Sensitron MULTISCAN++S1 Guide

MT3401E.doc rev.0 21/05/13 Pagina 1 di 86

MULTISCAN++S1

ATEX and SIL 1 certified

(64-128-256)

INSTALLATION AND USE

MANUAL

SENSITRON S.r.l. Viale della Repubblica, 48

20010 CORNAREDO MI - Italy

Tel: + 39 02 93548155 Fax: + 39 02 93548089

Technical Manual MULTISCAN++S1

MT3401E.doc rev.0 21/05/13 Pagina 2 di 86

Warning

THIS MANUAL MUST BE CAREFULLY READ BY ALL PERSONS WHO HAVE OR

WILL HAVE THE RESPONSIBILITY FOR INSTALLING, USING OR SERVICING THIS

PRODUCT.

Like any equipment, this product will perform as designed only if installed, used and

serviced in accordance with the manufacturer’s instructions. OTHERWISE, IT COULD

FAIL TO PERFORM AS DESIGNED AND PERSONS WHO RELY ON THIS PRODUCT

FOR THEIR SAFETY COULD SUFFER SEVERE PERSONAL INJURY OR DEATH.

The warranties made by Sensitron s.r.l. with respect to this product are voided if the

product is not installed, used and serviced in accordance with the instructions in this

user guide. Please protect yourself and others by following them.

We recommend our customers to write or call regarding this equipment prior to use or

for any additional information relative to use or repair.

Technical Manual MULTISCAN++S1

MT3401E.doc rev.0 21/05/13 Pagina 3 di 86

INDEX

1) INTRODUCTION................................................................................................................................... 5

1.1) SYSTEM CONFIGURATION.................................................................................................................. 6

1.2) TECHNICAL SPECIFICATIONS.............................................................................................................. 6

2) INSTALLATION.................................................................................................................................... 7

2.1) MOUNTING AND ELECTRICAL CONNECTIONS....................................................................................... 7

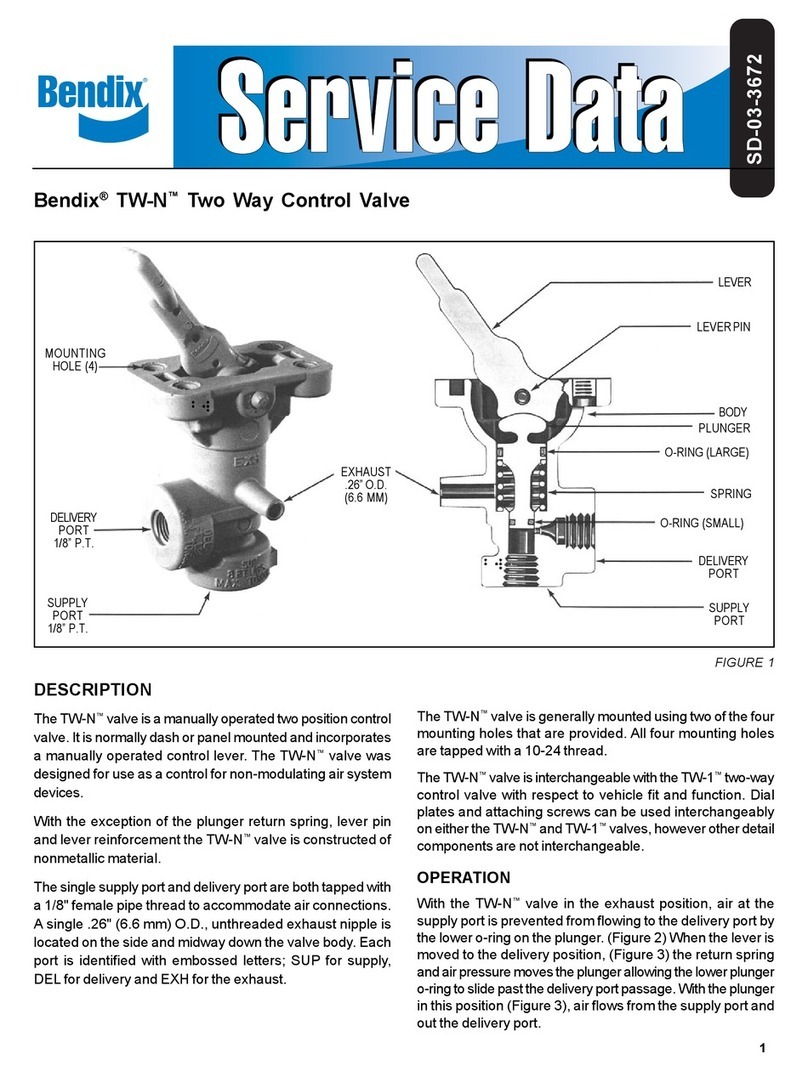

2.1.1) DIAGRAM AND PART IDENTIFICATION........................................................................................... 8

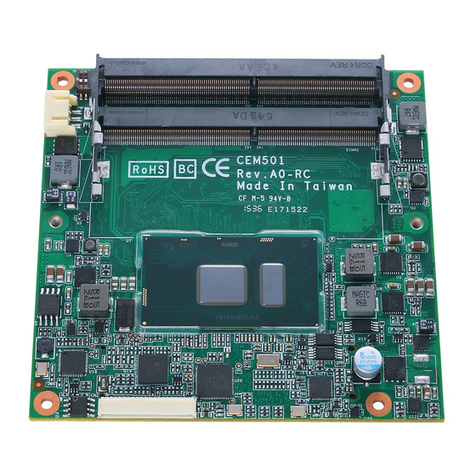

2.1.2) LAYOUT SCHEDA CENTRALE....................................................................................................... 9

2.1.3) POWER SUPPLY CONNECTIONS ................................................................................................ 10

2.1.4) DIP SWITCH SETTING FOR THE RS485 BUSS,PC COMMUNICATION AND CONTROL PANEL LANGUAGE

10

2.2) FIELD DEVICE CONNECTIONS........................................................................................................... 11

2.2.1) DETECTORS CONNECTION ....................................................................................................... 12

2.3) STG/IN8-S REMOTE INPUT MODULE................................................................................................ 17

2.1) STG/OUT16-S REMOTE OUTPUT MODULE ...................................................................................... 18

2.1.1) STG/8REL RELAY EXPANSION BOARD ..................................................................................... 19

2.1.2) STG/IN8-S AND STG/OUT16-S MODULE ADDRESSING............................................................ 19

2.1.3) DETECTOR IDENTIFICATION...................................................................................................... 21

2.2) PROGRAMMING BY PC.................................................................................................................... 21

3) SYSTEM POWER UP AND OPERATION.......................................................................................... 22

3.1) POWER ON.................................................................................................................................... 23

3.2) SYSTEM STATES AND OPERATION.................................................................................................... 24

3.2.1) SYSTEM STATES...................................................................................................................... 24

3.3) USER LEVELS................................................................................................................................. 28

3.3.1) OPERATOR LEVEL.............................................................................................................. 29

3.3.2) MAINTENANCE LEVEL.......................................................................................................... 30

3.3.3) ENGINEER LEVEL ................................................................................................................. 30

3.4) MENU DETAILS........................................................................................................................... 30

3.5) 1- MENU....................................................................................................................................... 30

3.5.1) ACTIVE EVENTS.................................................................................................................. 31

3.5.2) EVENT LOG.......................................................................................................................... 33

3.5.3) PRINT................................................................................................................................... 35

3.5.4) SYSTEM INFO...................................................................................................................... 36

3.6) 2-LOGOUT................................................................................................................................... 37

3.7) 4-LOGIN....................................................................................................................................... 37

3.8) 3-SYSTEM ................................................................................................................................... 38

3.8.1) ZONES.................................................................................................................................... 38

3.8.2) MODULES ............................................................................................................................... 40

3.8.3) RELAY OUTPUTS ..................................................................................................................... 40

3.8.4) DETECTORS (CHANNELS)........................................................................................................ 42

4) PC CONFIGURATION SOFTWARE .................................................................................................. 45

4.1) INTRODUCTION............................................................................................................................... 45

4.1.1) MINIMUN PC HARDWARE REQUIREMENTS .................................................................... 45

4.2) INSTALLATION................................................................................................................................. 45

4.3) LAUNCHING THE PROGRAM ............................................................................................................. 45

4.3.1) CONTROL PANEL SELECTION.................................................................................................... 46

4.3.2) PROGRAM HOMEPAGE............................................................................................................. 48

4.4) PROGRAM MENU............................................................................................................................. 48

4.4.1) FILE........................................................................................................................................ 49

4.4.2) SETTINGS............................................................................................................................... 53

4.4.3) USERS.................................................................................................................................... 53

4.4.4) COMMUNICATION .................................................................................................................... 57

4.4.5) REPORT ................................................................................................................................. 61

4.4.6) INFO....................................................................................................................................... 62

MT3401E.doc rev.0 21/05/13 Pagina 4 di 86

4.5) MODIFICATION OR CREATION OF A NEW CONFIGURATION FILE............................................................ 63

4.5.1) SYSTEM INFORMATION............................................................................................................. 63

4.5.2) GENERAL SETTINGS ................................................................................................................ 64

4.5.3) ZONES.................................................................................................................................... 65

4.5.5) CHANNELS.............................................................................................................................. 68

4.5.6) RELAY OUTPUS....................................................................................................................... 75

MT3401E.doc rev.0 21/05/13 Pagina 5 di 86

1) INTRODUCTION

The MULTISCAN++S1 is a gas detection control unit designed to meet the widest range of

flexibility required by the market.

The control panel is based on a powerful microprocessor which provides a wide range of self-

diagnostic procedures to detect and locate possible faults.

Extremely flexible and reliable, it can manage up to 64 or 128 or 256 gas detectors (according

to the different 4 versions). The detectors can be either of addressable type, directly connected

on buses, or 4-20mA analogical types connected via 8-input STG/IN8-S remote modules.

System architecture also includes 8 on-board machine relays and the potential to expand

outputs up to 256 using remote STG/OUT16-S modules and 8-relay boards. Up to 4 serial

buses can be connected to the unit.

The unit allows for three alarm thresholds to be set for each detector. The alarm threshold

activation mode changes according to the type of gas detection profile and connected detector

The unit is inserted in a plastic box complete with 27 Vdc 4 A power supply.

Summary table of the devices that can be connected to the various MULTISCAN++S1 unit

versions.

Panel type

Number of

serial bus

Detectors

max

number

Outputs

max number

ST.G/IN8-S

Max number

ST.G/OUT16

Max number

Notes

Multiscan++S1 64

4 open o 2

closed

64+8(*)

128+8(*)

8

8

Multiscan++S1 128

4 open or 2

closed

128+8(*)

256+8(*)

16

16

Multiscan++S1 256

4 open or 2

closed

256+8(*)

256+8(*)

32

16

(*) channels enclosed in the panel

Other MULTISCAN++S1 panel features:

Event log can be displayed on the screen or downloaded to a PC.

RS232 serial port for PC connection for programming and control via specific software.

Parallel port for printer connection.

MT3401E.doc rev.0 21/05/13 Pagina 6 di 86

1.1) System configuration

BUS 1

BUS 2

(1)

(4)

(3)

(2)

(5)

(6)

(1) (4)

(1) RILEVATORI GAS ANALOGICI 4-20 mA / 4-20 mA ANALOG GAS DETECTORS

(2) MODULO 8 INGRESSI ANALOGICI ST.G/IN8-S / ANALOG 8 INPUT MODULE

ST.G/IN8-S

(3) CAVO2 FILI TWISTATI PER Rs485 + 2 FILI PER ALIMENTAZIONE (12-24 Vdc) /

2 TWISTED WIRES FOR THE Rs485 BUS + 2 WIRES FOR THE POWER SUPPLY (12-24 Vdc)

(4) RILEVATORI GAS CON USCITASERIALE Rs485 / GAS DETECTORS WITH Rs485 OUTPUTS

(5) MODULO 16 USCITE O/C ST.G/OUT16-S / 16 O/C OUTPUTS MODULE ST.G/OUT16-S

(6) MODULO 8 RELE’ ST.G/8REL / 8 RELE’ ST.G/8REL MODULE

16 O/C

BUS 3

BUS 4

MULTISCAN ++ S1 CONTROL PANEL

E’ possibile realizzare il sistema con

4 BUS aperti oppure 2 BUS chiusi

It is possible to make the system with

4 oper BUS or 2 closed BUS

Fig. 1.1) System block diagram

1.2) Technical specifications

Technical specifications

Housing:

Plasticbox IP65 dim.L.470, H.426, D.148 mm.

Inputs:

Max. 256 detectors with RS485 communications connected on the bus or 4-20 mA via

STG/IN8 S modules

Outputs:

8 relays on the unit + 64 (or 128 or 256) Open Collector outputs on STG/OUT16-S modules

(optional STG/8REL relay board)

Unit relay contact and

optional ST.G/8REL board

capacity

16 A at 250 Vac

Serial ports:

4 x RS485 (2 for vers. 64)

1 x RS232 (PC connection)

Network connection

Optional TCP/IP module

Power:

100-120 Vac or 200-240 Vac selectable on the power supply via switch

Absorption:

Max 10 VA

Warm-up time:

Settable from 2 to 10 min. (default 3 min.)

Display:

Liquid crystal display (LCD)

Optic indications:

Double row of 9 leds

Working temp.

0/-55°C

Storage temp.

-20 ÷ +60 C°

Working RH:

15-85% (non condensed)

Storage RH

5-85% (non condensed)

MT3401E.doc rev.0 21/05/13 Pagina 7 di 86

2) INSTALLATION

2.1) Mounting and electrical connections

After opening the transparent unit door, also open the front panel by rotating the black lock to

UNLOCK.

Disconnect the two wires that lead from the unit board (JP47 and JP51 connectors) to the

bottom of the box for power connections (see fig. 2.1.1). Close the front panel turning the lock to

LOCK.

Remove the 4 screws at the 4 corners of the box and remove the front part of the unit box.

Holes can now be drilled in the back of the box for wire passage.

We recommend you use an IP65 wire clamp at wire entrance to maintain the same protection

level as the unit.

Secure the back of the unit to the wall using the holes (D) or by the enclosed brakets.

Fig. 2.1 a) Control panel box

Dimensions (mm): A 470, B 426, C 380, D 312, E 128, F 148, G 14, H 125, I 75, L 50, M 48, N

98, O 41

Connect the tri-polar mains wire to the power supply terminal board (minimum 1.5mm2

per pole) and secure it with the specific wire clamp.

Power the unit and, next, connect the red and black tipped faston wires to the 2 12 V 7

Ah max lead buffer battery power supply, housing them in the lower part of the cabinet

(bottom)

MT3401E.doc rev.0 21/05/13 Pagina 8 di 86

Vac

Power Supply

+-

BATTERIES

Fig. 2.1 b) Power supply

2.1.1) Diagram and part identification

Box version

1

2

3

8

4

5

6

7

7

1- Power Supply (27 Vdc 4A)

2- 2 x 12V 7Ah batteries (not included)

3- RS232 serial port (PC connection)

4- Parallel port (printer connection)

5- Relay outputs (8)

6- 8 detectors 4-20 mA inputs

7- Bus RS485 bus connections

8- Panel main board

Fig. 2.1.1) Unit diagram and part identification

MT3401E.doc rev.0 21/05/13 Pagina 9 di 86

2.1.2) Layout scheda centrale

Linea Rs485 1 / Rs485 Serial Line 1

Linea Rs485 2 / Rs485 Serial Line 2

Linea Rs485 3 /Rs485 Serial Line 3

Linea Rs485 4 / Rs485 Serial Line 4

Scheda Linea seriale 1

Serial Line 1 card

Scheda linea seriale 2

Serial line 2 card

Scheda linea seriale 3

Serial line 3 card

Scheda linea seriale 4

Serial line 4

CPU

Ingressi analogici 4-20 mA/ 4-20 mA analog inputs

8

7

6

5

4

3

2

1

Porta parallela stampante

Parallel printer port Porta seriale PC

PC serial port

Uscite relè

Relay outputs

Ingressi digitali

(not used)

Digital inputs

(not used)

Segnali di controllo dall’alimentatore

Control signals from power supply

Alimentazione +/- dall’alimentatore

+/- from Power Supply

+-

+-

Uscite ausiliarie di alimentazione 1 A cad.

Auxiliary power supply outputs 1 A each

Slot scheda SD

SD card slot

D3 switches: Control panel language

Language

English

Italian

Spanish

Portoguese

Sw4 Sw3 Sw2 Sw1

ON OFF OFF OFF

OFF

OFF

OFF OFF

ON ON ON

ON ON ON

ONON

Dip switch settaggio (vedi tabella)

Setting switches (see table)

Fusibile 3 A / 3A Fuse

1

2

3

4

5

6

7

8

Non usato / Not used

Fig. 2.1.2) Layout scheda centrale

MT3401E.doc rev.0 21/05/13 Pagina 10 di 86

2.1.3) Power supply connections

27,6 Vdc/ 4 A power supply

+

-

100-120 Vac

200-240 Vac

Earth

110 220

select the

input voltage

110/220V is selected by switch

Before power ON please check

Input voltage avoiding damage

Selezionare 110/220V con

lo switch all’interno. Verificare

prima di dare alimentazione,

per evitare danneggiamenti.

Scheda centrale

Control panel main board

Fig. 2.1.3) Main board power supply connection

2.1.4) DIP switch setting for the RS485 buss, PC communication and control

panel language

The series of SD2 dip-switches must be set for:

Communication (baud rate and protocol) for unit compatibility with various gas

detector versions and IN / OUT modules.

Communication (baud rate) of the RS232 serial port for the communication with

the PC

The SD3 dip switch series is for set the language text of the control panel display.

Note: the dip switch state is acquired at the control panel switch ON

D3 switches: Control panel language

Language

English

Italian

Spanish

Portoguese

Sw4 Sw3 Sw2 Sw1

ON OFF OFF OFF

OFF

OFF

OFF OFF

ON ON ON

ON ON ON

ONON

Dip switch settaggio (vedi tabella)

Setting switches (see table)

Non usato / Not used

Fig. 2.1.4) Dip-switch SD2 and SD3

MT3401E.doc rev.0 21/05/13 Pagina 11 di 86

Dip-switch 1: Baud Rate Bus RS485

Positione

Velocità comunicazione bus

Detector and Module compatibility

ON

115.200

Smart “S” gas detectors and ST.G/IN8-S /

ST.G/OUT16-S modules

OFF

9.600

Smart “3G” gas detectors and ST.G/IN8-S /

ST.G/OUT16-S modules

Dip-switches 2 and 3: RS485 bus communications protocol

Sw 2

Sw 3

Protocollo

Compatibilità Rilevatori e

Moduli

Note

ON

ON

Galileo

Smart “S” gas detectors and

ST.G/IN8-S / ST.G/OUT16-S

modules

Baud Rate 115.200

OFF

ON

IDI

OldSMARTIDI,SMART3CCand

CDdetectors.Old STG/IN8and

STG/OUT16modules.STG/IN8-N

and STG/OUT-16-Nmodules

Baud rate 9600

ON

OFF

Modbus

SMART3G gas detectors;

STG/IN8-S and STG/OUT16-S

modules

Baud rate 9600

(if SMART3G detectors are

not connected to the bus,

115.200 Bps can be set

(switch 1))

OFF

OFF

Configurazione non usata

Dip-switch 4 and 5: Communication (baud rate) of the RS232 serial port for the

communication with the PC

Sw 4

Sw 5

Baud Rate

ON

ON

9600 Bit/sec.

OFF

ON

19200 Bit/sec.

ON

OFF

38400 Bit/sec.

OFF

OFF

115200 Bit/sec. (default)

Dip-switches 6 and 7: not used

Dip-switch 8: restore default settings

Position

Function

ON

When turned on, restores unit default settings

OFF

Normal position

2.2) Field device connections

The unit has 4 RS485 data buse connected to field gas detectors. The 4 serial buses can be

used in "open" mode (4 bus) or "closed" (2 bus). The choice is set during programming with the

PC software.

Via serial bus the gas detectors are connected (directly on the bus if detectors with RS485

feature model or via the 8-input STG/IN8.S modules if 4-20 mA type) and ST.G/OUT16-S output

modules.

The length of each serial data bus is maximum 1000 mt.

MT3401E.doc rev.0 21/05/13 Pagina 12 di 86

4 conductors are required for device connections (meaning both Smart P detectors and IN and

OUT modules): 2 for the RS485 serial bus and two for device power. For this reason, two

different wires must be used or a single wire that has suitable characteristics, described below.

-) The RS485 serial bus must be connected with an EIA RS 485 connection wire: No. 2

conductors with 0.22/0.35 mm2section + shield (TWISTED PAIR). Nominal capacity between

conductors < 50 pF/m, nominal impedance 120 ohm. Total line length with this type of

connection must not exceed 1.000 meters. An example of a recommended wire is a BELDEN

9841 or similar wire (EIA RS485 data transmission wire). Only connect detectors (and IN and

OUT modules) in cascade. Avoid tree or delta connection since they reduce interference

immunity.

-) Detector power supply (and IN and OUT modules on the bus) must be connected with a 2-

core wire with adequate section based on the number of connected devices, their distance from

the power supply and each device’s consumption (please see the technical manual enclosed

with gas detectors for this purpose).

The different Multiscan++S1 unit versions can support a different number of detectors from 64

to 256.

Each device connected on the unit's RS485 bus must have its own univocal address. STG/IN8

S and STG/OUT16-S module address settings are described later in this manual. See the

manual of the detector for its address settings.

Note: for the MTS++S1 256 version, the maximum number of connectible points on a single bus

is 128.

2.2.1) Detectors connection

Gas detectors can be connected to the MULTISCAN++S1 control panel in two different

ways, based on the detector output signal.

1) 4-20 mA analogue proportional output.

The detector connected to the unit and ST.G/IN8 S modules will send a 4-20 mA signal

referring to its range (i.e. 0-300 ppm, 0-30 ppm, 0-100% LEL etc.) and the unit, suitably

programmed, will display the relevant gas concentration indication measured by the

detector and consequently activate the alarms when the set values are reached.

2) RS485 digital proportional output

The detector connected to the unit will send a data signal on the RS485 line. This signal

is referring to its range (i.e. 0-300 ppm, 0-300 ppm, etc.) and the unit, suitably

programmed, will display the relevant gas concentration indication measured by the

detector and consequently activate the alarms when the set values are reached.

MT3401E.doc rev.0 21/05/13 Pagina 13 di 86

Detectors with 4-20mA output

Detectors with 4-20mA analog output are connected to the unit via remote 8-input modules

STG/IN8-S. The modules are connected on the panel's bus to be field mounted far from the

control panel.

A 4-20mA transmitter requires a 3-core wire for connections: 2 wires for power supply (usually

12 to 28 Vdc but refer to the gas detector technical manual) and one wire for the 4-20mA signal.

A 3x0.75mm2shielded wire is recommended since it can cover a 100 m distance between the

gas detector and STG/IN8-S input module.

Detectors with 4-20 mA output directly connected to the unit

Scheda centrale / panel main board

Det.1

Det.2

Det.3

Det.4

Det.5

Det.6

Det.7

Det.8

S

Fig. 2.2.1 a) Connection of the 8 detectors of the control panel

Rilevatori con uscita 4-20 mA collegati a moduli ST.G/IN8-S

The following diagram illustrates connections between a 4-20mA gas detector and a STG/IN8 S

input module. When starting the system, make sure minimum 12Vdc voltage reaches each gas

detector.

-V

I8

I7

I6

I5

+V

-V

I4

I3

I2

I1

+V

-V

B

A

+V

REMOTE INPUT

MODULE ST/G.IN8

(+V) (-V)

(S)

Positive

Negative

4-20 mA

signal

4-20 mA

analog

gas

detector

Rilevatore

analogico

4-20 mA

MODULO INGR.

4-20 mA ST/G.IN8

Fig. 2.2.1 b) Connection of the 8 detectors of the ST.G/IN8-S module

MT3401E.doc rev.0 21/05/13 Pagina 14 di 86

Detectors with RS485 output

Detectors with RS485 digital outputs are directly connected to the RS485 bus.

4 wires are required in this type of connection: 2 for the RS485 serial bus and 2 for

device power supply. For this reason we suggest you use two different wires or a single

wire with suitable features as described below.

-) The RS485 serial bus must be connected with an EIA RS 485 connection wire: No. 2

wires with 0.22/0.35 mm2section with shield (TWISTED PAIR). Nominal capacity

between conductors < 50 pF/m, nominal impedance 120 ohm. Total line length with this

type of connection must not exceed 1,000 metres. An example of a recommended cable

is a BELDEN 9841 or similar wire (EIA RS485 data transmission wire). Only connect

detectors (and IN and OUT modules) in cascade. Avoid tree or star connections since

they reduce interference immunity.

-) The power supply to the detectors (and IN and OUT modules on the bus) must be

connected with a 2-core wire with adequate section based on the number of

connected devices, their distance from the power supply and each device’s

consumption (please see the technical manual enclosed with gas detectors for this

purpose).

Note: each detector connected on the RS485 line must have its own univocal address between

1 and 255 (247 for the ModBus protocol). Please see the gas detector technical manual for

address settings.

The following diagram illustrates the connection on the bus of gas detectors and remote

IN/8 or OUT/16 modules to the control panel.

MT3401E.doc rev.0 21/05/13 Pagina 15 di 86

Scheda centrale / panel main board

+ - AB

+ - AB

+ - AB

+ - AB

+ - A B

+-

+-

+-

+-+-

+-

+

-

A

B

Dalla centrale o dall’alimentatore ausiliario remoto

From the control panel or from the remote auxiliary power supply

Cavo twistato / schermato 2x022 (Belden 9841 o equivalente)

Twisted / shielded 2x0,2 cable (Belden 9841 or equivalent)

Loop1

Loop2

Loop3

Loop4

Al rilevatore o modulo

successivo

To the next detector

or module Come Loop 1

As Loop 1

Fig. 2.2.1 c) RS485 bus devices connection (Open bus)

MT3401E.doc rev.0 21/05/13 Pagina 16 di 86

Scheda centrale / panel main board

+ - AB

+ - AB

+ - AB

+ - AB

+ - A B

+-

+-

+-

+-+-

+-

+

-

Dalla centrale o dall’alimentatore ausiliario remoto

From the control panel or from the remote auxiliary power supply

Cavo twistato / schermato 2x022 (Belden 9841 o equivalente)

Twisted / shielded 2x0,2 cable (Belden 9841 or equivalent)

Bus1

Bus3

Bus4

Come Bus 1-2

As Bus 1-2

B

B

A

A

Bus2

Fig. 2.2.1 d) RS485 bus devices connection (Closed bus)

MT3401E.doc rev.0 21/05/13 Pagina 17 di 86

2.3) STG/IN8-S remote input module

STG/IN8-S remote modules are field mounted and are connected to the panel via

RS485 buses. They are used to connect 8 x 4-20mA analog gas detectors. Each

module must be addressed using the rotary switches on the PCB. The address must be

univocal and between 1 and 255. For the maximum number of modules, see the table at

chapter. 1- Introduction

Jumper da non manomettere

/ jumpers not to be touched

Jp1

Jp2

Jp3

Jp4

Jp9

Jp11

Jp12

Jp14

Closed 1-2

Closed

Closed

Open Open

Open

Closed 1-2

Led

DL1: Guasto WD /WD Faul

DL2: TX Data

DL3: RX Data

DL4: RTS

Jp10 Resistenza di file linea

(EOL resistor)

Se il modulo è l’ultimo della linea chiudere Jp10

/ If the module is the last of the bus line, close JP10

A

B

Rs485 serial line

Morsettiera alimentazione e linea seriale

(Power supply and serial line)

Jp13 Communication Baud Rate setting:

Closed 115.000 bps (Multiscan++ control panel

Open 9.600 bps (old Galileo Multiscan control panel)

Jp13 Settaggio velocità comunicazione:

Chiuso 115.000 bps (Centrale Multiscan ++)

Aperto 9.600 bps (vecchia centrale Galileo Multiscan)

Commutatori rotativi

per l’indirizzo del modulo

Channels 5-8 Channels 1-4

-V +V-V +V

Morsettiera rilevatori

(gas detector connections)

Open

Rotary switches for

the module address)

Fig. 2.3) ST.G/IN8-S module

MT3401E.doc rev.0 21/05/13 Pagina 18 di 86

2.1) STG/OUT16-S remote output module

STG/OUT16-S remote modules are field mounted and connected to the panel via RS485 buses.

They provide 16 Open Collector outputs (negative switch) with programmable functions to

remotely trigger Sirens, Solenoid valves, Relays, etc. Each STG/OUT16-S module can be

connected to up to 2 boards of 8 relays that convert the Open Collector output to a powerless

exchange contact.

Each module must be addressed using the rotary switches placed on the PCB. The address

must be univocal and between 1 and 255 (1-247 for the Modbus protocol).

For the maximum number of modules, see the table at chapter. 1- Introduction

Morsettiera alimentazione

e linea seriale

(Power supply and serial line)

Commutatori rotativi per

l’indirizzo del modulo

Jp13 Communication Baud Rate setting:

Closed 115.000 bps

(Multiscan++ control panel

Open 9.600 bps

(old Galileo Multiscan control panel)

Jp13 Settaggio velocità comunicazione:

Chiuso 115.000 bps

(Centrale Multiscan ++)

Aperto 9.600 bps

(vecchia centrale Galileo Multiscan)

Led

DL1: Guasto WD /WD Faul

DL2: TX Data

DL3: RX Data

DL4: RTS

Resistenza di file linea

(EOL resistor)

chiudere s

close i

è l’ultimo della linea /

f the module

is the last of the bus line

e il modulo

-V +V -V

Morsettiera uscite O/Ci

(O/C output connections)

Outputs 9-16 Out 1-8

A

B

Rs485 serial line

Collegamento scheda relè (opzionale)

/ Relay board connection (optional)

Jumper da non manomettere

/ jumpers not to be touched

Jp5

Jp6

Jp7

Jp8

Jp9

Jp11

Jp12

Closed 1-2

Closed

Closed

Open

Open

Open

Open

Rotary switches

for the module address

+V

+V

+V

Esempio di collegamento relè

Example of relay connection

Fig. 2.4) STG/OUT16-S module

MT3401E.doc rev.0 21/05/13 Pagina 19 di 86

2.1.1) STG/8REL relay expansion board

The STG/8REL 8-relay expansion board converts STG/OUT16-S O/C outputs into voltage free

changeover contact. Up to two relay boards can be connected to each output module. A relay

board is directly connected to the output module (J1 connector) and a second relay board is

connected to the first.

Esempiocollegamento

/ Connectionexample

Fig. 2.4.1) Relay board connection to the output module

2.1.2) STG/IN8-S and STG/OUT16-S module addressing

STG/IN8-S and STG/OUT16-S modules are addressed using the two rotary switches in

RSW 1 and 2 hexadecimals. Rotary switches permit hexadecimal settings (base 16).

Each switch as 16 positions (0-F) and the pointer is positioned on the number chosen

using a screwdriver to create a decimal value between 1 and 255 (see table 1).

For the maximum number of modules, see the table at chapter. 1- Introduction.

Each module must have univocal address in the system. Dual addresses are not

permitted even if modules are on different serial buses.

MT3401E.doc rev.0 21/05/13 Pagina 20 di 86

Example:

Se i due commutatori sono posizionati come sopra, RSW2 su 0 ed RSW1 su D, l’indirizzo

corrispondente in decimale è 13 (vedi tabella 1)

If the address switches are set in this manner, RSW2 at 0 and RSW1 at D, the corresponding address in

decimal number would be 13 (see table 1).

Tabella1: Conversione da decimale ad esadecimale

Table 1: Conversion from decimal to hexadecimal numbers

DEC

HEX

DEC

HEX

DEC

HEX

DEC

HEX

DEC

HEX

DEC

HEX

DEC

HEX

1

01

38

26

75

4B

112

70

149

95

186

BA

223

DF

2

02

39

27

76

4C

113

71

150

96

187

BB

224

E0

3

03

40

28

77

4D

114

72

151

97

188

BC

225

E1

4

04

41

29

78

4E

115

73

152

98

189

BD

226

E2

5

05

42

2A

79

4F

116

74

153

99

190

BE

227

E3

6

06

43

2B

80

50

117

75

154

9A

191

BF

228

E4

7

07

44

2C

81

51

118

76

155

9B

192

C0

229

E5

8

08

45

2D

82

52

119

77

156

9C

193

C1

230

E6

9

09

46

2E

83

53

120

78

157

9D

194

C2

231

E7

10

0A

47

2F

84

54

121

79

158

9E

195

C3

232

E8

11

0B

48

30

85

55

122

7A

159

9F

196

C4

233

E9

12

0C

49

31

86

56

123

7B

160

A0

197

C5

234

EA

13

0D

50

32

87

57

124

7C

161

A1

198

C6

235

EB

14

0E

51

33

88

58

125

7D

162

A2

199

C7

236

EC

15

0F

52

34

89

59

126

7E

163

A3

200

C8

237

ED

16

10

53

35

90

5A

127

7F

164

A4

201

C9

238

EE

17

11

54

36

91

5B

128

80

165

A5

202

CA

239

EF

18

12

55

37

92

5C

129

81

166

A6

203

CB

240

F0

19

13

56

38

93

5D

130

82

167

A7

204

CC

241

F1

20

14

57

39

94

5E

131

83

168

A8

205

CD

242

F2

21

15

58

3A

95

5F

132

84

169

A9

206

CE

243

F3

22

16

59

3B

96

60

133

85

170

AA

207

CF

244

F4

23

17

60

3C

97

61

134

86

171

AB

208

D0

245

F5

24

18

61

3D

98

62

135

87

172

AC

209

D1

246

F6

25

19

62

3E

99

63

136

88

173

AD

210

D2

247

F7

26

1A

63

3F

100

64

137

89

174

AE

211

D3

248 (*)

F8

27

1B

64

40

101

65

138

8A

175

AF

212

D4

249 (*)

F9

28

1C

65

41

102

66

139

8B

176

B0

213

D5

250 (*)

FA

29

1D

66

42

103

67

140

8C

177

B1

214

D6

251 (*)

FB

30

1E

67

43

104

68

141

8D

178

B2

215

D7

252 (*)

FC

31

1F

68

44

105

69

142

8E

179

B3

216

D8

253 (*)

FD

32

20

69

45

106

6A

143

8F

180

B4

217

D9

254 (*)

FE

33

21

70

46

107

6B

144

90

181

B5

218

DA

255

(**)

FF

34

22

71

47

108

6C

145

91

182

B6

219

DB

35

23

72

48

109

6D

146

92

183

B7

220

DC

36

24

73

49

110

6E

147

93

184

B8

221

DD

37

25

74

4A

111

6F

148

94

185

B9

222

DE

(*) Indirizzi non disponibili con protocollo Modbus / not available addresses for the Modbus protocol

(**)Indirizzo non disponibile con protocollo Galileo / not available addresse for the Galileo protocol

Other manuals for MULTISCAN++S1

1

This manual suits for next models

3

Table of contents

Other Sensitron Control Unit manuals

Popular Control Unit manuals by other brands

AXIOMTEK

AXIOMTEK CEM501 Quick installation guide

Spirax Sarco

Spirax Sarco HP70 Series Installation and maintenance instructions

Robostar

Robostar N1 Series Option DeviceNet manual

OPTILAB

OPTILAB DFB-CWDM-M user manual

Flycolor

Flycolor Francy 2 Series user manual

Quectel

Quectel LTE-A Series Hardware design