Sens EnerGenius DC COMPACT User manual

SENS EnerGenius® DC Compact Technical Manual

1

SENS Part Number: 101334

Document Revision: B

DCN Number: 107947

Date: April 27, 2021

PATENTED US 9,270,140; 9,385,556; 9,413,186; 9,509,164;

9,466,995; 9,948,125; 10,575,433

Installation or service questions?

Call SENS between 8 a.m. and 5 p.m. (Mountain Time),

Monday through Friday, or visit our website.

Copyright © Stored Energy Systems LLC 2020

The SENS name / logo, EnerGenius, HELIX, and Dynamic Boost are trademarks of Stored Energy Systems LLC

Installation & Operation Manual

COMPACT

Automatic Battery Charger/Power Supply

1840 Industrial Circle

Longmont, CO 80501

Phone: 303.678.7500

800.742.2326

Fax: 303.678.7504

Email: service@sens-usa.com

Web: www.sens-usa.com

SENS EnerGenius® DC Compact Technical Manual

2

TABLE OF CONTENTS

1IMPORTANT SAFETY INSTRUCTIONS FOR INSTALLER AND OPERATOR..........................................................4

2MODEL NUMBER BREAKOUT ........................................................................................................................6

3PERFORMANCE SPECIFICATIONS...................................................................................................................7

4SYSTEM OVERVIEW.....................................................................................................................................10

4.1. Physical Overview...............................................................................................................................10

4.2. Functional Overview...........................................................................................................................11

5MOUNTING INSTRUCTIONS ........................................................................................................................ 12

5.1. Mounting Location .............................................................................................................................12

5.2. Mounting Instructions........................................................................................................................12

6SETUP AND WIRING.................................................................................................................................... 13

6.1. Wire Ratings and Sizes........................................................................................................................13

6.2. Grounding Instructions and Connection..............................................................................................15

6.3. DC Connection ...................................................................................................................................15

6.4. AC Connection....................................................................................................................................15

6.5. Standard Alarm Connections ..............................................................................................................16

6.6. Optional High Current Relay Connections ...........................................................................................17

6.7. CANbus and RS-485 Connections........................................................................................................18

6.8. Ethernet.............................................................................................................................................20

6.9. SENSbus Connection...........................................................................................................................21

6.10. Verify Connections .............................................................................................................................22

7START-UP PROCEDURE ............................................................................................................................... 23

7.1. Connect Battery/Outputs ...................................................................................................................23

7.2. Verify Configuration ...........................................................................................................................23

7.3. Apply AC Input Voltage.......................................................................................................................24

7.4. Power Off...........................................................................................................................................24

8ALARMS, LEDS AND DISPLAY.......................................................................................................................25

8.1. LED Indicators ....................................................................................................................................25

8.2. Individual Alarm Relay Contacts..........................................................................................................25

8.3. LCD Panel...........................................................................................................................................26

8.4. Alarm Definitions ...............................................................................................................................26

9OPERATION................................................................................................................................................. 33

9.1. Charging Algorithms...........................................................................................................................33

9.2. Float Mode.........................................................................................................................................33

9.3. Dynamic Boost™ Mode.......................................................................................................................33

9.4. HELIX Mode........................................................................................................................................34

9.5. Charging Low or Zero-volt Batteries....................................................................................................34

9.6. Commissioning Batteries....................................................................................................................35

9.7. Battery Check.....................................................................................................................................35

9.8. Restore Factory Defaults ....................................................................................................................35

9.9. Keypad Operation ..............................................................................................................................35

9.10. Configuration and Monitoring with SENS Setup Utility ........................................................................40

9.11. Temperature Compensation...............................................................................................................40

9.12. Load Share Charger Operation............................................................................................................41

9.13. Remote Alarm/Communications Panel Accessory ...............................................................................41

9.14. Efficiency............................................................................................................................................41

10 SERVICE AND MAINTENANCE...................................................................................................................... 42

10.1. Recommended Annual Maintenance..................................................................................................42

10.2. Air Filter.............................................................................................................................................42

10.3. Fans ...................................................................................................................................................42

10.4. Supplemental Surge Protectors ..........................................................................................................42

11 MODBUS COMMUNICATIONS..................................................................................................................... 43

11.1. TCP/IP Modbus—Optional..................................................................................................................43

11.2. Modbus RS-485—Optional .................................................................................................................43

11.3. Modbus Holding Registers..................................................................................................................43

SENS EnerGenius® DC Compact Technical Manual

3

11.4. Basic Charging Alarms Bit Definition ...................................................................................................45

11.5. Charging Status Bit Definition .............................................................................................................46

11.6. Charging Alarms Extended Bit Definition.............................................................................................46

11.7. Charging AC Alarms Bit Definition.......................................................................................................47

11.8. Accessory Channel Alarms Bit Definition.............................................................................................47

11.9. Accessory System Alarms Bit Definition ..............................................................................................47

11.10. Accessory Assigned Channel Alarms Bit Definition ..............................................................................48

11.11. Writable Control Flags (Coils)..............................................................................................................48

12 TROUBLESHOOTING/ERROR CODES............................................................................................................ 49

12.1. Configuration Error Codes ..................................................................................................................49

12.2. Troubleshooting.................................................................................................................................53

13 GLOSSARY...................................................................................................................................................59

SENS EnerGenius® DC Compact Technical Manual

4

1IMPORTANT SAFETY INSTRUCTIONS FOR INSTALLER AND OPERATOR

1.1. SAVE THESE INSTRUCTIONS –This manual contains important safety and operating instructions for

EnerGenius DC compact battery chargers.

1.2. Before using battery charger, read all instructions and cautionary markings on battery charger, battery, and

product using battery.

1.3. Do not expose charger to rain or snow.

1.4. Use of an attachment not recommended or sold by the battery charger manufacturer may result in a risk of

fire, electric shock, or injury to persons.

1.5. This charger is intended for commercial and industrial use. ONLY TRAINED AND QUALIFIED PERSONNEL

MAY INSTALL AND SERVICE THIS UNIT.

1.6. Do not operate charger if it has received a sharp blow, been dropped, or otherwise damaged in any way;

shut off power at the branch circuit protectors and have the unit serviced or replaced by qualified

personnel.

1.7. To reduce risk of electric shock, disconnect the branch circuit feeding the charger before attempting any

maintenance or cleaning. Turning off controls will not reduce this risk.

1.8. Use appropriate lockout / tagout procedures to ensure safety of all personnel installing and servicing this

equipment. The input and output breakers are equipped with provision to lock breakers in the OFF

position.

1.9. WARNING –RISK OF EXPLOSIVE GASES

1.9.1. WORKING IN THE VICINITY OF A LEAD-ACID OR NICKEL-CADMIUM BATTERY IS DANGEROUS.

STORAGE BATTERIES GENERATE EXPLOSIVE GASES DURING NORMAL BATTERY OPERATION. FOR

THIS REASON, IT IS OF UTMOST IMPORTANCE THAT YOU READ THIS MANUAL AND FOLLOW THE

INSTRUCTIONS EACH TIME YOU USE THE CHARGER.

1.9.2. To reduce the risk of battery explosion, follow these instructions and those published by the battery

manufacturer and the manufacturer of any equipment you intend to use in the vicinity of a battery.

Review cautionary markings on these products and on the engine.

1.10. PERSONAL PRECAUTIONS

1.10.1. Someone should be within range of your voice or close enough to come to your aid when you work

near a storage battery.

1.10.2. Have plenty of fresh water and soap nearby in case battery electrolyte contacts skin, clothing, or

eyes.

1.10.3. Wear complete eye protection and clothing protection. Avoid touching eyes while working near a

storage battery.

1.10.4. If battery electrolyte contacts skin or clothing, wash immediately with soap and water. If electrolyte

enters eye, immediately flood the eye with running cold water for at least 10 minutes and get

medical attention immediately.

1.10.5. NEVER smoke or allow a spark or flame in vicinity of battery or engine.

1.10.6. Be extra cautious to reduce risk of dropping a metal tool onto the battery. It might spark or short

circuit the battery or another electrical part that may cause explosion. Using insulated tools reduces

this risk but will not eliminate it.

1.10.7. Remove personal metal items such as rings, bracelets, necklaces, and watches when working with a

storage battery. A storage battery can produce a short circuit current high enough to weld a ring or

SENS EnerGenius® DC Compact Technical Manual

5

the like to metal, causing a severe burn.

1.10.8. When charging batteries, charge LEAD-ACID or LIQUID ELECTROLYTE NICKEL-CADMIUM batteries

only. Consult SENS before using with any other type of battery - other batteries may burst and

cause injuries to persons and damage to property. NEVER charge a frozen battery.

1.10.9. Consult national and local ordinances to determine if additional battery fault protection is necessary

in your installation.

1.11. Preparing Battery For Charge

1.11.1. Be sure area around battery is well ventilated while battery is being charged.

1.11.2. Ensure battery terminals are clean and properly tightened. Be careful to keep corrosion from

coming in contact with eyes.

1.11.3. Add distilled water in each cell until battery acid reaches level specified by battery manufacturer.

Do not overfill. For a battery without removable cell caps, such as valve regulated lead acid

batteries, carefully follow manufacturer’s recharging instructions.

1.11.4. Study all battery manufacturer specific precautions such as removing or not removing cell caps

while charging and recommended rate of charge. The recommended charge current range must

include the rated output current of the charger.

1.12. Charger Location

1.12.1. Locate the charger as far away from the battery as DC cables permit.

1.12.2. Never place the charger directly above or below the battery being charged; gases from the battery

will corrode and damage charger.

1.12.3. Never allow battery acid to drip on charger when reading electrolyte specific gravity or filling

battery.

1.12.4. Do not operate charger in a closed-in area or restrict ventilation in any way.

1.12.5. Do not set anything on top of the charger.

SENS EnerGenius® DC Compact Technical Manual

6

2MODEL NUMBER BREAKOUT

D

S

-

F

-

120

-

050

-

A

0

A

-

0

00

A

B

-

C

-

E

-

G

-

K

L

M

-

N

P

Parameter

Code

Value

A

Product Family

D

EnerGenius DC

B

Enclosure Type

S

Compact

C

AC Input Voltage

F

Three Phase - 480VAC

E

DC Output Voltage

120

120 VDC

240

240 VDC

G

Output Current

120 VDC

240VDC

006

6A

✓

012

12A

✓

✓

025

25A

✓

✓

035

35A

✓

050

50A

✓

K

Comm and Display

A

Standard - (LCD, Keypad, 5 Form-C Relays,

Ethernet)

L

Accessory Hardware

0

None

A

High Current AC Alarm Relays (2X 120VAC, 5A)

M

Surge Protection

A

Standard Surge Protection

B

Supplemental AC/DC Surge Protection

N

Mounting

0

Wall mount

1

Portable

P

Configuration

00

Standard Configuration

01

PIP Compliant

(requires Accessory Hardware selection A)

##

Factory specified custom configuration

SENS EnerGenius® DC Compact Technical Manual

7

3PERFORMANCE SPECIFICATIONS

EnerGenius® DC is a high power industrial/utility class 3-phase switchmode battery charger/power supply,

specially hardened for use in harsh industrial environments. Advanced technology switch mode power conversion

is significantly smaller & lighter than conventional line frequency (e.g. SCR) power conversion and, even without a

battery connected, delivers lower output ripple and much faster dynamic response.

Forced ConductionTM cooling keeps the high efficiency power electronics free of dust and dirt, making EnerGenius

DC well-suited for operation in industrial, utility, power plant, and other harsh environments. Two variable speed,

premium ball-bearing fans cool each rectifier. Rectifiers maintain nearly full output capability even if one fan fails.

A fan failure alarm system with local and remote indication enables service dispatch while the second fan

continues to run. The fan module is easily replaced in the field with common tools.

5 Standard Form C contact alarms are factory set and field reconfigurable, with indication via communication

port, front panel LCD and assignable alarm relays. Two additional high current AC alarm relays are optional.

Options include supplemental surge suppression, and data communication including Modbus, DNP3 and IEC

61850. Chargers can be equipped with one or multiple communication protocols. Specifications are detailed in the

table below, see following sections for installation and operation instructions.

Table 1 –Specifications

AC Input

Voltage, frequency

Full output power: 358-528 VAC 3-phase line to line, 50%

power limit from 188-357 VAC. AC line to ground voltage

limited to 277VAC. 47-63 Hz.

Input current

12A maximum at 358VAC for maximum configured unit.

Overcurrent protection

3-pole UL 489 listed circuit breaker

10 kAIC, lockable

Loss of phase

Continues operating with current limit reduced to 50%

AC transient protection

Layered electrical transient defenses. Optional UL 1449 Type

1 Listed supplemental surge protection, alarmed and with

field replaceable elements, surge capacity rated 75kA 8/20

µs; visual and remote indications.

Loss of phase

Continues operating with current limit reduced to 50%

Efficiency

Up to 95%, see section 9.14

Power Factor and Total

Harmonic Distortion

>.98 typical at maximum rated load current and boost charge

voltage. Total Harmonic Distortion <3%

DC Output

Voltage

120 VDC or 240 VDC nominal. 120 VDC: output adjustable

from 8-160V. 240 VDC: output adjustable from 16-320V.

Current

Output limit: 7kW or 50A for 120VDC models whichever is

less, or 7kW or 25A for 240VDC models, whichever is less

Soft Start

System gradually increases current output from zero with a

maximum of 5 seconds to full required output

Charging modes

Multi-stage, including float, boost, HELIX, and commissioning

charge modes

Current limit

100% current capability subject to temperature limits and AC

voltage limits; field adjustable to max rated current.

Charging characteristic

Constant voltage, current limited; patented Dynamic Boost

and HELIX control

Line & load regulation

±0.5%

SENS EnerGenius® DC Compact Technical Manual

8

Output Ripple

< 30 mV with battery, <100mV off-battery for 120VDC,

<200mV off-battery for 240VDC. Delivers fast-responding,

stable, well-filtered DC without battery.

Step response

8ms typical without battery, to recover within 1% of rated

output voltage from load step change of 50% rated output

current

Output protection

Electronic current limit. 2-pole UL 489 listed circuit breaker.

10 kAIC, lockable

DC surge protection

Layered electrical transient defenses. Optional UL1449 Open

Type 2 Listed supplemental surge protection, alarmed and

with field replaceable elements, surge capacity rated 75kA

8/20 µs; visual and remote indications.

Battery types

Flooded lead-acid, AGM, Ni-Cd, VRLA, and lithium

DC power supply operation

Delivers fast-responding, stable, well-filtered DC without

battery

Battery temp.

compensation

Standard. On-board sensor modifies output voltage when

temperature is between 0°C and+40°C. Slope adjustable,

factory set to –0.18% per degree C. Optional remote battery

monitor provides battery temperature probe.

Dead battery charge

Starts into and recharges zero-volt battery

Parallel/load share

operation

Two or more independent chargers actively current share

and synchronize all modes for increased current or fault

tolerance when a common RJ-45 network cable is connected

to each charger’s paralleling bus

Output blocking protection

Prevents sparking during battery connection; serves as an

"OR" diode to isolate a non-functioning charger from others

in a redundant charger configuration

Adjustment &

Controls

Charge mode control

Fully automatic patented Dynamic Boost system. Manual

boost, timed boost & battery commissioning charging

options are available from front panel control.

Front panel control

Change all parameters including voltages, current limits,

alarm parameters, relay assignments, network

configurations, time-outs, and more

Local computer

Change all parameters, troubleshoot, create/save

configuration files for quick download to chargers using

network connection and SENS Setup Utility software

available at www.sens-usa.com

Status Reporting

LEDs

Two multi-color front panel status LEDs

Metering

AC/DC Voltmeter accurate to ±1%; AC/DC ammeter to ±1%;

AC frequency meter to ±1.5%; DC Output Watts; DC Output

as a percent of maximum rated output

Status display

20-character display of status & alarm messages.

Data logging

Data logging to internal nonvolatile memory, based on events

and at fixed times. Logs retrieved using computer network

connection.

Alarms

Alarm Outputs

Factory set, field reconfigurable, latching or non-latching.

Alarms available via communication port, alarm relays, and

on front panel display.

SENS EnerGenius® DC Compact Technical Manual

9

Alarm Inputs

Two optional input contacts (via optional battery monitor) to

monitor status of, and modify charger operation based on,

external devices such as battery room fan or hydrogen

monitor.

Alarm Form C contacts

Five Form C contacts, rated 30V, 2A resistive, assignable. Two

optional form C contacts 120VAC, 5A resistive, assignable

Pilot relay functions

Form C contacts configurable as pilot relays to switch

external loads based on user-configurable conditions.

Networking

Modbus communications

Optional Modbus RS-485 or TCP/IP on RJ-45 port

DNP3

Optional DNP3 RS-485 or TCP/IP on RJ-45 port

IEC 61850

Optional IEC 61850 TCP/IP on RJ-45 port

SENSbus

Proprietary bus for connection of paralleled chargers and

SENS accessories

Environmental

Operating temperature

-40C to +70C; full spec from -40C to +50C. Display may be

unreadable and suffer reduced life above 65°C. Cold starts

down to -40°C.

Ingress protection

IP 20; NEMA 1

Humidity

5% to 95%, non-condensing

Altitude

0-6,500 ft (2,000 meters). Above this altitude, output is

derated 0.012% per additional meter at rated ambient

temperature.

Vibration & shock

resistance

EN60068-2-6, EN 60068-2-64 & EN 60068-2-27

Electrical transient

ANSI/IEEE C62.41, EN 61000-4-12 on power terminals, IEC

61000-6-5 and ANSI/IEEE C37.90

Abuse

Protection

Reverse polarity

Charger self-protects without output protective device

clearing. Indication via LED & LCD.

Wrong voltage battery

Charger-battery voltage mismatch shuts down charger after 5

minutes. Indication via LED and LCD

Overvoltage shutdown

Selective; shutdown only operates if the overvoltage

condition is caused by the charger itself

Overtemperature

protection

Gradual output power reduction if heatsink temperature

becomes excessive; recovery is automatic.

Regulatory

Compliance

North America

C-UL Listed for US & Canada: CSA 22.2, No. 107.2, UL 1012,

UL 508A

NFPA-70, NEMA PE-5, PIP (optional)

FCC Part 15, Class A commercial use and ICES-003 (Canada)

Seismic: Rigid & non-structure wall and floor mount; max SDS

of 2.5G. IBC 2000-2018, Calif. BC 2007-2016

European Union (CE)

EMC: 2014/30/EU (EN 61000-6-2 & EN 61000-6-4)

LVD: 2014/35/EU (EN 60335-1 & EN 60335-2-29)

RoHS 2: 2017/2102/EU (EN 50581)

Construction

Housing

Wall mount or portable

Housing material

Aluminum with powder coated finish

Weight

38 lbs (17.2 Kg)

SENS EnerGenius® DC Compact Technical Manual

10

Cable entry

Side entry with one 1 inch opening for DC and three 1/2 inch

openings for AC and alarms/comms

Network/Alarm

connections

Modbus: RJ-45 or terminal blocks 28 to 16 AWG. Form C

alarms: 28 to 16 AWG.

Power connections

AC/DC terminal blocks: 14 –3AWG

4SYSTEM OVERVIEW

4.1. Physical Overview

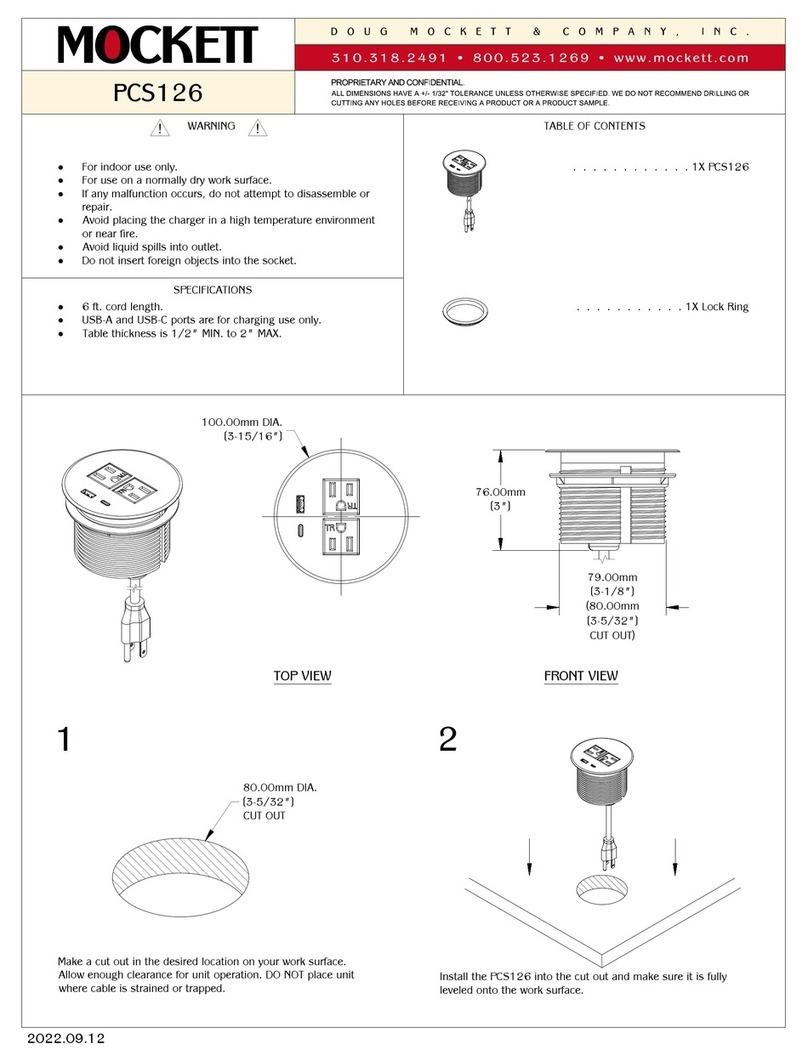

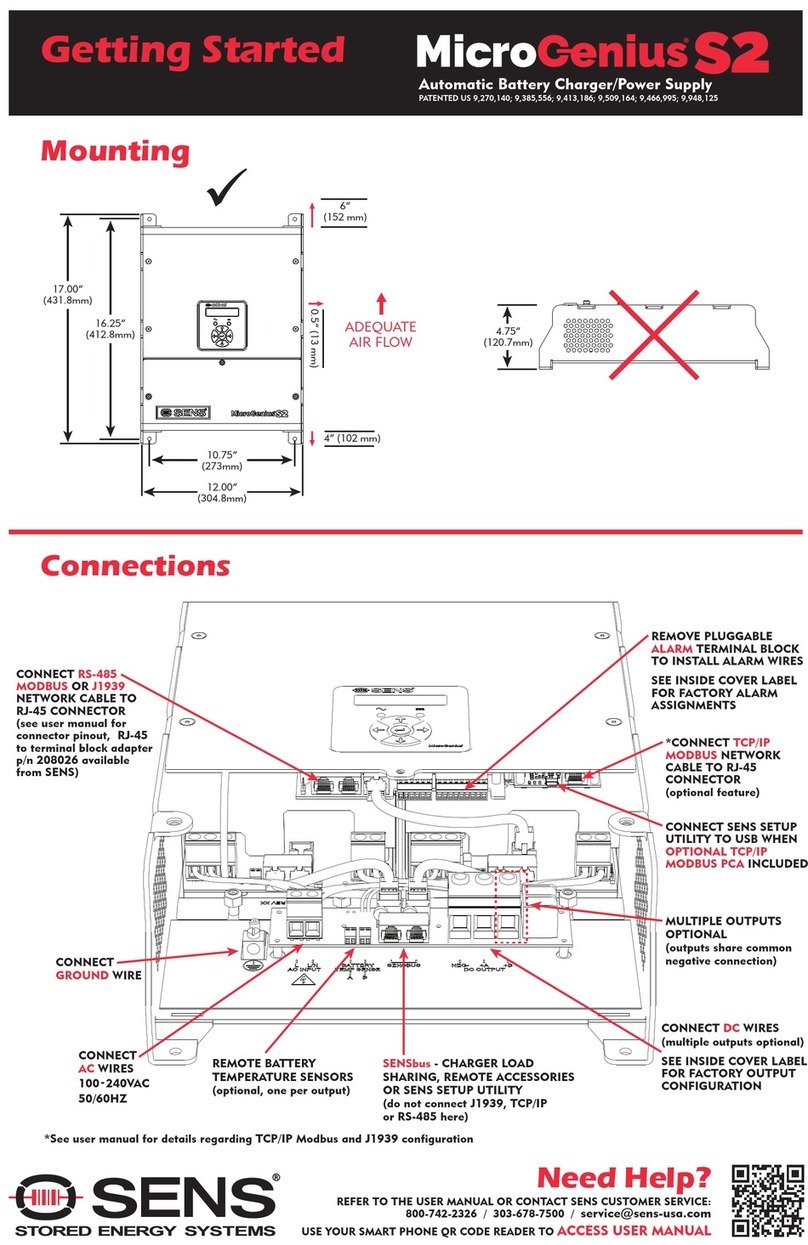

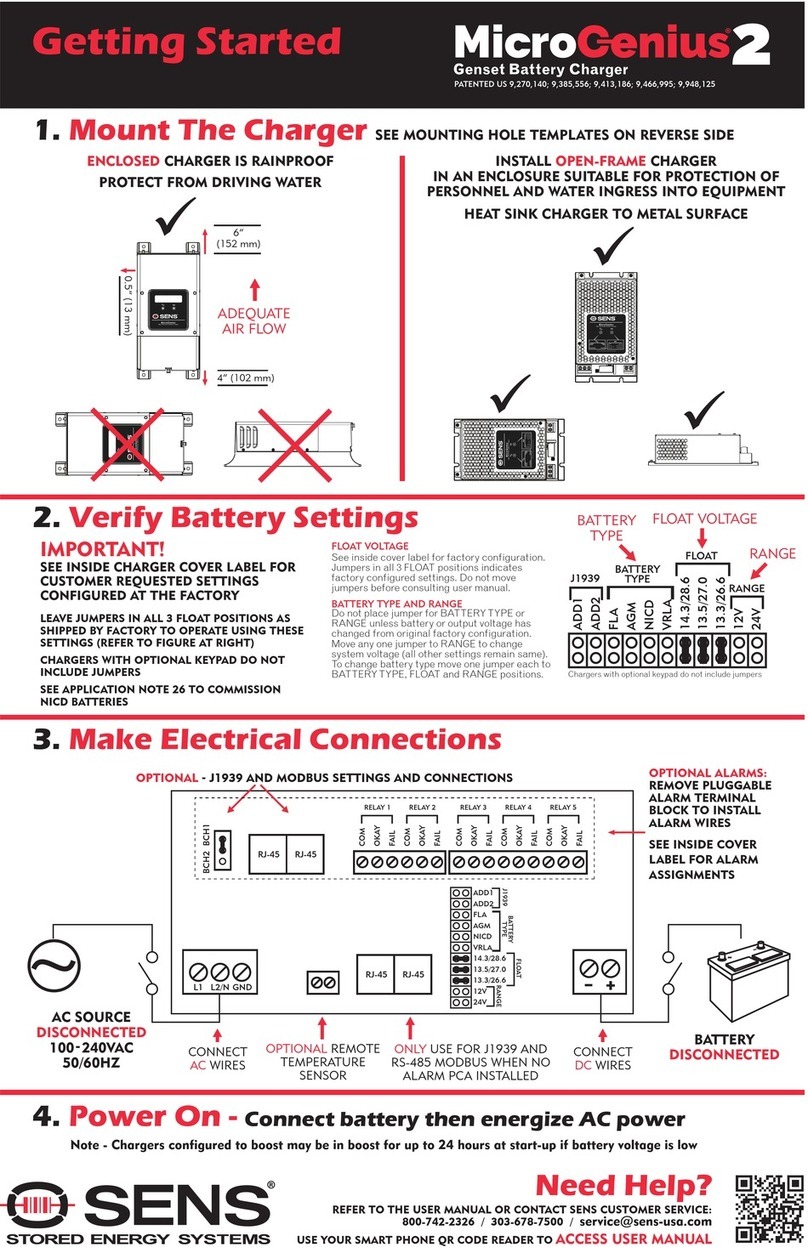

Figure 1 –EnerGenius DC Compact Overview

SENS EnerGenius® DC Compact Technical Manual

11

4.2. Functional Overview

4.2.1. Configuration

Each EnerGenius DC Compact System comes factory configured for its application from the

factory. Configuration details are given on the configuration label (see Figure 2). These values are

assigned according to the profile configuration selected during the customer order. Profiles are

available for various battery types and applications. Some of the available configuration options

may not be applicable to a given installation. Adjustments to settings can be made via the front

panel keypad or the SENS Setup Utility software via ethernet connection of the EnerGenius DC

Compact unit to a computer.

Figure 2 –Configuration Label (on inside lower cover)

4.2.2. Standard Items

4.2.2.1. AC Input Breaker, UL 489 listed. The breaker is lockable in the OFF position.

4.2.2.2. DC Output Breaker, UL 489 listed breaker. The breaker is lockable in the OFF position.

4.2.2.3. 5 Form C Relays Contacts for Alarm Relays

4.2.2.4. Ethernet communications

4.2.2.5. SENSbus communications

4.2.3. Factory Optional Items

4.2.3.1. Supplementary Surge Protectors

Supplementary Surge Protectors provide additional AC and DC protection in surge intensive

environments. These protectors are equipped with field-replaceable modules that can be

replaced when the surge protective device needs replacement. Alarm and status information

of the surge protective devices is included.

4.2.3.2. High Current Relays

Two high current Form C relay contacts available for alarms. Configurable using the SENS

Setup Utility.

4.2.3.3. Software

Optional communication protocols include Modbus (TCP/IP and RS-485), DNP3 (TCP/IP and

RS-485) and IEC 601850.

SENS EnerGenius® DC Compact Technical Manual

12

5MOUNTING INSTRUCTIONS

INSTALLATION OF THE UNIT MUST COMPLY WITH LOCAL ELECTRICAL CODES AND OTHER APPLICABLE

INSTALLATION CODES AND BE MADE ACCORDING TO THE INSTALLATION INSTRUCTIONS AND ALL

APPLICABLE SAFETY REGULATIONS.

Printed circuit boards contain static sensitive components. Damage can occur even when static levels are too

low to produce a noticeable discharge shock. To avoid static discharge damage, handle the charger by the

chassis only. Remove the cover only when access is essential for installation and service and replace it

promptly when finished.

5.1. Mounting Location

See diagrams at back of manual for dimensions and mounting information.

5.1.1. Charger is rated IP20.

5.1.2. Charger will operate at full specification when located where temperatures are within -40°C

(-40°F) to +50°C (122°F). Output power is gradually reduced at higher temperatures.

5.1.3. Leave clear space for ventilation all around the charger: at least 6 inches (15 cm) at the top; at

least 4 inches (10.16 cm) at the bottom; at least 0.5 inches (1.27 cm) on each side. Operating

temperature ranges stated above assume stated clearances.

5.1.4. Mount to a wall or other vertical support. The mounting surface must safely support the weight of

the charger and the fixed wiring. Charger weighs 43 lbs (19.5 Kg).

5.1.5. Allow sufficient room for routing the fixed wiring to the charger. All field connections enter the

charger from the side. See diagrams at back of manual for further information.

5.1.6. Do not mount the charger above any heat generating equipment or where it could get wet.

5.2. Mounting Instructions

5.2.1. Drill four wall mounting holes using dimensions provided on diagrams at back of manual.

IMPORTANT: Protect charger from all drill shavings!

5.2.2. Mount the charger before connecting AC, DC, communications and alarm wiring to ensure un-

obstructed access to mounting holes.

5.2.3. Mount the charger using four ¼ inch (M6) screws with standard flat washers. Mounting hardware

is not included with the charger and must be provided by the installer.

SENS EnerGenius® DC Compact Technical Manual

13

6SETUP AND WIRING

IMPORTANT! The charger is configured at the factory and typically requires no adjustments before operating.

Refer to the label on the inside lower cover for factory configured output and alarm relay assignments. The

charger can be reconfigured using the front panel keypad or by software programming using the SENS Setup

Utility that runs on a Windows PC.

All wiring must comply with applicable codes and local ordinances. The field wiring area is accessed by removing

the field wiring access cover by loosening the three captive Philips #2 screws. Use conduit entry holes as shown in

Figure 3.

Figure 3 –EnerGenius® DC Compact Conduit Openings

WARNING:

ENSURE THAT AC POWER IS DISCONNECTED AT THE MAINS CIRCUIT BREAKER

OR OTHER SAFETY DISCONNECT BEFORE WIRING THE CHARGER

6.1. Wire Ratings and Sizes

6.1.1. All power conductors should be rated for use at 90°C or higher and 600V or higher. Alarm relay

conductors and communications data cable should be rated for use at 75°C or higher.

6.1.2. Coordinate the AC input conductor size with the customer-provided feeder branch circuit

protection device.

6.1.3. For best performance and recharge time, refer to the following table to determine the

appropriate output conductor gauge and length. Use of a remote temperature sensor (see section

9.11) is highly recommended for best charging performance.

SENS EnerGenius® DC Compact Technical Manual

14

Table 2 –DC Output Cable Size

Charger Rated

Output Current

(Amps)

Wire Size

Resistance per

Foot (mΩ/Ft.)

Maximum Charger to

Battery Distance (Ft.)

AWG

mm2

120V

240V

6

14

2.5

2.5

160

320

12

4

1.6

250

500

10

6

1

400

800

8

10

0.63

635

1270

6

16

0.4

1000

2000

12

14

2.5

2.5

80

160

12

4

1.6

125

250

10

6

1

200

400

8

10

0.63

317

634

6

16

0.4

500

1000

25

14

2.5

2.5

38

76

12

4

1.6

60

120

10

6

1

96

192

8

10

0.63

152

304

6

16

0.4

240

480

35

14

2.5

2.5

NEC - not allowed

12

4

1.6

NEC - not allowed

10

6

1

69

138

8

10

0.63

109

218

6

16

0.4

171

342

4

25

0.25

274

548

2

35

0.16

429

858

50

14

2.5

2.5

NEC - not allowed

12

4

1.6

NEC - not allowed

10

6

1

48

96

8

10

0.63

76

152

6

16

0.4

120

240

4

25

0.25

192

384

2

35

0.16

300

600

The above lengths consider the resistance of the battery and cables only and do not take into

account any additional interconnects. The above lengths factor in a maximum voltage drop of 2% of

the nominal voltage. The above lengths are for operation at 25°C/77°F. For high temperature

installations (50°C/122°F) increase wire gauge by 20%.

SENS EnerGenius® DC Compact Technical Manual

15

6.2. Grounding Instructions and Connection

6.2.1. Charger must be grounded to reduce risk of electric shock. The charger must be connected to a

grounded, metal, permanent wiring system, or an equipment-grounding conductor (earthing

conductor) must be run with the circuit conductors and connected to equipment-grounding

terminal on charger.

6.2.2. Connect the equipment grounding conductor to the ground lug in the charger (see Figure 1). This

lug is marked with the ground symbol. This should always be the first wire connected and the last

wire disconnected. Tighten connections to torque specified in Table 3.

Table 3 –Ground Allowed Wire Gauge and Torque Requirements

Ground

Connection Type

Allowed Wire Gauge

Required Torque

Tool

Terminal Block

14-4 AWG (2.5-25 mm2)

50.0 In-Lb (5.65 Nm)

Flat Screwdriver

6.3. DC Connection

Ensure that any battery disconnect devices in the system, if used, are opened (battery disconnected from

DC bus). Connect the DC output conductors to the DC output terminal block/breaker in the charger (see

Figure 1). Always observe proper polarity of the DC output leads. Always connect the output leads in the

following order –charger output to ungrounded battery terminal, followed by charger output to

grounded battery terminal. If the battery must be disconnected for service, remove the output wiring in

the reverse order. Tighten connections to torque specified in Table 4. Route DC wiring at least ¼ inch

(6 mm) away from AC wiring, alarm wiring, and the circuit board.

Table 4 –DC Allowed Wire Gauge and Torque Requirements

DC Connection

Type

Allowed Wire Gauge

Required Torque

Tool

Terminal Block

14–2/0 AWG (2.5-70 mm2)

14-10 AWG: 35 in-lb (4 Nm)

8 AWG: 40 in-lb (4.5 Nm)

6 –2/0 AWG: 120 in-lb (13.6 Nm)

3/16 inch hex

Table 5 –DC Output Breaker Rating

Charger Nominal

Output Voltage

(VDC)

DC Breaker

Rating (Amps)

DC Breaker Interrupt

Rating (KAIC)

120

63

10

240

32

10

6.4. AC Connection

This unit is to be permanently connected to the AC circuit and to the battery. The charger is rated to

operate at full power on any 3-phase AC input within the range of 358-528VAC, 47-63Hz. The AC line to

ground voltage is limited to 277VAC maximum. The unit is rated to operate at 50% power from 188-

357VAC, 47-63Hz.

Ensure that the AC input supply is de-energized. Connect the AC line conductors to the AC input terminal

block in the charger (see Figure 1). Tighten connections to torque specified in Table 6. Route AC wiring at

least ¼ inch (6 mm) away from DC wiring, alarm wiring, and the circuit board.

Table 6 –AC Allowed Wire Gauge and Torque Requirements

AC Connection Type

Allowed Wire Gauge

Required Torque

Tool

Terminal Block, ring lug type

16-6 AWG (1.5-16.0 mm2)

20.0 In-Lb (2.26 Nm)

Phillips P2

SENS EnerGenius® DC Compact Technical Manual

16

Table 7 –AC Input Current and Breaker Rating

Charger Nominal

Output Voltage

(VDC)

Charger Rated

Output Current

(Amps)

AC Rated Input Current

Maximum per phase

(Amps)

AC Breaker

Rating

(Amps)

AC Breaker

Interrupt Rating

(KAIC)

120

12

2.7

15

10

120

25

5.4

15

10

120

35

7.6

15

10

120

50

10.8

15

10

240

6

2.7

15

10

240

12

5.4

15

10

240

25

10.8

15

10

6.5. Standard Alarm Connections

See charger inside cover label for original factory alarm relay assignments (see Figure 2). Alarm relay

assignments are custom configurable using the SENS Setup Utility. Alarm circuits are rated 2A at 30V AC

or DC. Connect alarm wiring to the respective terminals on the pluggable terminal block in the charger

(see Figure 4). To make wiring easier, the terminal block unplugs from its header. Pull terminal block

straight out from header to remove. Connect wires to terminal block by tightening screws at each

position. After wires are connected, plug terminal block securely back into header. Wire from FAIL or OK

to COM depending on whether the alarm should be present on an open or closed circuit (see Table 8).

Connect alarm terminals only to low voltage, limited energy (“Class 2”) circuits. The terminals accept 28-

16 AWG (0.08-1.5 mm2) conductors. Tighten connections to 2.0 Lb-In (0.22 Nm) using a small slotted

driver. Route alarm wiring at least ¼ inch (6 mm) away from DC wiring, AC wiring, and the circuit board.

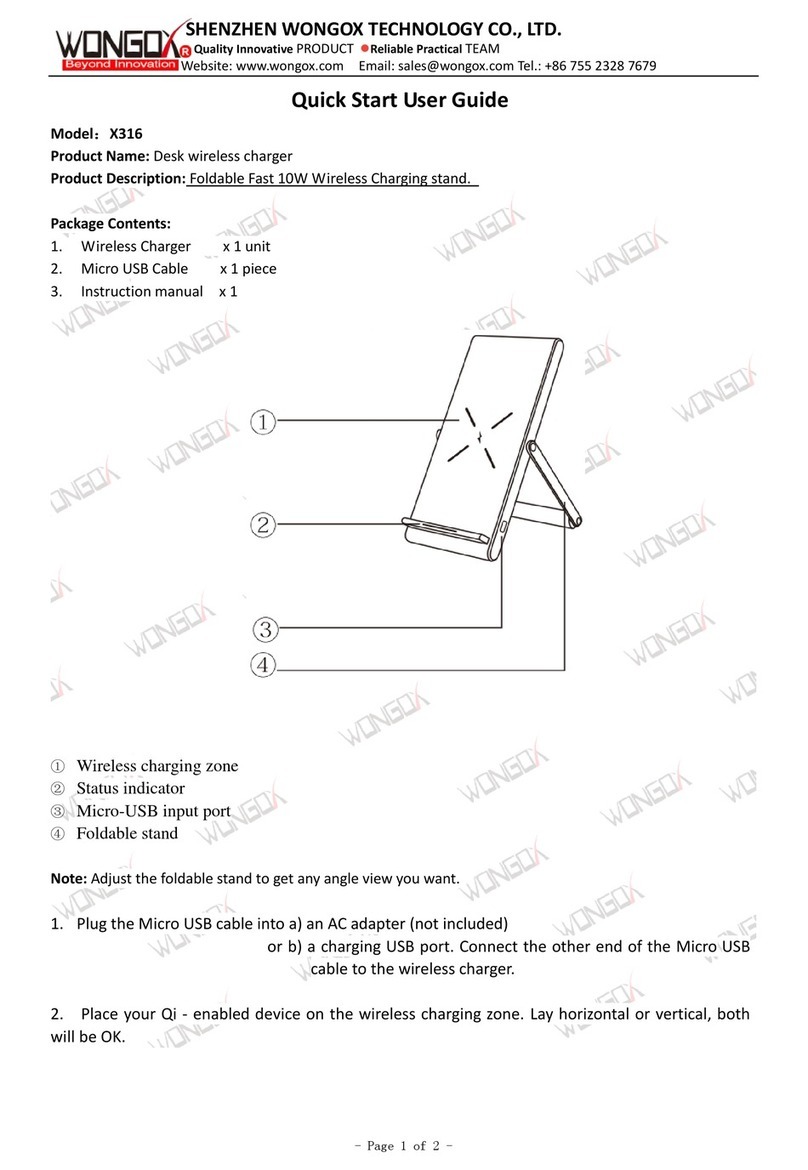

Figure 4 –Standard Alarm Connections

(TB1 - pins 1-15 shown)

5 RELAYS,

3 POSITIONS PER

RELAY:

COM, OK, FAIL

PULL TO REMOVE

FROM HEADER

SENS EnerGenius® DC Compact Technical Manual

17

Table 8 –Alarm Relay Contact Wiring for Stationary Power Configuration

Wire from COM to OK for alarm present on open circuit or from COM to FAIL for present on closed circuit.

RELAY 1

Non-latching Coil

RELAY 2

Non-latching Coil

RELAY 3

Latching Coil

RELAY 4

Latching Coil

RELAY 5

Latching Coil

Relay

Contacts

Summary

Alarm*

AC Fail and

Charger Fail

Battery

Discharging

Alarm

High DC Alarm

Low DC Alarm

Common

COM (TB1-1)

COM (TB1-4)

COM (TB1-7)

COM (TB1-10)

COM (TB1-13)

Open on

alarm

OK (TB1-2)

OK (TB1-5)

OK (TB1-8)

OK (TB1-11)

OK (TB1-14)

Close on

alarm

FAIL (TB1-3)

Defaults to FAIL

with no AC and

DC power

(normally closed)

FAIL (TB1-6)

Defaults to FAIL

with no AC and

DC power

(normally closed)

FAIL (TB1-9)

FAIL (TB1-12)

FAIL (TB1-15)

*Summary alarm includes AC Fail, Charger Fail, Battery Discharging, High DC and Low DC alarms.

Functions and operation assigned to each relay are typical. Different functions and assignments are available

both from the factory and by reassignment using the SENS Setup Utility.

6.6. Optional High Current Relay Connections

Optional high current relay assignments are custom configurable using the SENS Setup Utility. Alarm

circuits are rated 5A at 120VAC. Connect external wiring to the respective terminals on the pluggable

terminal block in the charger (see Figure 5). To make wiring easier, the terminal block unplugs from the

header. Pull terminal block straight out from header to remove. Connect wires to terminal block by

tightening screws at each position. After wires are connected, plug terminal block securely back into

header. Wire from FAIL or OK to COM depending on whether the alarm should be present on an open or

closed circuit (See Table 9). The terminals accept 26-12 AWG (0.14-4.0 mm2) conductors. Tighten

connections to 5.5 Lb-In (0.62 Nm) using a small slotted driver. Route alarm wiring at least ¼ inch (6 mm)

away from DC wiring, charger input AC wiring, low voltage wiring, communication wiring, and the circuit

board.

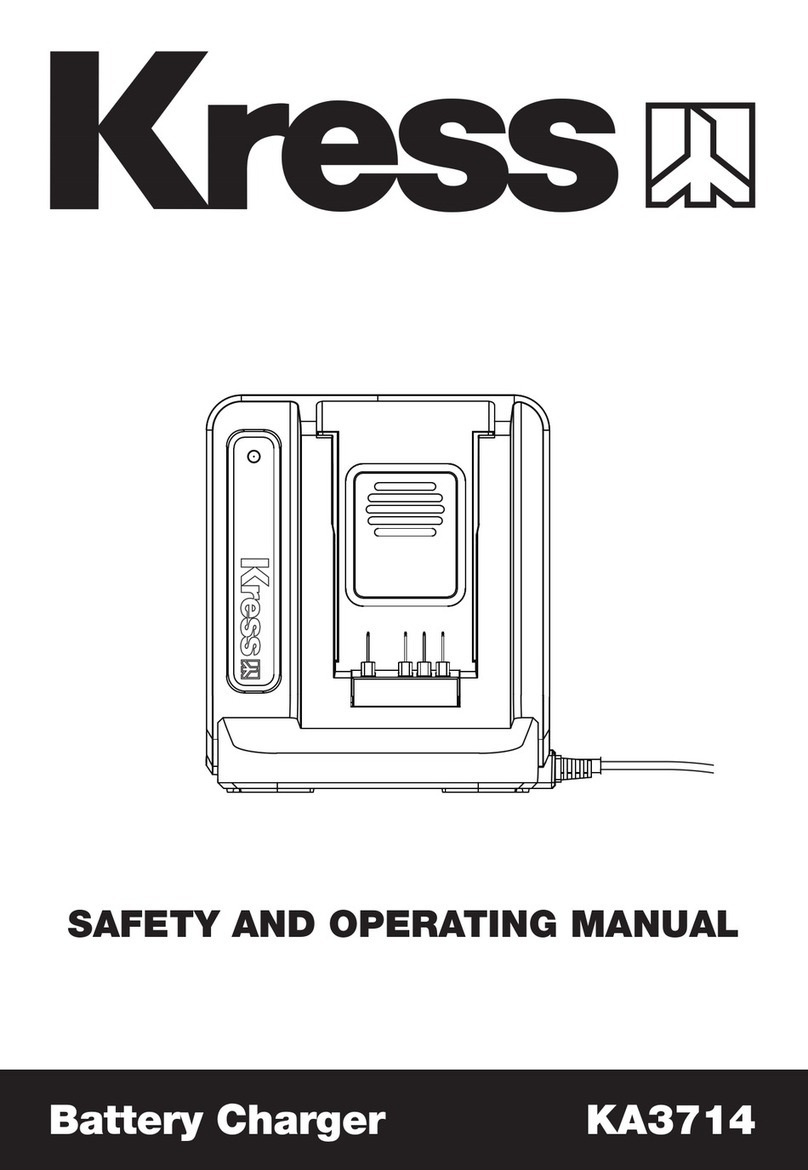

Figure 5 –Optional High Current Relay Connections

(TB1 - pins 1-6 shown)

SENS EnerGenius® DC Compact Technical Manual

18

Table 9 –Optional High Current Relay Connections

Wire from COM to OK for alarm present on open circuit or from COM to FAIL for present on closed circuit.

RELAY 1

Non-latching Coil

RELAY 2

Non-latching Coil

Relay Contacts

Summary

Assignable

Open on alarm

OK (TB1-1)

OK (TB1-4)

Close on alarm

Defaults to FAIL with

no AC and DC power

(normally closed)

FAIL (TB1-2)

FAIL (TB1-5)

Common

COM (TB1-3)

COM (TB1-6)

6.7. CANbus and RS-485 Connections

Every charger includes CANbus and RS-485 communications via two RJ-45 jacks.

6.7.1. CANbus

The unit is equipped with CANbus communications support via the RJ45 ports. This interface is

intended for communication with customer devices including battery monitoring systems, user

interfaces, and customer-specific CAN protocol communications. Consult the factory for

configuration and setup.

6.7.2. RS-485

The unit is equipped with serial RS-485 communications support via the RJ45 ports. This interface

is intended for monitoring and communicating with the charger. Available protocols include

Modbus and DNP3. See manual sections on specific protocols for more information.

6.7.3. Connection

Connect communications using a twisted pair cable at the RJ-45 connector on the

alarm/communications circuit board located on the inside front cover (see Figure 6 for detail).

Two RJ-45 ports are provided. The ports are in parallel and either port may be used. See Table 10

for connector pinout. Communications are isolated. An adapter from RJ-45 to an 8-position

terminal block may be connected to the RJ-45 connector and is available to order separately

(SENS p/n 208026, see Figure 7).

2 RELAYS,

3 POSITIONS PER

RELAY:

COM, OK, FAIL

PULL TO REMOVE

FROM HEADER

SENS EnerGenius® DC Compact Technical Manual

19

Pin 1

TWO PORTS:

Connect CANbus and/or

Modbus to one or both

ports

Pin 1

Pin 1

Figure 6 –CANbus and RS-485 RJ-45 Connections

Table 10 –Connector Pinout

Pin #

Purpose

1

CANbus

2

CANbus

3

No connect pass-through

4

Modbus –D0 (B)

5

Modbus +D1 (A)

6

No connect pass-through

7

Power*

8

Common (isolated)

*Main circuit PCA only, used for interconnect between SENS devices

Figure 7 –RJ-45 to Terminal Block Adapter —Optional

6.7.4. Termination

For proper operation, a 120-ohm terminator is required at the ends of the CAN and/or RS-485

bus. If multiple devices are on the bus, only the devices on the ends of the network bus need

termination resistors. Figure 8 shows an example of how to terminate the network. Termination

may be provided as part of the network cabling or 120-ohm termination plugs for the RJ-45

SENS EnerGenius® DC Compact Technical Manual

20

communications connector on the charger are available to order separately (SENS p/n 803707).

SENS chargers are slave devices. Pull-up and pull-down resistors are optional per Modbus

specifications.

Figure 8 –Typical RS-485 Termination

LT = Line Termination 120-ohm resistor

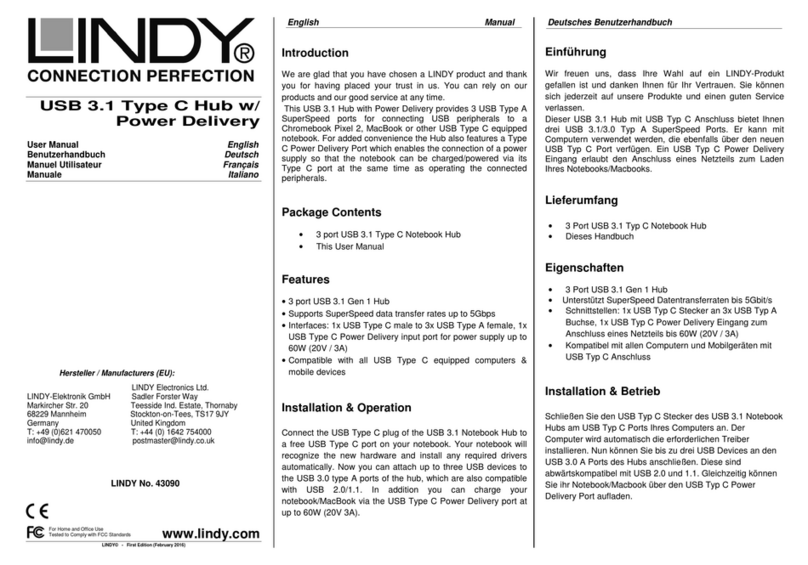

6.8. Ethernet

The unit is equipped with an ethernet RJ45 port (see Figure 9). Connect Cat5 or better ethernet cable.

This provides a 10/100 ethernet connection. Ethernet communication includes ethernet connectivity to

the charger for monitoring and configuration via the SENS Setup Utility, Modbus TCP/IP (optional) and

DNP3 (optional).

Figure 9 –Ethernet Connection

6.8.1. Configure TCP/IP Address

Configure TCP/IP settings using the SENS Setup Utility or the keypad. To adjust settings using the

keypad, ensure the access level is set to allow adjustments. Set the IP address as desired. It may

take up to 10 seconds for the network setting changes to apply. A TCP/IP address of 0.0.0.0

implies DHCP (Dynamic) addressing. Adjust the Gateway and Subnet Mask values as required.

The displayed Hardware Address is the MAC address corresponding to the Ethernet interface. This

value is not adjustable.

Other manuals for EnerGenius DC COMPACT

1

This manual suits for next models

1

Table of contents

Other Sens Batteries Charger manuals

Sens

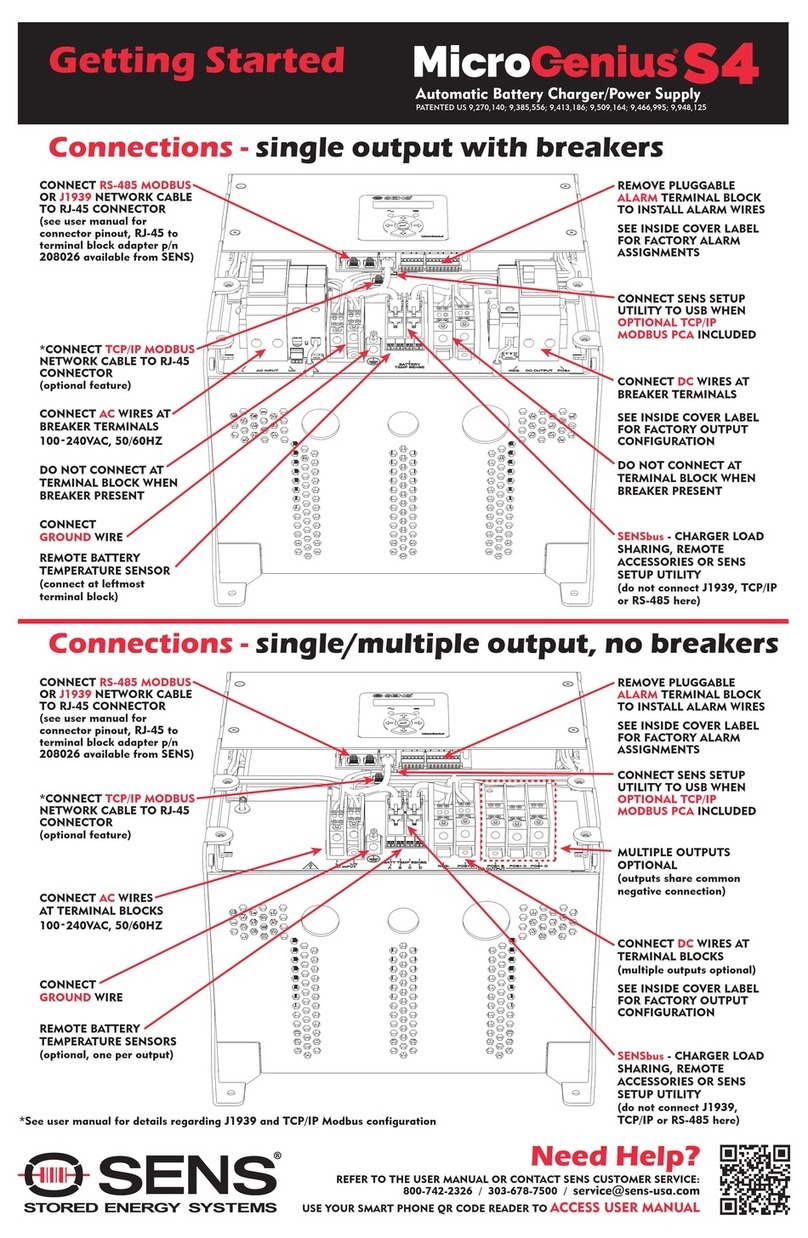

Sens MicroGenius S4 User manual

Sens

Sens MicroGenius S2 User manual

Sens

Sens DCT Series Operating manual

Sens

Sens EnerGenius IQ2 User manual

Sens

Sens MicroGenius S2 User manual

Sens

Sens EnerGenius NRG12-20 User manual

Sens

Sens NRG12-10 User manual

Sens

Sens MicroGenius 2 User manual

Sens

Sens EnerGenius NRG22-20 User manual

Sens

Sens EnerGenius NRG24-20 User manual