Sens DCT Series Operating manual

DCT SERIES

CASE SIZE 2A

FILTERED BATTERY CHARGER

12V/100A

24V/75-100A

32V/50-100A

48V/50-75A

120V/25-35A

240V/12A

OPERATION & MAINTENANCE

GUIDE

SENS part number: 101137-2

Document revision: B

DCN number: 105286

Date: 1/17/2007

1840 Industrial Circle

Longmont, CO 80501

Fax: (303) 678-7504

Tel: (303) 678-7500

Web: www.sens-usa.com

Installation or service questions? Call SENS at 1-800-742-2326 (303-678-7500) between 8 a.m.

and 5 p.m. (Mountain Time) Monday through Friday, or visit our website.

Copyright © Stored Energy Systems LLC 2006

DCT Series Charger Manual

2

IMPORTANT SAFETY INSTRUCTIONS

SAVE THESE INSTRUCTIONS

This manual contains important safety and operating instructions for Stored Energy Systems (SENS)

model DCT.

Before using the battery charger, read all instructions and cautionary markings on the battery charger,

battery and equipment connected to the battery system.

WARNING:

Please read

these safety

warnings and

heed them.

Failure to do so

could result in

either severe

personal injury

or equipment

damage.

This equipment uses and generates potentially lethal voltages. The equipment should only be installed and

maintained by trained persons. Do not attempt to install or operate this equipment unless you are certain

you are adequately trained.

To reduce the risk of injury, charge only properly sized lead-acid or nickel cadmium batteries. Other types

of batteries or under-sized batteries may burst, causing personal injury and damage.

“GROUND INSTRUCTIONS – This battery charger should be connected to a grounded, metal

permanent wiring system; or an equipment – grounding conductor should be run with circuit conductors

and connected to equipment – grounding terminal or lead on battery charger. Connections to battery

charger should comply with all local codes and ordinances.

• Do not install or operate charger if it has been dropped or otherwise damaged. Return it to the factory for

repair.

• Install the charger in accordance with all local codes.

• Do not expose charger to rain or snow.

• Do not disassemble charger. Return to factory when service or repair is required. Incorrect assembly

may result in a risk of electric shock or fire.

• To reduce risk of electric shock, de-energize and disconnect the AC input and the battery from the

charger before attempting maintenance or cleaning.

• Use of an accessory not recommended or sold by SENS may result in a risk of fire, electric shock or

personal injury.

• During normal operation, batteries may produce explosive hydrogen gas. Never smoke, use an open

flame, or create sparks near the battery or charger.

• Remove jewelry, watches, rings, etc. before installing battery or charger.

Maintenance

Instructions User maintenance is limited to charger adjustment. All on-site servicing should be performed by qualified

service personnel. If qualified personnel are not available, return the charger to the factory for repair, or

contact the factory to arrange for field service.

When returning a unit to the factory for repair, ship it in the original factory packaging if possible. If the

original carton is not available, pack in a carton with at least two inches of approved packaging material on

all sides of the charger to help prevent shipping damage.

DCT Series Charger Manual

3

1

Overview

This manual covers installation, operation and troubleshooting of SENS model DCT filtered battery

charger in case size 2A.

1.1 READ THIS FIRST

Please follow the installation and use instructions. They are vital to the satisfactory operation of the

charger. If you have any doubts about adjusting, maintaining or servicing the equipment, contact SENS’

service department.

Changing factory-set potentiometers voids the warranty. Contact the factory if you believe the settings on

your charger are incorrect.

Before determining the charger is not working correctly, check the following:

1. Is AC power available to the charger?

2. Are any circuit breakers tripped or fuses blown?

3. Is the charger connected to a battery of the correct voltage?

4. Was the charger damaged in transit or installation?

5. If you determine that the charger is not working because it is not putting out any current, check the

battery’s state of charge. If the battery is fully charged it is normal for the charger to indicate zero

current flow.

6. The charger may have shut down due to excessive output voltage. To ensure that the high volt

shutdown has been reset, turn off both the AC input breaker and DC output breaker for five minutes.

This is more than sufficient time for the DC voltage to decay and reset the shutdown.

7. If the battery is being over- or undercharged, check whether the output voltage settings have been

tampered with. The pots should be covered with either white adhesive paper dots or a hard colored

varnish.

1.2 Description and Application

The DCT is a fully automatic battery charger and DC current source offering the following features:

• Constant voltage output

• Electronic current limiting

• Filtered output. Output ripple on battery rated in AH four times amp rating of charger for 12, 24, 48 volt

units is 30 mV rms. 120 volt units: 150 mV rms; 240 volt units: 300 mV rms.

• Temperature compensation to maximize battery performance and life

• Optional remote temperature compensation

• Circuit breakers for AC input and DC output

The chargers are designed to power equipment requiring a low ripple DC source and to simultaneously

recharge and maintain lead-acid or nickel-cadmium batteries.

1.3 Upon Delivery

Inspect the charger for damage caused during transit, and report damage to the carrier immediately. Then

contact SENS to determine how to best repair/replace the damaged unit.

2

Installation

2.1 Mechanical Installation

Caution: Heed the following warning to prevent damaging the lower cover of the charger.

DCT Series Charger Manual

4

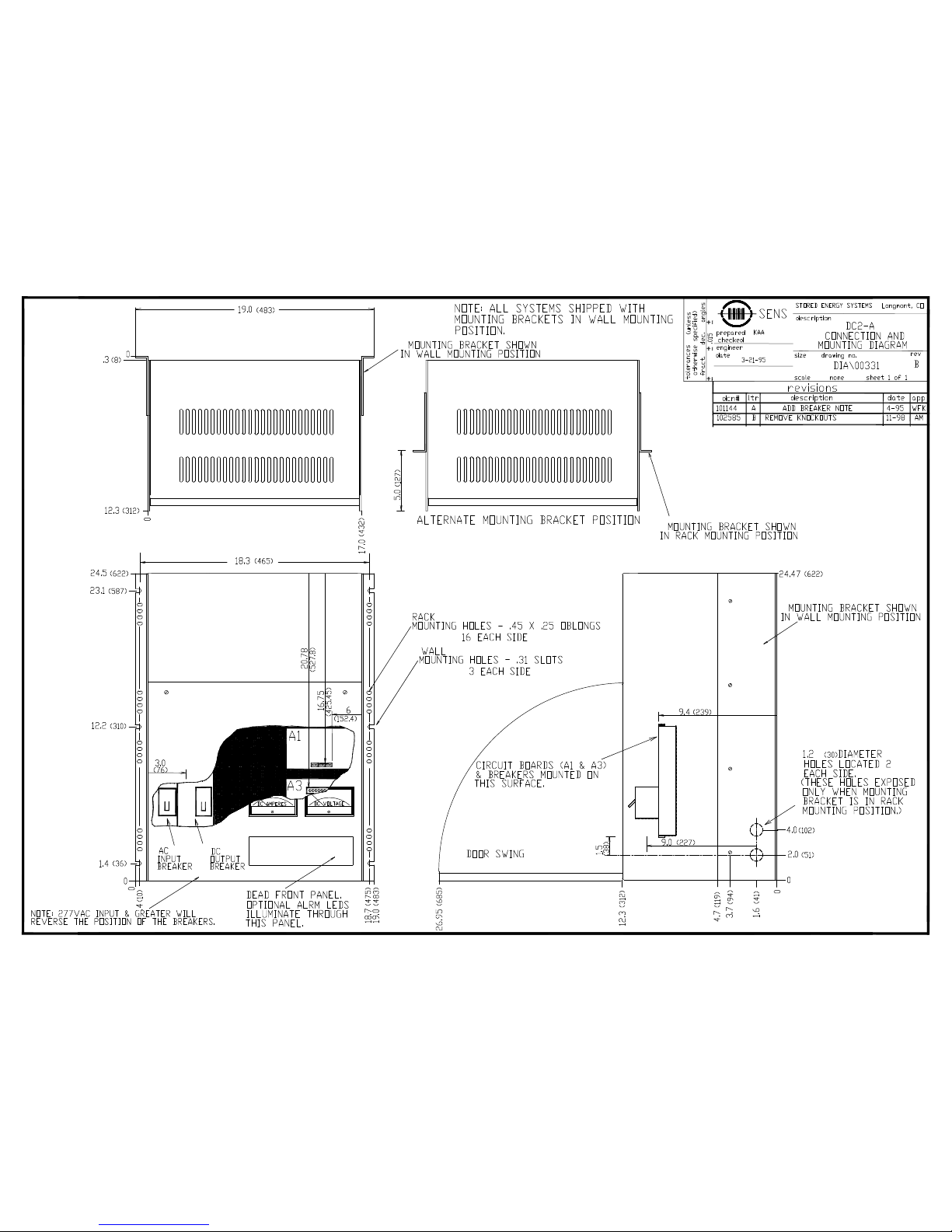

FIGURE 2.1

Lifting Instructions

WHEN INSTALLING

DO NOT LIFT UNIT

FROM MIDDLE OF

LOWER COVER - THE

COVER WILL BEND.

USE A SPREADER

PLATE EQUIVALENT TO

1" THICK PLYWOOD

ACROSS THE BOTTOM

OF THE UNIT WHEN

LIFTING

The charger can be mounted either on a wall or in a standard 19” relay rack. Locate the charger in a

dry place as close to the battery and load as possible to minimize voltage drop.

WARNING: These chargers are not approved for operation in areas with explosive atmospheres!

Wall Mounting

Mount the system to a robust wall using 1/4” bolts with flat washers behind the mounting holes, if

necessary, to level the charger on an uneven wall. The charger should be located as close to the

battery and load as possible to reduce voltage drop in the charging leads. Refer to the mechanical

drawings at the end of this document for case and mounting dimensions.

Relay Rack Mounting

The charger is shipped on its back with the mounting flanges in the wall-mount position. Place the

charger in a vertical position, then unbolt and reverse the mounting flanges. CAUTION: When

changing the angles from wall mount (the standard shipping configuration) to rack mount, you

MUST either stand the charger up vertically, or otherwise remove the charger’s weight from the

rack angles when removing the rack angle bolts. If you do not, the bolts in heavy chargers may strip

on their way out.

Protect the charger from construction grit, metal chips, paint or other debris. Clean away debris after

installation and before turning on the charger.

2.2 Electrical - Power Wiring

WARNING: Heat sinks and many other metallic components inside the charger are LIVE with

either line or output voltage. These voltages can be lethal. Do not touch any exposed metal surfaces

inside the enclosure while the charger is operating.

Remove the two 1/4-turn fasteners securing the charger's top front panel and open the front panel.

Make AC and DC connections direct to the AC and DC circuit breakers in accordance with either

diagram 2.2a or 2.2b.

Caution: Small sense leads are connected to the output side of the DC breaker. These must remain

connected to the output side of the breaker after installation of the DC cabling, or the charger will not

function properly.

DCT Series Charger Manual

5

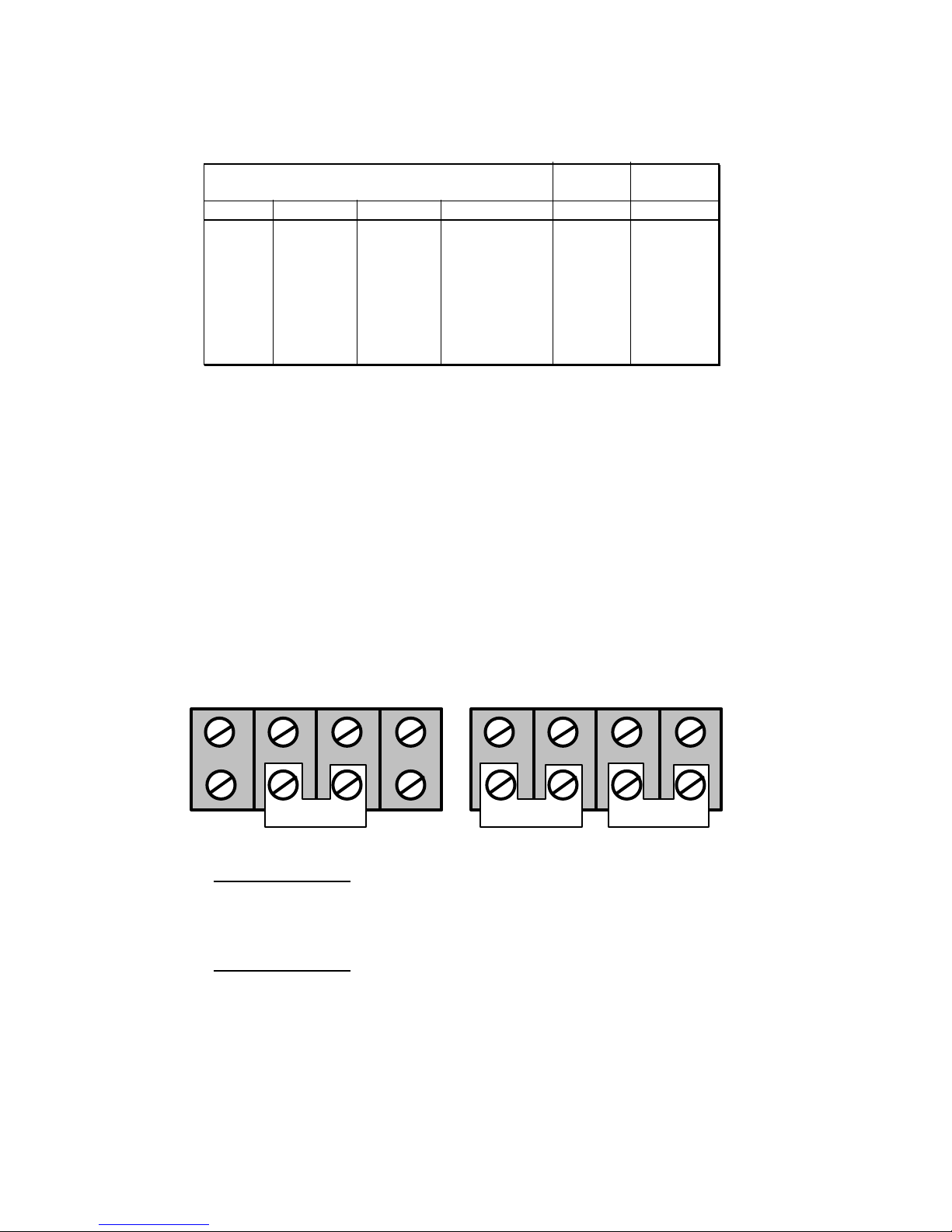

FIGURE 2.2a

Power Connections - 240 Volts AC Input or Lower

AC INPUT DC OUTPUT 240 VAC OR LESS

MAKE INPUT & OUTPUT

CONNECTIONS DIRECT

TO CIRCUIT BREAKERS

AS SHOWN.

LN

or

L

-+

FIGURE 2.2b

Power Connections - 277, 380, 415 or 480 VAC

277, 380, 415 OR 480 VAC

MAKE INPUT & OUTPUT

CONNECTIONS DIRECT

TO CIRCUIT BREAKERS

AS SHOWN.

AC INPUT

LN

or

L

DC OUTPUT

-+

Connections should be made by a qualified installer in accordance with national and local electrical

codes. The installer should determine the gauge of wire to be used based on the length of cable runs

and the ampere requirements of the charger.

Refer to Table 2.2 for ratings of the charger’s AC breaker. Chargers supplied with field-selectable

input voltage are identified with an “A” as the first digit of the part number suffix. In these units the

AC breaker is sized for 115-volt operation. When the field setting is made for 115-volt operation,

size the AC feed to provide a maximum of 20% less than the breaker ratings listed in Table 2.2.

(The charger’s maximum power consumption is less than 20% below the breaker rating). When set

for 230-volt operation the current consumption will be half of the 115 volt figure.

Chargers with 480-volt input require half the current of 230 VAC units.

Use the charger’s rated DC amperes to determine DC cable gauge.

WARNING: The battery charger should be connected to a grounded permanent wiring system.

A ground stud or terminal is provided for this purpose.

DCT Series Charger Manual

6

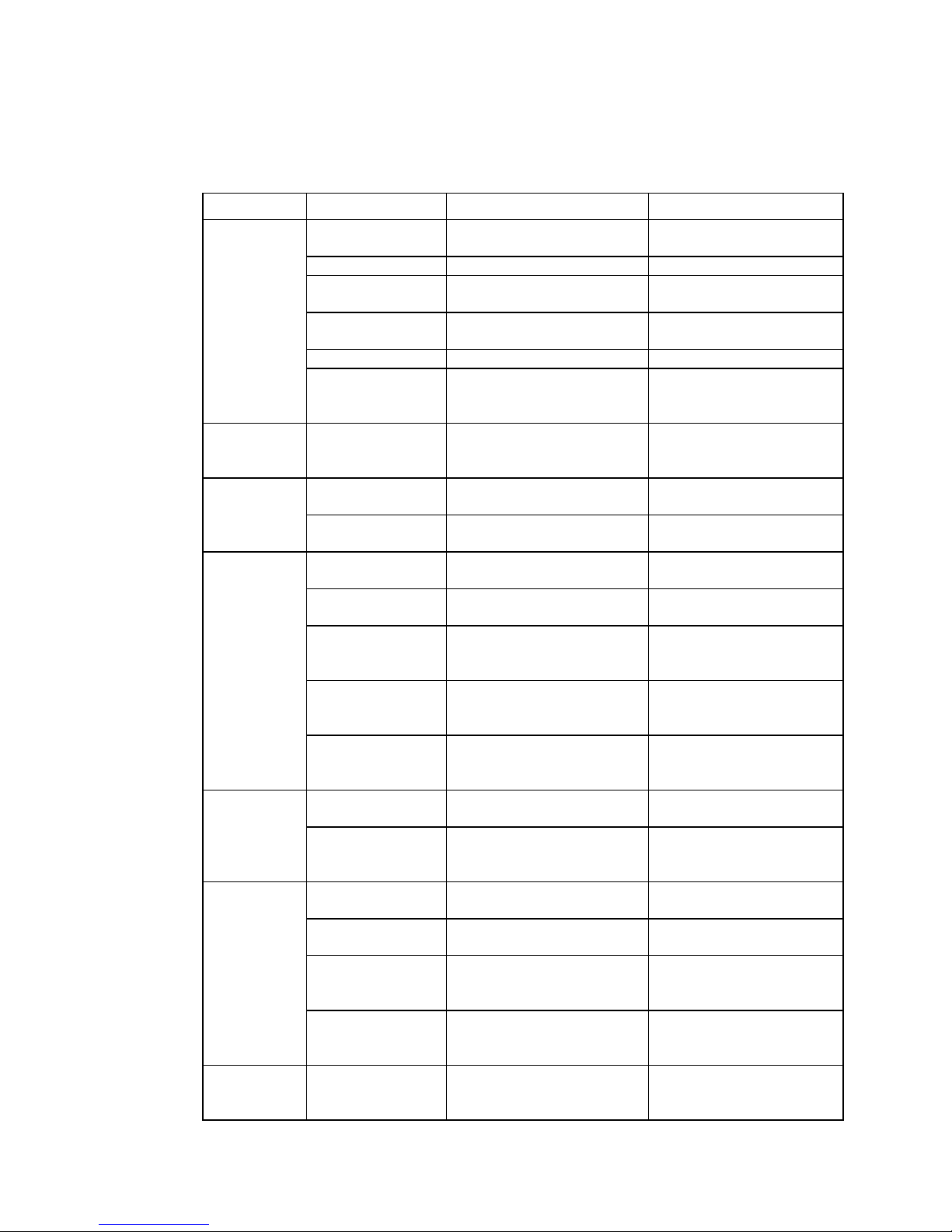

TABLE 2.2

AC Input Circuit Breaker Ratings

Charger output Breaker Breaker

115 V 230 V

V A V A V A V A amps amps

24 75 40 same

24 100 50 same

48 75 50

240 6 20 same

120 25 240 12 60 same

120 35 45

Caution: Do NOT connect the battery backwards; charger damage may result.

The voltmeter will show battery voltage as soon as the DC connection is completed. Check the

voltmeter as soon as the DC connection has been made. If the meter reads zero or is deflecting

below zero, reverse the polarity of the battery connections.

2.3 115/230 Volt Strapping

Chargers equipped with field-selectable, dual-voltage input are factory-set at 230 volts. If your input

supply is 115 volts, change the voltage selection terminal block to the configuration shown below.

The input voltage selection block is located inside the charger front door.

Figure 2.3

115/230 Volt Strapping Configurations

230 volt configuration 115 volt configuration

230 V Configuration

If 115 VAC is accidentally applied, the charger output voltage may sag, even though the “AC On”

and Float LEDs are lit. “Low DC” and “Charge Fail” may be dimly lit. Please strap accordingly for

the proper input voltage.

115 V Configuration

If 230 VAC is accidentally applied, the charger will enter a high voltage shutdown (HVSD)

condition, turning off the control board and the charger. No output voltage or current will be present.

Please strap accordingly for the proper input voltage.

2.4 Alarm Connections

DCT chargers are supplied with one of three following alarms configurations:

DCT Series Charger Manual

7

TABLE 2.4

Charger Part Number Suffix and Alarms Configuration

-4042, -6042,

-7042, -8042

Alarms “0”

-4642, -6642,

-7642, -8642

Alarms “6”

Charger alarm system code

Indication

None Float or boost mode LED

None AC fail LED & Form C contact

None Charger fail LED & Form C contact

None Low battery voltage LED & Form C contact

None High battery voltage LED & Form C contact

None Ground fault + LED

None Ground fault - LED

None Ground fault + or - Form C contact

None Summary of above Form C contact

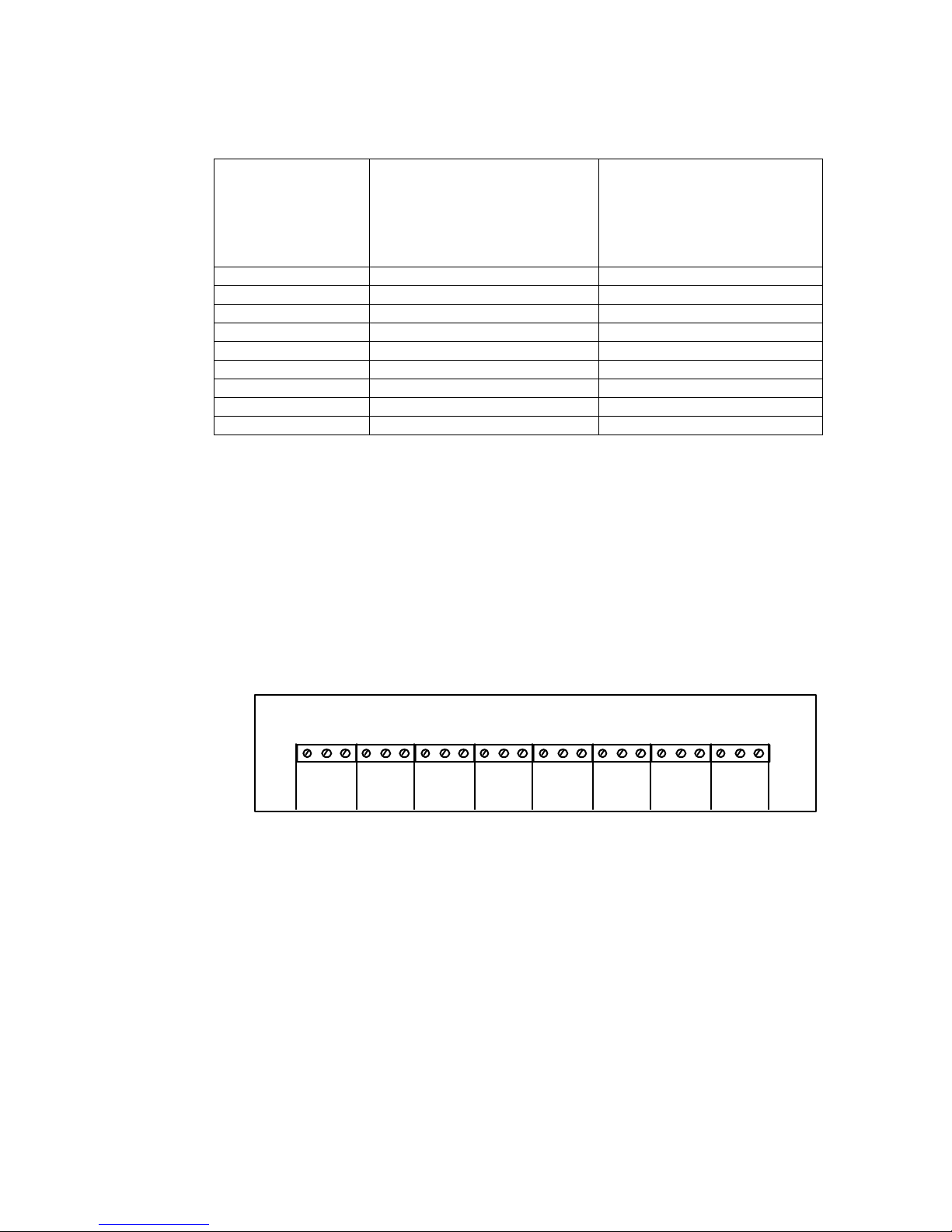

Connect to the charger’s Form C contacts according to Figure 2.4.

1. Make connections to the system's Form C alarm contacts as shown.

2. Run alarm wiring out of the charger separately from the AC supply wiring.

3. Use 16 to 22-gauge wire.

NOTE: Do not exceed the relay maximum current rating of 1A @ 117 VAC or 2A @ 26 VDC.

The remote alarm connection board is located on the circuit breaker pan, adjacent to the control

board. See Figure 2.4.

FIGURE 2.4

Remote Contact Terminal Block

FAIL

OK

COM

GROUND

FAULT

AC

FAIL

CHARGE

FAIL

LOW DC

VOLTS

HIGH DC

VOLTS

LOW DC

DISC.

OPTIONSUMMARY

FAIL

OK

COM

FAIL

OK

COM

FAIL

OK

COM

FAIL

OK

COM

FAIL

OK

COM

FAIL

OK

COM

FAIL

OK

COM

2.5 Temperature Compensation

DCT chargers include battery temperature compensation (TC). TC is required by all batteries for

maximum performance and life. The TC feature automatically reduces the charger’s output voltage

at high temperatures and vice-versa.

The factory configuration is for charger local sensing of battery temperature (i.e. at the cooling air

intake of the charger). The charger also includes, as standard, the provision for extension of a

temperature sensor to a remote location. At installations where the battery is located in a different

room, or is otherwise subject to ambient temperatures different from the charger, it is necessary to

sense temperature at the battery. If this is the case, the optional SENS remote temperature sensor

(RTS) should be obtained from the factory. When the optional remote sensor is attached correctly

to the charger control board the charger automatically selects the remote sensor over the local

sensor. If the remote sensor becomes damaged or disconnected, temperature sensing automatically

reverts to local.

DCT Series Charger Manual

8

The two leads of the optional RTS are connected to a port on the control board as follows: Connect

the yellow lead of the sensor to J7 “YEL” and the violet lead to J7 “VIO”. If the sensor is

connected properly “RTS OFF” will not illuminate when the charger is in operation. If “RTS OFF”

stays lit, check that RTS leads are not reversed, and check that the remote sensor is not damaged.

Any excess length of the RTS leads should be cut off rather than coiled, to ensure the shortest

possible length. The RTS leads should be routed separately and away from all other AC power, DC

power, and alarm wires and cables to prevent noise coupling that may cause abnormal operation of

the charger.

NOTE: “RTS OFF” on the control board will remain lit whenever the remote temperature sensor is

either not used or if the remote sensor is disabled. This is normal when RTS is not used.

3

Operation

3.1 Start-up, Shut-down

Start with both input and output breakers OFF.

First, check that the connected battery voltage is correct (e.g. 120 volts for a 120-volt charger). It is

OK if the battery voltage is different from the nominal value by a few percent. If the battery

voltage is more than 10% different from the rated voltage of the charger, recheck your connections

BEFORE turning on either breaker.

Then close the AC input breaker. Check that the charger voltage comes up to approximately 15%

above nominal. (Some voltage overshoot on initial startup is normal).

Next, close the DC output breaker. The charger will immediately begin to supply current, if

required by the battery or load.

In chargers with alarms code “6”, the front panel AC FAIL and CHARGE FAIL lights will

extinguish, and it should be replaced by the green AC ON light.

The charger will automatically supply power to the load and maintain the battery without further

attention. If the charger does not start as described, or appears to have failed, check the following:

• Verify that AC mains power is available

• Verify that no external circuit breakers are tripped

• Verify that contractor-installed AC, DC and alarm connections are correct

• Disconnect AC and DC power sources. Open the charger. Verify that no components (e.g. main

DC output fuse, if fitted) or harness connections are blown, loose or damaged.

If all of the above appear to be in order, contact SENS at the toll-free service number on the front of

this document for troubleshooting assistance.

At power down or disconnection of charger from battery. The DC output breaker must not be

operated from the closed to open position when AC power is present. Always open AC breaker

before opening the DC output breaker.

3.2 FLOAT/BOOST MODES

Two modes of voltage control are provided in all DCT chargers as follows:

FLOAT

The float mode is the battery “maintenance” voltage. It is the normally fully charged voltage of the

battery. This is the normal charging position for all batteries and the recommended charging

position at all times for Valve Regulated Lead Acid (VRLA) batteries.

DCT Series Charger Manual

9

BOOST

This voltage is slightly higher than the float setting. Boost slightly overcharges the battery in order

to ensure that all the cells of a battery are fully charged to the same voltage. Continued operation in

boost is not recommended because the high charging voltage will cause battery electrolyte to boil

away quickly. This is a particular problem with VRLA batteries where there is no way to replenish

lost electrolyte.

3.3 FLOAT/BOOST CONTROL

DCT chargers are equipped with one of the four following float/boost voltage control systems,

depending on the configuration ordered:

FLOAT/BOOST front panel rotary switch

The charger will operate indefinitely in the mode that is selected. The AUTO position may be

shown on the front panel. If the AUTO position is locked out, the AUTOBOOST feature is not

supplied.

AUTO/FLOAT/BOOST front panel rotary switch

When the selector switch is in the FLOAT or BOOST mode, the charger will operate indefinitely in

the mode that is selected.

The AUTO mode selects automatic equalization of the battery. The charger determines when the

battery is in need of fast charging, and it operates in the fast charge boost mode only until the

battery is fully charged. The charger determines state of charge by measuring the amount of current

drawn from the output terminals. When the selector switch is in the AUTO position the charger

will start in the BOOST mode and stay there until current demanded drops below about 50% of the

charger’s rated current. When current demand increases to about 70% of the charger’s rated output,

the charger will resume operation in the BOOST mode.

Please see the Appendix for a diagram of how the AUTOBOOST system works. The AUTO

setting eliminates the need to periodically equalize the cells of a battery as the charger does this

automatically. The AUTO position should not be selected when the continuous load on the charger

is greater than about 50% of the charger’s maximum rated current.

Manually initiated boost timer (either 0-24 hours or 0-72 hours)

When the timer is turned clockwise the charger will be in BOOST mode, where it will remain until

the timer returns to 0 hours. At the end of the selected time the charger will return to FLOAT

mode.

Manually initiated boost timer, plus AUTO/FLOAT/BOOST rotary switch

Selection of the AUTO position allows the charger to operate in the AUTOBOOST mode.

Selection of the FLOAT mode forces the charger to remain in the FLOAT mode unless the boost

timer is activated by turning past zero. If the boost timer is activated, the charger will revert to

FLOAT mode after the time selected on the timer expires.

Selection of the BOOST mode forces the charger into boost charge, where it will remain until

BOOST is deselected manually.

3.4 Alarm Indications

NOTE: Chargers are equipped with a “dead-front” panel. Alarm LEDs are behind the dead-front

panel and will be visible when they illuminate due to an alarm condition, or when the TEST button

is pressed. See Figure 3.4 for the location of LED indicators. Chargers with no alarms (alarms

code “0”) have no LEDs or test button.

DCT Series Charger Manual

10

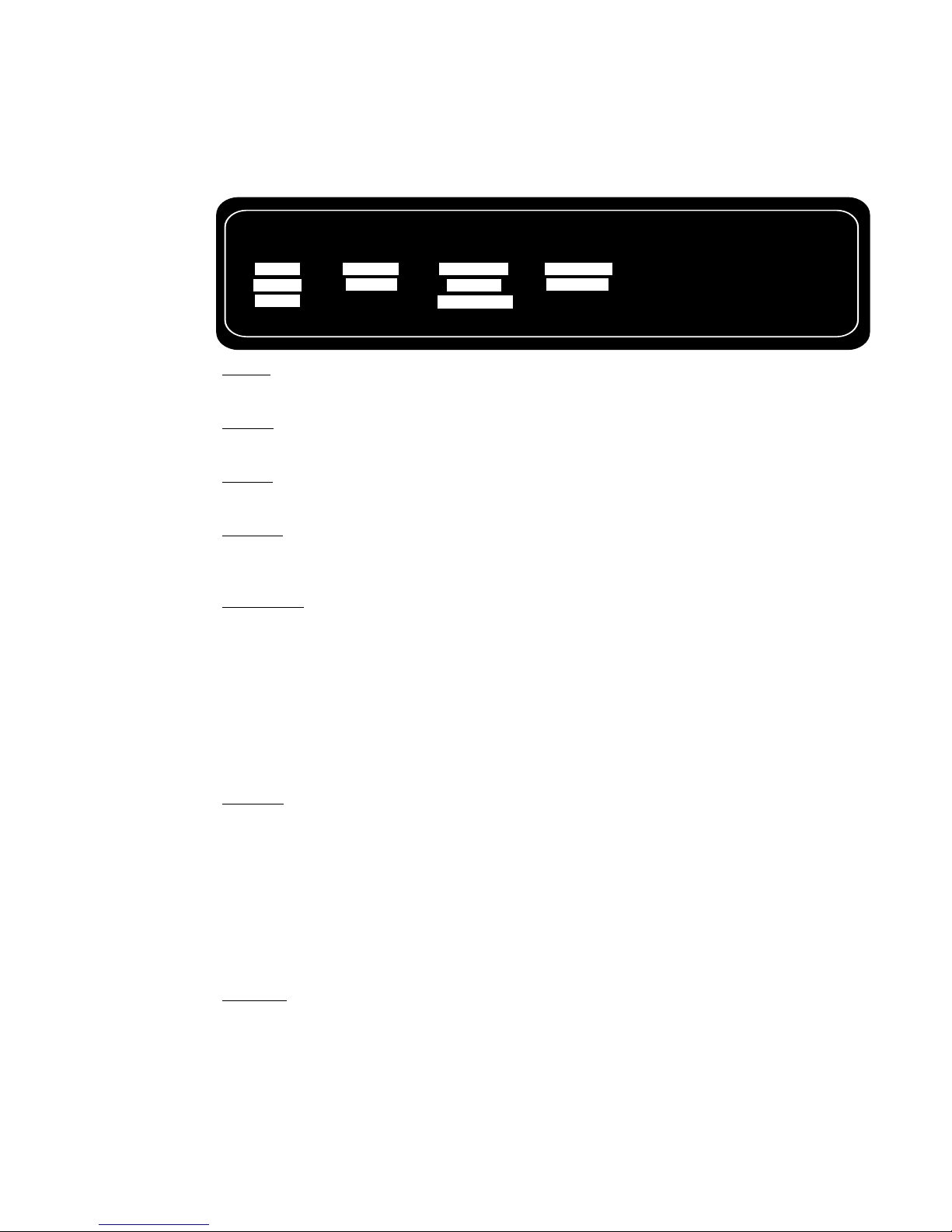

FIGURE 3.4

LED Indicators on Charger Front Panel

LOW DC

AC FAIL + GROUND

- GROUND

LAMP TEST

FLOAT

BOOST

AC ON CHGR FAIL

HIGH DC

SHUTDOWN

AC ON

Indicates that AC power is being supplied to the charger.

BOOST

The charger is operating in the BOOST mode.

FLOAT

The charger is operating in the FLOAT mode.

AC FAIL

Indicates that AC power is not available to the charger. Input AC is failed, or AC breaker is

tripped.

CHGR FAIL

Indicates that the charger is failing to produce the output current required by the battery and load.

When the battery and load demand no current, the failure alarm will not activate.

In the event that the CHARGE FAIL and AC ON lights are illuminated simultaneously, then the

charger has failed. The probable causes of an alarm, in descending order of likelihood, are:

a) A failure of AC power

b) A tripped AC breaker

c) The charger has malfunctioned

LOW DC

Indicates that DC voltage has dropped to approximately 8.5% below nominal battery voltage (e.g.

21 volts for a 24-volt system). Probable causes:

a) The AC power has failed, and the battery has become discharged

b) The charger has malfunctioned and the battery has become discharged

c) The battery is defective

There is a time delay in the low voltage alarm which prevents the alarm from activating until

approximately 30 seconds after the low voltage condition starts.

HIGH DC

Indicates that the charger’s output has exceeded a pre-set threshold level (approximately 20% above

nominal battery voltage - e.g. 29 volts for a 24-volt system). If this alarm stays activated for any

period of time, the charger should be shut down and serviced. The charger may have

malfunctioned, or the alarm card may be misadjusted. The alarm activates immediately upon high

voltage condition, but stays activated for approximately 30 seconds after the condition disappears.

DCT Series Charger Manual

11

HIGH DC SHTDN

Indicates that the charger has been shut down by the high output voltage shutdown circuit.

Probable causes of a high DC shutdown are as follows:

a) The float or boost voltages have been increased above the pre-set shutdown voltage.

b) The high voltage shutdown set point has been changed from the factory setting.

c) The charger has malfunctioned and is not regulating properly.

There is a delay of approximately five seconds after the onset of the high voltage condition until the

unit shuts down. When a high volt shutdown occurs, the red HVS LED on the control board will

illuminate, along with the SHUTDOWN LED on the front panel.

If the high DC shutdown activates, the charger will stay off until the battery voltage drops to

approximately nominal, at which point the circuit will reset and the charger will start. Manual reset

of the shutdown is accomplished as follows:

1) Turn off the AC input breaker. (Note that while the SHUTDOWN LED will extinguish, the

charger is still locked out. This is because the shutdown LED is driven by the control board's

power supply, which is derived from the AC supply, rather than from the battery).

2) Turn off the DC output breaker.

3) Wait for about one minute for capacitor voltage to decay through the capacitor bleeder resistor.

4) Turn on the DC output breaker.

5) Turn on the AC input breaker. If the charger is still in high DC shutdown, repeat steps 1 through

3, waiting longer before turning DC and AC breakers back on.

The control board includes two sets of Form C contacts for high volt shutdown indication. Either

one of these can be used for remote indication of high voltage shutdown.

GROUND (optional)

This is a ground fault alarm. If either the charger’s positive or negative is connected to ground,

even through a high resistance path, this alarm will activate. LEDs indicate either positive or

negative grounding. The Form C contact only indicates that a fault has occurred.

Some applications require that ground be referenced to either the positive or negative output. In

this case, the activated ground fault alarm will be a nuisance. The alarm can be safely disabled by

placing the ground fault jumper, located on the alarm board (mounted on the charger’s front door),

in the “disabled” position. When pins 1 and 2 of J5 are connected together the ground fault alarm is

disabled. When pins 2 and 3 are connected the ground fault alarm is enabled.

4

Adjustments

4.1 Output Voltage Adjustment

WARNING: Working inside the charger exposes you to dangerous AC and DC voltages. Do not

touch circuit breakers, filter capacitors, heat sinks or any other exposed metal surfaces.

NOTE: Do not tamper with factory adjustments unless sure adjustment is necessary.

Temperature-compensated control circuitry automatically adjusts the output voltage, depending on

temperature. Adjust the output only under these circumstances:

a) To correct a previous unauthorized adjustment

b) To adjust the charger for a different type of battery (e.g. from lead-acid to nickel-cadmium)

c) If your battery is consistently being over-charged or under-charged

NOTE: Unless authorized by SENS, any charger adjustment, including output voltage adjustment,

voids the warranty.

Procedure

1. Use a precision external voltmeter connected directly to the charger output terminals.

2. Set the charger’s front panel FLOAT/BOOST control to FLOAT.

3. Open the charger’s front panel and locate the control card. It contains two potentiometers labeled

“FLOAT” (R14) and “BOOST” (R15), both located near the center of the board.

DCT Series Charger Manual

12

4. Adjust the FLOAT pot until the desired voltage is achieved.

Adjustment of the BOOST voltage is similar to adjustment of FLOAT, except that you adjust the

BOOST pot instead of the FLOAT pot. Be sure that the charger front panel mode switch is in

BOOST when you make adjustments.

Please note that the BOOST adjustment controls the level above FLOAT voltage, not the absolute

voltage. Therefore, whenever the FLOAT voltage is changed, the BOOST voltage also changes.

4.2 Factory-Set Output and Alarm Voltages

NOTE: Output voltages are temperature compensated (vary with temperature). The factory

settings below are at 20 degrees C. The compensation is -0.18% per degree C. The alarm voltage

settings are NOT temperature compensated.

Chargers set for sealed maintenance-free lead-acid battery

12 Volt 24 Volt 32 Volt 48 Volt 120 Volt 240 Volt

Float voltage 13.62 27.24 36.32 54.48 136.20 272.40

Boost voltage 13.80 27.60 36.80 55.20 138.00 276.00

Low DC alarm 11.00 22.00 29.33 44.00 110.00 220.00

High DC alarm 14.61 29.22 38.96 58.44 146.10 292.21

High DC shutdown 15.19 30.39 40.52 60.78 151.95 303.89

Chargers set for flooded lead-acid battery

12 Volt 24 Volt 32 Volt 48 Volt 120 Volt 240 Volt

Float voltage 13.32 26.64 35.52 53.28 133.20 266.40

Boost voltage 14.00 28.00 37.28 55.92 139.80 279.60

Low DC alarm 11.00 22.00 29.33 44.00 110.00 220.00

High DC alarm 14.82 29.64 39.47 59.20 148.01 296.02

High DC shutdown 15.41 30.83 41.05 61.57 153.93 307.86

Chargers set for nickel cadmium battery. Multiply volts per cell times number of cells for actual voltage.

Per Cell

Float voltage 1.43

Boost voltage 1.52

Low DC alarm 1.19

High DC alarm 1.61

High DC shutdown 1.67

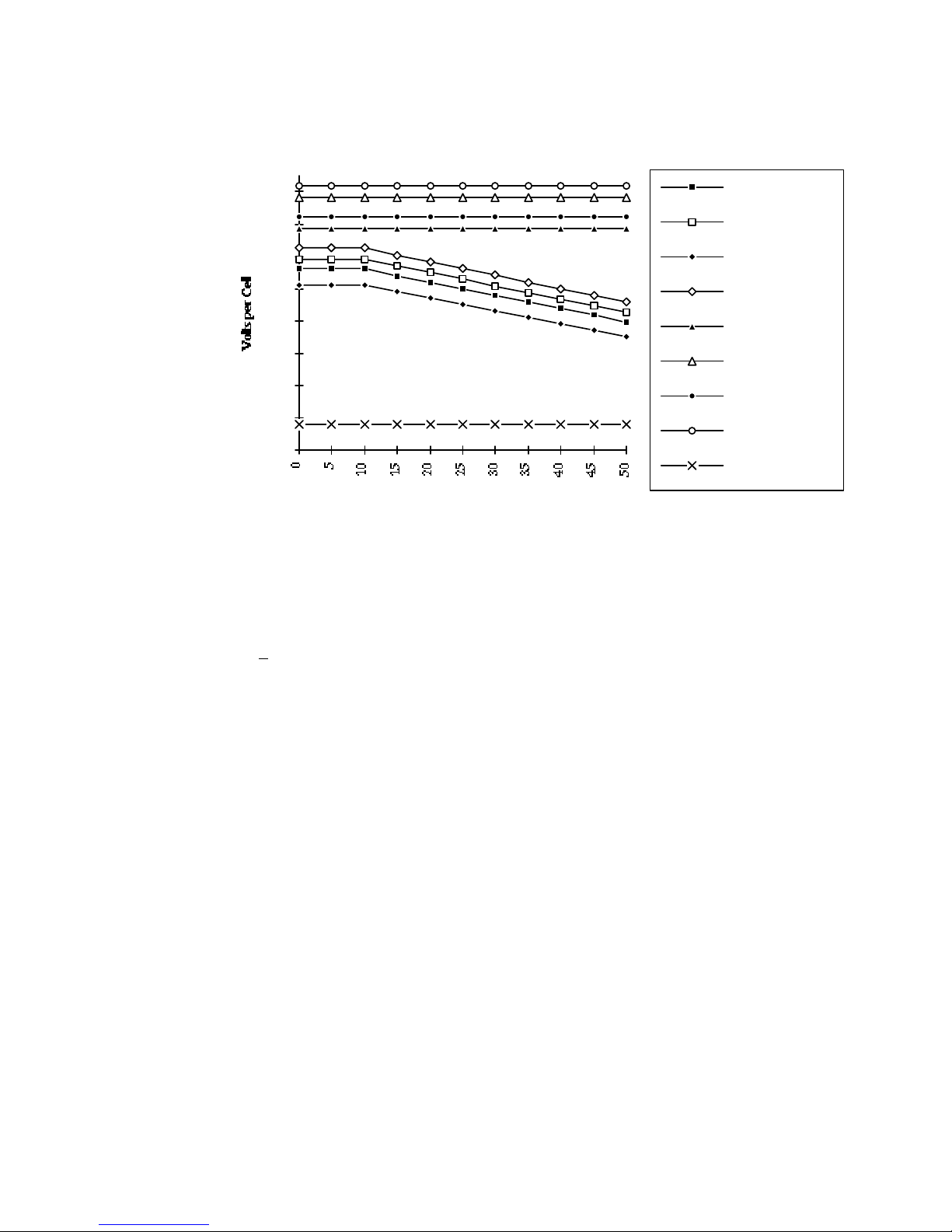

Chart 4.2 shows the relationship between charger output voltage, alarms and high voltage shutdown

Note: The output voltage is temperature compensated down to 10 degrees C, below which the

compensation ends.

To determine the charger’s voltage at temperatures other than 20 degrees C., multiply the number of

degrees Celsius difference between your ambient and 20 degrees times .0018. Multiply that product

times the factory voltage setting (e.g. 27.24), and add it to the factory setting.

Example 1: Float voltage at 10 degrees C of a 24 volt charger set for 27.24 volts at 20 degrees C:

20-10 (.0018) (27.24) + 27.24 = 27.73 volts

Example 2: Float voltage at 50 degrees C of a 24 volt charger set for 27.24 volts at 20 degrees C:

20-50 (.0018) (27.24) + 27.24 = 25.77 volts

DCT Series Charger Manual

13

CHART 4.2

Graph of Factory-Set Output, Alarm and Shutdown Voltages

Degrees C

1.75

1.85

1.95

2.05

2.15

2.25

2.35

2.45

2.55 VRLA Float

VRLA Boost

Flooded Float

Flooded Boost

HV Alm VRLA

HV Shtdn VRLA

HV Alm Flooded

HV Shtdn Flooded

Low DC Alarm

4.3 Forced Load Sharing

Chargers can be set up for forced load sharing when used in parallel with units of the same current

rating. Forced load sharing causes the chargers to share the load from light loading to full load,

except when either charger is in BOOST mode (whether activated manually or via the

AUTOBOOST system) or if either charger is operating in current limit. Chargers will share the load

within + 10% of each other.

To set up, ensure that the DC output leads from each charger are identical in length and wire gauge.

Install a Load Share Cable (supplied by SENS or assembled by user) between terminals on both

control boards where labeled “PAR”.

To assemble a Load Share Cable:

1. Cut desired length of signal wire (18 or 22 AWG).

2. Connect a 10KΏ, 2 Watts or more, resistor inline with signal wire. Connect resistor to wire

using a Butt Connector or twist wires together and cover with Heat – shrink.

DCT Series Charger Manual

14

5

Trouble-

shooting

5.1 Troubleshooting Table

If there is a problem and you suspect the charger is at fault, turn off the AC mains supply before

proceeding. Ensure that the following are correct: AC input wiring, battery and/or load connections

and PC card connectors. Ensure no foreign objects are in the charger.

Symptom

Possible Cause

Test

Corrective Action

No output /

fail alarm

Control board failure Replace with known good

board

Replace board

DC fuse blown Check fuse for continuity Replace if open

High DC shutdown Check HVS LED on control

board

If lit, see "High Output

Voltage" symptom below

Power rectifier

circuit failure

Test all power diodes with

meter; test SCRs

Replace all shorted, open, or

bad parts

AC failure Check input supply Restore AC input supply

Shutdown due to

excessive output

voltage

Check whether HVS LED on

control board is lit

Shut off AC and DC breakers

for at least 2 minutes, then

restore

AC breaker

trips

repeatedly

Power diode, SCR,

or freewheeling

diode short

Check all power devices for

shorts

Replace shorted device(s)

DC brkr trips

repeatedly

Control board failure Replace with known good

board

Replace board, send bad

board to SENS for repair

Freewheeling diode

short

Check diode for short Replace diode

Low output

volts / alarm

Control board failure Replace with known good

board

Replace board

Misadjusted float

voltage

Adjust pot to see if output

voltage is affected

Adjust float pot to correct

output voltage

Overloaded charger Turn off DC breaker, check

voltage on INSIDE breaker

terminals

Check load for problems, and

check battery condition

Bad filter capacitor Disconnect capacitors one at a

time and check for change in

output voltage

Replace capacitor that

corrected output voltage

when removed

Line voltage less

than charger's

operating range

Measure AC line voltage Use larger gauge AC wires or

contact utility company

High output

volts /alarm

Control board failure Replace with known good

board

Replace board

Misadjusted float

voltage pot on

control board

Adjust pot and see if output

voltage is affected

Adjust float pot to correct

output voltage

High ripple

voltage

Control board failure Replace with known good

board

Replace board

Power diode / SCR

failure

Test power diodes; perform

SCR test on SCRs

Replace all open or bad parts

AC line voltage too

high

Check for AC line voltage

over charger's specified

operating range

Contact utility company

Bad filter capacitor Disconnect capacitors one at a

time and check for change in

output voltage

Replace capacitor that

corrected output voltage

when removed

Improperly

functioning

indicators

Alarm, display, or

control board failure

Replace each board in turn

with a known good board

Replace failed board(s)

DCT Series Charger Manual

15

5.2 Component Diagnostic Tests

Test #1: With transformer leads disconnected, energize the transformer with the normal AC supply

voltage. Measure entire secondary voltage. It should be 1.5 to 2 times the nominal battery voltage.

Test #2: With one or both leads disconnected from the inductor, measure the resistance across the

inductor terminals. If the resistance is near a short circuit condition, the inductor is OK.

Test #3: Using a digital multimeter set to the diode testing function, measure the junction voltage

across the diode. A reading of between 0.4 volt and 0.8 volt in the forward polarity direction and

infinity in the reverse polarity direction indicate a good diode.

Test #4: Refer to Figure 5.2. Disconnect all the leads to the SCR and its heat sink. Connect a

voltmeter across the 1KΩresistor to measure the voltage drop. With the battery connected as shown,

Vdrop should read approximately 2.3V (Vsource-0.7V). Remove the voltage source to the gate, but

keep it connected to the 1KΩresistor and cathode. Vdrop should equal zero. Reconnect the gate and

reverse the batteries polarity. Vdrop should read zero volts. Readings other than these indicate a

defective SCR.

Test #5: Due to the modest cost of the control circuit, we recommend that the entire unit be replaced

rather than attempting to repair it. If the troubleshooting guide has not revealed any defective

components (tests #1-4), the control circuit should be replaced as a unit.

Test #6: Remove all wires from the current shunt. Place a milliohmmeter across the two terminals.

The following formula should be used to determine the correct resistance:

Resistance in ohms should equal 0.5/Output current rating of the charger, except in 35 amp units

when resistance should equal 0.1 ohms.

If the resistance is more than 20% too low, the current shunt should be replaced.

FIGURE 5.2

SCR test setup

25 ž

approx. 3 volt source(2 "D"

batteries in series)

Cathode Gate

SCR

Anode

-

+

+

-

Vdrop 1 Kž

DCT Series Charger Manual

16

Appendix Diagram of Automatic Boost Operation (Optional Feature)

Boost voltage

Float voltage

Point at which charger changes

from current limit to voltage limit

Point at which AUTOBOOST

returns charger to float voltage

100% charger

output current

50% to 75% of

charger current limit

Amps

Volts

Charger output current

Battery voltage

NOTE:

Zero current flow

0Time

When the charger switches from BOOST to FLOAT mode,

no current will flow into the battery for a while due to the battery's

high state of charge. This is completely normal, and indicates

that the charger is working properly.

CFOK CFOK

HIGH VOLT

SHUTDOWN

HIGH VOLT

SHUTDOWN

KA

PAR

PARRALLEL

TEMPERATURE

SENSING

REMOTE

FOR COMPLETE

SEE BODY OF

OF ALARM

EXPLANATION

USER GUIDE

CONNECTIONS.

FUNCTION &

MAXIMUM WIRE

SIZE-#14.

ALARM

CONNECTIONS:

FAIL

CHARGE

FAIL

FAIL

LOW DC

VOLTS GROUND

FAIL

FAIL

FAULTFAIL

AC

COM

OK

OK

OK

COM

COM

OK

LOW DC

FAIL

FAIL

DISC.

SUMMARY OPTION

COM

FAIL

HIGH DC

VOLTS

FAIL

COM

OK

COM

OK

COM

OK

COM

OK

A3

BATTERY AND LOAD ALARM

CONNECTIONS

OUTPUT

INPUT DC

AC

1. INPUT VOLTAGES OF 277VAC

2. A3 OPTIONAL ONLY IF UNIT IS

EQUIPPED WITH ALARMS.

POSITION OF BREAKERS.

& GREATER WILL REVERSE THE

MAKE INPUT & OUTPUT CONNECTIONS

MAXIMUM WIRE SIZE: AC-#8, DC-#2

DIRECT TO CIRCUIT BREAKERS

GRND

FOR

NOTES:

#10

STUD

AM11-96CORRECT INPUT & OUTPUT

ltrdcn# NRC101751 description

revisions date app

A1

N/A

B

none

scale

DIA\00335

1 OF 1

sheet

4-25-95

release date

TITLE

SIZE

Longmont, CO

STORED ENERGY SYSTEMS

DCT 1 & 2A CASE

SENS

rev

FSCM NO.

CONNECTION DIAGRAM

DWG NO.

otherwise specified)

fract.

tolerances

DESIGN ACTIVITY

CUSTOMER

angles

(unless

.015

dec.

DATE

DRAWN

CONTRACT NO.

KAA

DESIGN

CHECKED

Table of contents

Other Sens Batteries Charger manuals

Sens

Sens EnerGenius NRG24-20 User manual

Sens

Sens EnerGenius IQ2 User manual

Sens

Sens EnerGenius NRG24-10 User manual

Sens

Sens EnerGenius DC COMPACT User manual

Sens

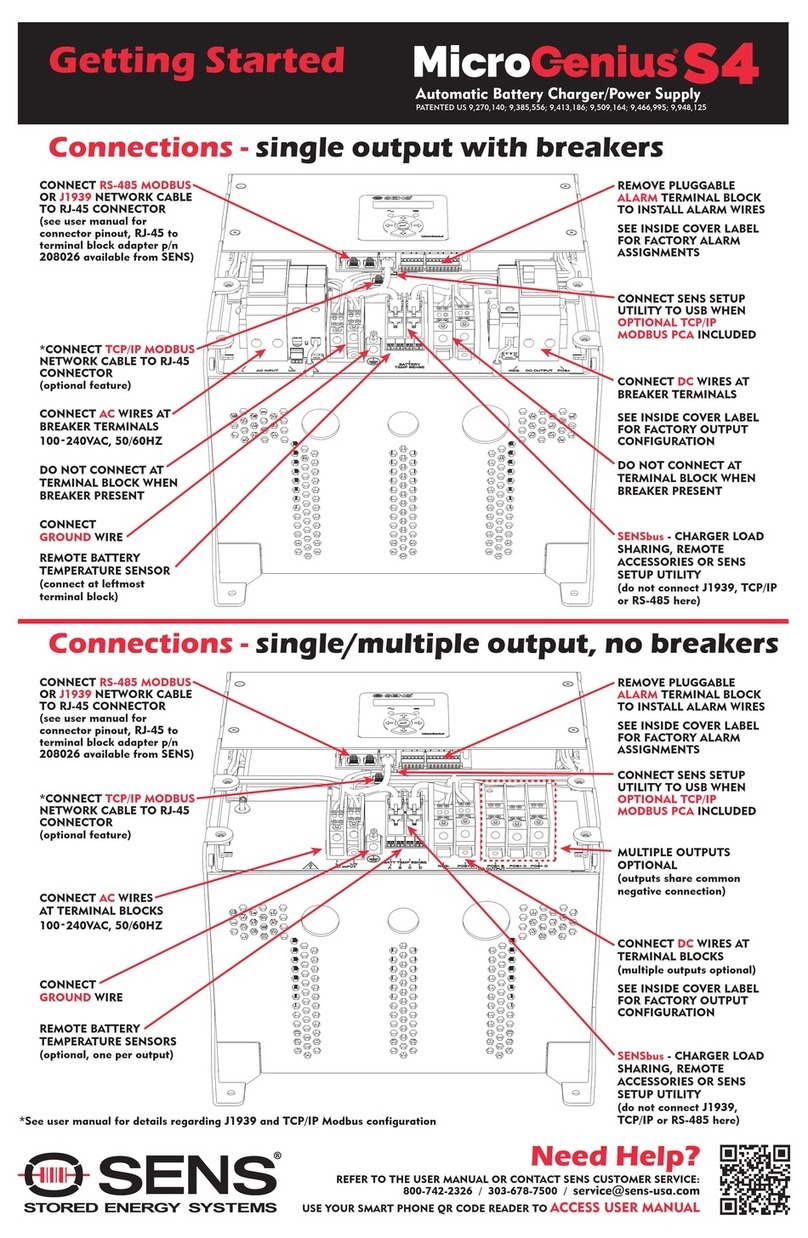

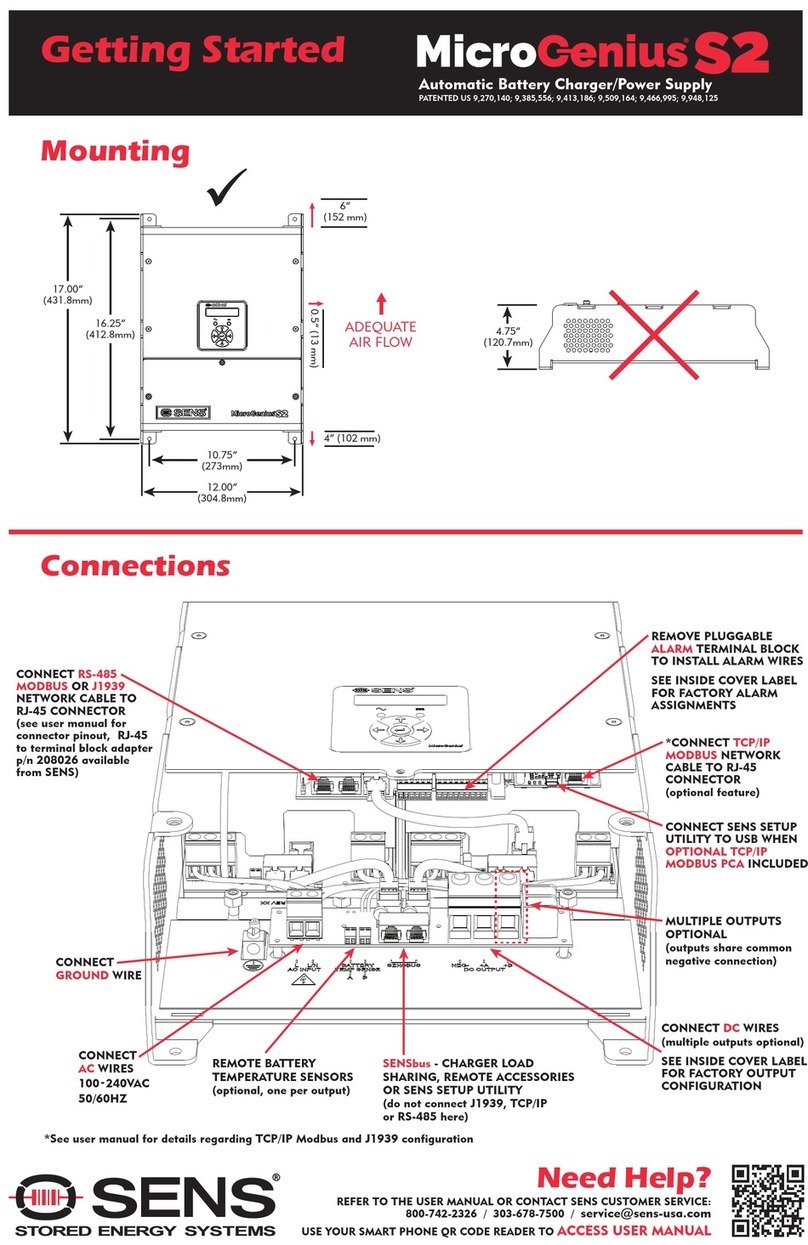

Sens MicroGenius S2 User manual

Sens

Sens MicroGenius 2 User manual

Sens

Sens MicroGenius 2 User manual

Sens

Sens TD Series Operating manual

Sens

Sens MicroGenius User manual

Sens

Sens F3 SERIES Manual

Sens

Sens EnerGenius NRG12-20 User manual

Sens

Sens MicroGenius S4 User manual

Sens

Sens NRG12-10 User manual

Sens

Sens MicroGenius S2 User manual

Sens

Sens EnerGenius DC Wallbox User manual

Sens

Sens F3 SERIES Manual

Sens

Sens FC Operating manual

Sens

Sens Q012-012 User manual

Sens

Sens EnerGenius NRG22-20 User manual