTALLER

WARNING” that provides cau-

tions with respect to handling

and installation of sprinkler sys-

tems and components. Improp-

er handling and installation can

permanently damage a sprin-

kler system or its components

and cause the sprinkler to fail

to operate in a fire situation or cause

it to operate prematurely.

Worldwide

Contacts

www.tyco-fire.com

Pipe Thread Connection

3/4 inch NPT

Discharge Coefficients

K=8.0 gpm/psi1/2

(115,2 lpm / bar1/2)

Temperature Ratings

135°F (57°C) and 155°F (68°C)

Finish

Sprinkler: Refer to Table A

Recessed Escutcheon: Natural Brass,

Signal White, Chrome Plated

Physical Characteristics

Frame ............................Bronze

Button............................Bronze

Sealing Assembly ...........Beryllium Nickel

w/TEFLON

Bulb .....................Glass (3 mm dia.)

Compression Screw . . . . . . . . . . . . . . . . Bronze

Deflector...........................Brass

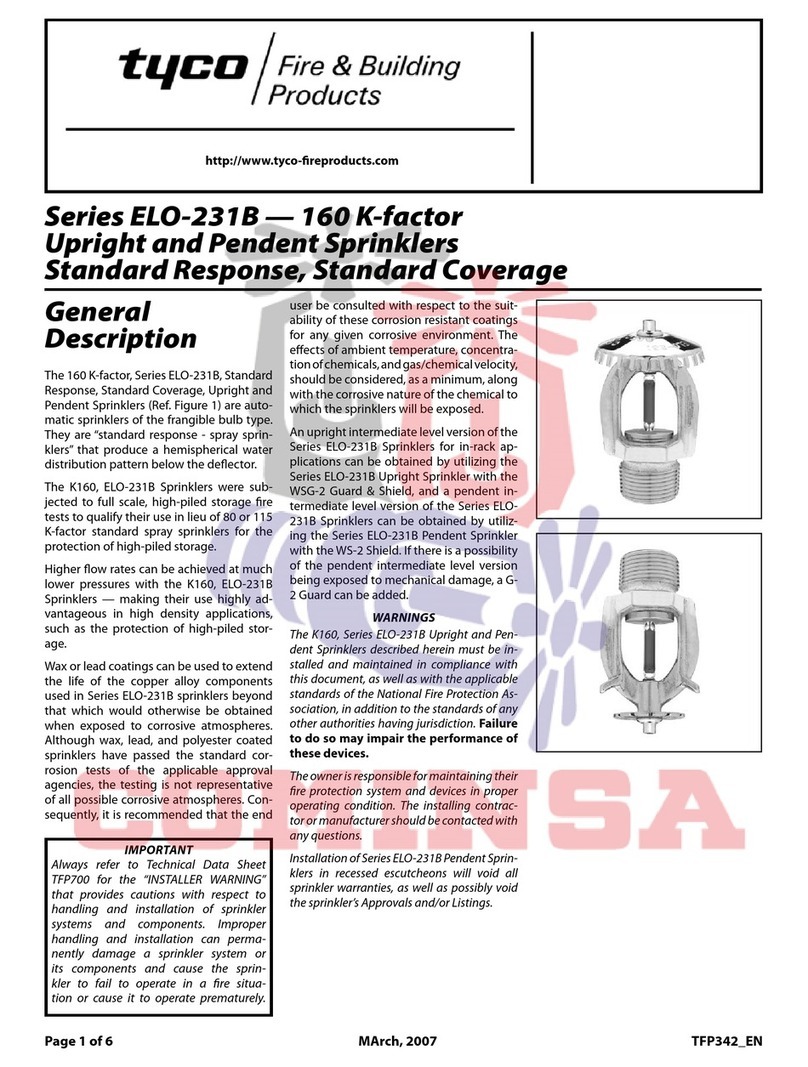

General

Description

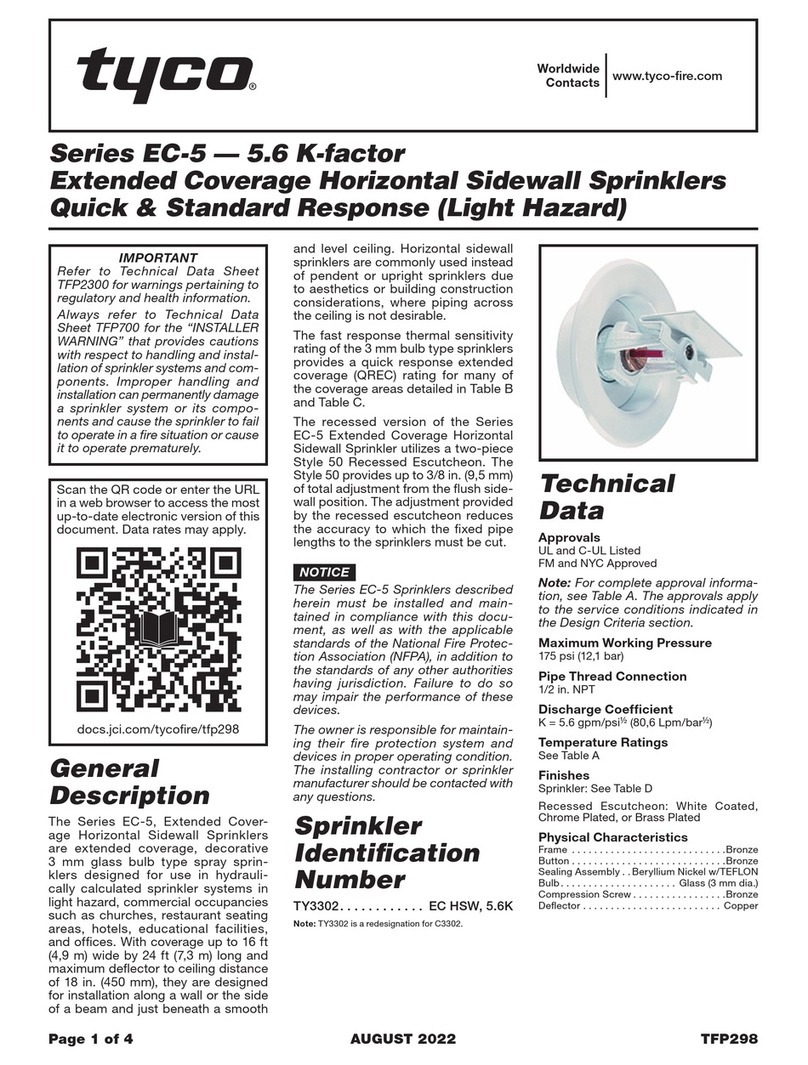

The Series EC-8 Extended Cover-

age Pendent Sprinklers are decora-

tive glass bulb sprinklers designed

for use in light hazard occupancies.

They are intended for use in automatic

sprinkler systems designed in accor-

dance with standard installation rules

(e.g., NFPA 13) for a maximum cover-

age area of 400 ft2( 37, 2 m 2), as com-

pared to the maximum coverage area

of 225 ft2(20,6 m2) for standard cov-

erage sprinklers used in light hazard

occupancies.

The recessed version of the EC-8, in-

tended for use in areas with a finished

ceiling, uses either the two-piece

Style 30 or 40 Recessed Escutcheon.

The Style 30 Recessed Escutcheon

provides up to 1/2 inch (12,7 mm) of

total adjustment from the flush pen-

dent position, whereas, the Style 40

provides 3/4 inch (19,1 mm) of verti-

cal adjustment from the flush pendent

position. The adjustment provided by

the Recessed Escutcheons reduces

the accuracy to which the fixed pipe

drops to the sprinklers must be cut.

Corrosion resistant coatings, where

applicable, are utilized to extend the

life of copper alloy sprinklers beyond

that which would otherwise be ob-

tained when exposed to corrosive at-

mospheres. Although corrosion resis-

tant coated sprinklers have passed

the standard corrosion tests of the ap-

plicable approval agencies, the test-

ing is not representative of all possible

corrosive atmospheres. Consequent-

ly, it is recommended that the end

user be consulted with respect to the

suitability of these corrosion resistant

coatings for any given corrosive envi-

ronment. The effects of ambient tem-

perature, concentration of chemicals,

and gas/chemical velocity, should be

considered, as a minimum, along with

the corrosive nature of the chemical to

which the sprinklers will be exposed.

NOTICE

The Series EC-8 Extended Coverage

Sprinklers described herein must be

installed and maintained in compli-

ance with this document, as well as

with the applicable standards of the

National Fire Protection Association,

in addition to the standards of any oth-

er authorities having jurisdiction. Fail-

ure to do so may impair the perfor-

mance of these devices.

The owner is responsible for main-

taining their fire protection system

and devices in proper operating con-

dition. Contact the installing contrac-

tor or product manufacturer with any

questions.

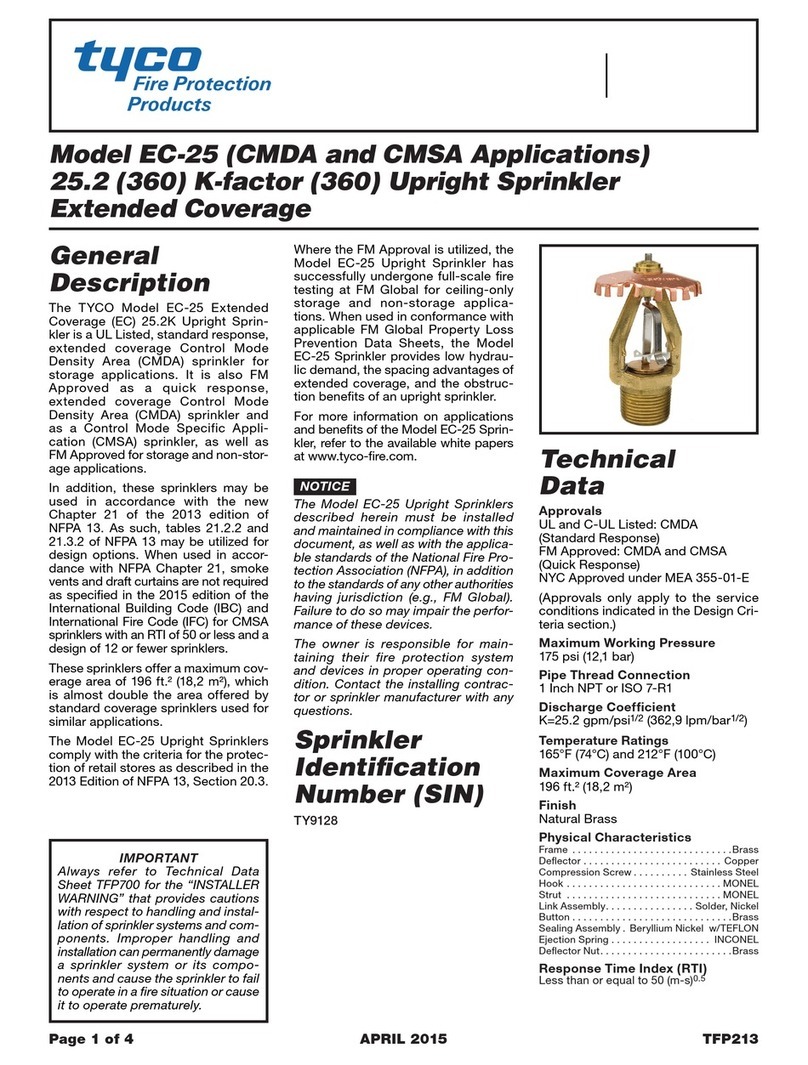

Sprinkler

Identification

Number (SIN)

T Y42 32 - Pendent, 8.0K

TY4232 is a re-designation for C4232

Technical

Data

Approvals

UL and C-UL Listed.

FM Approved

NYC Approved.

(Refer to Table A for complete approv-

al information including corrosion re-

sistant status. The Approvals apply to

the service conditions indicated in the

Design Criteria section.)

Maximum Working Pressure

175 psi (12,1 bar)