2

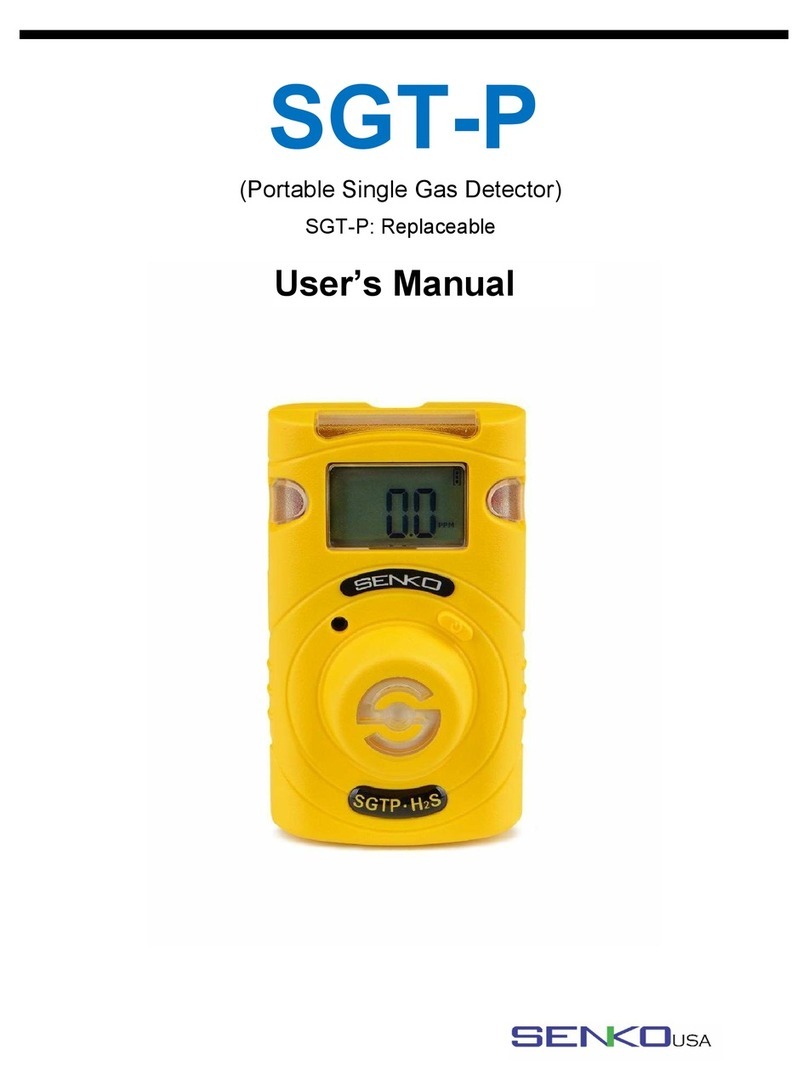

ⓒCopyright SENKO CO., LTD.

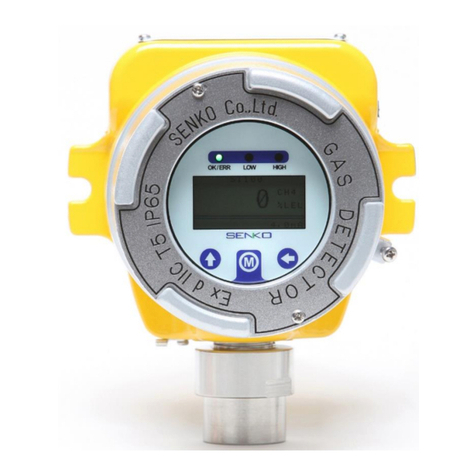

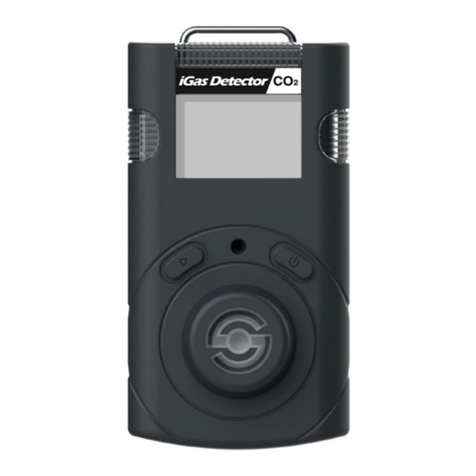

This manual contains operating instructions for stationary gas monitoring instruments

designed for area air quality and safety applications, and should be STUDIED CAREFULLY

by all persons responsible for the operation and maintenance of the instruments. All

SENKO equipment described herein is designed or manufactured for use only as set forth

herein and by the labels affixed, or other literature accompanying the product.

Where WARNINGS or CAUTIONS are herein set forth, they must be followed. If SENKO

equipment is used in a manner or under conditions not specifically authorized or

prescribed by this manual, or by other materials or written instructions either

accompanying the product or authorized by SENKO in writing, or if it is used or

maintained by unqualified or improperly trained personnel, SENKO Co., Ltd. disclaims all

responsibility of every kind for said equipment. While basic connection installation

instructions are included, all equipment must be installed by qualified personnel.

FOLLOWING ALL ASPECTS OF THE LOCAL CODE REQUIREMENTS. Also, the instruments

must be calibrated and alarms tested periodically by trained personnel for proper

functioning of the instruments.

CAUTION: The overall system, especially where gas monitoring sensors are used, must

be CALIBRATED BY QUALIFIED PERSONNEL. Thereafter, a monthly calibration check is

recommended to assure reliability and accuracy.

Please call the factory if any problems are encountered.

WARRANTY

SENKO sensors and instruments are designed for area air quality and safety applications.

SENKO gas monitoring instruments are provided with a one year warranty. This warranty

covers only defective parts or workmanship in normal use and service. Instruments

which fail to function due to factory defect

Within one year of date of shipment are to be returned to SENKO for warranty repair.

SENKO will determine the nature and responsibility for the defect. In all cases the

warranty is limited to the original cost of the equipment. Any misuse of equipment is the

customer’s responsibility. SENKO will either repair or replace (at SENKO’s option)

returned instruments subject to the warranty, at no charge. No field service is included

in this warranty. For field service requirements please contact SENKO.

This warranty is voided by:

1. Improper application of instrument.

2. Misuse of instrument.

3. Intentional or accidental damaging of instrument.

4. Not returning the sensor to factory for warranty validation.

For any queries regarding warranty repair or replacements, please include the

instrument model and serial number in any transmittals to SENKO. SENKO instruments

are supplied with operating and installation manuals and other literature. These are the

only source of specific details regarding proper operation and maintenance of the

equipment. These instructions must be carefully read and the precautions followed in

detail. Instruments must be calibrated and alarms checked periodically to

assure proper equipment operation. Please refer to the manual for details.