Contents

1. Product Overview ..............................................................................................................................................................5

2 Activation...............................................................................................................................................................................6

2.1. Switch On............................................................................................................................................................................... 6

2.2. Switch Off .............................................................................................................................................................................. 6

3. Pump .......................................................................................................................................................................................6

3.1. Pump Test ................................................................................................................................................................................... 7

3.2 Filter Replacement ................................................................................................................................................................... 7

3.3 Regulator ...................................................................................................................................................................................... 7

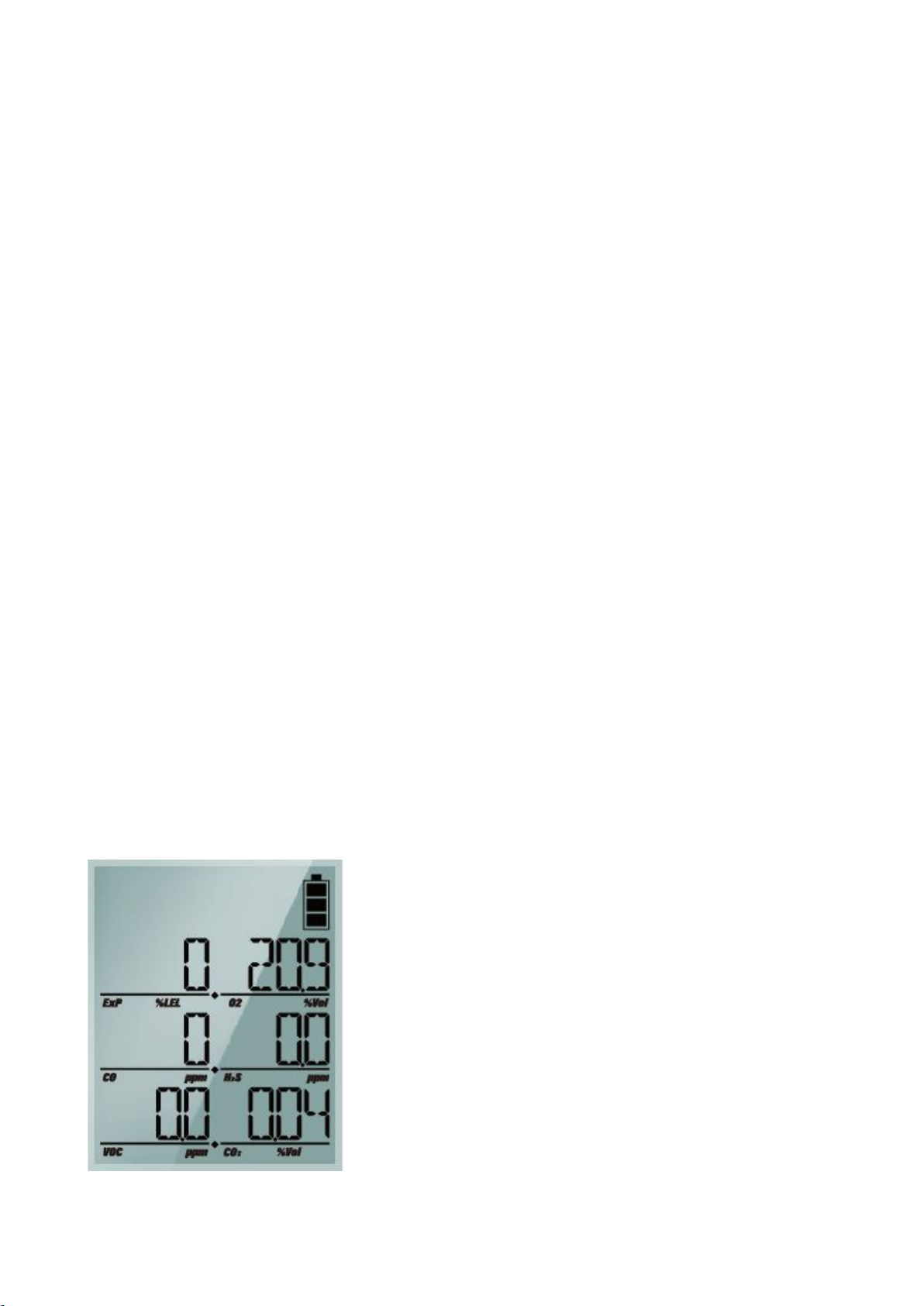

4. Display ....................................................................................................................................................................................7

4.1. Measuring Mode ................................................................................................................................................................ 7

4.2. Display Mode ....................................................................................................................................................................... 8

4.2.1 Display Mode in Detail ...................................................................................................................................... 9

4.3. Alarm Display .....................................................................................................................................................................11

4.3. Battery Display...................................................................................................................................................................13

5. Setting and Operation ................................................................................................................................................. 13

5.1. Alarm Menu ........................................................................................................................................................................14

5.2. Calibration Menu..............................................................................................................................................................15

5.2.1. Span Calibration Environment............................................................................................................................15

5.2.2. Zero Calibration (Fresh Air Calibration) .........................................................................................................16

5.2.3. Span Calibration (Standard Gas Calibration) ...............................................................................................16

5.3. Test (Inspection) Menu ..................................................................................................................................................17

5.4. Set Menu..............................................................................................................................................................................18

6. Log......................................................................................................................................................................................... 19

7. Specification...................................................................................................................................................................... 19

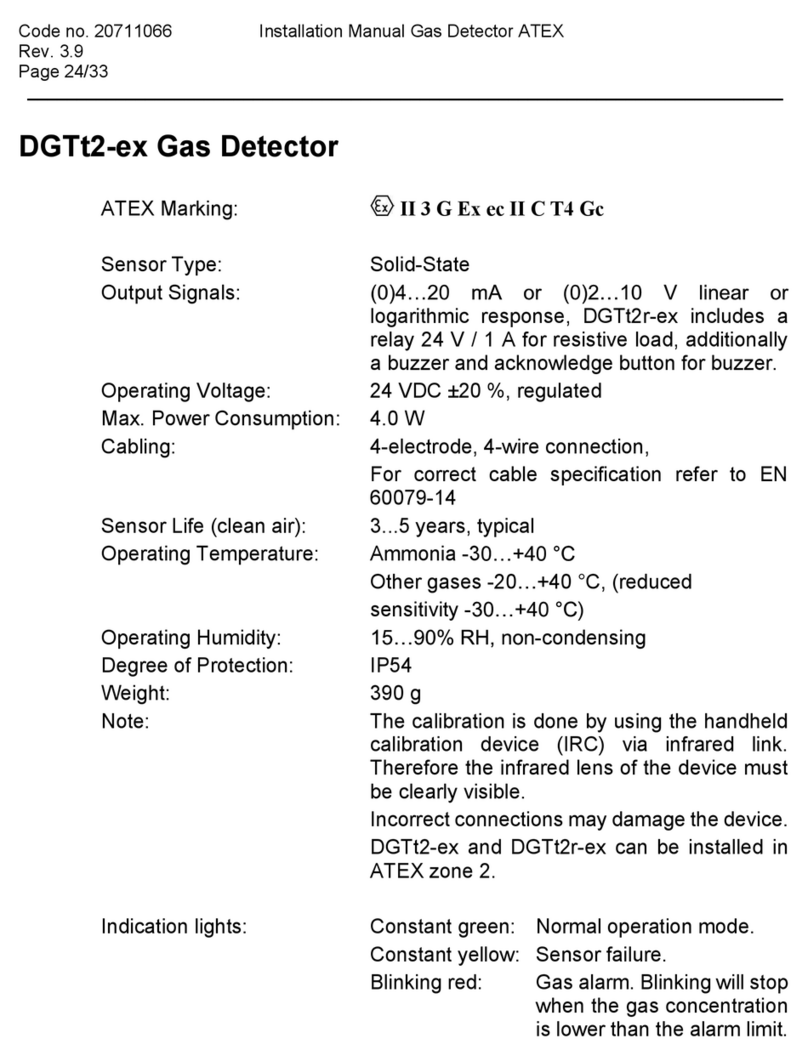

7.1. Operating condition.............................................................................................................................................................19

7.2. Storage condition..................................................................................................................................................................20

7.3. Certification..............................................................................................................................................................................20

8. Failure / Escape................................................................................................................................................................ 22

9. Trouble-shooting............................................................................................................................................................. 23

10. Maintenance & Replacement...................................................................................................................................... 23

10.1. Charging..................................................................................................................................................................................23

10.2. Gas Cylinder ..........................................................................................................................................................................24

10.3. Battery......................................................................................................................................................................................24

10.4. Pump.........................................................................................................................................................................................24

10.5. Filter ..........................................................................................................................................................................................24