SENSTAR Intelli-FLEX II User manual

Intelli-FLEX™II

Perimeter Protection System-Relay Output Processor

Product

Guide

C6DA0602-001, Rev K

First edition

October 9, 2008

Senstar Corporation

119 John Cavanaugh Road

Carp, Ontario

Canada K0A 1L0

Tel: +1 (613)-839-5572

Fax: +1 (613)-839-5830

Website: www.senstar.com

Email address: info@senstar.com

See back cover for regional offices.

C6DA0602-001, Rev K

First edition

October 9, 2008

Senstar is a registered trademark, and Intelli-FLEX and the Senstar logo are trademarks of Senstar Corporation. Product names

and Company names used in this manual are included for identification purposes only, and are the property of, and may be

trademarks of, their respective owners. Copyright © 2008, 2006, 2004, 2003, 2002, 1999 Senstar Corporation. All rights

reserved. Printed in Canada.

The information provided in this guide has been prepared by Senstar Corporation to the best of its ability. Senstar Corporation is

not responsible for any damage or accidents that may occur due to errors or omissions in this manual. Senstar Corporation is not

liable for any damages, or incidental consequences, arising from the use of, or the inability to use, the software and equipment

described in this guide. Senstar Corporation is not responsible for any damage or accidents that may occur due to information

about items of equipment or components manufactured by other companies. Features and specifications are subject to change

without notice. Any changes or modifications to the software or equipment that are not expressly approved by Senstar

Corporation void the manufacturer’s warranty, and could void the user’s authority to operate the equipment.

Senstar’s Quality Management System is IS0 9001:2000 registered.

Approvals

Canada: This Class B digital apparatus meets all requirements of the Canadian Interference -Causing Equipment Regulations.

Cet appareil numérique de la classe B respecte toutes les exigences du Règlement sur le matériel brouilleur du Canada.

USA: This device complies with part 15 of the FCC Rules. Operation is subject to the following two conditions: (1) This device may

not cause harmful interference, and (2) this device must accept any interference received, including any interference that may

cause undesired operation.

The use of shielded cables is required for compliance.

Any changes or modifications not expressly approved by Senstar Corporation could void the user’s authority to operate the

equipment.

Note: This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant to part 15 of the

FCC Rules. These limits are designed to provide reasonable protection against harmful interference in a residential

installation.This equipment generates, uses and can radiate radio frequency energy and, if not installed and used in accordance

with the instructions, may cause harmful interference to radio communications. However, there is no guarantee that interference

will not occur in a particular installation. If this equipment does cause harmful interference to radio or television reception, which

can be determined by turning off and on, the user is encouraged to try to correct the interference by one or more of the following

measures:

- Reorient or relocate the receiving antenna.

- Increase the separation distance between the equipment and the receiver.

- Connect the equipment into an outlet on a circuit different from that to which the receiver is connected.

- Consult the dealer or an experienced radio/TV technician for help.

The use of shielded cables is required for compliance.

Intelli-FLEX IIproductguide • • • toc-1

Table of contents

1Overview

What is Intelli-FLEX II - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-1

Purpose of this guide - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-2

2 Principles of operation

Adaptive signal processing - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-1

Intruder detection - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-2

System supervision - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-3

3 System components

Standard components - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-2

Optional components - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-7

4 Site planning

Site planning guidelines- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-1

Site Survey - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-2

Upgrade existing structures - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-3

Perimeter layout guidelines - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-8

Equipment requirements - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-17

5 Installation instructions

Overview- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-1

Basic sensor cable installation - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-2

Cable installation on different fence types - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-9

Installation of cable at gates - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-13

Gate bypass module - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-23

Cable devices - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-34

Installing the Intelli-FLEX II processor - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-37

Intelli-FLEX II processor settings- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-39

tableof contents

toc -2 • • • Intelli-FLEXII product guide

6 The Configuration module

Modes of operation - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6-2

7 System calibration

Connecting the Configuration module - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7-1

Configuration settings - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7-3

Zone profile evaluation - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7-10

a Maintenance/Troubleshooting

Maintenance - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - a-1

Troubleshooting - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - a-2

Supervision related problems - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - a-3

Detection problems - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - a-7

False/Nuisance alarm problems - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - a-10

Power problems - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - a-12

Configuration module problems- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - a-15

b Spare parts list

c Component specifications

Intelli-FLEX II Processor - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - c-1

Gate bypass module - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - c-2

Glossary

Index

Mark 2 sensor cable installation procedure

Introduction - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -1

Cable stabilization procedure- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -1

Sensor cable installation guidelines - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2

Installation procedure - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -3

Adjusting low sensitivity detection spots - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -4

Intelli-FLEX IIproduct guide • • • 1 - 1

1Overview

What is Intelli-FLEX II

Intelli-FLEX II is an outdoor perimeter intrusion detection sensor system. It

employs a passive coaxial cable detector, which is installed on the perimeter

fence, to detect intrusion attempts. The cables can sense any vibration along the

fence caused by climbing, cutting, or otherwise disturbing the fence fabric.

Each Intelli-FLEX II processor contains the electronics necessary to monitor one

or two sensor zones, and to report sensor alarms and supervision status via relay

contacts.

Features

•Easytoinstall

• Low cost, highly sensitive, consistent detection

• State of the art microcontroller-based processor

• User definable configuration parameters

• Detachable configuration module

• Discriminates between intrusion attempts and weather related events

• Lightning, EMI, and RFI protection

• Separate relay outputs for intrusion alarms and supervision in each zone

•Tampersensor

• AC-powered float charger - Provides 13.5 VDC to power processor and charge

battery (requires backup battery)

• 12 VDC Gel Cell backup battery - 8 hours of standby operation

• Wide voltage range DC/DC converter input for larger site installations

Purposeof this guide

1- 2 • • • Intelli-FLEX IIproductguide

Purpose of this guide

This is the product guide for the Intelli-FLEX II DC/DC powered relay output

processor. This guide includes information to assist you in selecting, installing,

calibrating and maintaining the components of your Intelli-FLEX II system.

Intelli-FLEX IIproduct guide • • • 2 - 1

2Principles of operation

The Intelli-FLEX II system uses a disturbance sensitive sensor cable to detect

intrusion attempts. The sensor cable acts as a distributed microphone along a

perimeter fence. It can be used as an alarm sensor, anywhere that there is

significant noise caused by an intrusion event.

Sensor cables, installed on an existing fence, detect vibrations in the fence fabric.

The signals generated by the vibrations are continually evaluated by the

Intelli-FLEX II processor to determine if an alarm should be generated.

The vibrations of the fence could be the result of the weather or they could be

caused by an intruder attempting to penetrate the perimeter by climbing over,

lifting, or cutting through the fence. The Intelli-FLEX II processor evaluates the

signals and discriminates between actual intrusion attempts and weather related

events.

The Intelli-FLEX II system monitors the processor’s power level. If there is a

significant fluctuation in the power, a supervision alarm will be generated.

In most applications, the processor can be programmed by the user for optimum

performance. In addition, the system firmware can be modified at the factory, for

unusual applications.

Adaptive signal processing

The Intelli-FLEX II system continuously monitors and evaluates signals from the

sensor cables. To avoid nuisance alarms, the system compensates for signals that

are picked up by the sensor cables due to wind and rain.

Intruder detection

2- 2 • • • Intelli-FLEX IIproductguide

Intruder detection

There are three basic intrusion attempt scenarios:

• Cut scenario - An intruder attempts to gain access to a secure area by cutting

the fence fabric until enough links have been separated to allow the intruder

to gain entry.

• Climb scenario variation 1 (climb-over) - An intruder attempts to gain access

to a secure area by climbing over the fence.

•Climbscenariovariation2(crawl-under) - An intruder attempts to gain access

to a secure area by lifting the fence fabric, and crawling under it.

The Intelli-FLEX II system recognizes these scenarios and can discriminate

between them and environmental activity.

Cutdetection

The processor detects an attempt to cut through the fence if:

• sensor cable stimulation exceeds the preset cut threshold parameter;

• the number of times that the cut threshold is exceeded is greater than the

preset cut count; and

• the preset cut count is exceeded within the preset cut window (time frame).

When the fence fabric is cut an impulse of energy produces a high initial

amplitude signal that exceeds the cut threshold. Each time the cut threshold is

exceeded a cut event is recorded. Cut activity will activate a cut counter. The cut

counter has a preset number of cuts that must occur within a preset time window

in order for the system to indicate that an intrusion attempt has occurred.

If the cut count is not exceeded within the preset time window, the counter

resets. If it is exceeded, the system identifies an intrusion attempt and will

generate a cut alarm.

Climbdetection

The processor detects an attempt to climb over or crawl under the security

perimeter if:

• sensor cable stimulation is sufficient to exceed the preset climb threshold

parameter;

• the climb threshold is exceeded for a preset cumulative period called the

climb time; and

• the climb time is accumulated within the preset climb window (time frame).

Systemsupervision

Intelli-FLEX IIproduct guide • • • 2 - 3

When an intruder attempts to climb over the fence, the action of feet and hands

pulling on and impacting the fence fabric, as well as strain in the fence fabric, will

cause a large number of energy pulses to rapidly occur. Pulling up on the fabric to

crawl under the fence creates a similar scenario. This type of contact with the

fence fabric will cause the preset climb threshold to be exceeded.

The initial contact will activate a climb time counter. The climb time counter

accumulates energy caused by climbing action. A preset number of climb contacts

must occur within a preset climb window time in order for the system to indicate

that an intrusion attempt has occurred.

If the climb activity count is not exceeded within the preset climb window the

climb counter resets. If the number is exceeded, the system identifies the activity

as an intrusion attempt and will generate a climb alarm.

System supervision

The Intelli-FLEX II system monitors itself to ensure that its protection capability is

not compromised. If that capability has been compromised, the system will

generate a supervision alarm. Supervision alarms can occur for several reasons:

• a sensor cable line supervision current fluctuation, which may indicate:

• sensor cable damage,

• a defective splice, or

• a defective terminator

• power failure, or low DC power

• processor enclosure door open

Unlike the intrusion alarm, which resets after detection, the supervision alarm

remains on until the problem is corrected.

Sensorcable linesupervision currentfluctuation

A terminator device is installed at the end of the sensor cable, to permit a small

DC supervision current throughout the entire length of the sensor cable. If the

current exceeds the defined limits, a supervision alarm will occur for that zone.

Systemsupervision

2- 4 • • • Intelli-FLEX IIproductguide

Damagedor defectivecomponents

A defect or cut in the sensor cable, non-sensitive feed cable, cable splice or

terminator will cause a supervision alarm.

If the terminator device is defective or damaged the supervision current will

fluctuate, causing a supervision alarm.

Powerfail

A voltage sensor monitors the internal 12 volt line and signals the system if the DC

voltage is too low. If the DC voltage drops, but remains above the low DC

threshold, the system will generate a power fail supervision alarm in both zones.

The system will maintain normal zone alarm detection capabilities while in this

condition.

LowDC voltageshutdown

When the DC voltage on the internal 12 volt line drops below the voltage

required to operate the system reliably (8 VDC), a low DC voltage condition

occurs. When this happens, the alarm and supervision relays for both zones

activate and the entire system shuts down. Once the DC voltage on the 12 volt

line increases to at least 11 VDC, the condition will clear and the system will

resume operation.

Tamper

The Intelli-FLEX II system uses a solid-state sensor to detect if the enclosure door

is open.

A magnet is mounted on a standoff on the enclosure door. The magnet must be

close to the tamper sensor located on the processor for the tamper alarm to be

deactivated. When the enclosure door is opened the magnet is moved away from

the sensor. This action causes a supervision alarm to occur in the zones that are

connected to the processor. The system will maintain normal zone alarm

detection capabilities while in this alarm condition.

Refer to Appendix a - Troubleshooting, Tamper Supervision for instructions on

clearing tamper alarms.

Intelli-FLEX IIproduct guide • • • 3 - 1

3System components

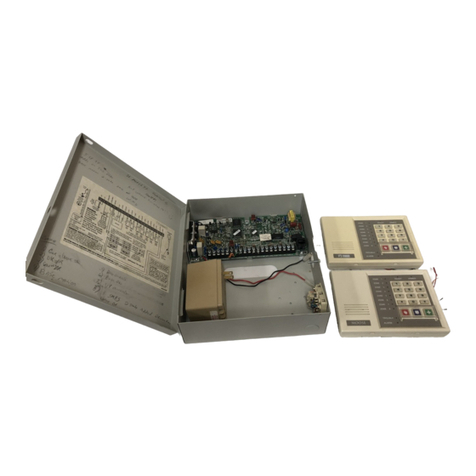

Figure 3-1 Intelli-FLEX II system diagram

Each Intelli-FLEX II system is a self contained detection system.

The basic Intelli-FLEX II system requires the following

components:

The following optional components can be added to

the basic system:

• Intelli-FLEX II dual zone

processor

• cable splice kit • sliding gate disconnect assembly

• tie wraps • gate bypass module

• sensor cable • enclosure

• non-sensitive feed cable • power supply

• cable terminator kit • configuration module

(order separately)

Zone 1

Zone 2

Cut

Climb

Time Window

Threshold

Cut Count

Climb Time

Display

Select

Increase

Decrease

Load /

Self Test

Configure

Monitor

Mode

Select

Alarm

Supervision

Clear

Level

Relay Time

Cut Profile

Peak Trigger

Ambient Comp

Common Mode

Function

Select

Intelli-FLEX™

zone 2

zone 1

dual zone processor

24 VDC gel-cell battery

& float charger

(optional) configuration module

sensor cable

non-sensitive feed cable

cable terminator

cable splice

At least one Configuration

module is required at each

installation for system

configuration and

calibration.

Standardcomponents

3- 2 • • • Intelli-FLEX IIproductguide

Standard components

Dualzone processor

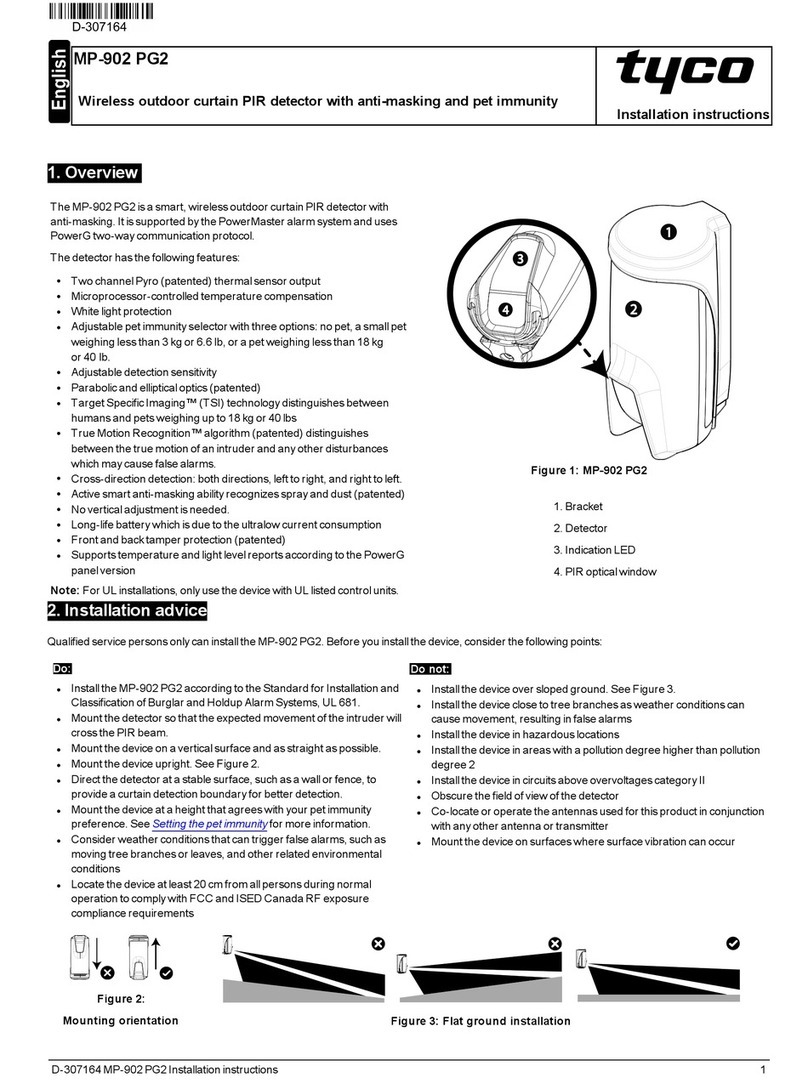

Figure 3-2 Dual zone processor

The Intelli-FLEX II dual zone processor contains the circuitry necessary to

monitor one or two independent sensor zones. Generally, these two zones are

located beside each other. When used to monitor two zones, the Intelli-FLEX II

dual zone processor is capable of monitoring 610 meters (2,000 ft.) of sensor

cable, 305 meters (1,000 feet) per zone. For a single cable pass installation, with

service and corner loops included, this means that approximately 575 m (1885 ft.)

of fence can be monitored by one dual zone processor.

Non-sensitive feed cables are spliced together with the sensor cables and

connected to the processor at the F-connectors located at the top of the processor

card.

The terminal blocks along the bottom of the processor card contain connection

capacity for the processor power supply, alarm monitoring/reporting systems.

Corresponding LEDs indicate supervision and intrusion alarms for both zones 1

and 2, and system power on status.

Standardcomponents

Intelli-FLEX IIproduct guide • • • 3 - 3

A plug-in connector allows you to connect the configuration module to the

processor.

Intelli-FLEX II processors containing relay outputs can be used with existing

E-Flex sensor cable installations. They can replace existing EIIA, EIIAHR, EIIB,

EIIBHR and E3i processors.

Sensorcables

Intelli-FLEX sensor cables are sensitive to physical disturbance. Because they are

mounted directly on existing fences, anything that causes the fence fabric to

vibrate, such as shaking or hitting the fence, will be transferred to the sensor

cable.

These disturbances generate electronic signals that are representative of the fence

activity. The signals are passed from the sensor cables to the processor where they

are analyzed.

Non-sensitivefeed cable

The non-sensitive coaxial feed cable does not detect vibrations. It is used

primarily in two instances. In both cases, the non-sensitive feed cable allows the

signals that are generated through the sensor cable to be routed to the processor.

The sensor cable cannot be connected directly to the processor, therefore, a

section of non-sensitive feed cable, complete with an F-connector, is spliced to

the end of the sensor cable. The feed cable is then connected to the processor at

the F-connector.

The non-sensitive feed cable is also used to bypass gates or buildings. This is

accomplished by splicing a section of the feed cable to the sensor cable zone at

the location of the gate or building.

The input power of the Intelli-FLEX II processor may be different

from the existing one. Be sure to use the new power transformer. If

you are using distributed power, consult Senstar to determine the

compatibility with existing installations.

Caution

Standardcomponents

3- 4 • • • Intelli-FLEX IIproductguide

Cableterminator

Figure 3-3 Cable terminator

The cable terminator is a moisture proof termination device that enables the

supervision current to pass through the sensor cable. It is installed at the end of

the sensor cable away from the processor.

Cablesplice

Figure 3-4 Cable splice

The cable junction device is a moisture proof splice kit. It is used to splice

non-sensitive feed cable to sensor cable, or to connect two pieces of sensor cable

together.

Standardcomponents

Intelli-FLEX IIproduct guide • • • 3 - 5

Tiewraps

UV-resistant nylon tie wraps are used to secure the cables, cable terminator and

cable splice kits to the fence fabric.

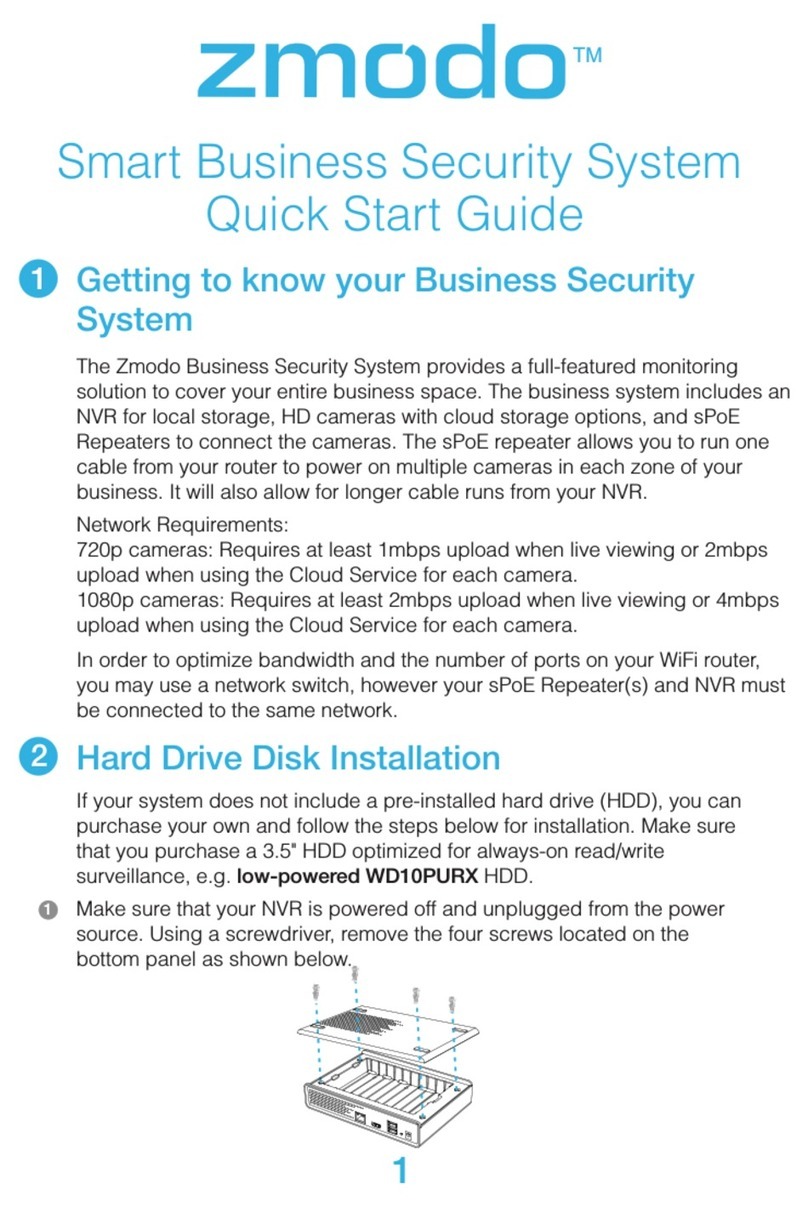

Configurationmodule

Figure 3-5 Configuration module

A detachable configuration module enables the operator to monitor the system

operation and response, and to view or change the system configuration.

Powersupplyoptions

The Intelli-FLEX II DC/DC dual zone processor can be powered one of two ways:

• DC power/float charger and rechargeable battery

• a centrally located low voltage DC power source (18 to 56 VDC)

DC power/float charger and rechargeable battery

The DC power/float charger is the most feasible option when AC power is

convenient and the AC power receptacle is protected from the weather. The DC

power/float charger is merely plugged into the AC power source and 12 VDC is

applied to the processor in parallel with a 12 VDC Gel Cell battery. This is often

the best case for small installations that involve one or two processors. The DC

power/float charger is capable of supplying 12 VDC to the processor, and

charging the 12 volt Gel Cell Battery. A battery must be located at each processor

or at the DC power/float charger.

Cut

Increase

Decrease

Mode

Select

Clear

Level

Peak Trigger

Function

Select

Standardcomponents

3- 6 • • • Intelli-FLEX IIproductguide

Centrally located low voltage DC power source

A centrally located low voltage DC power source is more appropriate when

multiple processors are to be deployed around a larger perimeter, or where the

power run to even a single processor exceeds several meters (a few hundred

feet). This option allows DC power to be conveniently distributed from a central

power source to all processors and other equipment around a perimeter. In this

configuration, a DC power supply may be located indoors, and the 24 VDC

output, (48 VDC in large installations), is run along the perimeter to each of the

Intelli-FLEX II processors. The central DC power supply may be plugged into a

readily accessible UPS system to provide additional isolation and a non-

interruptible source of power.

The DC/DC converters on the processor boards accept a wide input voltage range

(18 to 56 VDC) and produce a regulated +12 VDC output voltage. Thus, large

voltage drops in the distribution system are not a problem. The distribution

voltage around the perimeter is also isolated from the output of the converter on

the processor to protect the processor from electrical surges.

Backup power (UPS)

When the central low voltage power supply is used, it should be powered from a

non-interruptible source of AC power. This power source will usually be provided

for the computer system that is often a part of larger installations, or will be part

of a UPS system for the overall security system. If a UPS system is not already a

part of the overall security installation, a small standalone UPS system may be

used to power the Intelli-FLEX II perimeter system. The UPS system may be

purchased from a local supplier or from Senstar.

Each Intelli-FLEX II processor requires approximately 1 watt of power, making the

total power consumption of even large systems very small. A small UPS system

that is designed to run a personal computer system (typically 300 watts) for 15 or

20 minutes will power an Intelli-FLEX II perimeter system for several hours.

Enclosure

The fibreglass NEMA 4 rated weatherproof enclosure provides a protective

covering for the processor. The processor circuit board is mounted on a metal

plate, inside the enclosure. There are two cable entry ports on the bottom of the

enclosure for the sensor cables, alarm communication wiring, and power &

ground cables. The enclosure measures 34.8 cm h X 30 cm w X 17.3 cm d (13.7

in. X 11.8 in. X 6.8 in.) and includes four mounting feet. The enclosure can be

mounted on a wall, or other flat stable surface, located close to the sensor zone.

Optionalcomponents

Intelli-FLEX IIproduct guide • • • 3 - 7

Optional components

Slidinggate disconnectassembly

The sliding gate disconnect assembly is used to provide security across a sliding

gate within an Intelli-FLEX II zone that is not frequently used. With this device the

gate may be left securely unattended, however, the gate can be opened and closed

by manually separating the connection to open the cable line. A supervision alarm

is generated when the cable line is opened.

Gatebypassmodule

The Intelli-FLEX Gate bypass module is used to bypass a protected gate without

triggering an intrusion alarm.

The module operates in secure and access modes. When the unit is in secure

mode, the gate is monitored by the system. It acts as any other section of

protected fence and an alarm triggers whenever an intrusion attempt occurs. In

access mode the gate is unprotected, hence no alarm is triggered when the gate is

used.

Figure 3-6 Sliding gate disconnect assembly

disconnect

assembly

weather boot

hose clamp

Optional components

3- 8 • • • Intelli-FLEX IIproductguide

Two options of the gate bypass module are available:

• Model 2490-1 - manual (or local) operation (keylock switch)

• Model 2490-2 - remote operation (remote-controlled relay).

Figure 3-7 Local and remote gate bypass modules

MODEL 2490-2

Local gate bypass module Remote gate bypass module

SECURE ACCESS

MODEL 2490-1

Intelli-FLEX IIproduct guide • • • 4 - 1

4Site planning

Site planning guidelines

Follow these guidelines to create an operating environment that allows the

Intelli-FLEX II system to perform well. Perform regular inspections to ensure that

the fence remains in good condition. Timely repairs to fence damage, the control

of vegetation, and regular visual inspections of all detection zones, will provide

years of effective operation.

Site planning includes four main steps. These steps will be detailed in the

following sections:

For installation guidelines refer to Chapter 5, Installation instructions.

survey site Site Survey on page 4-2

upgrade existing structures

as necessary Upgrade existing structures on page 4-3

layout components on site

plan in accordance with

guidelines

Perimeter layout guidelines on page 4-8

determine equipment

requirements Equipment requirements on page 4-17

SiteSurvey

4- 2 • • • Intelli-FLEX IIproductguide

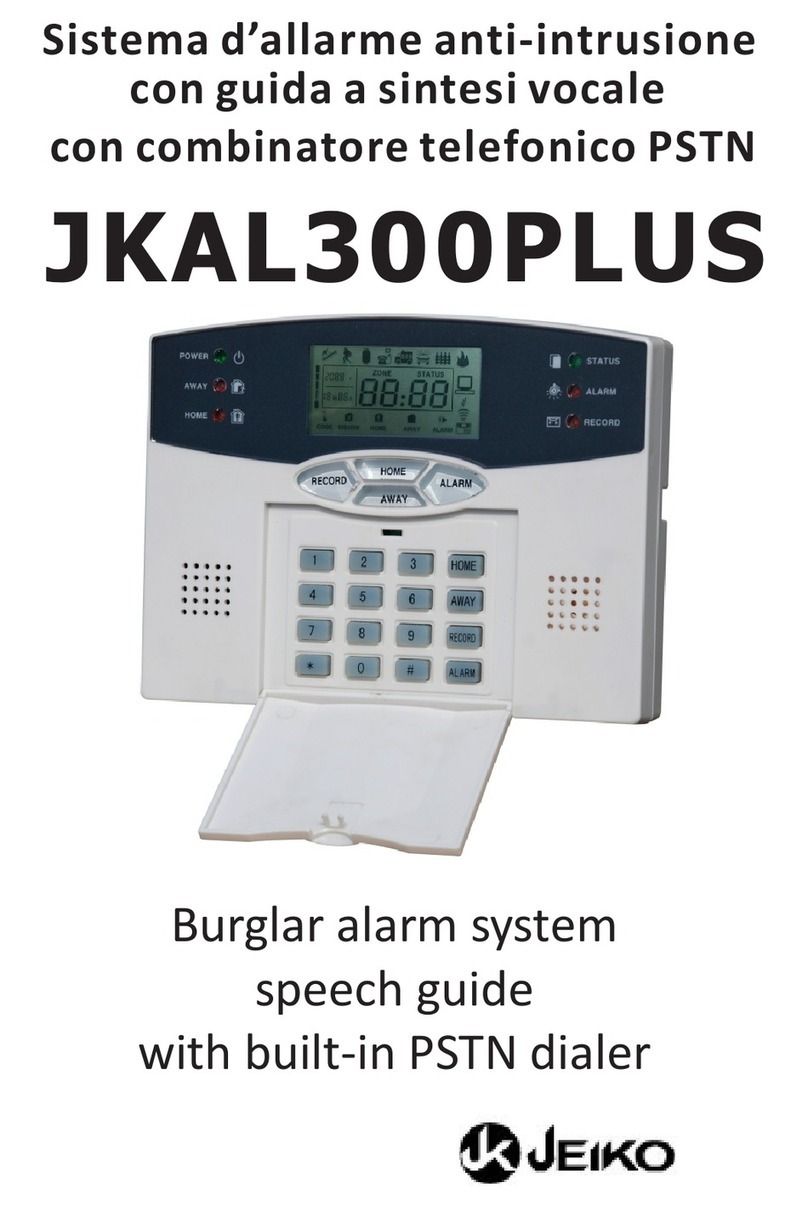

Site Survey

A survey should be conducted before installing any system hardware to ensure

that the site conditions are suitable for optimum function of an Intelli-FLEX II

system. The primary concern of the site survey is the condition of the fences and

gates where the sensor cable will be attached.

When conducting the site survey indicate the following on the site plan:

• locations of existing structures (include fences, gates, buildings, etc.) Check

that the mounting surfaces are in compliance with established standards with

respect to stability.

• location of obstacles such as vegetation.

Figure 4-1 Sample site plan

Z1 Z2

Z3

Z4

Z5

Z6

Z7

Z8

Z9

proc #4

proc #1

proc #2

proc #3

terminator (typical)

sally port gate

(included in Z6)

microwave

sensors main

building

swinging gate

(included in Z3)

NOTE:

not required

gate disconnect

- extra sensor cable at corner poles

service

loops

- drip loops at each splice/termination

sally port

gate

end of zone overlap

(approx. 1.5 m (5 ft.))

Also required at start points

max 290 m (950 ft.)

non-sensitive feed cable

(typical)

- service loops

gate disconnect

Table of contents

Other SENSTAR Security System manuals

Popular Security System manuals by other brands

Safety Link

Safety Link GO Trek quick start guide

Metasys

Metasys IFC-1010 Technical Manual Programming Section

ELRO

ELRO CZ60RIP11S manual

Buffalo

Buffalo LinkStation HD-H120LAN user manual

Wireless Alarms

Wireless Alarms S100KP Installation and operating instructions

Fireboy- Xintex

Fireboy- Xintex DU-RBH-01 Owner's Manual & Installation Instructions