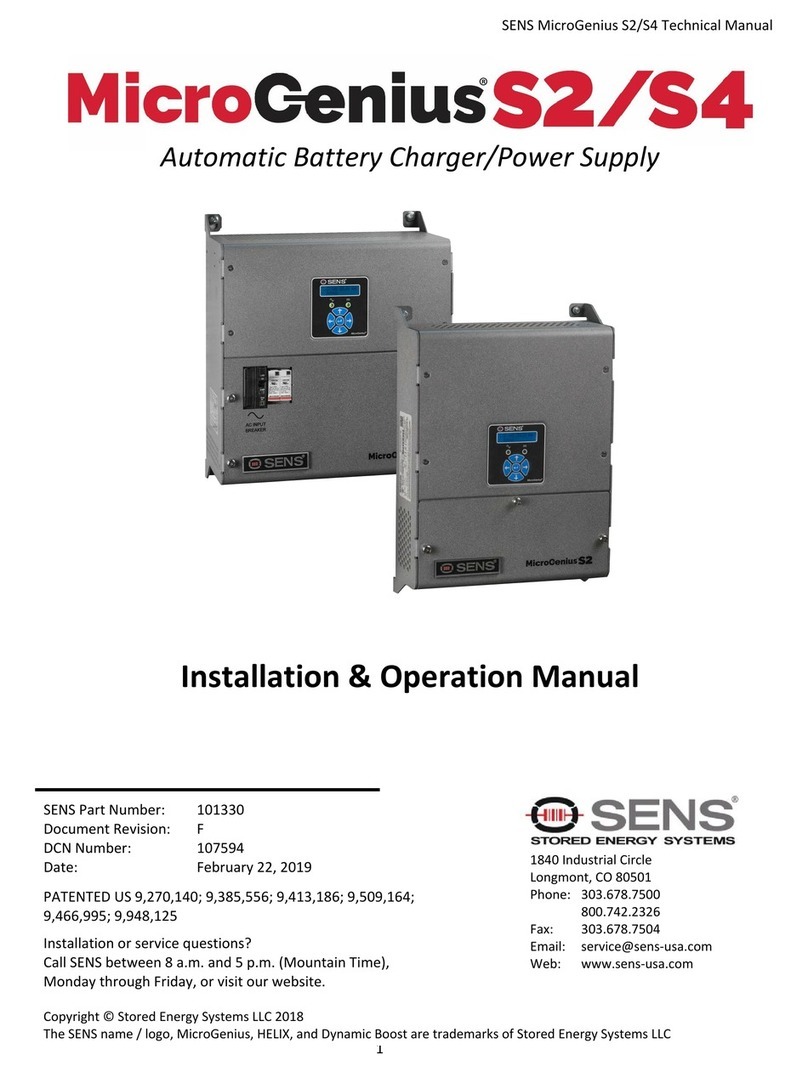

Sens MicroGenius 2 User manual

SENS MicroGenius 2 Technical Manual

1

Installation & Operation Manual

180W: 12V, 10A; 24V, 6A

300W: 12V, 12A; 24V, 10A

450W: 12/24V, 15A

Genset, Marine & Stationary Battery

Charger

PATENTED US 9,270,140; 9,385,556; 9,413,186; 9,509,164;

PATENTS PENDING

Installation or service questions?

Call SENS between 8 a.m. and 5 p.m. (Mountain Time),

Monday through Friday, or visit our website.

Copyright © Stored Energy Systems LLC 2017

The SENS name / logo, MicroGenius, HELIX, and Dynamic Boost are trademarks of Stored Energy Systems LLC

SENS Part Number: 101324

Document Revision: J

DCN Number: 107448

Date: March 22, 2018

1840 Industrial Circle

Longmont, CO 80501

Phone:

303.678.7500

800.742.2326

Fax:

303.678.7504

Email:

service@sens-usa.com

Web:

www.sens-usa.com

SENS MicroGenius 2 Technical Manual

2

TABLE OF CONTENTS

1IMPORTANT SAFETY INSTRUCTIONS FOR INSTALLER AND OPERATOR................................................................................ 3

2MODEL NUMBER BREAKOUT................................................................................................................................................. 4

3PERFORMANCE SPECIFICATIONS ........................................................................................................................................... 5

4SYSTEM OVERVIEW.............................................................................................................................................................. 10

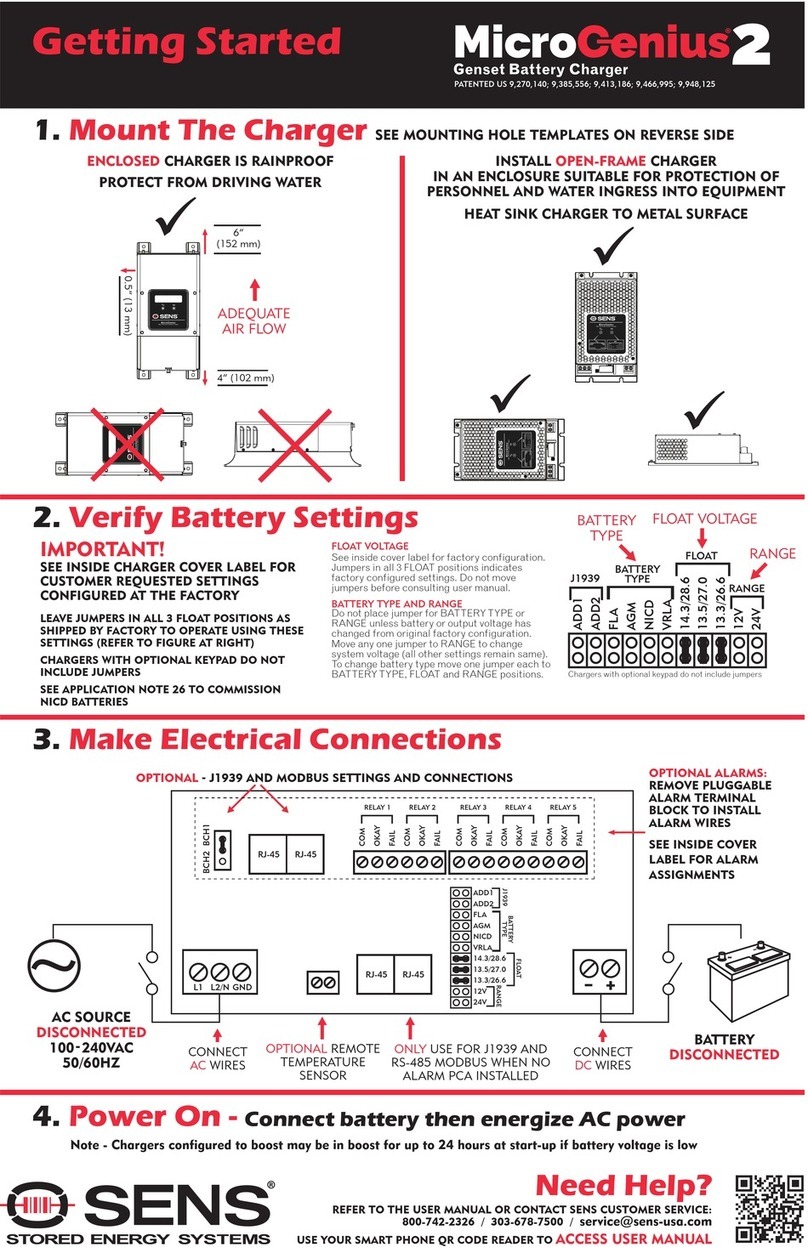

5MOUNTING INSTRUCTIONS ................................................................................................................................................. 11

5.1. Mounting Location............................................................................................................................................................... 11

5.2. Mounting Instructions ......................................................................................................................................................... 12

6CHARGER SETUP................................................................................................................................................................... 13

6.1. Factory Jumper Configuration.............................................................................................................................................. 13

6.2. Standard Jumper Configuration........................................................................................................................................... 14

6.3. Keypad Configuration—Optional ......................................................................................................................................... 16

6.4. Ultracapacitor Mode Setup.................................................................................................................................................. 16

6.5. Program Mode ..................................................................................................................................................................... 17

6.6. Load Share Charger Setup.................................................................................................................................................... 17

6.7. SAE J1939 Communications Setup (CANbus) ....................................................................................................................... 17

6.8. Modbus Communications Setup.......................................................................................................................................... 18

7WIRING................................................................................................................................................................................. 19

7.1. Wire Ratings and Sizes ......................................................................................................................................................... 20

7.2. Grounding Instructions and Connection .............................................................................................................................. 21

7.3. DC Connection ..................................................................................................................................................................... 21

7.4. AC Connection ..................................................................................................................................................................... 21

7.5. Alarm Connections—Optional ............................................................................................................................................. 21

7.6. Remote Temperature Sensor Connection—Optional .......................................................................................................... 23

7.7. J1939/Modbus Communications Connection...................................................................................................................... 23

7.8. Load Share Connection—Optional....................................................................................................................................... 24

7.9. Remote Alarm/Communications Panel Accessory Connection—Optional .......................................................................... 24

7.10. Verify Connections............................................................................................................................................................... 25

8POWER ON/POWER OFF PROCEDURE................................................................................................................................. 25

8.1. Connect Battery ................................................................................................................................................................... 25

8.2. Apply AC Input Voltage ........................................................................................................................................................ 25

8.3. Power Off............................................................................................................................................................................. 25

9ALARMS, LEDS AND DISPLAY ............................................................................................................................................... 25

9.1. LED Indicators ...................................................................................................................................................................... 25

9.2. Individual Alarm Relay Contacts—Optional ......................................................................................................................... 26

9.3. LCD Panel—Optional............................................................................................................................................................ 26

9.4. Alarm Definitions ................................................................................................................................................................. 26

10 OPERATION .......................................................................................................................................................................... 34

10.1. Charging Algorithms............................................................................................................................................................. 34

10.2. Float Mode........................................................................................................................................................................... 34

10.3. Dynamic Boost™ Mode........................................................................................................................................................ 35

10.4. HELIX Mode.......................................................................................................................................................................... 36

10.5. Ultracapacitor Mode............................................................................................................................................................ 37

10.6. Charging Low or Zero-volt Batteries .................................................................................................................................... 37

10.7. Commissioning Batteries ..................................................................................................................................................... 37

10.8. Battery Check....................................................................................................................................................................... 37

10.9. Keypad Operation ................................................................................................................................................................ 38

10.10. Program Mode..................................................................................................................................................................... 42

10.11. Temperature Compensation................................................................................................................................................ 42

10.12. Load Share Charger Operation............................................................................................................................................. 43

10.13. Remote Alarm/Communications Panel Accessory............................................................................................................... 44

11 J1939 COMMUNICATIONS ................................................................................................................................................... 44

11.1. J1939 Data Messages........................................................................................................................................................... 44

12 MODBUS COMMUNICATIONS............................................................................................................................................. 45

12.1. Modbus Holding Registers ................................................................................................................................................... 45

12.2. Status Definition .................................................................................................................................................................. 47

12.3. Alarm Bit Definition ............................................................................................................................................................. 48

12.4. Extended Status Bit Definition ............................................................................................................................................. 49

12.5. Writable Control Flags (Coils)............................................................................................................................................... 49

13 TROUBLESHOOTING/ERROR CODES .................................................................................................................................... 50

13.1. Configuration Error Codes ................................................................................................................................................... 50

13.2. Troubleshooting................................................................................................................................................................... 52

14 GLOSSARY............................................................................................................................................................................. 58

SENS MicroGenius 2 Technical Manual

3

1IMPORTANT SAFETY INSTRUCTIONS FOR INSTALLER AND OPERATOR

1.1. SAVE THESE INSTRUCTIONS – This manual contains important safety and operating instructions for

MicroGenius® 2 battery chargers.

1.2. Do not expose open-frame charger to rain or snow.

1.3. Use of an attachment not recommended or sold by the battery charger manufacturer may result in a risk of

fire, electric shock, or injury to persons.

1.4. This charger is intended for commercial and industrial use. ONLY TRAINED AND QUALIFIED PERSONNEL

MAY INSTALL AND SERVICE THIS UNIT.

1.5. Do not operate charger if it has received a sharp blow, been dropped, or otherwise damaged in any way;

shut off power at the branch circuit protectors and have the unit serviced or replaced by qualified

personnel.

1.6. To reduce risk of electric shock, disconnect the branch circuit feeding the charger before attempting any

maintenance or cleaning. Turning off controls will not reduce this risk.

1.7. WARNING – RISK OF EXPLOSIVE GASES

1.7.1. WORKING IN THE VICINITY OF A LEAD-ACID OR NICKEL-CADMIUM BATTERY IS DANGEROUS.

STORAGE BATTERIES GENERATE EXPLOSIVE GASES DURING NORMAL BATTERY OPERATION. FOR

THIS REASON, IT IS OF UTMOST IMPORTANCE THAT YOU READ THIS MANUAL AND FOLLOW THE

INSTRUCTIONS EACH TIME YOU USE THE CHARGER.

1.7.2. To reduce the risk of battery explosion, follow these instructions and those published by the battery

manufacturer and the manufacturer of any equipment you intend to use in the vicinity of a battery.

Review cautionary markings on these products and on the engine.

1.8. PERSONAL PRECAUTIONS

1.8.1. Someone should be within range of your voice or close enough to come to your aid when you work

near a storage battery.

1.8.2. Have plenty of fresh water and soap nearby in case battery electrolyte contacts skin, clothing, or

eyes.

1.8.3. Wear complete eye protection and clothing protection. Avoid touching eyes while working near a

storage battery.

1.8.4. If battery electrolyte contacts skin or clothing, wash immediately with soap and water. If electrolyte

enters eye, immediately flood the eye with running cold water for at least 10 minutes and get

medical attention immediately.

1.8.5. NEVER smoke or allow a spark or flame in vicinity of battery or engine.

1.8.6. Be extra cautious to reduce risk of dropping a metal tool onto the battery. It might spark or short

circuit the battery or another electrical part that may cause explosion. Using insulated tools reduces

this risk, but will not eliminate it.

1.8.7. Remove personal metal items such as rings, bracelets, necklaces, and watches when working with a

storage battery. A storage battery can produce a short circuit current high enough to weld a ring or

the like to metal, causing a severe burn.

1.8.8. When charging batteries, charge 6 and 12 cell LEAD-ACID or 10 and 20 cell LIQUID ELECTROLYTE

NICKEL-CADMIUM batteries only, with rated capacity of 30 to 300 Ampere hours.Charger certified

for fire pump and emergency generator applications at 200 Ampere hours. Do not use this battery

SENS MicroGenius 2 Technical Manual

4

charger to supply power to an extra-low voltage electrical system or to charge any type of non-

rechargeable, dry cell, alkaline, lithium, nickel-metal-hydride, or sealed nickel-cadmium batteries

that are commonly used with home appliances. These batteries may burst and cause injuries to

persons and damage to property.

1.8.9. NEVER charge a frozen battery.

1.8.10. The charger contains a DC output fuse for internal fault protection, but this will not protect the DC

wiring from fault currents available from the battery. Consult national and local ordinances to

determine if additional battery fault protection is necessary in your installation.

1.9. Preparing Battery For Charge

1.9.1. Be sure area around battery is well ventilated while battery is being charged.

1.9.2. Ensure battery terminals are clean and properly tightened. Be careful to keep corrosion from

coming in contact with eyes.

1.9.3. Add distilled water in each cell until battery acid reaches level specified by battery manufacturer.

Do not overfill. For a battery without removable cell caps, such as valve regulated lead acid

batteries, carefully follow manufacturer’s recharging instructions.

1.9.4. Study all battery manufacturer specific precautions such as removing or not removing cell caps

while charging and recommended rate of charge. The recommended charge current range must

include the rated output current of the charger.

1.10. Charger Location

1.10.1. Locate the charger as far away from the battery as DC cables permit.

1.10.2. Never place the charger directly above or below the battery being charged; gases from the battery

will corrode and damage charger.

1.10.3. Never allow battery acid to drip on charger when reading electrolyte specific gravity or filling

battery.

1.10.4. Do not operate charger in a closed-in area or restrict ventilation in any way.

1.10.5. Do not set anything on top of the charger.

2MODEL NUMBER BREAKOUT

M ---

Model

Power

1: 180W, enclosed

3: 300W, enclosed

4: 450W, enclosed

F: 180W, open-frame

G: 300W, open-

frame

H: 450W, open-frame

Output Voltage

22: 12/24 Volts

Output Current

1006: 10A @ 12V

6A @ 24V

(180W only)

1210: 12A @ 12V

10A @ 24V

(300W only)

1515: 15A @ 12V

15A @ 24V

(450W only)

Alarms/Communications*

A: base model; includes J-1939 & Modbus

D: base model + LCD + 5 Form C alarm relays

E: base model + LCD + 2 Form C alarm relays

F: base model + LCD + 5 Form C alarm relays + keypad

*LCD, Form C alarm relays and keypad not available on

open-frame charger. Remote accessory with these

options available as a separate line item for open-frame

chargers and option A enclosed chargers.

SENS MicroGenius 2 Technical Manual

5

3PERFORMANCE SPECIFICATIONS

MicroGenius® 2 is a switchmode, regulated, filtered, microprocessor-controlled, current limited battery charger

designed for heavy-duty industrial service. Chargers may be configured for three primary applications: 1) quick

recharge and long life maintenance of engine start batteries, 2) DC power supply and battery charging for marine

environments, and 3) DC power and standby battery charging for industrial control and safety systems. The

charger is provided as 180W, 300W or 450W models and in either fully enclosed or open-frame enclosures. Every

model provides 12V and 24V output voltage as well as J1939 and Modbus communications. Optional features

include alarm relays, easily readable alpha-numeric display and keypad. Charger specifications are detailed in the

table below, see following sections for installation and operation instructions.

Table 1 – Specifications

AC Input

Voltage, Frequency

90-265 VAC , 47-63 Hz

Current (maximum)

180W: 2.0 Amps

300W: 3.3 Amps

450W: 4.0 Amps

Protection

Supplementary overcurrent protection fuse (non-replaceable);

transient protected to EN61000-4-5 level 4

Efficiency

Up to 93%; meets CA Energy Commission (CEC) Title 20 Appliance

Efficiency Regulations; standby AC draw < 3W

Power factor

>.95 typical at maximum rated load current and boost charge voltage

60.0%

65.0%

70.0%

75.0%

80.0%

85.0%

90.0%

95.0%

0

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

Efficiency

Load (Amps)

Efficiency at 15VDC Output

115 VAC

230 VAC

60.0%

65.0%

70.0%

75.0%

80.0%

85.0%

90.0%

95.0%

0

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

Efficiency

Load (Amps)

Efficiency at 30VDC Output

115 VAC

230 VAC

SENS MicroGenius 2 Technical Manual

6

DC output

Voltage

12/24V nominal; field selectable; adjustable from 0-34V using

computer to charger cable and SENS Setup Utility Kit (SENS p/n

209254 plus SENS software available at www.sens-usa.com)

Current

180W: 10A at 12V nominal and 6A at 24V nominal, 180W maximum

300W: 12A at 12V nominal and 10A at 24V nominal, 300W maximum

450W: 15A at 12/24V nominal, 450W maximum (12A max below

170VAC input voltage in 24V configuration)

Soft start

Charger gradually increases current with a maximum of 5 seconds to

full-required output

Charging modes

Float voltage, boost voltage; two additional HELIX charging voltages in

flooded lead-acid battery program

Battery type programs

Flooded lead-acid, AGM or Ni-Cd for engine starting; VRLA for reserve

power; ultracapacitor

DC power supply

operation

Delivers fast-responding, stable, well-filtered DC without battery

Factory adjustment

All charger adjustments factory set to customer specifications; field

reconfigurable

Field voltage

adjustment

3 manually selectable voltage settings; optional keypad; infinite

adjustment using computer to charger cable and SENS Setup Utility

Kit (SENS p/n 209254 plus SENS software available at www.sens-

usa.com)

Current limit

100% current capability subject to temperature limits and AC voltage

limits on 450W; field adjustable

Charging characteristic

Constant voltage, current limited; patented Dynamic Boost control

Line/load regulation

+0.5%

Output ripple

<30mVrms with or without battery

Battery temperature

compensation

On-board sensor controls changes in output voltage when

temperature is between 0°C and +40°C at a rate of – 0.18% per

degree C; optional remote battery temperature probe (SENS p/n

209481)

Output protection

Current limit, supplementary overcurrent protection fuse (non-

replaceable), transient protected

Overvoltage protection

Self-resetting and selective

4

6

8

10

12

14

16

12.00

13.00

14.00

15.00

16.00

17.00

23.00

23.33

25.33

27.33

29.33

31.33

33.00

Output voltage

450W amps, 208-

240 VAC input

450W amps, 100-

120 VAC input

300W amps @

12V setting

300W amps @

24V setting

180W amps @

12V setting

180W amps @

24V setting

Output Current Limit vs. Output Voltage

SENS MicroGenius 2 Technical Manual

7

Dead battery charge

Starts into and recharges zero volt battery without user intervention

Parallel/Load Share

operation

Two or more load-sharing chargers operate with all modes

synchronized for increased current or fault tolerance, requires

standard RJ-45 network cable to connect paralleling bus (SENS p/n

208118-72 for 72-inch length or p/n 208118-180 for 180-inch length)

Load Dump protection

Output voltage over-shoot is limited to 15% to prevent damage to

connected devices if battery is disconnected while charger is

operating

Output Blocking

protection

Prevents sparking during battery connection when battery is first

connected to charger; serves as an "OR" diode to isolate a non-

functioning charger from others in a redundant charger configuration

Adjustment

& Controls

Charge mode control

Fully automatic patented Dynamic Boost system. Fully automatic

HELIX system for flooded lead-acid starting batteries that reduces

power use and extends battery life.

Internal adjustments

12 or 24 volt; battery type program; fine voltage setting

Battery type programs

Flooded lead-acid, AGM or Ni-Cd for engine starting; VRLA for reserve

power; ultracapacitor

Computer adjustment

Change or customize settings from computer using computer to

charger cable and SENS Setup Utility Kit (SENS p/n 209254 plus SENS

software available at www.sens-usa.com)

Keypad adjustment

Enable or change all settings from front panel (requires optional

keypad)

Status

display

LEDs

Dual multi-color front panel status LEDs

Digital metering

DC voltmeter accurate to +2%; DC ammeter to +5% (meters require

optional display or network connection to a compatible device with a

display). AC input voltage is for reference only. If AC waveform is not

sinusoidal or is distorted the AC voltage will not be reported

accurately.

Status messages

20-character display of status and alarm messages (requires optional

display or network connection to a compatible device with a display)

Alarms

Alarms

Factory set and field reconfigurable.

Output via network

Alarms available via either J1939 or Modbus ports. Alarm indication

delayed by configured alarm delay value.

Form C contacts

Two or five Form C contacts, each rated 30VDC/VAC, 2A resistive,

assignable at factory or by using SENS Setup Utility. Alarm indication

delayed by configured alarm delay value.

Alarm Delay

30 seconds by default, programmable between 5 to 60 seconds using

keypad or SENS Setup Utility. Alarm indication delayed for

communications ports and relay contacts, LED indication not delayed.

Networking

J1939 communications

CAN 2.0 extended ID on RJ-45 port

Modbus

communications

Modbus RS-485 on RJ-45 port

SENSbus

Proprietary bus for connection of paralleled chargers and future SENS

accessories

SENS MicroGenius 2 Technical Manual

8

Environ-

mental

Operating temperature

180W, enclosed: -40°C to +70°C; meets full specification from

-40°C to +55°C

180W, open-frame: -40°C to +70°C; meets full specification from -

40°C to +60°C

300W: -40°C to +70°C; meets full specification from -40°C to +50°C

450W: -40°C to +70°C; meets full specification from -40°C to +40°C

LCD: display may be unreadable and life reduced above 65°C

Cooling

Natural convection cooled

Storage temperature

-40°C to +85°C

Cold Start

Cold starts down to -40°C. Requires approximately five seconds

additional time to start at temperatures below -20°C.

Humidity

5% to 95%, non-condensing

Water ingress

Enclosed Models: IP 22; NEMA 3R; UL Rainproof

Vibration

Swept Sine (EN60068-2-6): 4G, 18-500 Hz, 3 primary axes

Random: 20-500Hz, .01G2/Hz

Shock

EN 60068-2-27 (15G)

Electrical transient

ANSI/IEEE C62.41 and EN 61000-4-12 on power terminals

Abuse

protection

Reverse polarity

Charger self-protects without fuse clearing; indication via LED and

optional LCD; charger recovers automatically after removal of the

fault condition

Wrong voltage battery

Charger-battery voltage mismatch shuts down charger after 5

minutes; indication via LED and optional LCD

Overvoltage shutdown

Selective; shutdown only operates if charger causes the overvoltage

condition. Overvoltage caused by an external voltage source does not

shut down the charger.

Over temperature

protection

Gradual output power reduction if heatsink temperature becomes

excessive

Regulatory

compliance

North America

C-UL-US Listed (enclosed chassis): CSA 22.2, No. 107.2; UL 1236, File

E109740 for category BBGQ and File EX6409 for categories BBHH,

BBJY and QWIR; certified to UL 1236 supplements SB (marine), SC

(fire pump) and SE (emergency generator) E109740

Note: 180W unit configured for 24V output is not compliant with

QWIR2

C-UL-US Recognized (open-frame chassis): CSA 22.2, No. 107.2; UL

1236, File E109740 for category BBGQ2 and File EX6409 for categories

BBHH2, BBJY2 and QWIR2; certified to UL 1236 supplements SC (fire

pump) and SE (emergency generator)

Note: 180W unit configured for 24V output is not compliant with

QWIR2

NFPA-70; NFPA-110 when annunciating to the genset control panel

the charger’s output voltage & current, and alarm status via J1939, or

when equipped with optional alarm relays

FCC: Part 15, Class B for home or commercial use and ICES-003

(Canada).

This device complies with part 15 of the FCC Rules. Operation is

subject to the following two conditions: (1) This device may not cause

harmful interference, and (2) this device must accept any

interference received, including interference that may cause

undesired operation.

SENS MicroGenius 2 Technical Manual

9

Seismic: rigid and non-structure wall mount; max S

DS

of 2.5G; IBC

2000-2015; California BC 2007-2016

American Bureau of Shipping: Type Approved

California Energy Commission: Title 20 Appliance Efficiency

Regulations

European Union (CE)

EMC: 2014/30/EU

EN 61000-6-4 (Emissions – Class B)

CISPR 11 – Class B

EN 61000-6-2 (Immunity – Industrial Environments)

EN 61000-4-2 Electro Static Discharge 4 kV contact, 8 kV air

EN 61000-4-3 Radiated Immunity – at 10V/m

EN 61000-4-4 Electrical Fast Transients – 2kV AC, 1kV I/O

EN 61000-4-5 Surge Immunity – 2 kV cm, 1 kV diff

EN 61000-4-6 Conducted power line immunity – 10 V r.m.s.

EN 61000-4-8 Power frequency magnetic field testing – 30 A/m

EN 61000-4-11 Voltage dips and interruptions – per the standard

LVD: 2014/35/EU

EN 60335-1 & EN 60335-2-29

RoHS 2: 2011/65/EU

EN 50581

WEEE: 2012/19/EU

This charger is considered electrical and electronic equipment (EEE)

for non-household use and should be recycled accordingly. Do not

dispose as unsorted municipal waste. See SENS website (www.sens-

usa.com) for information on how to properly recycle.

Construction

Housing/configuration

Enclosed chassis: die-cast aluminum heatsink base with stainless steel

covers and fasteners; includes two ½ inch conduit openings and one

¾ inch conduit opening

Open-frame chassis: aluminum heatsink base and cover

Dimensions

See drawings and dimensions at back of manual

Weight

Enclosed: 6.0 lbs (2.7 Kg)

Open-frame: 3.2 lbs (1.45 Kg)

Connections

AC and DC terminal blocks: 20 to 10 AWG solid copper; 20 to 6 AWG

stranded copper

J-1939 and Modbus-485: RJ-45

Form C alarms terminal block plug: 28 to 16 AWG

SENS MicroGenius 2 Technical Manual

10

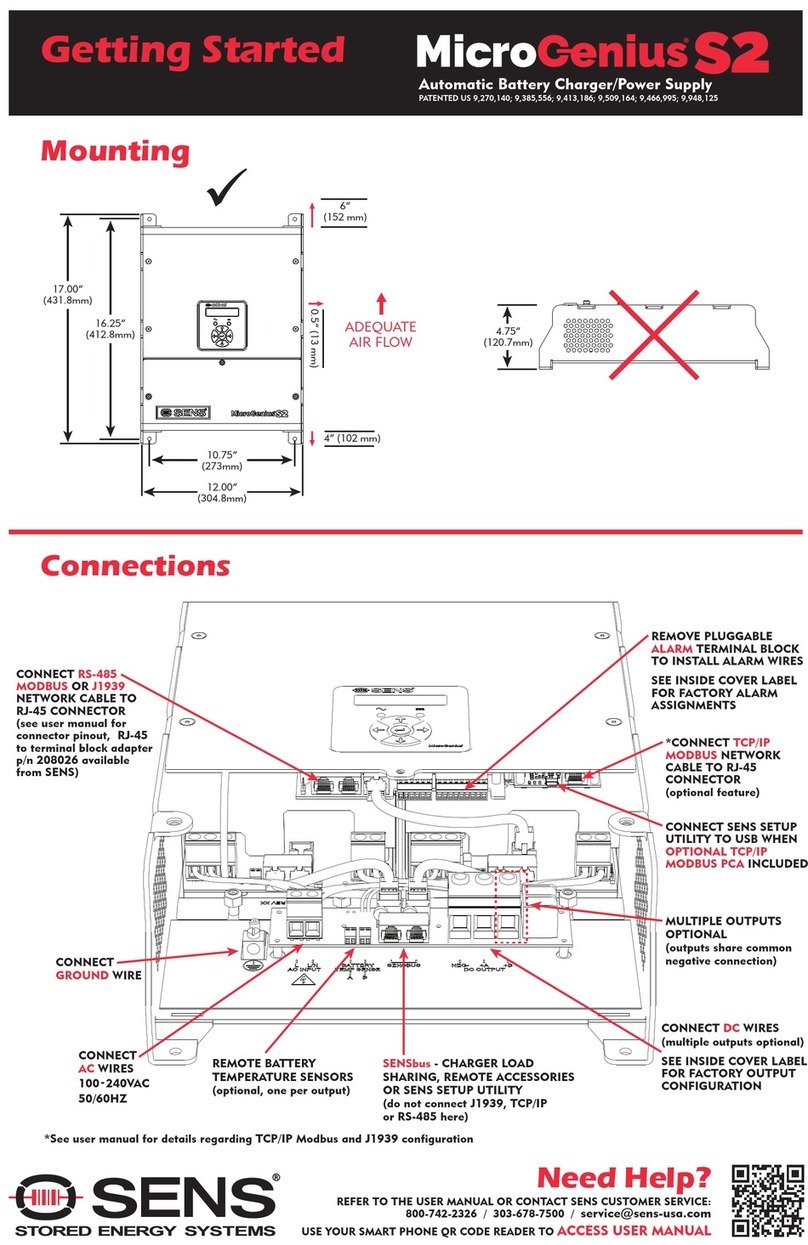

4SYSTEM OVERVIEW

Fully enclosed model with optional alarm/communications circuit board shown. Refer to the nameplate label or

the label on the inside lower cover for factory configured output and alarm relay assignments.

OPTIONAL J1939 JUMPERS:

Select Charger 1 or 2 on

alarm/comms PCA, if included

OUTPUT JUMPERS:

Leave in Factory Configuration

(3 jumpers in FLOAT)

Move only if system voltage or

battery type change from

original factory configuration

Jumpers removed for adjustable

keypad or Program Mode

MAIN PCA J1939 ADDR

JUMPERS:

Select Charger 1 or 2 on

main PCA unless optional

alarm/comms PCA is included

OPTIONAL DUAL RJ-45

PORT:

Connect J1939/Modbus

cable if alarm/comms PCA

is included

MAIN PCA DUAL RJ-45 PORT:

Connect J1939/Modbus cable to

main PCA unless optional

alarm/comms PCA is included

Always connect load share or remote

accessory cable to main PCA

CONDUIT OR CORD

BUSHINGS:

Customer supplied

MOUNTING FASTENERS:

Use four ¼ inch (M6)

screws to mount enclosed

and open-frame chargers,

fasteners supplied by installer

MOUNTING:

Mount enclosed chassis

charger vertically

Mount open-frame

charger in any orientation

OPTIONAL LCD:

Status and alarms

AC STATUS LED

DC STATUS LED

AC INPUT TERMINALS:

20–10 AWG (0.5–6 mm2) solid

20–6 AWG (0.5–13.5 mm2) stranded

Tighten to 10.5 In-Lb (1.2 Nm)

OPTIONAL ALARM

TERMINAL BLOCKS:

28–16 AWG (0.08–1.5 mm2)

Tighten connections to 2.0

In-Lb (0.22 Nm)

REMOTE TEMPERATURE

SENSOR TERMINALS:

28–16 AWG (0.08–1.5 mm2)

Tighten connections to 2.0

In-Lb (0.22 Nm)

DC OUTPUT TERMINALS:

20–10 AWG (0.5–6 mm2) solid

20–6AWG (0.5–13.5 mm2) stranded

Tighten to 10.5 In-Lb (1.2 Nm)

GROUND FAULT JUMPER

SENS MicroGenius 2 Technical Manual

11

5MOUNTING INSTRUCTIONS

INSTALLATION OF THE UNIT MUST COMPLY WITH LOCAL ELECTRICAL CODES AND OTHER APPLICABLE

INSTALLATION CODES AND BE MADE ACCORDING TO THE INSTALLATION INSTRUCTIONS AND ALL

APPLICABLE SAFETY REGULATIONS.

Printed circuit boards contain static sensitive components. Damage can occur even when static levels are too

low to produce a noticeable discharge shock. To avoid static discharge damage, handle the charger by the

chassis only. Remove the cover only when access is essential for installation and service, and replace it

promptly when finished.

5.1. Mounting Location

The charger is provided in two different chassis options, fully enclosed or open-frame. See diagrams at

back of manual for mounting information.

5.1.1. Enclosed Chassis

5.1.1.1. The fully enclosed charger is rated IP22 and is approved as “rainproof” by UL. It can withstand

dripping liquid but may require additional protection from spraying, splashing, or blowing

liquid.

5.1.1.2. The charger will operate at full specification when located where temperatures are within the

following ranges. Output power is gradually reduced at higher temperatures.

Power

Rating

Operating Temperature

180W

-40°C (-40°F) to +55°C (131°F)

300W

-40°C (-40°F) to +50°C (122°F)

450W

-40°C (-40°F) to +40°C (104°F)

5.1.1.3. Mount charger vertically to ensure adequate ventilation.

5.1.1.4. Leave clear space for ventilation all around the enclosed unit: at least 6 inches (15 cm) at the

top; at least 4 inches (10.16 cm) at the bottom; at least 0.5 inches (1.27 cm) on each side.

Operating temperature ranges stated above assume clearances shown in diagram below.

5.1.1.5. Mount to a wall or other vertical support. The mounting surface must safely support the

weight of the charger and the fixed wiring. The weight of the enclosed charger is 6 pounds

(2.7 Kg).

5.1.2. Open-frame Chassis

5.1.2.1. The open-frame chassis charger is designed for installation inside a customer-provided

enclosure, protected from rain, snow and blowing or dripping liquid.

5.1.2.2. Heat sink the charger to a metal surface that is not subject to heating from another source.

Base plate temperature should not exceed 83°C measured at top front of base plate when

SENS MicroGenius 2 Technical Manual

12

charger is operating at full current load and maximum ambient temperature.

5.1.2.3. The charger will operate at full specification when located where temperatures are within the

following ranges. Output power is gradually reduced at higher temperatures.

Power

Rating

Operating Temperature

180W

-40°C (-40°F) to +60°C (140°F)

300W

-40°C (-40°F) to +50°C (122°F)

450W

-40°C (-40°F) to +40°C (104°F)

5.1.2.4. Mount charger in any orientation.

5.1.2.5. The mounting surface must safely support the weight of the charger and the fixed wiring. The

weight of the open-frame charger is 3.2 pounds (1.45 Kg).

5.1.3. Allow sufficient room for routing the fixed wiring to the charger. All wires enter the charger from

the bottom. See diagrams at back of manual for further information.

5.1.4. Do not mount the charger above any heat generating equipment.

5.2. Mounting Instructions

5.2.1. Drill four mounting holes using the mounting template provided with the charger.

IMPORTANT: Protect charger from all drill shavings!

5.2.2. Mount the charger before connecting AC, DC, communications and alarm wiring to ensure un-

obstructed access to mounting holes.

5.2.3. Mount the charger using four ¼ inch (M6) screws with standard flat washers. Mounting hardware

is not included with the charger and must be provided by the installer.

SENS MicroGenius 2 Technical Manual

13

6CHARGER SETUP

IMPORTANT! The charger is configured at the factory and typically requires no adjustments before operating.

Leave the jumpers in the three FLOAT positions to operate the charger using settings configured at the factory per

customer order. Refer to the label on the inside lower cover for factory configured output and alarm relay

assignments (see Figure 3). If the system voltage or battery type is different than the factory configuration, or if

other custom settings are required, the charger may be reconfigured using the jumpers, the optional front panel

keypad, or by software programming using the SENS Setup Utility.

Figure 1 – Jumper Settings

(fully enclosed model with optional alarm/communications circuit board shown)

6.1. Factory Jumper Configuration

The charger is shipped from the factory with three jumpers in the three FLOAT positions on the main

circuit board. Jumpers in the three FLOAT positions indicate the charger is operating using settings

configured at the factory per customer order. Refer to the label on the inside lower cover for factory

configured output and alarm relay assignments (see Figure 3). Leave jumpers in the factory

configuration unless system voltage or battery type changes.

Figure 2 – Factory Configuration

OPTIONAL J1939

JUMPERS:

Select Charger 1 or 2

on alarm/comms

PCA if included

OUTPUT JUMPERS:

Leave in Factory

Configuration (3

jumpers in FLOAT)

Move only if system

voltage or battery type

change from original

factory configuration

Jumpers removed for

adjustable keypad or

Program Mode

MAIN PCA J1939 ADD

JUMPERS:

Select Charger 1 or 2

on main PCA unless

optional alarm/comms

PCA is included

GROUND FAULT JUMPER

SENS MicroGenius 2 Technical Manual

14

Figure 3 – Configuration Label (on inside lower cover)

6.1.1. Changing Voltage Range Using Factory Jumpers Mode

The voltage range (12-volt or 24-volt battery) of the charger may be changed without changing

factory settings by moving any one of the three FLOAT jumpers to the appropriate RANGE

position. Set the RANGE jumper to 12V or 24V depending on nominal battery voltage. Leave the

other two jumpers in the FLOAT positions. In this configuration the charging algorithm, output

settings and alarm relay assignments remain as originally configured at the factory but all

setpoints are doubled when changing from a 12V setting to a 24V setting or halved when

changing from a 24V setting to a 12V setting. Replacing the jumpers in the three FLOAT positions

will return the charger to original factory configuration.

Figure 4 – Change System Voltage

6.1.2. Changing Battery Type Using Jumpers

If battery type changes from original factory configuration, the Standard Jumper Configuration

must be used (see section 6.2).

6.2. Standard Jumper Configuration

If battery type changes from the original factory configuration all jumpers must be moved into the

standard jumper configuration - one jumper each in BATTERY TYPE, FLOAT and RANGE positions. In this

configuration the alarm relay assignments remain as originally configured at the factory. Replacing the

jumpers in the three FLOAT positions will return the charger to original factory configuration.

View output voltage,

battery type and

configuration code

set at the factory

View alarm relay

assignments set

at the factory

SENS MicroGenius 2 Technical Manual

15

Figure 5 – Standard Jumper Configuration

6.2.1. Battery Type Jumper

Set the BATTERY TYPE jumper appropriate for the battery type used.

Table 2 – Charging Algorithms by Battery Type

Battery Type

Charging Algorithm

Float

Mode

Dynamic

Boost Mode

HELIX

Mode

FLA

AGM

NICD

VRLA

6.2.1.1. FLA

This setting is ideal for flooded lead-acid batteries used in engine starting applications. Set

the BATTERY TYPE jumper to FLA when using flooded lead-acid batteries. The charging

algorithm for flooded lead-acid batteries includes Float mode (see section 10.2), Dynamic

Boost™ mode (see section 10.3) and HELIX mode (see section 10.4).

6.2.1.2. AGM

The term, “AGM” in this manual and for the MicroGenius charger refers to AGM type

batteries that are employed in engine starting applications. For AGM type batteries

employed in non-engine starting applications please see “VRLA” in section 6.2.1.4 below. Set

the BATTERY TYPE jumper to AGM when using engine starting AGM batteries. . The charging

algorithm for absorbed glass mat batteries includes Float mode (see section 10.2) and

Dynamic Boost™ mode (see section 10.3).

6.2.1.3. NICD

Set the BATTERY TYPE jumper to NICD when using nickel-cadmium batteries. The charging

algorithm for nickel-cadmium batteries includes Float mode (see section 10.2) and Dynamic

Boost™ mode (see section 10.3). Nickel-cadmium batteries are used in all applications.

6.2.1.4. VRLA

The “VRLA” battery profile includes all valve regulated batteries, including AGM types, which

are employed in non-engine starting applications. For AGM batteries employed in engine

starting applications please see “AGM” in section 6.2.1.2 above. Set the BATTERY TYPE

jumper to VRLA when using valve-regulated lead-acid batteries, of which AGM is a subset.

The charging algorithm for valve-regulated lead-acid batteries includes Float mode only (see

section 10.2).

SENS MicroGenius 2 Technical Manual

16

6.2.1.5. Ultracapacitors

Place one jumper each in the AGM and NICD battery type positions and leave one jumper in

the RANGE position if charging ultracapacitors rather than batteries (see section 10.5).

6.2.2. Float Voltage Jumpers

When the charger is in Float mode the output voltage is maintained at the float voltage setting. If

adjustment from the factory set float voltage is necessary, move the FLOAT output voltage

jumper to the setting that is closest to the battery manufacturer’s recommended 25°C (77°F) float

voltage. Incorrect charge voltage can undercharge or accelerate generation of explosive gases,

increasing the risk of fire or explosion.

Jumper options:

14.3/28.6 volts for 10 or 20 cell nickel cadmium at 1.43V/cell

13.5/27.0 volts for 6 or 12 cell (VRLA, AGM or high capacity) lead-acid at 2.25V/cell and 19

cell nickel cadmium at 1.42V/cell

13.3/26.6 volts for 6 or 12 cell (flooded) lead-acid at 2.22V/cell and 19 cell nickel cadmium

at 1.40V/cell

The FLOAT output voltage setting is not used for charging ultracapacitors (see section 6.4 for

ultracapacitor setup).

6.2.3. Range Jumper

Set the RANGE jumper to 12V or 24V depending on nominal battery voltage.

6.3. Keypad Configuration—Optional

Charger adjustment may also be made using the optional keypad. The keypad is either integral to the

charger or located remotely from the charger and connected with a network cable. See section 7.9 for

more information on the Remote Alarm/Communications Panel Accessory. Chargers including a keypad

are supplied without jumpers and are configured per customer order at the factory. Jumpers must not

be present to allow adjustment using the keypad. See section 10.9for additional details on keypad

navigation.

6.3.1. Security Code Protection

Chargers with the optional keypad may be security code protected to ensure only authorized

personnel may adjust charger settings. The default security code is 000000 meaning security code

is not enabled. Change the security code to a unique value by scrolling to the “Service Tools”

menu and then the “Change Security Code” option.See section 10.9 for further keypad

information.

6.4. Ultracapacitor Mode Setup

Ultracapacitor mode is used to charge ultracapacitors rather than batteries. Place a jumper in the 12V or

24V RANGE position and jumpers in both the AGM and NICD battery type positions (no jumpers are

placed in the FLOAT settings) to enable operation with ultracapacitors.

WARNING:

ULTRACAPACITORS ACCEPT AND DISCHARGE CURRENT RAPIDLY. NEVER ATTEMPT TO

JUMP OR CONNECT A BATTERY TO AN ULTRACAPACITOR.

SENS MicroGenius 2 Technical Manual

17

Figure 6 – Ultracapcitor Mode Jumper Configuration

6.5. Program Mode

Removing all jumpers from the BATTERY TYPE, FLOAT and RANGE positions enables Program Mode. In

Program Mode the charger output is determined by values programmed in the charger using the SENS

Setup Utility (see section 10.10). If the charger has not been specially programmed, removing all jumpers

will result in an error state and the charger will not produce output. If the charger includes the optional

keypad removing the jumpers is required to adjust settings and will not result in an error state (see

section 6.3).

6.6. Load Share Charger Setup

Multiple chargers may be connected in parallel to provide charger redundancy and increased charging

current. Connection of a network cable between up to 30 chargers (see section 7.8) automatically

initiates load sharing. Use of this sharing cable is essential to synchronizing operation of the Dynamic

Boost and HELIX modes, and helps insure that current is shared within +10% between chargers. Remove

the ADD jumper from the main circuit board of any charger connected to load share (see Figure 8).

Chargers intended for load sharing must be configured with the same output settings in order to load

share. See section 10.12for further information.

6.6.1. Load Share Termination

For proper load share operation, a 120-ohm terminator is required at the ends of the bus. Figure

9 below shows an example of how to terminate the network. The charger is not equipped with

terminators. Termination may be provided as part of the network cabling or 120-ohm

termination plugs for the RJ-45 communications connector on the charger are available to order

separately (SENS p/n 803707).

6.7. SAE J1939 Communications Setup (CANbus)

Every charger includes SAE J1939 (CANbus) communications. The J1939 interface provides a highly

reliable, low cost method of delivering to the genset controller all information that NFPA 110 requires

the battery charger to deliver. This eliminates the need for a volt/amp display and alarm relays in the

charger. To be operational, the genset controller must support the charger’s J1939 connection. Contact

your genset supplier to determine if your genset supports a J1939-connected charger. See section 10.14

for further information on J1939 operation and registers.

6.7.1. Battery Charger J1939 Address Jumper

Configure the address jumper on the optional alarm/communications circuit board if present (see

Figure 7). Otherwise, configure the address jumper on the main circuit board (see Figure 8).

J1939 supports two chargers per network cable. Set the address jumper to position 1 for main

charger or position 2 for auxiliary charger. The jumper is set to position 1 by default.

SENS MicroGenius 2 Technical Manual

18

Figure 7 – Optional Circuit Board J1939 Battery Charger (BCH) Jumper

Figure 8 – Main Circuit Board J1939 ADD Jumper

6.7.2. Termination

For proper J1939 operation, a 120-ohm terminator is required at the ends of the J1939 bus. If

multiple devices are on the bus, only the devices on the ends of the network bus need

termination resistors. Figure 9 shows an example of how to terminate the network. The charger is

not equipped with terminators. Termination may be provided as part of the network cabling or

120-ohm termination plugs for the RJ-45 communications connector on the charger are available

to order separately (SENS p/n 803707).

Figure 9 – J1939 Termination

6.8. Modbus Communications Setup

Every charger includes Modbus (RS-485) communications. Modbus is an application layer messaging

protocol used for client/server communication and is implemented according to specifications provided

by Modbus Organization (http://www.modbus.org/specs.php). Modbus communications settings must

be configured using the optional keypad or SENS Setup Utility prior to initiating. See section 10.15for

further information on Modbus operation and configuration.

6.8.1. Termination

For proper Modbus RS-485 operation, a 120-ohm terminator is required at the ends of the RS-485

bus. If multiple devices are on the bus, only the devices on the ends of the network bus need

termination resistors. Figure 10 shows an example of how to terminate the network. The charger

is not equipped with terminators. Termination may be provided as part of the network cabling or

120-ohm termination plugs for the RJ-45 communications connector on the charger are available

to order separately (SENS 803707).

SENS MicroGenius 2 Technical Manual

19

Figure 10 – Modbus Termination

LT = Line Termination 120-ohm resistor

7WIRING

All wiring must comply with applicable codes and local ordinances.

WARNING:

ENSURE THAT AC POWER IS DISCONNECTED AT A CIRCUIT BREAKER

OR OTHER SAFETY DISCONNECT BEFORE WIRING THE CHARGER

Figure 11 – Wire Connections

(Fully enclosed model with optional alarm/communications circuit board shown)

OPTIONAL ALARM

TERMINAL BLOCKS:

28–16 AWG (0.08–1.5 mm2)

Tighten connections to 2.0

In-Lb (0.22 Nm)

OPTIONAL RJ-45 PORT:

Connect J1939/Modbus

cable if alarm/comms

PCA is included

CONDUIT OR CORD

BUSHINGS:

Customer supplied

DC OUTPUT TERMINALS:

20–10 AWG (0.5–6 mm2)

solid

20–6AWG (0.5–13.5 mm2)

stranded

Tighten to 10.5 In-Lb (1.2 Nm)

AC INPUT TERMINALS:

20–10 AWG (0.5–6 mm2) solid

20–6AWG (0.5–13.5 mm2)

stranded

Tighten to 10.5 In-Lb (1.2 Nm)

AC L2/N

GND

DC NEG (-)

REMOTE TEMPERATURE

SENSOR TERMINALS:

28–16 AWG (0.08–1.5 mm2)

Tighten connections to 2.0

In-Lb (0.22 Nm)

MAIN PCA RJ-45 PORT:

Connect J1939/Modbus cable to main PCA

unless optional alarm/comms PCA is included

Always connect load share or remote accessory

cable to main PCA

AC L1

DC POS (+)

SENS MicroGenius 2 Technical Manual

20

7.1. Wire Ratings and Sizes

7.1.1. All power conductors should be rated for use at 90°C or higher and 400V or higher. Alarm relay

conductors and J1939 data cable should be rated for use at 75°C or higher.

7.1.2. Coordinate the AC input conductor size with the customer-provided branch circuit protection

device.

7.1.3. For best performance and recharge time, refer to the following table to determine the

appropriate output conductor gauge and length. Use of a remote temperature sensor (SENS p/n

209481, see section 7.6) is highly recommended for best charging performance.

Table 3 – DC Output Cable Size

Charger Rated

Output Current

(Amps)

Wire Size

Resistance

per Foot

(mΩ/Ft.)

Maximum Charger to

Battery Distance (Ft.)

Recommended Charger to

Battery Distance (Ft.)

AWG

mm2

12V

24V

12V

24V

6

14

2.5

2.50

N/A

33

N/A

13

12

4.0

1.60

N/A

52

N/A

21

10

6.0

1.00

N/A

83

N/A

33

8

10

0.63

N/A

132

N/A

53

6

16

0.40

N/A

208

N/A

83

10

14

2.5

2.50

10

20

4

8

12

4.0

1.60

16

32

6

12

10

6.0

1.00

25

50

10

20

8

10

0.63

40

80

15

30

6

16

0.40

63

126

24

48

12

14

2.5

2.50

8

N/A

3

N/A

12

4.0

1.60

13

N/A

5

N/A

10

6.0

1.00

21

N/A

8

N/A

8

10

0.63

33

N/A

13

N/A

6

16

0.40

52

N/A

21

N/A

15

14

2.5

2.50

6

12

2

4

12

4.0

1.60

10

20

4

8

10

6.0

1.00

17

34

7

14

8

10

0.63

26

52

11

22

6

16

0.40

42

84

17

34

The above lengths consider the resistance of the battery and cables only and do not take into account any additional

interconnects. The above lengths are for operation at 25°C/77°F. For high temperature installations (40°C/104°F) increase wire

gauge by 10%.

7.1.4. The charger terminal blocks accept the following wire gauge ranges:

AC input terminal block: 20 – 10 AWG (0.5 – 6 mm2) solid; 20 – 6 AWG (0.5 – 13.5 mm2)

stranded

Remote temperature sensor terminal block: 28 – 16 AWG (0.08 – 1.5 mm2)

DC output terminal block: 20 – 10 AWG (0.5 – 6 mm2) solid; 20 – 6 AWG (0.5 – 13.5 mm2)

stranded

Alarm terminal block: 28 – 16 AWG (0.08 – 1.5 mm2)

Other manuals for MicroGenius 2

1

Table of contents

Other Sens Batteries Charger manuals

Sens

Sens MicroGenius S2 User manual

Sens

Sens FC Operating manual

Sens

Sens EnerGenius DC Wallbox User manual

Sens

Sens MicroGenius User manual

Sens

Sens EnerGenius IQ2 User manual

Sens

Sens EnerGenius NRG12-20 User manual

Sens

Sens F3 SERIES Manual

Sens

Sens MicroGenius S2 User manual

Sens

Sens F3 SERIES Manual

Sens

Sens EnerGenius DC COMPACT User manual

Sens

Sens NRG12-10 User manual

Sens

Sens Q012-012 User manual

Sens

Sens EnerGenius NRG24-10 User manual

Sens

Sens MicroGenius S4 User manual

Sens

Sens TD Series Operating manual

Sens

Sens EnerGenius NRG22-20 User manual

Sens

Sens DCT Series Operating manual

Sens

Sens EnerGenius NRG24-20 User manual

Sens

Sens MicroGenius 2 User manual