SENKO SP secure User manual

MODEL: SP secure

(Combustible Gas Leak Detector)

Operating Manual

Version 2.2

01

Guarantee and Repair

Senko Co., Ltd. guarantees the products of SP series for 12 months from the

shipping date and repairs or replaces the defected product during warranty

period. Nevertheless, Senko is not responsible for the following cases and would

not repair or replace the product at no cost, such cases as the product has been

purchased through the route that Senko does not approve, or as the product

has been damaged or deformed mechanically by misuse of the user, or as the

product has not been calibrated or replaced the parts according to processes in

the operating manual.

In the event that any defect or issue of the product occurred during warranty

period, Senko will cover all the expenses except transportation fee. After the

period of warranty, the expenses of repair or replacement of the product and

transportation will be in principle borne by the user. Senko will not be

responsible for any indirect occurrence or accident and/or damage during the

use of the product, and the guarantee shall be limited to the replacement of

parts and product. The guarantee is applied only to the users who purchased

the product at Senko’s authorized dealers or agents, and the guarantied repair is

to be performed by the expert engineers of Senko’s authorized aftercare center.

Product Introduction

SP secure is a portable gas leak detector necessary to secure user’s safety and

protect industrial facilities by detecting leakage of gas in earlier stage at the

dangerous work environment where risk of explosion always exists. As it is

configured with two buttons only, the method of operation and sensor

calibration is easy and convenient. Also the %LEL and concentration value of

inflammable gas (LPG/LNG, hydrogen, etc) can be displayed on a digital LCD

monitor.

For the safety of users, workers and operators are to be fully alerted about the

alarm circumstances by the loud alarm sound and warning icon displayed on

LCD monitor when gas concentration is detected in excess of regulatory

standard. In addition, a suction pump is built-in it and also featured with the

function of On/Off for the pump and alarm sound so that the user can set up

alarm values to properly meet with the circumstances involved and the alarm

value such set up can be adjusted to best fit to the type of gas and

circumstances of leakage. SP secure provides quick response to inflammable gas

and also prevents in advance workers from the explosion by the leakage of gas

and high risk of asphyxiation that may be resulted by the exposure to toxic gas

for a certain period of time.

Contents of Operating Manual

Product Specification ---------------------------------- 03

Names of Exterior and Display ----------------------- 04

Start and End of Operation -------------------------- 05

Operation Method ------------------------------------- 06

Backlight, ON/OFF of Sound and Pump ------------- 07

Calibration ---------------------------------------------- 07

Method of Alarm Set and Display ------------------- 09

Recharging --------------------------------------------- 11

Battery & Sensor replacement------------------------ 11

Applicable Battery ------------------------------------- 13

Notice for User ----------------------------------------- 14

02

03

Model SP secure

Detecting Gas LNG, LPG H2

(KGS701/SS1178) Xylene

Sampling

Method Auto sampling type

Sensor Type Catalytic Electrochemical IR

Detecting

Range 0~100%LEL 0~1000ppm 0~100%LEL

Response

Time(T90) Within 10 sec. Within 10 sec.

Within 75 sec. Within 90 sec.

Resolution 1 %LEL 1 ppm 1 %LEL

Display Digital LCD(Alarm, Buzzer, Pump On-off, Battery, Backlight)

Alarm Buzzer alarm & LCD Display

Gas

Concentration

Display

0~1% LEL –Digital bar

1~100% LEL –Numerical

display

0~20 ppm –Digital bar

0~1,000 ppm –

Numerical display

0~1% LEL –Digital bar

1~100% LEL –Numerical

display

Explosion

Proof Ex d ia IIB T3

Operating

Temperature - 20˚C ~ 50˚C

Power Recharger or AA Alkaline battery 3ea

Continuous

Operation More than 12 hours

Dimensions /

Weight 55m(W) x 241mm(H) x33 mm(D) / 260g

Standard

Accessories Protect Cover, Adapter for charge

Options Extension Probe(5M/10M)

1. Product Specification

04

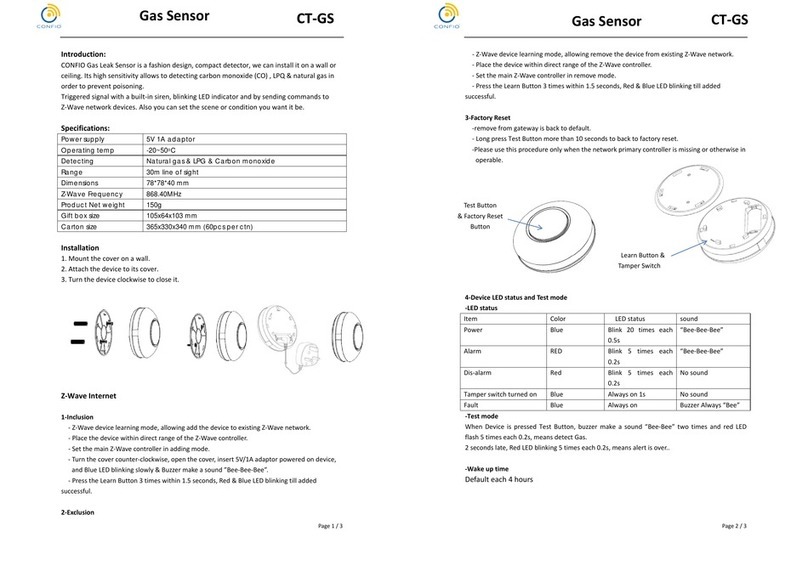

1. Gas inlet probe

2. Gas inlet filter

3. Gas outlet

4. Gas sensor

5. Buzzer

6. LCD display

7. Gas type

8. On/Off key &

Pump On/Off key

9. Buzzer On/Off key &

Back light On keyOn/Off

10. Battery cover

11. Protection Rubber Case

4

5

6

7

3

2

1

8

9

10

11

LCD display symbols

2. Names and Functions of Exterior

05

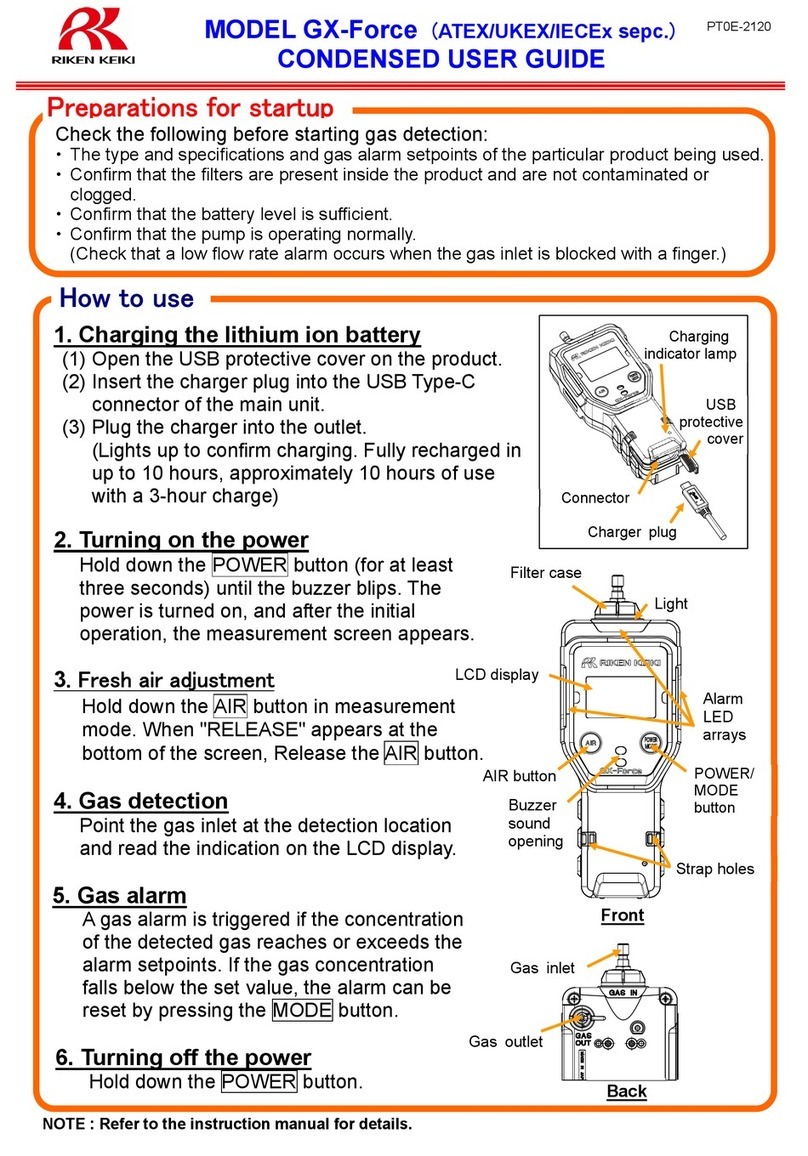

Press Power Key for 3 seconds and the digit 3,2 and 1 shall appear on the

monitor in turn. After then power is turned off.

3. Start and End of Operation

Instrument Power-On

Press Power Key and power is turned on displaying 3,2 and 1 in order and

all icons on LCD shall be blinking three times. Afterwards during the device

is being stabilized, countdown is displayed on the screen. When

stabilization of the device is completed, mark appears with alarm sound

and then converted to Gas Detection Mode.

Under normal status, mark disappears in about 30 seconds and

concentration of the gas detected of the moment is indicated. In the

events that stabilization of the device fails, it would not convert to Gas

Detection Mode, blinking the mark with alarm sound. In this case,

calibration of sensor or A/S of the device is required.

Instrument Power-Off

Test Success Test Fail

<Caution> Appropriate calibration of the device is always required prior to

operation at the work site. Make sure if the device shows proper response to the

pertinent gas and if the part sucking gas is not blocked with foreign materials that

interfere the gas detection.

06

Set Up of LPG/LNG gas

When buzzer key is pressed under the state of power Off, type of gas presently

set shall be indicated. While buzzer key is pressed for 5 seconds, the set up for

the type of gas shall be changed to LNG from LPG. Set up for LPG can be made in

same manner as that done for LNG.

In case of LPG/LNG Detector, the device is converted to Gas

Measure Mode as shown below when power button is turned

on. Gas Measure Mode indicates the concentration of gas,

operating status of suction pump, alarm sound On/Off status,

battery level on LCD and it displays the concentration of

flammable gas by %LEL and by PPM unit for Hydrogen. In the

event that gases are detected, it indicates the value of

concentration in real time and, if it exceeds the 1st and 2nd

alarm standard, the measured value shall be displayed blinking repeatedly along

with mark and LO or HI indication.

The gas leakage detector raises an alarm along with digital bar when gas leakage

is detected even in small amount, and the concentration value shall be reduced

and alarm also shall be ceased when moved out to safe region where normal

concentration value is measured. The alarm sound raised by the detection in the

beginning stage can be stopped (OFF) with the Alarm Sound Off Button but the

1st and 2nd alarm sound can not be stopped. (Once alarm sound is raised, the

mark shall not be disappeared even though the device is moved out to safe region

(Can delete it by the OFF of Power Key). When the concentration value of the gas

measured exceeds the maximum measuring range, it is indicated as the max value

and it will be kept blink with one second interval. Also alarm sound relevant to the

standard of 2nd alarm shall be raised along with indication.

4. Operation Method

Detection Mode

07

On/Off of Pump

On/Off of Backlight and Sound

Alarm sound is also set to turn ON state when power key is pressed. All the

following operations for ON/OFF of the Alarm Sound can be performed in the

same way as that for suction pump above by using Alarm Sound key.

Suction pump is set to turn ON when

power key is pressed. Press power key

one more time to OFF suction pump.

When power key is input once again, the

function of suction pump returns to ON

state as initially set.

<Caution> Gas leakage detection can not be properly performed if the Suction

Pump key is laid in OFF state. As the setting of OFF mode is to save battery while

the device is not in service, Suction Pump has to be set ON all the time during the

measure of gas leakage.

5. Backlight, ON/OFF of Sound and Pump

6. Calibration

08

icons shall blink if buzzer key is pressed for 3 seconds under the state power

key is pressed simultaneously. Press power key at this state to enter into standby

calibration mode. Calibration shall be completed in 10 second while processing

countdown from 10,9,8…down to 3,2,1. When calibration is successfully completed,

it returns to Gas Measure Mode with alarm sound after the icons being blinked

for 3 seconds.

…

In case standby calibration is failed, it returns to Gas Measure

Mode with alarm sound after the icons being blinked for 3

seconds but the icons shall remain appeared in this case. If

such occurrence happens repeatedly, please contact our agent or

A/S center as the sensor is required to be replaced.

Press buzzer key for three seconds simultaneously at state pressing power key.

Then icon blinks. At this time, icon blinks if press buzzer key. After press

power key for five seconds, it enters to Standard Gas Calibration Mode. Initial

concentration is 20%LEL.

Press power key to change value, and press buzzer key to save value. Calibration

starts to setting concentration if press buzzer key at final number. For canceling

calibration, press buzzer key.

Calibration is done for 20 seconds countdown. When calibration is successfully

completed, icon blinks and it appears concentration of standard gas. After this

time, standard gas is not connected, it returns to Gas Measure Mode.

Fresh air Calibration

Standard Gas Calibration

<Caution> As the calibration is conducted under the assumption that the concen-

tration of oxygen in fresh air is 29.9% and that of flammable gas is 0%LEL and the

same of toxic gas is 0ppm, the fresh air calibration must be conducted in fresh air

where no influences of other gases are effective. Hence, it is not desirable conducting

fresh air calibration in a closed space and should be very careful not to conduct

under the working environment where gases can be inhaled by workers or operators.

09

5초

Change value

Save value and

Start calibration

…

In case standby calibration is failed, it returns to Gas Measure

Mode with alarm sound after the icons being blinked for 3

seconds but the icons shall remain appeared in this case. If

such occurrence happens repeatedly, please contact our agent or

A/S center as the sensor is required to be replaced.

Gas Combustible gas Hydrogen Xylene

Concentration 20%LEL

(1%vol CH4) 500 ppm 0.54%vol

(Propane)

9. Method of Alarm Set and Display

Alarm Set

Concentration of Calibration Gas Set to Instrument

When power key and buzzer key is pressed for 3 seconds under the state of

power OFF, icons shall appear blinking on LCD and indicates LO. Press

power key one more time under this state to enter into alarm set up mode. When

power key is pressed at this point, system shall be entering into the 1st alarm

change mode and, when buzzer key is pressed, HI shall be displayed on the

monitor and then moves to the 2nd alarm set up mode. In order to return to Gas

Measure Mode without changing alarm set value, use buzzer key to move.

10

Power OFF

Save value

Change value

Save value

Change value

In case 1st alarm is raised and power key is pressed by a worker or operator who

perceived the status of 1st alarm, the alarm sound only shall be stopped but the

device shall still remain in operation state. When 2nd alarm is raised, the workers

should quickly escape from the work site to safe region. Termination of alarm in

this case is possible only by turning power key Off at a place where gas

concentration indicates normal value (Alarm shall be continuously raised unless the

power key is turned off at an area of normal concentration value).

The alarm sound of 1st battery is same as that of the 1st alarm and, when power

key is pressed, the alarm and vibration only shall be ceased but icons shall be kept

blinking. The alarm sound of 2nd battery is same as that of 2nd alarm and the

blink of icons can not be deleted by the users. The alarm and power shall be off 10

seconds after the raise of alarm.

In case of failure of test and calibration, icons shall blink with alarm sound.

Gas Combustible gas Hydrogen Xylene

1st 20%LEL 100 ppm 20%LEL

2nd 40%LEL 500 ppm 40%LEL

Alarm Set Point

Alarm Display

After setting the 1st alarm value, returns to the 1st alarm set up mode that is the

alarm mode initially set. Use arrow key to enter into the 2nd alarm set up mode or

to return to Gas Measure Mode. Method of 2nd alarm set up is same as that of the

1st alarm setting.

While returning to Gas Measure Mode through the 2nd alarm set up mode,

countdown shall be proceeded. When countdown is completed, system shall be

converted to Gas Measure Mode.

11

Alarm Standard for Alarm

LCD Display Alarm Sound

1st Alarm

When

exceeding th

e

value set for 1st a

larm

and

indicates

LO

2nd Alarm

When

exceeding th

e

value set for 2nd

alarm

and

indicates

HI

Low

One

level only left

unused

Blinking

Battery

Dead

is

exhausted

Blinking

Battery

Test Failure

Failure

of sensor te

st

or calibration

Displays icon

8. Recharging

When adapter for recharge is equipped

with the device, battery recharge mode

shall be displayed on screen even under

the mode of gas measure or power Off

state. Power shall be Off when adapter

is removed.

Recharging End recharge

9. Replacement of Battery and Sensor

<Caution> The values set for alarm of the device are set in conformity with the

alarming standards internationally required by gases. Therefore, the set value for

alarm by gases can be modified by the approval of the manager responsible for the

area where the device is used.

Following tools and parts are necessary to replace sensor and battery of SPsecure.

- Tool : + Driver

- Energizer No.E91, EN91 battery for replacement or rechargeable battery

- Sensor for replacement

- Sensor filter for replacement

12

<Caution>

1. No battery replacements or disassembly of product are permitted at potential

explosion or dangerous area.

2. Please be noted that replacement of parts may cause damage to the fundamental

safety capabilities of the device.

3. Sensors for replacement must be the one exclusively for SP Secure. The use of

other sensors may cause problems in the detection of gas leakage or cause errors in

the measurements.

4. The device is to be disassembled only for the replacement of battery or sensor and

it has to be calibrated by utilizing standard gas during reassembly.

- Finish operation of the device.

- Replace sensor and battery referring to the picture below.

- Operate the device after replacing sensor and then adjust zero point and

standardize the device.

- Conduct gas calibration (When battery only is replaced, standard gas calibration

shall not be carried out)

9

1 2

3

4

5

8

6

11 12

7 10

1. Label(Membrane)

2. Front Cover

3. Upper cover

4. Sensor bracket

5. Sensor

6. Pump

7. PCB

8. Packing body

9. Rear Cover

10.Machine Screw

11.Battery

12.Battery Cover

Disassembly

13

<Caution> It is absolutely prohibited to replace battery at potential explosion areas

or dangerous regions. Specifications of the batteries applicable to this device are as

follows.

- Disposable alkaline battery : Energizer No. E91, Energizer No.EN91

- Rechargeable battery : Panasonic Rechargeable BATTERY

HHR-3MRT, 1.2V

Batteries other than specified above are not allowed to use in dangerous area.

<Caution> Throwing battery into fire or disassembly by force may cause explosion.

Disposal of used battery should be performed in accordance with the guideline of the

pertinent country or the work site.

10. Applicable Battery

14

Please use the instrument in the range of the applicable temperature, humidity and

pressure that are appropriate for the specification of the product. Using the

instrument beyond this range may cause malfunction or glitch of the instrument. .

Gas concentration measurement value by the sensor or the instrument can vary

according to the environment at site (temperature, pressure and humidity). Therefore

the calibration of the instrument should be performed at the same or similar

environment as that of the instrument use (temperature, pressure and humidity),

If temperature changes sharply during use of the instrument (for instance, using the

instrument at places of far different temperatures between indoor and outdoor), the

value of the measured gas concentration can be changed suddenly. Please use it

after the gas concentration value is stabilized. .

Severe vibration or shock to the instrument may cause the sudden change of value

of the measured gas concentration. Please use it after the value of gas concentration

is stabilized. Excessive shock to the unit can lead to trouble of the sensor or the

instrument.

11. Notice for User

15

Other manuals for SP secure

1

Table of contents

Other SENKO Gas Detector manuals