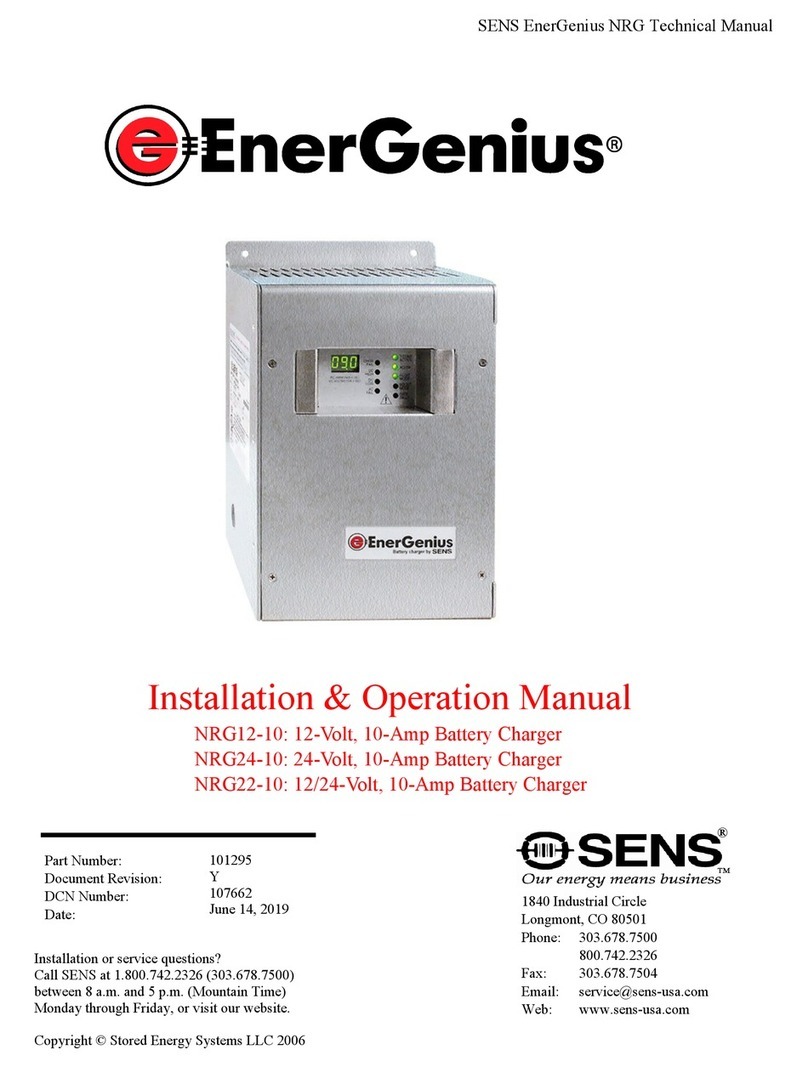

SENS EnerGenius IQ2 Technical Manual

2

TABLE OF CONTENTS

1IMPORTANT SAFETY INSTRUCTIONS FOR INSTALLER AND OPERATOR ..........................................................4

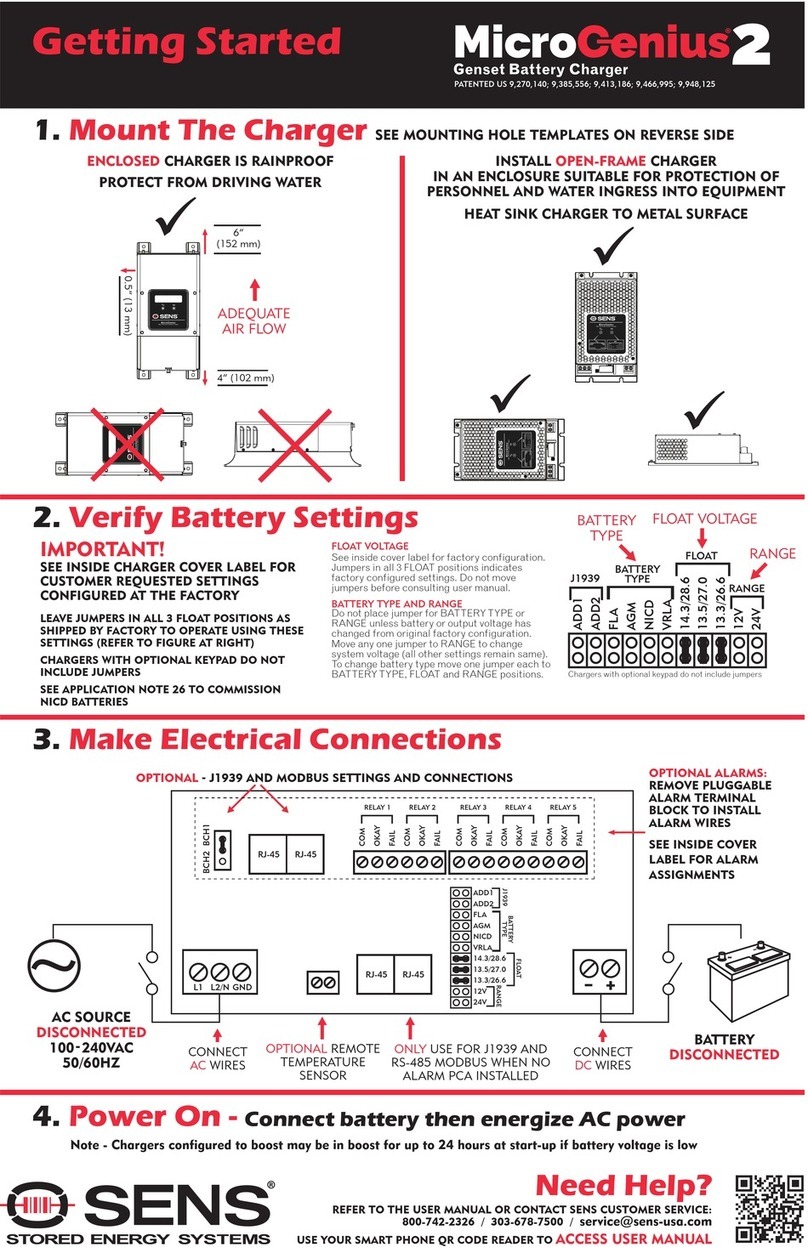

2QUICK INSTALLATION GUIDE ........................................................................................................................6

3PERFORMANCE SPECIFICATIONS...................................................................................................................7

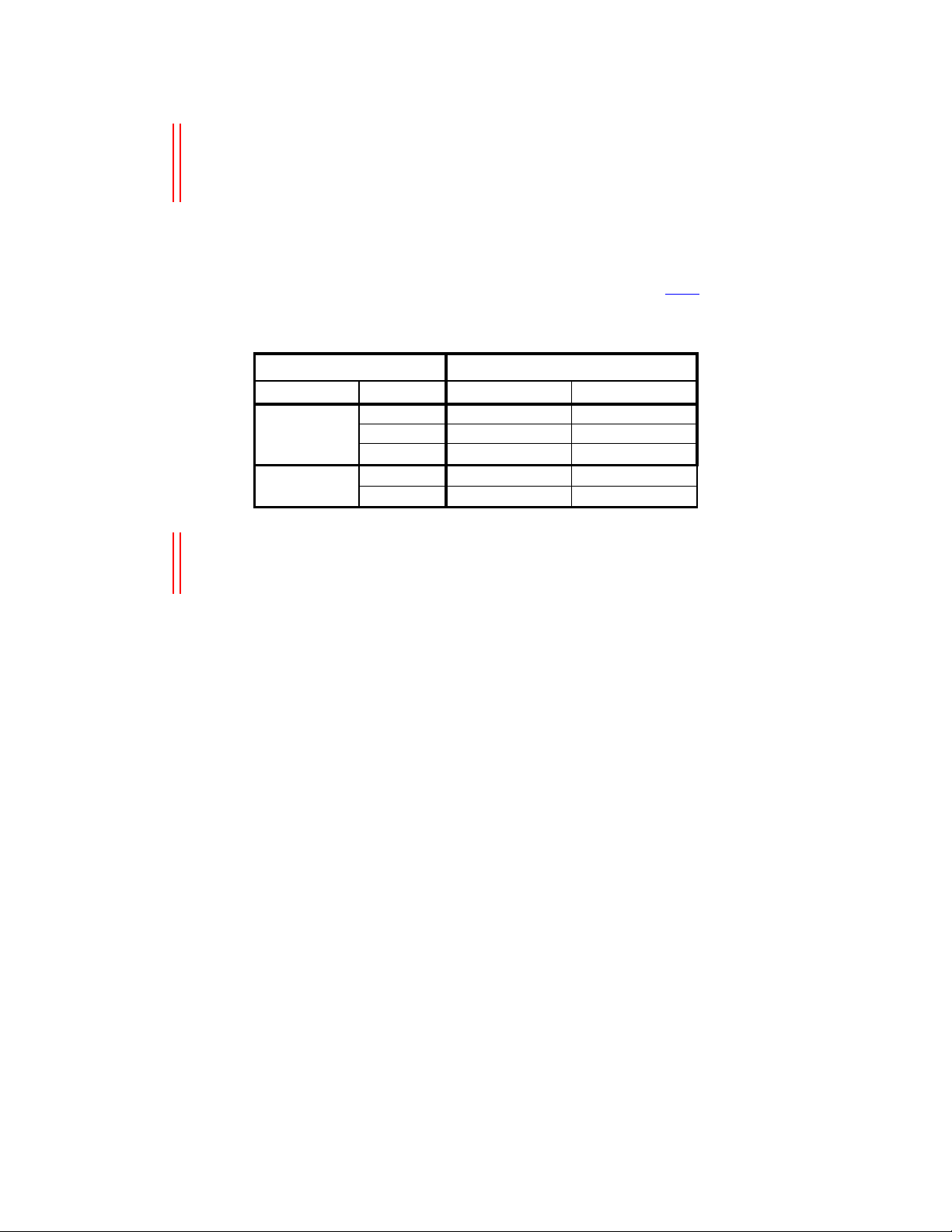

4MODEL NUMBER BREAKOUT ........................................................................................................................8

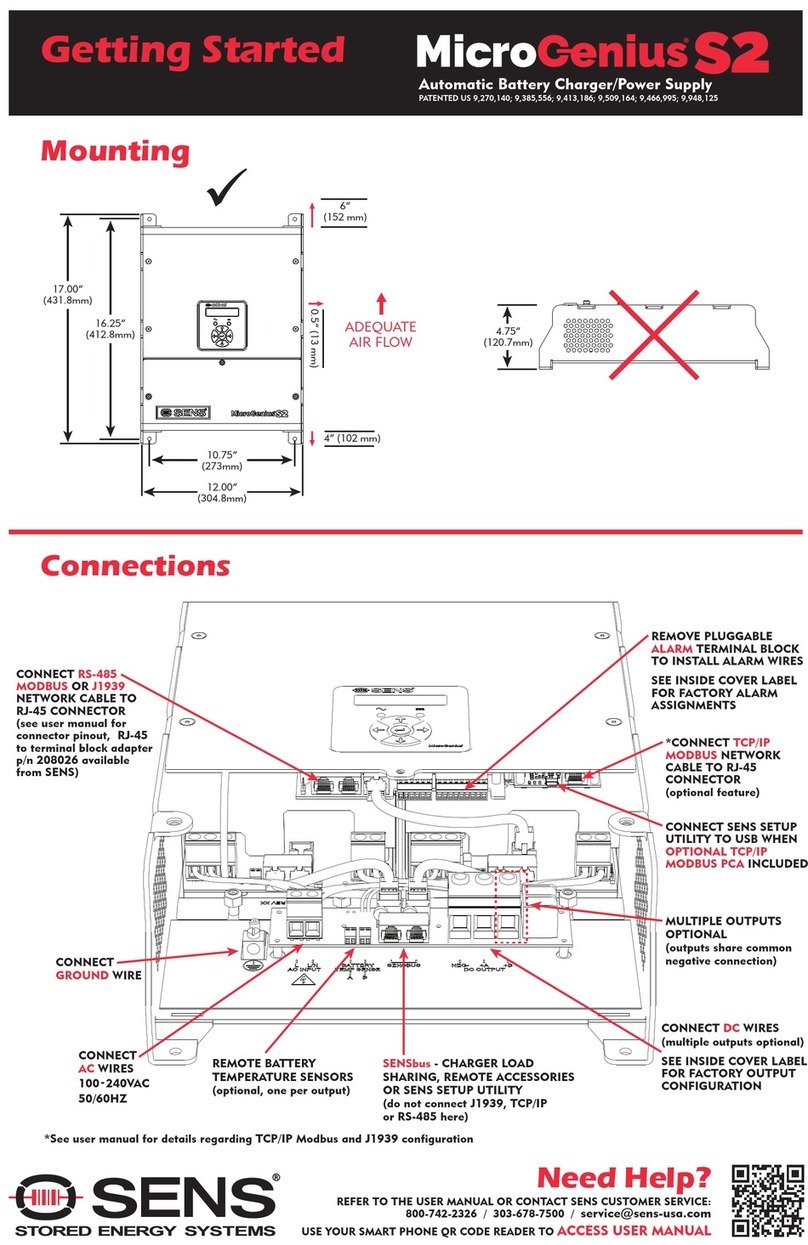

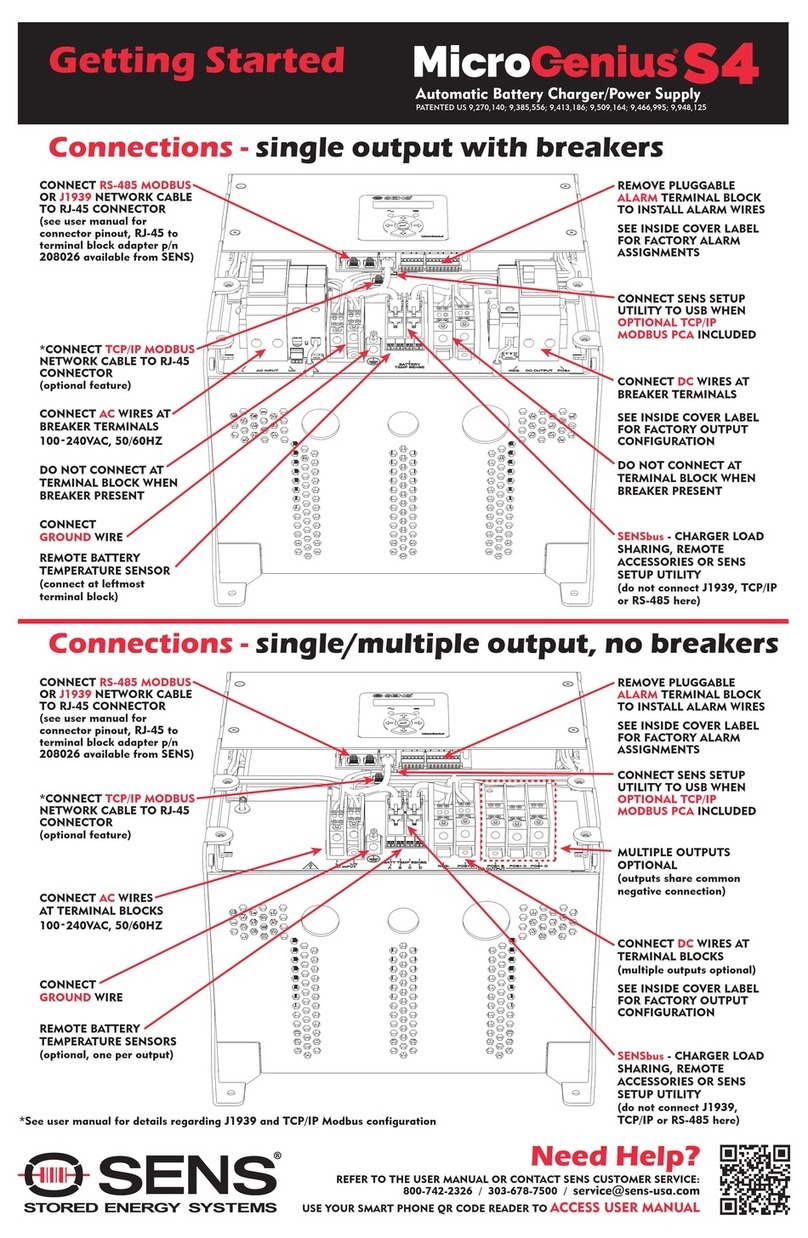

5MECHANICAL INSTALLATION ........................................................................................................................9

5.1. Lifting...................................................................................................................................................9

5.2. Charger Mounting Options ...................................................................................................................9

5.3. Ventilation ...........................................................................................................................................9

5.4. Environmental Considerations..............................................................................................................9

6ELECTRICAL INSTALLATION ...........................................................................................................................9

6.1. AC Input Connections...........................................................................................................................9

6.2. DC Output Connections......................................................................................................................11

6.3. Alarm Wiring......................................................................................................................................12

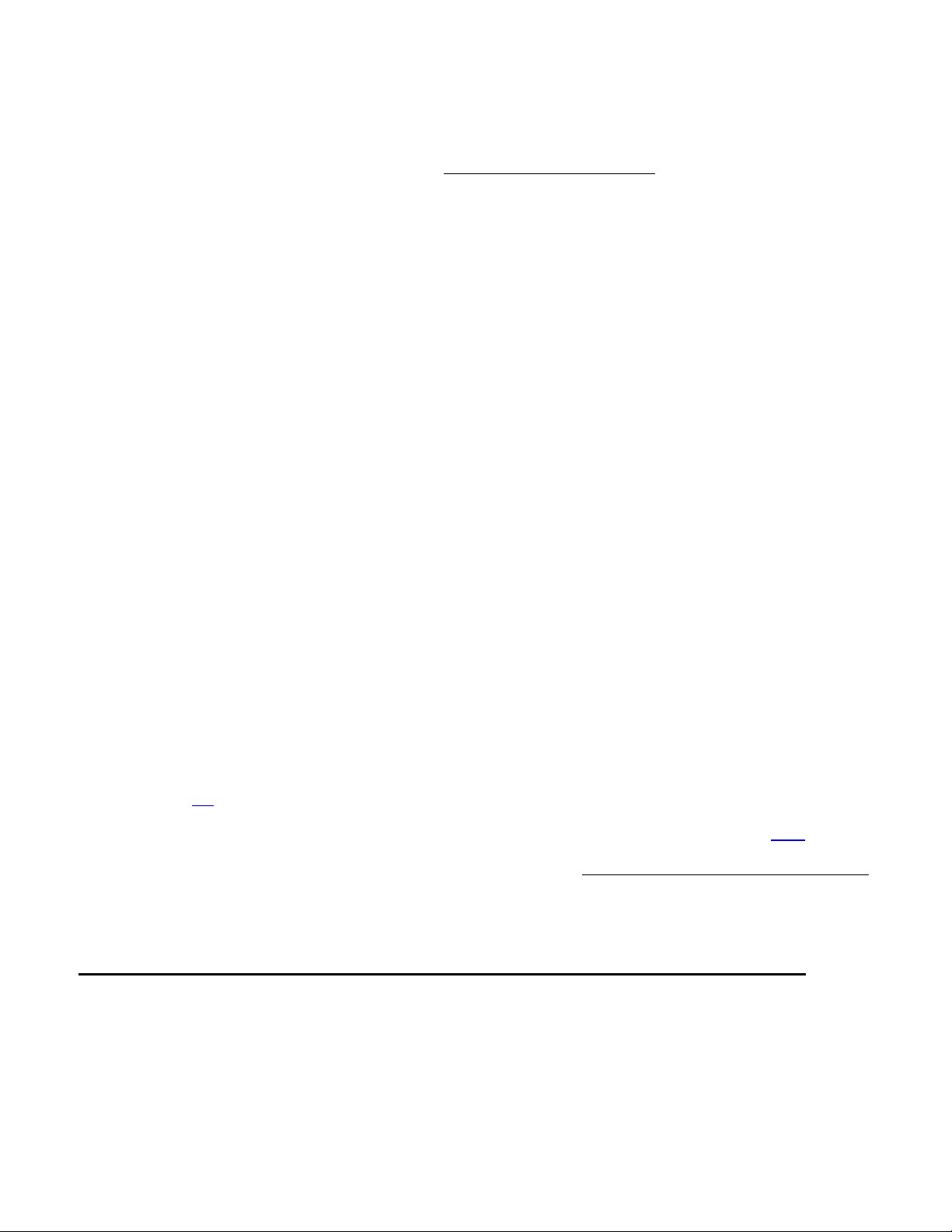

6.4. Operating Chargers in Parallel.............................................................................................................14

6.5. CANbus and RS-485 Connections—Optional .......................................................................................14

6.6. Ethernet—Optional ............................................................................................................................16

6.7. SENSbus Connection—Optional..........................................................................................................17

6.8. Remote Temperature Sensor Connection—Optional...........................................................................19

7POWER ON/POWER OFF PROCEDURES....................................................................................................... 20

7.1. Verify Input AC Supply........................................................................................................................20

7.2. Verify Configuration ...........................................................................................................................20

7.3. Verify Charger Output.........................................................................................................................21

7.4. Begin Charging ...................................................................................................................................21

7.5. Power Off...........................................................................................................................................21

8ALARMS, LEDS AND DISPLAY....................................................................................................................... 22

8.1. Front Panel User Interface..................................................................................................................22

8.2. LCD Panel...........................................................................................................................................22

8.3. AC and DC LED Indicators ...................................................................................................................22

8.4. Mimic Panel LEDs...............................................................................................................................23

8.5. Individual Alarm Relay Contacts..........................................................................................................24

8.6. Latched Alarms...................................................................................................................................24

8.7. Alarm Definitions ...............................................................................................................................24

9OPERATION................................................................................................................................................. 31

9.1. Charging Algorithms...........................................................................................................................31

9.2. Float Mode.........................................................................................................................................31

9.3. Dynamic Boost™ Mode.......................................................................................................................31

9.4. HELIX Mode........................................................................................................................................32

9.5. Charging Low or Zero-volt Batteries....................................................................................................32

9.6. Commissioning Batteries ....................................................................................................................33

9.7. Battery Check.....................................................................................................................................33

9.8. Restore Factory Defaults ....................................................................................................................33

9.9. Keypad Operation ..............................................................................................................................33

9.9.3. Menu Options ....................................................................................................................................34

9.10. Configuration with SENS Setup Utility.................................................................................................39

9.11. Temperature Compensation...............................................................................................................39

9.12. Load Share Charger Operation............................................................................................................40

10 MODBUS COMMUNICATIONS..................................................................................................................... 40

10.1. TCP/IP Modbus—Optional..................................................................................................................40

10.2. RS-485 Modbus—Optional .................................................................................................................40

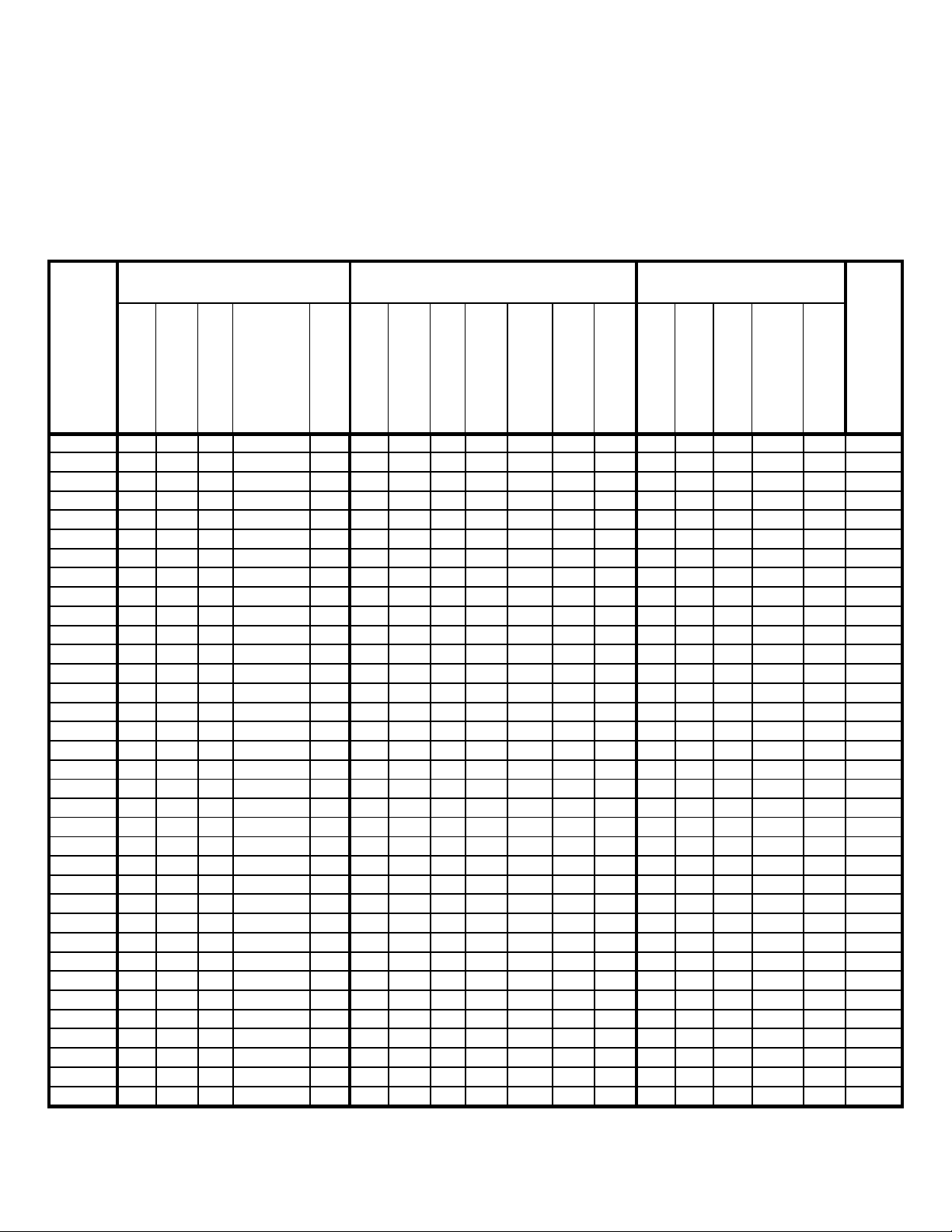

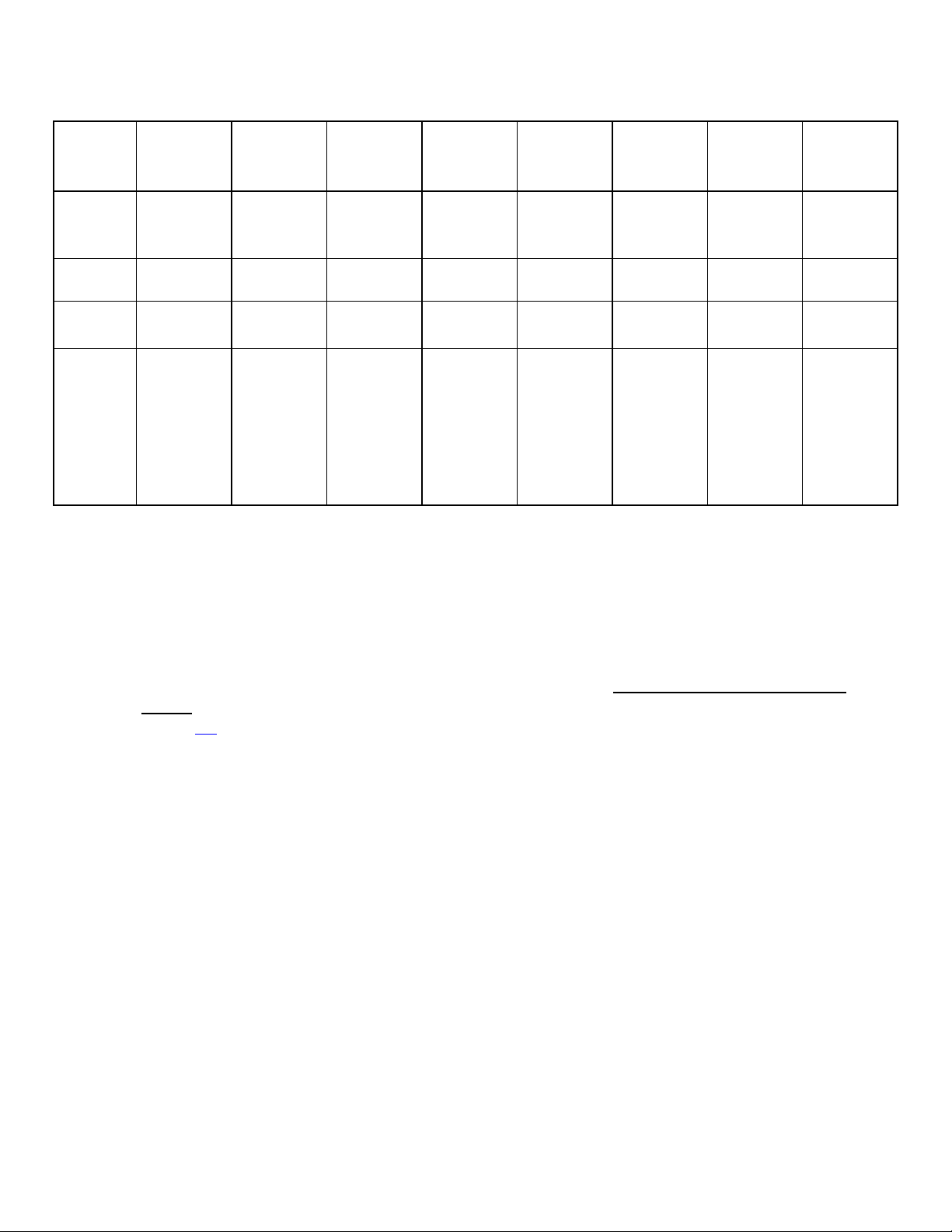

10.3. Modbus Holding Registers..................................................................................................................41

10.4. Basic Charging Alarms Bit Definition ...................................................................................................42

10.5. Charging Status Bit Definition .............................................................................................................43

10.6. Charging Alarms Extended Bit Definition.............................................................................................44

10.7. Charging AC Alarms Bit Definition.......................................................................................................44

10.8. Accessory Channel Alarms Bit Definition.............................................................................................44