Sens EnerGenius NRG12-20 User manual

SENS EnerGenius Technical Manual

Service hotline: 1.800.742.2326

1.303.678.7500

1

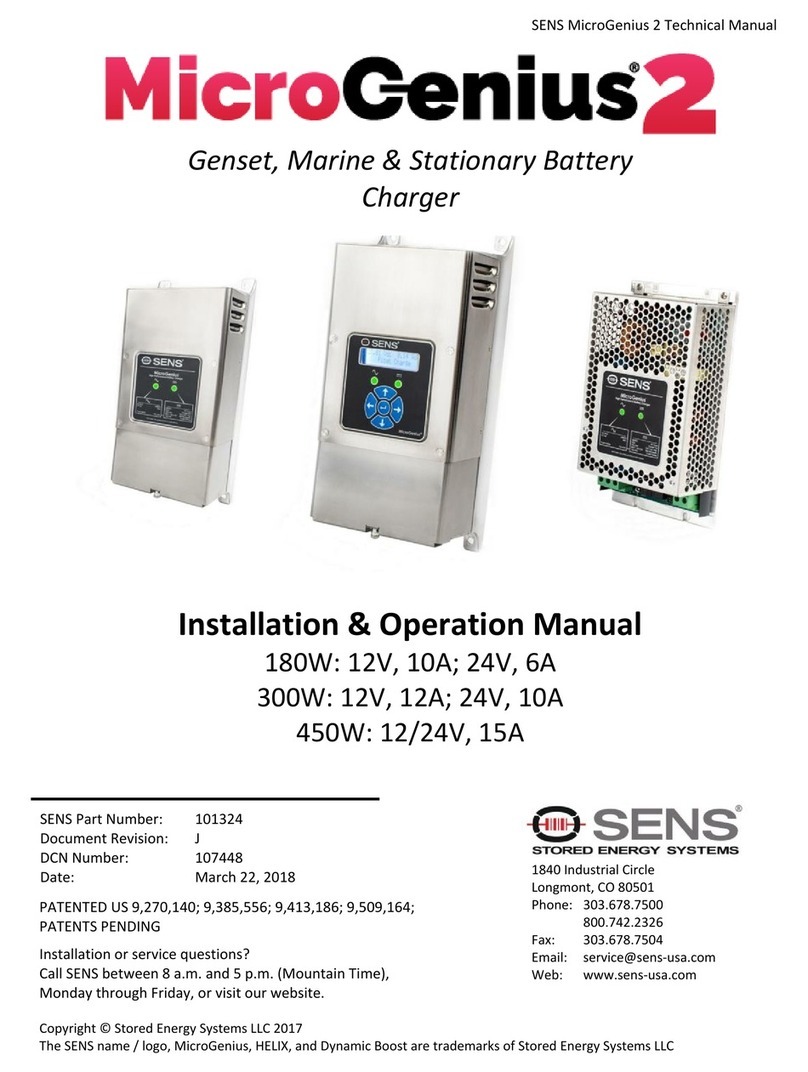

Installation & Operation Manual

NRG12-20: 12-Volt, 20-Amp Battery Charger

NRG24-20: 24-Volt, 20-Amp Battery Charger

NRG22-20: 12/24-Volt, 20-Amp Battery Charger

SENS Part Number:

Document Revision:

DCN Number:

Date:

101298

P

106295

May 20, 2013

Installation or service questions?

Call SENS at 1.800.742.2326 (303.678.7500)

between 8 a.m. and 5 p.m. (Mountain Time)

Monday through Friday, or visit our website.

Copyright © Stored Energy Systems LLC 2007

1840 Industrial Circle

Longmont, CO 80501

Phone: 303.678.7500

800.742.2326

Fax: 303.678.7504

Web: www.sens-usa.com

™

®

SENS EnerGenius Technical Manual

2

Service hotline: 1.800.742.2326

1.303.678.7500

IMPORTANT SAFETY INSTRUCTIONS FOR INSTALLER AND OPERATOR

1. SAVE THESE INSTRUCTIONS.

2. DO NOT EXPOSE CHARGER TO RAIN OR SNOW.

3. Use of an attachment not recommended or sold by SENS may result in a risk of fire, electric shock,

or injury to persons.

4. ONLY TRAINED AND QUALIFIED PERSONNEL MAY INSTALL AND SERVICE THIS

UNIT.

5. Do not operate charger if it has received a sharp blow, been dropped, or otherwise damaged in any way; shut

off power at the branch circuit protectors and have the unit serviced or replaced by qualified personnel.

6. To reduce risk of electric shock, disconnect the branch circuit feeding the charger before attempting any

maintenance or cleaning. Turning off controls will not reduce this risk.

WARNING:

RISK OF EXPLOSIVE

GASES.

A. WORKING IN THE VICINITY OF A LEAD-ACID OR NICKEL-CADMIUM BATTERY IS

DANGEROUS. STORAGE BATTERIES GENERATE EXPLOSIVE GASES DURING NORMAL

BATTERY OPERATION. FOR THIS REASON, IT IS OF UTMOST IMPORTANCE THAT EACH

TIME BEFORE USING YOUR CHARGER, YOU READ THIS MANUAL AND FOLLOW THE

INSTRUCTIONS EXACTLY.

B. To reduce the risk battery explosion, follow these instructions and those published by the battery

manufacturer and the manufacturer of any equipment you intend to use in the vicinity of a battery. Review

cautionary markings on these products and on the engine.

A. Someone should be within range of your voice or close enough to come to your aid when you work near a

storage battery.

B. Have plenty of fresh water and soap nearby in case battery electrolyte contacts skin, clothing, or eyes.

C. Wear complete eye protection and clothing protection. Avoid touching eyes while working near a storage

battery.

D. If battery electrolyte contacts skin or clothing, wash immediately with soap and water. If electrolyte enters

eye, immediately flood the eye with running cold water for at least 10 minutes and get medical attention

immediately.

E. NEVER smoke or allow a spark or flame in vicinity of battery or engine.

F. Be extra cautious to reduce risk of dropping a metal tool onto battery. It might spark or short circuit battery

or other electrical part that may cause explosion. Using insulated tools reduces this risk, but will not

eliminate it.

G. Remove personal metal items such as rings, bracelets, necklaces, and watches when working with a storage

battery. A storage battery can produce a short circuit current high enough to weld a ring or the like to metal,

causing a severe burn.

H. Use this charger for charging LEAD-ACID or LIQUID ELECTROLYTE NICKEL-CADMIUM

batteries only. Do not use this battery charger for charging dry cells, alkaline, lithium, nickel-metal-

hydride, or sealed nickel-cadmium batteries that are commonly used with home appliances. These batteries

may burst and cause injuries to persons and damage to property.

I. NEVER charge a frozen battery.

7. PERSONAL PRECAUTIONS

SENS EnerGenius Technical Manual

Service hotline: 1.800.742.2326

1.303.678.7500

3

This manual contains important safety, installation and operating instructions for SENS battery charger model

NRG12-20 (configured for 12V,20A only), NRG24-20 (configured for 24V, 20A only) and NRG22-20 (field

configurable for 12V or 24V, 20A).

INSTALLATION INSTRUCTIONS

WARNING:

ONLY TRAINED AND QUALIFIED PERSONNEL

MAY INSTALL AND SERVICE THIS UNIT.

MODEL NUMBER CONFIGURATION

Model Number Breakout

NRG 22-20-

Model Output Output Input Voltage Alarm System Agency Category

Voltage Current Frequency Code Code Code

12: 12 volts 20: 20 Amps H: 120/208-240V, C: 5 Alarms L: UL, CUL Listed S: Standard

24: 24 volts 50/60 Hz** R: Recognized E: OSHPD labeled***

22: 12/24 volts R: 120/208-240V, Component

60 Hz*

NOTE: Not all configurations are available on all models.

Contact the factory for confirmation.

*UL listed, CSA certified

**UL listed, CSA certified and CE marked

***California Special Seismic Certification Pre-Approval

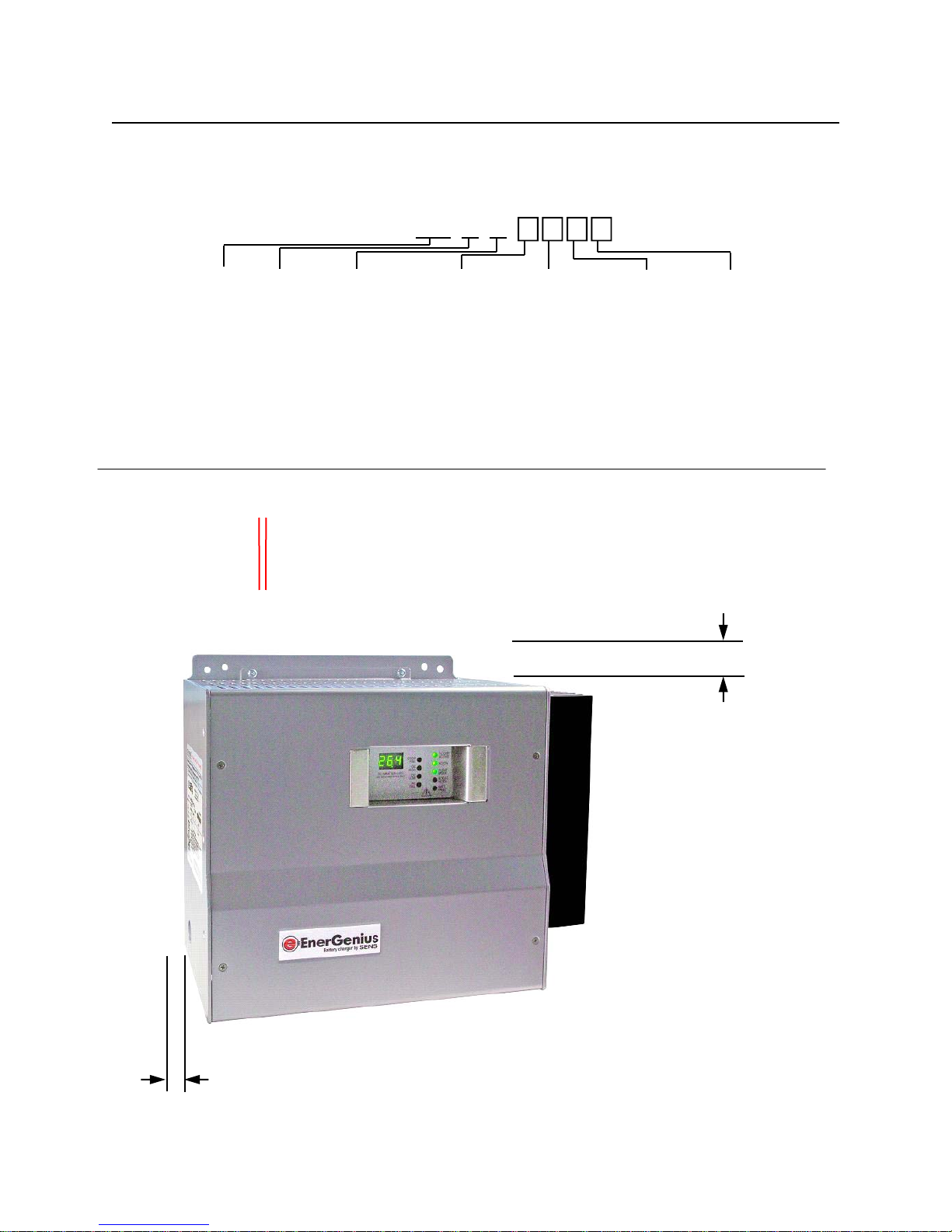

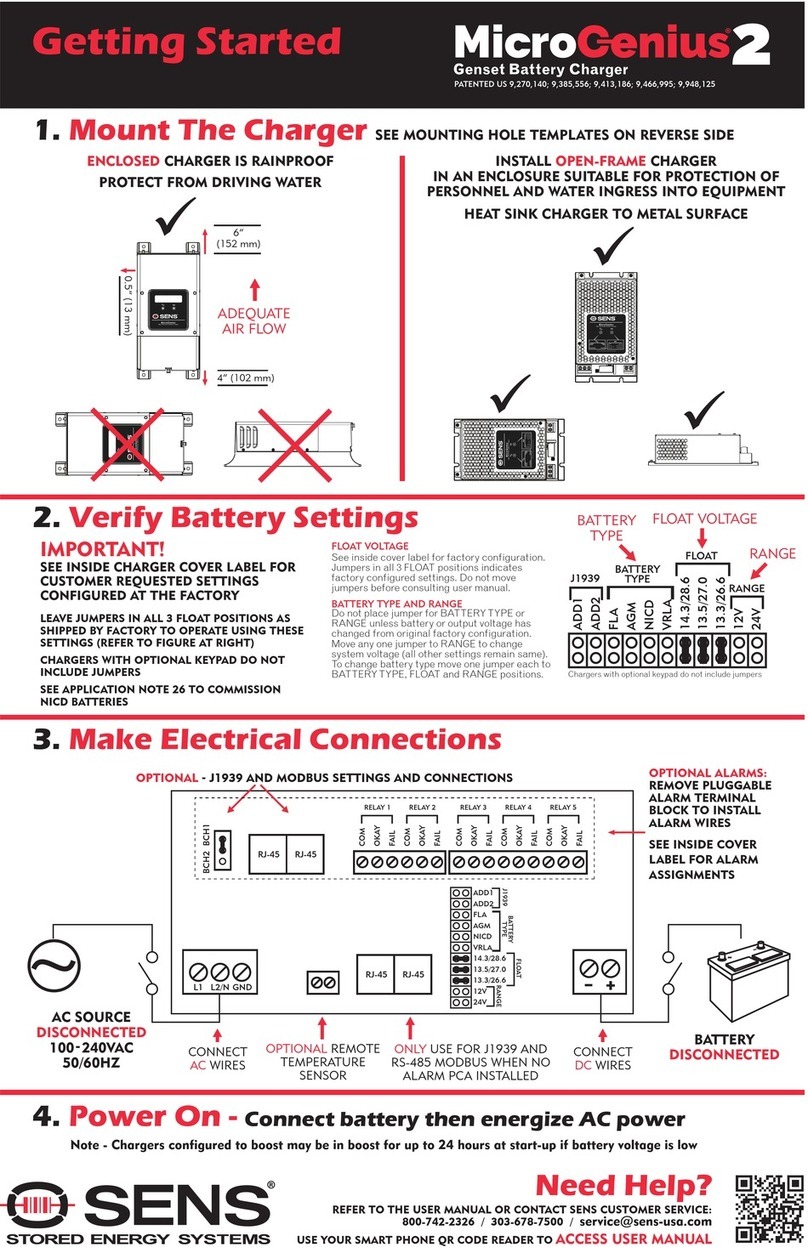

Mount to vertical surface of 3/4” (19 mm) plywood or other

material of equal strength and durability, using four 1/4” (6

mm) diameter mounting screws. For mounting in a high

vibration environment, use of six fasteners is recommended.

6” (150 mm) minimum

ventilation clearance

top and bottom

2” (50 mm) minimum

ventilation clearance

on both sides

SENS EnerGenius Technical Manual

4

Service hotline: 1.800.742.2326

1.303.678.7500

1. PREPARING FOR USE:

A. INSTALLATION OF THE UNIT MUST COMPLY WITH LOCAL ELECTRICAL CODES

AND OTHER APPLICABLE INSTALLATION CODES.

B. INSTALLATION MUST BE MADE ACCORDING TO THE INSTALLATION

INSTRUCTIONS AND ALL APPLICABLE SAFETY REGULATIONS.

WARNING:

ONLY TRAINED AND QUALIFIED

PERSONNEL MAY INSTALL AND

SERVICE THIS UNIT.

W = 13.95”

H = 13.06”

D = 6.83”

SENS EnerGenius Technical Manual

Service hotline: 1.800.742.2326

1.303.678.7500

5

C. This unit is permanently connected to the AC circuit and to the battery. An external disconnect device with a minimum of

0.12”(3 mm) pole separation must be located in the AC input to the charger.

Do not energize the AC supply circuit until ALL wiring is connected, internal controls are properly set, and the cover is

secured. Always shut the AC supply circuit off before installing or removing any wiring or opening the cover for any

reason.

Always observe proper polarity of the DC output leads.

Always connect the output leads in this order: ungrounded charger output first, then ungrounded battery terminal, then

grounded charger output, and grounded battery terminal last. If the battery must be disconnected for service, remove the

output wiring in the reverse of the order given above.

D. Be sure battery terminals are clean and properly tightened. Be careful to keep corrosion from coming in contact with eyes.

E. Add distilled water to each cell until the electrolyte reaches the level specified by the battery manufacturer. This helps

purge excess gas from the cells. Do not over fill. For a battery without cell caps, carefully follow the manufacturer’s

recharging instructions.

F. Study all battery manufacturer’s specific precautions such as removing or not removing cell caps while charging and

recommended rates of charge.

The recommended charge current range must include the rated output current of this charger, which is 20 amperes.

Set the float voltage jumper to the battery manufacturer’s recommended float charge voltage. Incorrect charge voltage

will accelerate generation of explosive gases, increasing the risk of fire or explosion.

G. Enable the automatic boost charge mode (equalizing charge) only if recommended by the battery manufacturer

H. Determine the voltage of the battery by referring to the engine or battery owner’s manual and make sure that the 12V/24V

select jumper is set to the correct voltage.

Use wire routing devices to hold

alarm and temperature sensor

conductors at least 1/4” (6.3 mm)

away from power conductors

Grounding

Conductor

Use conductors rated 90C or higher.

Input conductors must be suitable for 15A circuits.

Battery conductors must be suitable for 40A circuits. See Section 5.

Alarm and temperature sensor may use low power conductors.

Neutral

115/230VAC Temperature sensor

Alarm contacts

+Battery

-Battery

SENS EnerGenius Technical Manual

6

Service hotline: 1.800.742.2326

1.303.678.7500

TABLE 1

12V 24V

Maximum Resistance 36m71m

D. To determine the appropriate cable and length, please refer to the following table:

TABLE 2

The above lengths consider the resistance of the battery and cables only and do not take into account any

additional interconnects.

The above lengths are for operation at 25C. For high temperature installations (40C) reduce lengths by 10%.

In the case of high resistance in the cables to the battery the charger Battery Fault LED may flash

(approximately once every 60 seconds). Cable runs exceeding the proper length for the cable gauge used most

often cause this problem. The appropriate solution is to change the cable gauge to properly correspond with the

necessary cable length (see TABLE 2). In some cases where the resistance is not too far above maximum, the

charger may recover after some time (approximately 10 minutes) and start charging the batteries. If it is not

possible to decrease the system resistance the Battery Fault feature can be disabled. Please contact SENS at 1-

800-742-2326 for further information.

E. Refer to local electrical codes for additional requirements.

F. See Section 10 for Terminal Block wire ranges.

6. FUSE RATINGS

A. CAUTION: For continued protection against risk of fire, replace only with same type and rating of fuse.

B. DC Output Fuse – SENS part number 304532. Littelfuse 299040, 40A, 32V, Slo-Blo, blade type

C. AC Input Fuse – SENS part number 304468. Bussmann Type BK/ABC-15, or Littelfuse 314015P, 15A,

250VAC, fast acting, ferrule type cylindrical, ¼” X 1-¼”

2. CHARGER LOCATION

Do not set a battery or any other object on top of the charger. This will obstruct the ventilation openings and cause

excessive heating. Ensure the charger is protected from blowing or dripping water.

3. GROUNDING INSTRUCTIONS

This battery charger should be connected to a grounded, metal, permanent wiring system; or an equipment grounding

conductor (earthing conductor) should be run with the circuit conductors and connected to the equipment grounding

terminal in the charger. This terminal is marked with the ground symbol. Connections to the battery charger should

comply with all local codes and ordinances.

4. NEUTRAL CONNECTION

The grounded circuit conductor (neutral) should be connected to the terminal marked “N” on the input terminal block, TB1.

5. WIRE RATINGS

A. All conductors should be rated for use at 90º C or higher.

B. All input and output conductor sizes should be coordinated with the fault protection devices: 15A on AC input (14

AWG, 2.5 mm2typical), 40A on DC output (8 AWG, 6.0 mm2typical), 1 A on Alarm terminal block (20 AWG, 0.5

mm2typical).

C. Before installation, ensure adequate battery to charger wire gauge. Wire gauge that is too small may activate the open

battery detector and the charger will shut down. The maximum allowed resistance seen by the charger is found in

TABLE 1. These figures already include an allowance for charger variations (they are 80% of the typical trip-point)

and are for the complete circuit: total of battery leads, battery's internal resistance, and any external equipment. The

total resistance seen by the charger must not exceed the following values:

Wire Size Resistance

per Foot

Maximum Charger to

Battery Distance (Ft.) Recommended Charger to

Battery Distance (Ft.)

AWG mm2 mΩ/Ft. 12V 24V 12V 24V

8 10 0.63 24 48 7 15

6 16 0.40 38 77 12 24

SENS EnerGenius Technical Manual

Service hotline: 1.800.742.2326

1.303.678.7500

7

A. See the safety instructions for important information concerning the charger location.

B. The charger should be installed in a sheltered area, protected from rain and snow.

C. The charger should not be located where temperatures are expected to be colder than -20º C, or hotter than +40º C

for operation at rated output current.

D. Allow sufficient room for routing the fixed wiring to the charger. AC input enters the left side; DC output and

alarms exit on the right.

E. Leave clear space for ventilation all around the unit: at least 6 inches (15 cm) at the top and bottom; at least

2 inches (5 cm) on the sides.

F. Charger should be mounted on a flat vertical surface so that the chassis does not warp when tightened to the wall

G. The charger should be mounted vertically, with the input and output terminal blocks lowermost.

H. Do not mount the charger over any heat generating equipment.

I. Minimize vibrations that the charger will be subjected to.

WARNING:

OTHER MOUNTING ORIENTATIONS INTERFERE WITH PROPER

VENTILATION AND MAY CAUSE THE CHARGER TO OVERHEAT.

8. STATIC DISCHARGE PRECAUTIONS

The printed circuit board contains static sensitive components. Damage can occur even when static levels are too

low to produce a noticeable discharge shock. To avoid static discharge damage:

A. Handle the charger by the chassis only. Remove the cover only when access is essential for installation and

service, and replace it promptly when finished.

B. If possible, wear an approved static protection strap. If one is not available, touch one hand to the chassis before

contacting any other part of the charger.

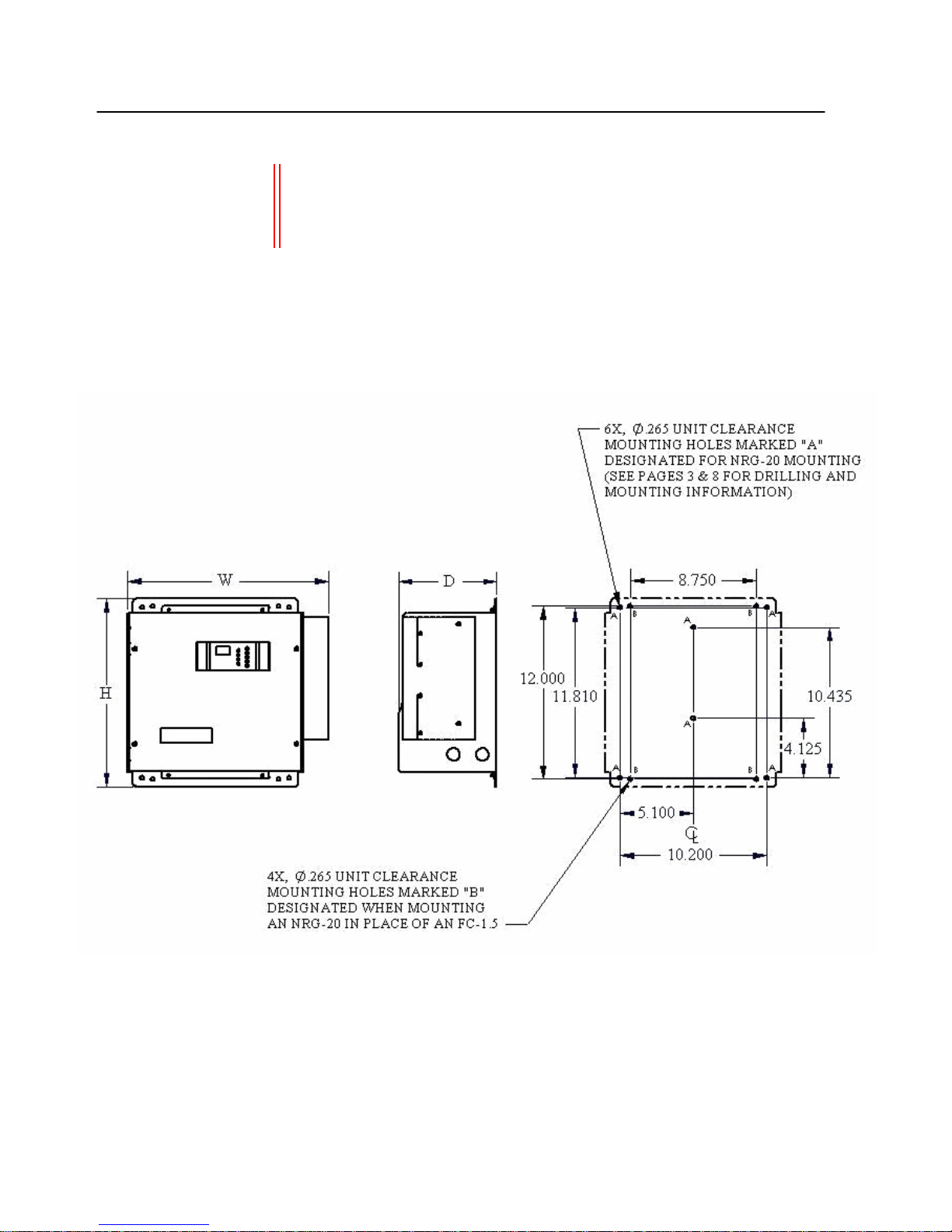

9. MOUNTING PROCEDURES

The charger mounts to a wall or other vertical support. The mounting surface must safely support the charger’s

weight, which is 40 pounds (18 kg), and also the weight of the fixed wiring.

*ATTENTION: FOR MOUNTING IN A HIGH VIBRATION ENVIRONMENT YOU MAY USE 6 FASTENERS

AS SHOWN ON PAGE 4.

Mounting on a concrete surface:

All mounting hardware is provided by the installer.

Use optional ¾ in. thick, 18 in. x 24 in. sheet of marine plywood (not provided) to provide a suitable

mounting surface for the charger.

Drill four holes to secure the plywood to the wall using a minimum of four ¼ in. drive pin type expansion

anchors to secure the plywood to the wall. Secure the plywood to the wall.

Drill four (or six*) holes using the diagram on pg. 4 for ¼ (or M6) draw nut type expansion anchors through

the plywood into the cement wall.

Insert the four (or six*) draw nut type expansion anchors through the plywood into the cement wall.

Mount charger to draw nut type expansion anchors with nuts and flat washers.

WARNING:

THIS CHARGER IS INTENDED FOR COMMERCIAL AND INDUSTRIAL

USE. ONLY TRAINED PERSONNEL WHO ARE QUALIFIED TO

PERFORM ELECTRICAL INSTALLATIONS SHOULD INSTALL OR

SERVICE THIS UNIT.

WARNING:

NEVER CHARGE STORAGE BATTERIES AT TEMPERATURES ABOVE

OR BELOW THE LIMITS SPECIFIED BY THE BATTERY

MANUFACTURER. NEVER ATTEMPT TO CHARGE A FROZEN BATTERY.

7. MOUNTING LOCATION

SENS EnerGenius Technical Manual

8

Service hotline: 1.800.742.2326

1.303.678.7500

Mounting on a drywall:

Use ¾ in. thick plywood to span two vertical support members in the wall. The plywood sheet normally does

not have to be more that 2 ft. by 2 ft. square.

Place plywood to avoid electrical wiring, plumbing, etc., concealed behind wall.

Secure the plywood to the vertical support members using ¼ in. by 2 in. lag bolts and flat washers in a

minimum of four places.

Mark four (or six*) holes on the plywood using the diagram on pg. 4. Drill pilot holes into the plywood to

secure the mounting bolts.

Mount charger using four (or six*) 1/4 in. by ½ in. (or M6) lag bolts and flat washers.

Mounting on a metal surface:

Mount charger using four (or six*) ¼-20 by 3/4 in (or M6) hex head bolts, flat washers and split lock

washers to attach the battery charger to a frame, panel or cross member in four (or six*) places. Use the

diagram on pg. 4 to place the pilot holes, if needed.

Tighten all bolts to recommended torque of 45-50 inch pounds.

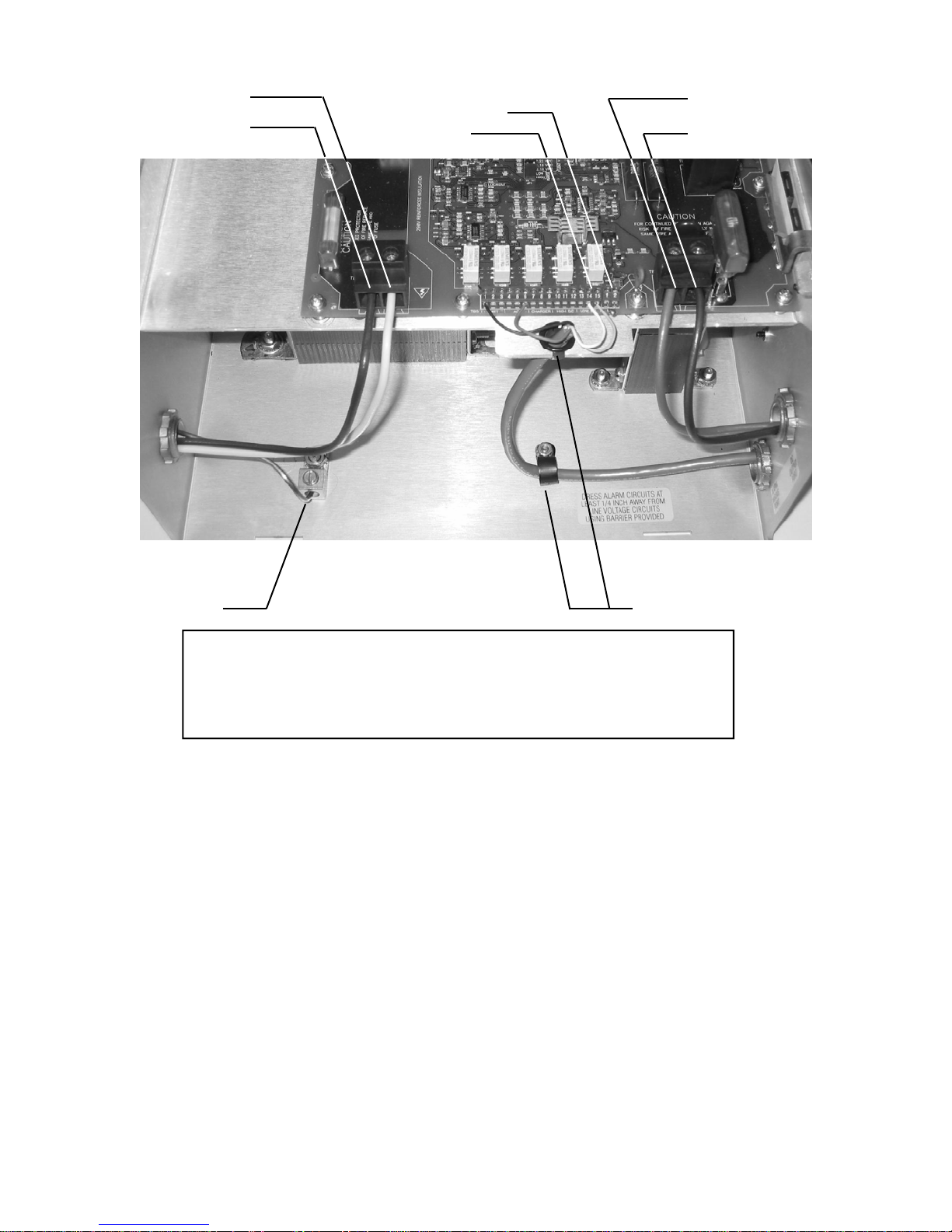

9. WIRING

A. All wiring must comply with applicable codes and local ordinances. See Section 5 for recommended gauges.

B. The charger contains a DC output fuse for internal fault protection, but this will not protect the DC

wiring from fault currents available from the battery. CONSULT NATIONAL CODES AND LOCAL

ORDINANCES TO DETERMINE IF ADDITIONAL BATTERY FAULT PROTECTION IS

NECESSARY IN YOUR INSTALLATION.

C. Connect the equipment grounding conductor (earthing) to the charger’s grounding terminal. This should

always be the first wire connected and the last wire disconnected.

D. Connect the DC output conductors to TB3. Make the connections in the order shown in Figure 2A (negative

ground) or Figure 2B (positive ground). The terminals accept 14 through 6 AWG (2.5 through 16 mm2)

conductors. Tighten connections to 10.5 Lb-In (1.2 Nm).

WARNING:

ENSURE THAT AC POWER IS DISCONNECTED AT THE

CIRCUIT BREAKER OR OTHER SAFETY DISCONNECT

BEFORE WIRING THE CHARGER.

CAUTION:

OBSERVE POLARITY. THE POSITIVE CHARGER OUTPUT

TERMINAL IS LABELED “+” AND THE NEGATIVE

TERMINAL IS LABELED “-”.

WARNING:

BE SURE TO ROUTE DC POWER WIRING AT LEAST ¼ INCH (6.3

MM) AWAY FROM AC WIRING, ALARM WIRING, AND THE

CIRCUIT BOARD.

SENS EnerGenius Technical Manual

Service hotline: 1.800.742.2326

1.303.678.7500

9

FIGURE 2B

E. Connect the AC line and neutral conductors at TB1. If there is an identified grounded circuit conductor

(neutral), attach it to the terminal marked N. TB1 will accept 14-6 AWG (2.5-16 mm2) conductors.

Tighten connections to 10.5 Lb-In (1.2 Nm).

WARNING:

BE SURE TO ROUTE ALL AC WIRING AT LEAST ¼ INCH

(6 MM) AWAY FROM DC WIRING, ALARM WIRING, AND

THE CIRCUIT BOARD.

F. If the optional alarms are used, connect the alarm wiring to their respective terminals on TB5. Route

alarm wiring through the plastic bushing below TB5, keeping the conductors at least ¼ inch (6 mm)

away from DC wiring, AC wiring, and the circuit board. The terminals accept 24-14 AWG (0.25-1.5

mm2) conductors. Tighten connections to 4.4 Lb-In (0.5 Nm).

WARNING:

CONNECT ALARM TERMINALS ONLY TO LOW

VOLTAGE, LIMITED ENERGY (“CLASS 2”) CIRCUITS.

ALARM CIRCUITS ARE RATED 2A AT 30 VDC, 0.5A AT 125

VAC, MAXIMUM SWITCHING CAPACITY 62.5VA, 60W.

RELAY

CONTACTS

BATTERY

FAIL

ALARM

AC

FAIL

ALARM

CHARGER

FAIL

ALARM

HIGH

BATTERY

ALARM

(HI DC)

LOW

BATTERY

ALARM

(LO DC)

COMMON TB5-1

TB5-4

TB5-7

TB5-10

TB5-13

OPEN ON

ALARM TB5-2

TB5-5

TB5-8

TB5-11

TB5-14

CLOSE ON

ALARM TB5-3

TB5-6

TB5-9

TB5-12

TB5-15

FIGURE 2A

SENS EnerGenius Technical Manual

10

Service hotline: 1.800.742.2326

1.303.678.7500

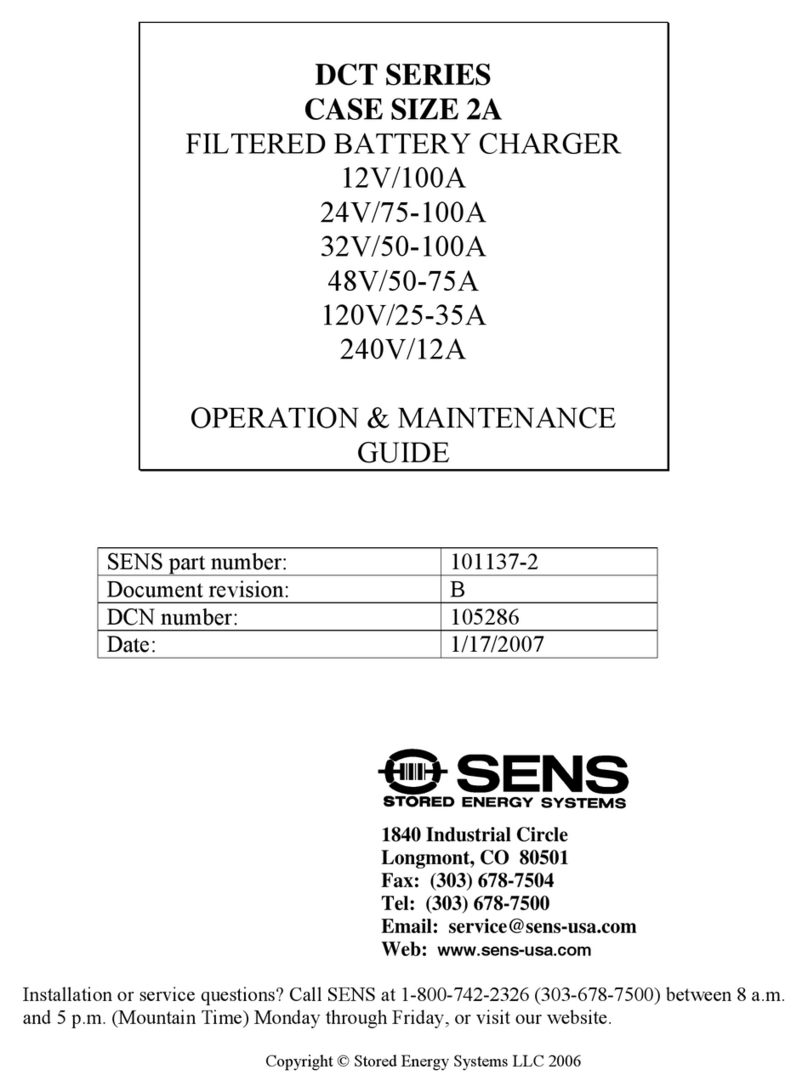

Jumper JP1.

Configure battery and

output voltage settings.

G. If the optional remote temperature sensor is used:

Remove the internal sensor at TB4, if it is present.

Locate the remote sensor where it will accurately detect the battery temperature.

Connect the remote sensor leads to TB4. The sensor is not polarized, so it does not matter which lead

connects to terminal #1.

Route sensor wiring through the plastic bushing below TB5, keeping the conductors at least ¼ inch

(6 mm) away from DC wiring, AC wiring, and the circuit board.

H. Verify that all connections are secure and in the proper locations. Tighten all unused screws on the terminal

blocks to secure them against vibration.

I. Ensure all wires are routed so the cover will not pinch them.

10. INTERNAL ADJUSTMENTS

WARNING:

MAKE SURE THE AC POWER TO THE CHARGER IS SHUT

OFF WHILE MAKING THE FOLLOWING ADJUSTMENTS.

AC line voltage switch

110-120V: Use 115V position

208-240V: Use 230V position

Battery range jumper

(12V or 24V battery)

Automatic boost jumper

Use NORM setting for

fast charge. Use Off

setting for float charge

Float voltage jumper

Set according to

battery supplier’s

specifications

“Jump start” battery

initialization mode

SAME FOR ALL

MODELS

A. Set the AC voltage select switch (SW100) according to the line voltage. Use the 115V position for nominal

mains voltages between 110V and 120V. Use the 230V position for nominal mains voltages between 208V

and 240V.

B. Set the battery range jumper (JP1A) according to nominal battery voltage. Use the 12V position for 12V

batteries. Use the 24V position for 24V batteries.

C. Set the boost mode jumper (JP1B) according to whether the battery should have automatic boost charging. If

the battery manufacturer recommends boost charging (equalization) use the NORMAL position. If not, use the

OFF position.

Meter Display Jumper

JP800. Choose VOLTS,

AMPS, or AUTO for meter

display view.

SENS EnerGenius Technical Manual

Service hotline: 1.800.742.2326

1.303.678.7500

11

D. Set the float voltage select jumper (JP1C) according to the battery manufacturer’s recommended 25ºC

float voltage. The settings are:

14.30/28.60 for 10 or 20 cell Nickel Cadmium at 1.43V/cell

13.62/27.24 for 6 or 12 cell (VRLA) lead-acid at 2.27V/cell, and for 19 cell Nickel Cadmium at 1.43V/cell

13.50/27.00 for 6 or 12 cell (VRLA or high capacity) lead-acid at 2.25V/cell, and for 19 cell Nickel Cadmium at

1.42V/cell

13.31/26.62 for 6 or 12 cell (flooded) lead-acid at 2.22V/cell, and for 19 cell Nickel Cadmium at 1.40V/cell

13.08/26.16 for 6 or 12 cell lead-acid at 2.18V/cell

12.87/25.74 for 9 or 18 cell Nickel Cadmium at 1.43V/cell

E. Set the Display Selector jumper to one of the 3 available positions on JP800 (see photograph previous page):

VOLTS – Place the short jumper in the “upper” position next to the word “VOLTS”. The 3-digit LED meter display

will show DC Volts only

AUTO – Place the short jumper in the center position next to the word “AUTO”. The 3-digit LED meter display

will automatically and continuously alternate between DC Amps and DC Volts. The display shows DC Amps for

approximately 6 seconds and DC Volts for approximately 3 seconds.

AMPS – Place the short jumper in the “lower” position next to the word “AMPS”. The 3-digit LED meter display

will show DC Amps only.

F. The JUMP position allows initial charging of Nickel Cadmium batteries, or new lead acid batteries supplied from the

manufacturer dry and discharged, from a zero charge state. The JUMP feature can also be used when recharging

excessively discharged batteries already in service. To initially charge/commission zero charge batteries, place a

jumper (spare provided with charger) in the JUMP position on JP1. Operate the charger long enough to retain more

than 1.5V/cell for lead acid and 1.0V/cell for nickel cadmium batteries or until the charger returns to FLOAT MODE

(FLOAT MODE LED will be green). See SENS Application Note 10 to finish fully commissioning the batteries, as

using the JUMP feature alone is not sufficient. Once the batteries are fully charged, the jumper may be removed or

left in the JUMP position permanently. The jumper may remain in the JUMP position permanently to ensure that the

charger is able to recharge very low or dead batteries. If battery voltage is below 9V (12V system) or 18V (24V

system) when AC power is restored and the JUMP feature is not activated, the charger will go into Battery Fault

(alarm state that disables charger). In this situation the charger will not charge the batteries. If the JUMP feature is

enabled when AC power is restored, the charger will begin charging. Depending on the battery state of charge, the

charger may go into Battery Fault and remain so for some period of time (generally 12 – 24 hours) while the batteries

are slowly charged. The Battery Fault LED will cycle (approximately once every minute) during this time. Once

Battery Fault stops cycling, the charger will return to FLOAT or BOOST MODE as normally demanded.

WARNING:

USE ONE JUMPER ONLY ON THE DISPLAY SELECTOR JP800. USE ONLY THE

“SHORT” JUMPER PROVIDED FOR JP800, TO AVOID INTERFERENCE WHEN

REPLACING THE COVER (“TALL” JUMPERS ARE TO BE USED ONLY ON JP1).

WARNING:

USE THE JUMP FEATURE ONLY WITH LIQUID ELECTROLYTE NICKEL-

CADMIUM BATTERIES, OR WITH RECENTLY FILLED NEW LEAD ACID

BATTERIES SUPPLIED FROM THE MANUFACTURER DRY AND DISCHARGED.

WHILE THE JUMP FEATURE MAY BE USED TO CHARGE EXCESSIVELY

DISCHARGED LEAD ACID BATTERIES THAT HAVE ALREADY BEEN IN

SERVICE, CONSULT THE BATTERY MANUFACTURER TO DETERMINE IF

AND HOW THEY CAN SAFELY BE RESTORED TO SERVICE.

WARNING:

LEAVING A JUMPER IN THE JUMP POSITION DISABLES THE BATTERY

VOLTAGE INTERLOCK, WHICH INCREASES THE RISK OF ACCIDENTALLY

OVERCHARGING 12V BATTERIES WITH 24V SETTINGS. INCORRECT

CHARGE VOLTAGE WILL ACCELERATE GENERATION OF EXPLOSIVE

GASES, INCREASING THE RISK OF FIRE OR EXPLOSION.

G. For fully enclosed models, replace the cover by sliding it straight onto the charger. Ensure the cover’s locating

tabs engage the slots in the chassis. Secure the cover with its four mounting screws.

SENS EnerGenius Technical Manual

12

Service hotline: 1.800.742.2326

1.303.678.7500

11. CHECK OUT

See OPERATOR INSTRUCTION section for LED indicator definitions:

A. Verify the status LEDs:

AC FAIL should be ON. If not, the DC output may be open or reversed, or the battery may be

extremely discharged.

BATT FAULT should be OFF. If it lights, check for reversed polarity of the DC wiring.

The DC LOW (Low Battery) LED may be either on or off, depending on the battery’s state of charge.

All other LEDs and the meter display should be off.

If the DC HIGH LED is on, check battery voltage jumper setting.

B. Apply AC power by closing the branch circuit breaker and any other disconnect devices.

C. The meter display should light immediately after power on. The green AC /ON LED should be lighted. If a

temperature sensor is present, either internal or remote, the green T-COMP (Temperature Compensation)

LED should be lighted.

D. If the BATT FAULT LED lights when AC is applied, this indicates that the battery voltage does not agree

with the Range jumper setting. The charger is interlocked, and will not operate in this condition.

Disconnect AC power, then correct the jumper setting or battery voltage before proceeding.

E. After a short delay (typically 10 seconds or less), the charger will produce output.

F. If the meter display jumper is selected to read Amps or automatic Volts/Amps:

Current should be close to 20A if the battery requires recharging. If automatic boost is enabled, the

BOOST MODE LED may light, in which case the battery will be charged until it reaches 106% of the

float voltage. If boost is disabled, the green FLOAT MODE LED should be on and the battery will

charge until it reaches the float voltage setting.

Output current will be low if the battery is fully charged, possibly too low to read on the meter. This is

normal, provided the correct charging voltage is present. The green FLOAT MODE LED should light

when output current is below approximately 18A.

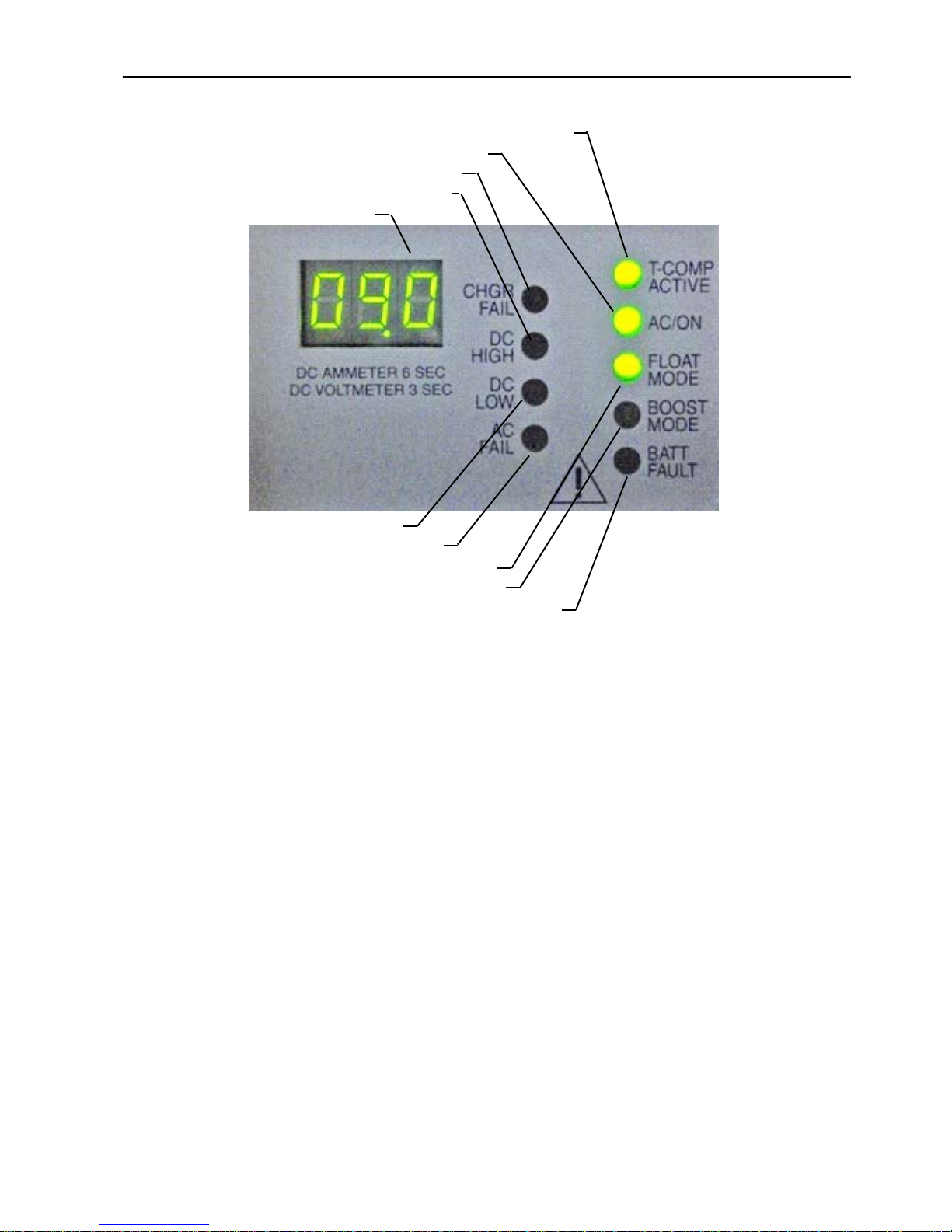

Red for low battery voltage

Red for low or missing AC input

Green for normal voltage (float charge)

Yellow for boost voltage (fast charge)

Green for normal AC input

Red for excessive battery voltage

Red for internal charger failure

DC Volt/Amp Meter Display

Green for temperature-corrected charger voltage

*Red for open, wrong voltage, reversed battery, or defective battery

SENS EnerGenius Technical Manual

Service hotline: 1.800.742.2326

1.303.678.7500

13

OPERATOR INSTRUCTIONS

WARNING:

NO OPERATOR SERVICEABLE PARTS INSIDE.

DO NOT OPEN. COVER MUST BE IN PLACE DURING USE.

USE THIS CHARGER FOR CHARGING LEAD-ACID OR

NICKEL-CADMIUM BATTERIES ONLY.

A. ADVANCED DESIGN FEATURES

Battery Friendly:

Float and boost voltage selectable at install per specific battery vendor recommendations.

Remote temperature compensation for most accurate float and boost voltage control.

Able to charge a dead battery.

Float and Boost voltage electronically controlled with a 4-rate fast charge program. See chart below.

Temperature Compensation:

The battery charger is temperature compensated to match the negative temperature coefficient of the battery.

Thus, the output voltage will increase slightly as the temperature decreases and decrease as temperature in-

creases.

The output voltage is clamped at 0 and +40 Degrees C to protect against extremely high or low output voltage.

See chart below.

Fault Tolerant: The charger is protected from the following faults:

Internal power component failures.

Over heating (over temperature output power reduction).

Protected against power line transients and surges.

Battery Fault Protection and Alarm:

The battery charger automatically checks the battery voltage before power-on startup. If the battery voltage is

13

Temperature vs. volts per cell lead acid

2

2.1

2.2

2.3

2.4

2.5

2.6

2.7

-30 020 40 60 80

Temperature Degrees C

Float volts per cell

SB

A

G

M

Gel

NR

G

SENS limits here to prevent damaging

high voltages at customer equipment

AUTOMATIC TEMPERATURE COMPENSATION

Maintainingcharge

Battery voltage

Charger in “float mode”

Finishingcharge

Transition: charger shifts to

float mode when battery

current acceptance drops

Float voltage limit

Highratetapercharge

Constantcurrentcharge

Battery current acceptanceBattery current acceptance

Charger in “fast charge (boost) mode”

Currentlimit

Boost voltage limit

Vb

Once boost voltage is

achieved current tapers off

4-RATE CHARGING

SENS EnerGenius Technical Manual

14

Service hotline: 1.800.742.2326

1.303.678.7500

B. FRONT PANEL LED INDICATOR DEFINITIONS AND TROUBLE SHOOTING:

either too high or too low, the charger enters a “lockout” period for approximately 10 seconds before attempting

an automatic restart.

The “JUMP” feature (described in Section 11-F in this manual) may be used to allow the battery charger to over-

ride the lockout and start charging a low-voltage discharged battery.

The battery charger will not start if the battery or battery cables have a short circuit, and will start automatically

with a good battery if the short circuit is removed.

In addition to detecting low battery voltage and short circuits, the battery charger also monitors the peak voltage

at its DC output terminals and will enter lockout if the DC cable resistance is too high or if the battery’s internal

resistance is too high.

If a battery is connected backwards, this reverse polarity condition will keep the battery charger in lockout and it

will remain in lockout until the battery is disconnected. A reverse polarity condition will not blow a fuse; the

battery charger will start and run normally when a good battery is connected with correct polarity.

Whenever one of these fault conditions triggers the battery fault protection circuitry as described above, the

“Batt Fault” relay and LED are both activated.

If polarity is correct, DC cables OK, and the “JUMP” feature attempted, the battery fault alarm most likely indi-

cates a defective battery. Replace with a new battery.

Robust Hardened Construction:

Shock and Vibration tested to UL 991, 2G.

Shock and Vibration tested to UL 991, 5G option available.

Lightning transient immunity to ANSI/IEEE C62.41 Cat. B and EN 50082-2 heavy industrial.

Wide operating temperature range: -20 to + 40 Degrees C. Charger will operate at reduced output current rating

up to +60 Degrees C.

Conformal coated printed wiring boards for erosion protection.

Worldwide Agency Approvals:

UL listed, UL 1236.

CUL listed to CSA C22.2 107.2- M89.

CE marked for EMC directive (industrial environment) and EN 60335-2-29.

Worldwide operating voltage and frequency ranges.

Red for low battery voltage

Red for low or missing AC input

Green for normal voltage (float charge)

Yellow for boost voltage (fast charge)

Green for normal AC input

Red for excessive battery voltage

Red for internal charger failure

DC Volt/Amp Meter Display

Green for temperature-corrected charger voltage

*Red for open, wrong voltage, reversed battery,

or defective battery

SENS EnerGenius Technical Manual

Service hotline: 1.800.742.2326

1.303.678.7500

15

ITEM TEXT LED Meaning Troubleshooting

1 CHGR FAIL RED Charger Fail Charger unable to provide charging current

to battery. Replace unit.

AC input voltage is too low to supply prop-

er current when load is applied.

Control board is damaged and should be

replaced.

2 DC HIGH RED Battery DC Voltage High Check that the battery range voltage jumper

setting agrees with battery used.

High battery alarm voltage is 17v for 12v

system and 34v for 24v system.

3 DC LOW RED Battery DC Voltage Low Check that battery range voltage jumper

setting agrees with battery used. Check for

defective battery.

Check DC load.

Low battery alarm voltage is 12v for 12v

System and 24v for 24v system

4 AC FAIL RED Input AC Missing Check AC input voltage to charger. Have

qualified installer check AC line voltage

switch setting. Setting must agree with AC

voltage at site. Check AC fuse.

5 T-COMP GREEN On if Temperature Com-

pensation Working, Off if

Temperature Compensa-

Confirm if temperature compensation is

intended to be used. Only one sensor (Local

or remote) should be connected.

6 AC/ ON GREEN AC input good Should be on in normal use.

If LED is OFF, AC FAIL should be ON.

7 FLOAT

MODE GREEN Charger Output in Float

Mode If the automatic boost jumper is in the OFF

location, this LED will always be on.

If the automatic boost jumper is in the

“NORM” location, this LED will come on

after the battery is nearly charged up and

will stay on.

8 BOOST

MODE AMBER Charger Output in Boost

Mode This LED will not be on if the automatic

boost jumper is in the OFF location, or if

the automatic boost jumper is in the

“NORM” location and the battery is nearly

fully charged up.

9 BATT FAULT RED Battery Fault-Charger

automatically disabled:

Battery reversed.

High resistance in charger leads (leads

too small, too long , poorly connected,

open). See Section 5 for information on

wire length and gauge.

Battery internal open circuit.

Battery voltage does not match charger

voltage range

Defective battery, replace with new

battery

SENS EnerGenius Technical Manual

16

Service hotline: 1.800.742.2326

1.303.678.7500

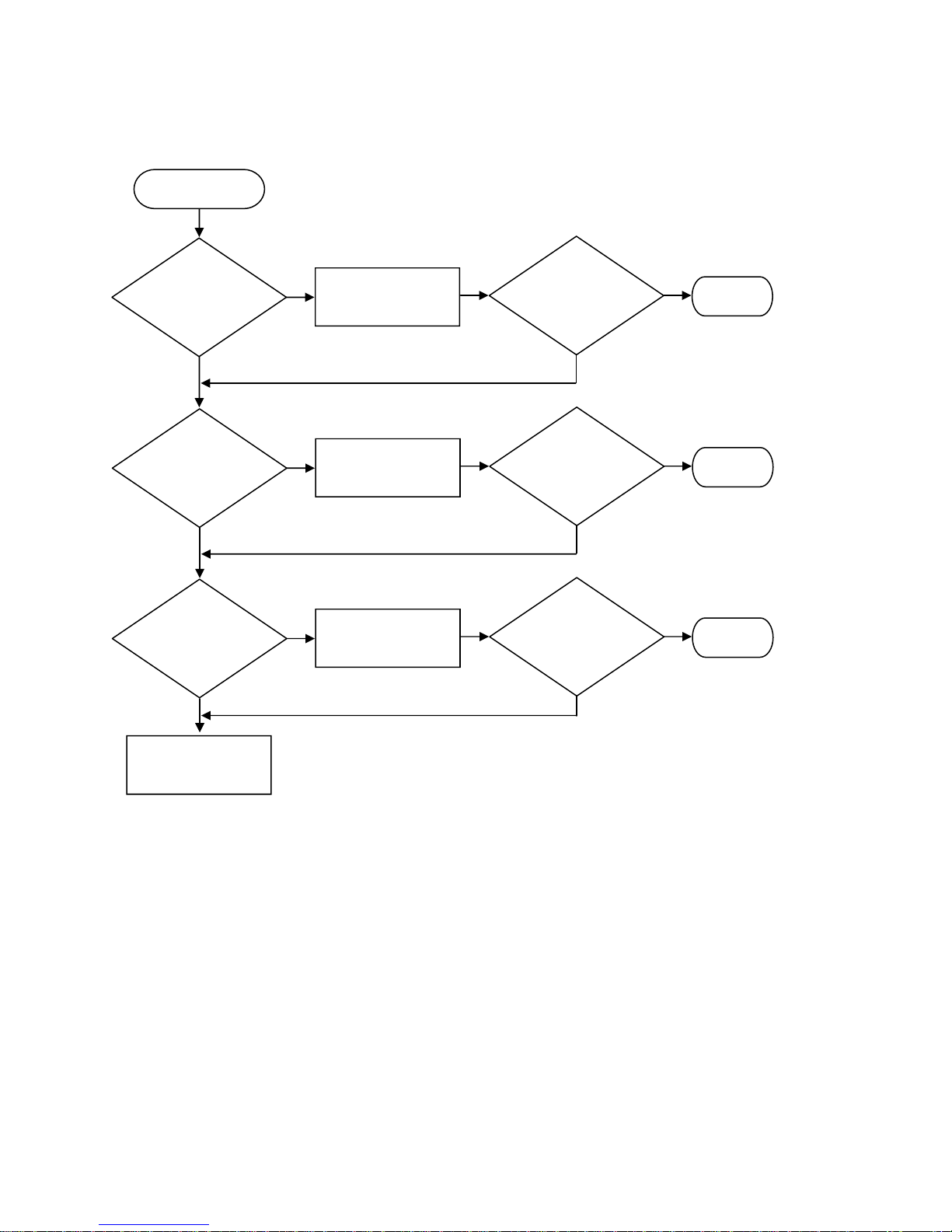

TROUBLESHOOTING GUIDE—REPEATED BLOWN AC FUSE

CONTACT CUSTOMER

SERVICE

START:

AC FAIL LED red

INPUT

SWITCH

CONFIGURED FOR

115V BUT SOURCE

IS 230V?

Y

N

END

PROPERLY CONFIGURE

SELECTION SWITCH

FUSE

STILL

BLOWS?

Y

N

AC VOLTS

CORRECT

(MEASURE WITH

MULTIMETER)?

N

Y

END

CORRECT AC INPUT

SUPPLY PROBLEM

FUSE

STILL

BLOWS?

Y

N

AC FREQUENCY

LOW? Y

N

END

CORRECT AC INPUT

SUPPLY PROBLEM

FUSE

STILL

BLOWS?

Y

N

SENS EnerGenius Technical Manual

Service hotline: 1.800.742.2326

1.303.678.7500

17

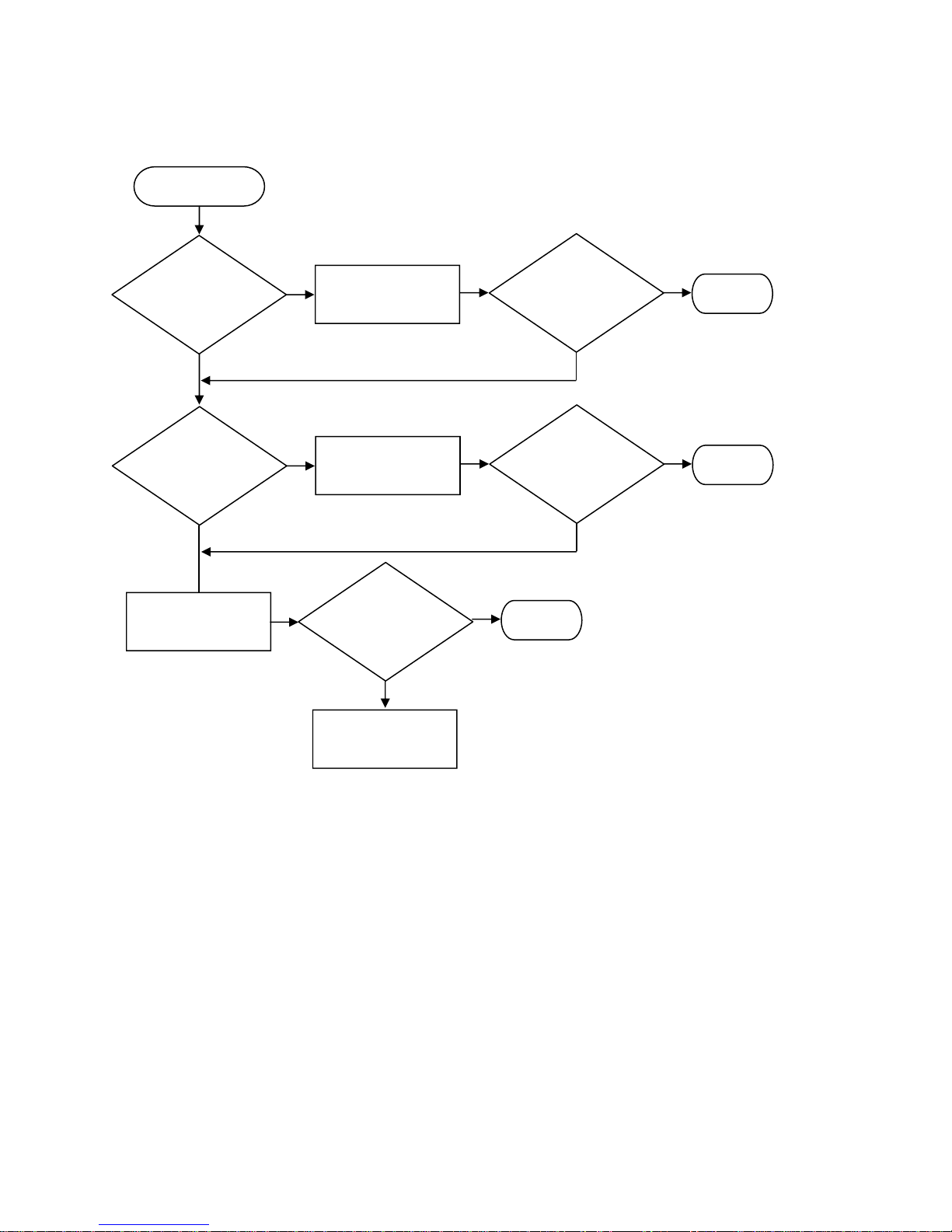

TROUBLESHOOTING GUIDE—AC FAIL ALARM

START:

AC FAIL LED red

INPUT

SELECTION

SWITCH PROPERLY

CONFIGURED?

N

Y

END

PROPERLY

CONFIGURE

SELECTION SWITCH

ALARM

STILL

PRESENT?

Y

N

AC VOLTS AND

FREQ CORRECT

(MEASURE WITH

MULTIMETER)?

N

Y

END

CORRECT AC INPUT

SUPPLY PROBLEM

ALARM

STILL

PRESENT?

Y

N

AC INPUT FUSE

BLOWN? Y

N

END

REPLACE AC

INPUT FUSE

ALARM

STILL

PRESENT?

Y

N

CONTACT CUSTOMER

SERVICE

ALL CONNECTORS

FIRMLY SEATED? N

Y

END

FIX

CONNECTIONS

ALARM

STILL

PRESENT?

Y

N

END

REPLACE CIRCUIT

BOARD TRAY

ALARM

STILL

PRESENT?

Y

N

SENS EnerGenius Technical Manual

18

Service hotline: 1.800.742.2326

1.303.678.7500

TROUBLESHOOTING GUIDE—CHARGER FAIL ALARM

START:

CHGR FAIL LED red

AC VOLTS LOW

(MEASURE WITH

MULTIMETER)? Y

N

END

CORRECT AC INPUT

SUPPLY PROBLEM

ALARM

STILL

PRESENT?

Y

N

ALL

CONNECTORS

FIRMLY SEATED?

N

Y

END

FIX

CONNECTIONS

ALARM

STILL

PRESENT?

Y

N

CONTACT CUSTOMER

SERVICE

END

REPLACE CIRCUIT

BOARD TRAY

ALARM

STILL

PRESENT?

Y

N

SENS EnerGenius Technical Manual

Service hotline: 1.800.742.2326

1.303.678.7500

19

TROUBLESHOOTING GUIDE—DC HIGH ALARM

CONTACT CUSTOMER

SERVICE

BATTERY RANGE

VOLTAGE JUMPER

PROPERLY SET?

N

Y

END

ADJUST JUMPER

FOR 12V OR 24V

BATTERY

ALARM

STILL

PRESENT?

Y

N

DC VOLTS HIGH

(MEASURE WITH

MULTIMETER)?

Y

N

END

CORRECT BATTERY/

LOAD VOLTAGE

(CONSIDER SURFACE

CHARGE, ALTERNATOR,

EQUIPMENT)

ALARM

STILL

PRESENT?

Y

N

END

REPLACE CIRCUIT

BOARD TRAY

ALARM

STILL

PRESENT?

Y

N

START:

DC HIGH LED red

SENS EnerGenius Technical Manual

20

Service hotline: 1.800.742.2326

1.303.678.7500

TROUBLESHOOTING GUIDE—DC LOW ALARM

ADJUST JUMPER

FOR 12V OR 24V

BATTERY

START:

DC LOW LED red

N

Y

END

ALARM

STILL

PRESENT?

Y

N

N

Y

END

CORRECT AC INPUT

SUPPLY PROBLEM

ALARM

STILL

PRESENT?

Y

N

CHARGER IN

CURRENT LIMIT

(MAX CURRENT,

LOW VOLTAGE)?

Y

N

END

DETERMINE CAUSE OF

CURRENT LIMIT AND

CORRECT PROBLEM

ALARM

STILL

PRESENT?

Y

N

BATTERY RANGE

VOLTAGE JUMPER

PROPERLY SET?

AC VOLTS AND

FREQ CORRECT

(MEASURE WITH

MULTIMETER)?

CONTACT CUSTOMER

SERVICE

END

REPLACE CIRCUIT

BOARD TRAY

ALARM

STILL

PRESENT?

Y

N

This manual suits for next models

2

Table of contents

Other Sens Batteries Charger manuals

Sens

Sens F3 SERIES Manual

Sens

Sens MicroGenius 2 User manual

Sens

Sens EnerGenius DC COMPACT User manual

Sens

Sens EnerGenius DC Wallbox User manual

Sens

Sens Q012-012 User manual

Sens

Sens DCT Series Operating manual

Sens

Sens TD Series Operating manual

Sens

Sens MicroGenius 2 User manual

Sens

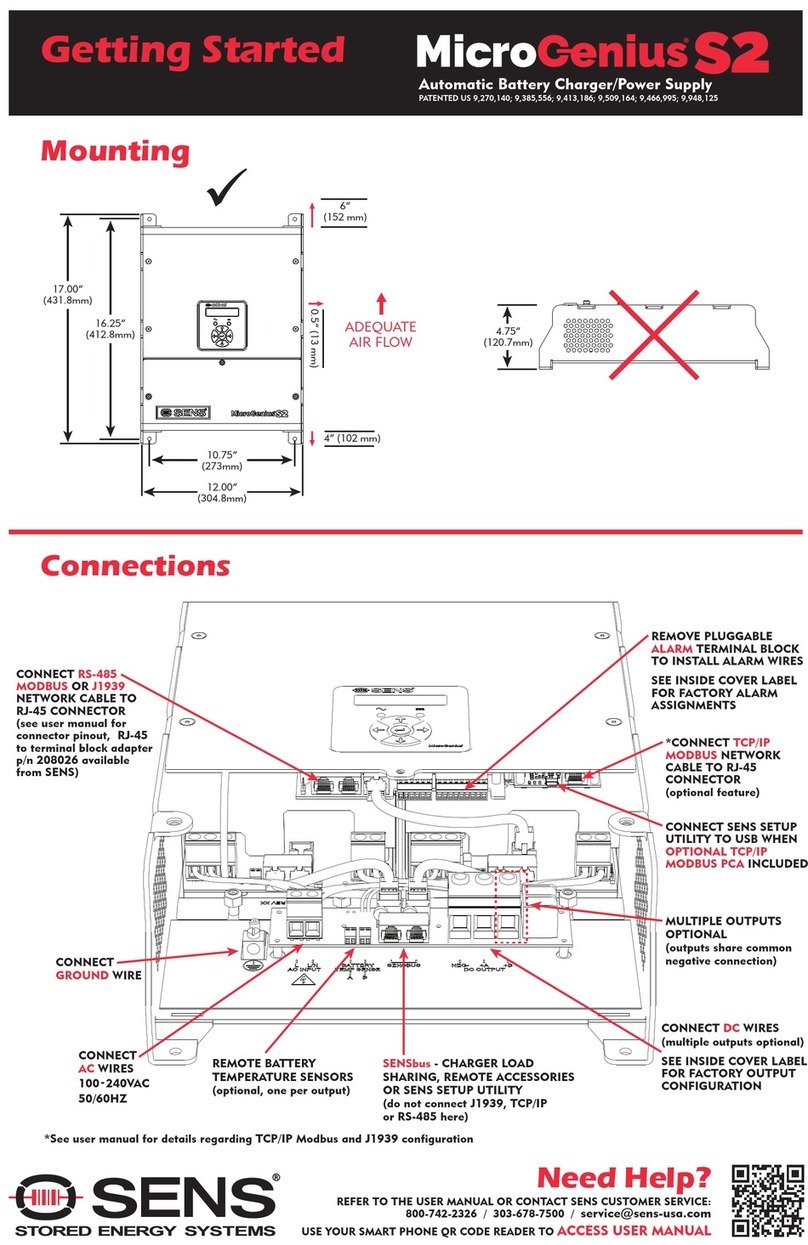

Sens MicroGenius S2 User manual

Sens

Sens MicroGenius User manual

Sens

Sens EnerGenius IQ2 User manual

Sens

Sens NRG12-10 User manual

Sens

Sens EnerGenius NRG24-20 User manual

Sens

Sens F3 SERIES Manual

Sens

Sens MicroGenius S2 User manual

Sens

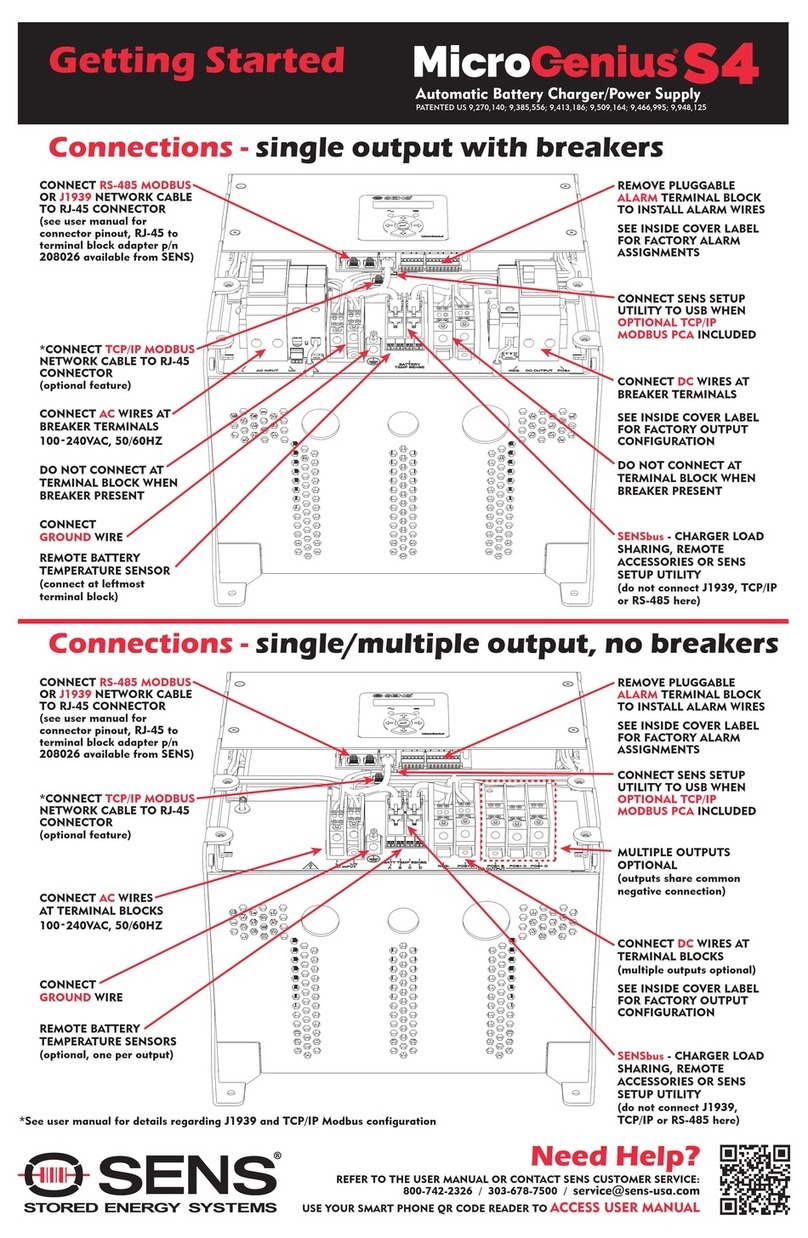

Sens MicroGenius S4 User manual

Sens

Sens EnerGenius NRG22-20 User manual

Sens

Sens FC Operating manual

Sens

Sens EnerGenius NRG24-10 User manual