Serai KIT/30 F User manual

Page 1/18

KIT/30-39F I E

!

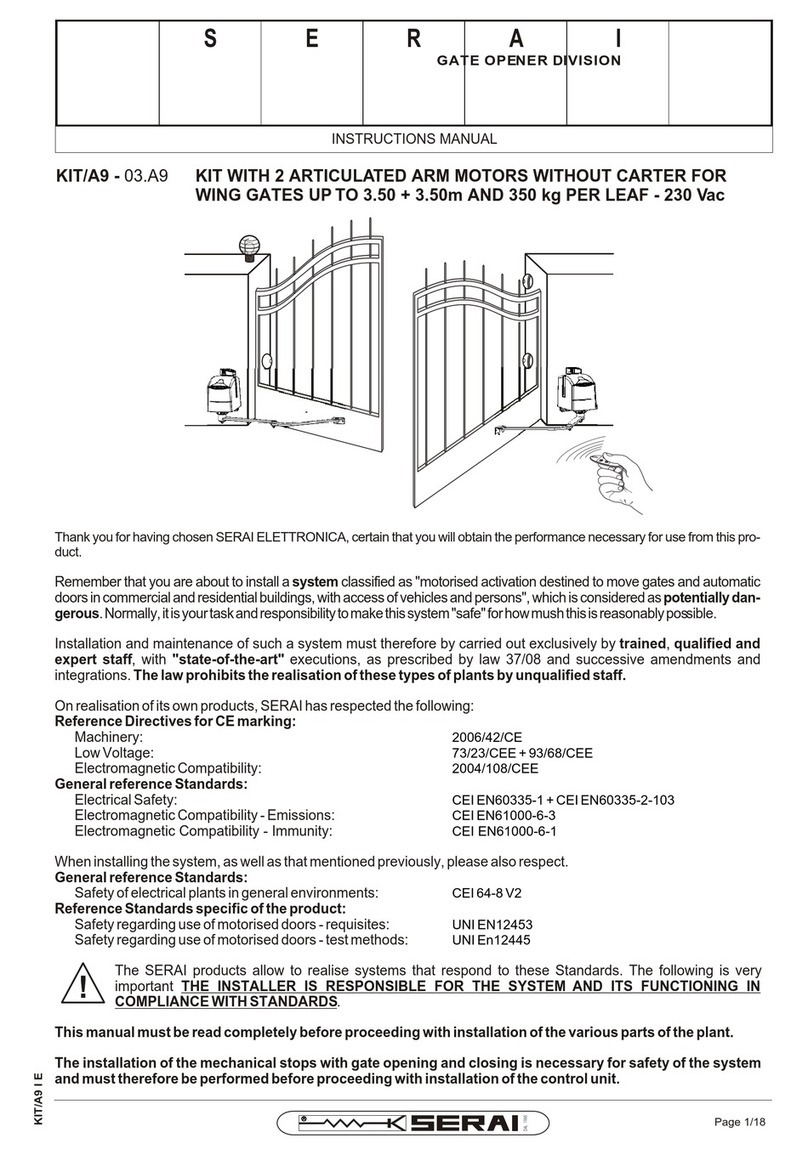

Thank you for choosing a SERAI ELETTRONICA product, which we are confident will perform to your requirements.

Please be advised that you are about to fit a system classified as “a power-operated drive designed to move automatic ga-

tes and doors in commercial or residential buildings accessed by vehicles and persons”, and as such, the system must be

considered potentially hazardous. By law, you are responsible for rendering this equipment as “safe” as is reasonably pos-

sible.

Installation and maintenance of equipment of this kind must therefore be carried out by skilled, qualified and trained

personnel, working in a professional manner, as provided for by law n. 37/08 and any subsequent amendments and

supplements. The law in question prohibits the construction of these types of systems by non-qualified personnel.

SERAI manufacturing complies with the following legislation:

Applicable directives for the CE marking :

Machines: 2006/42/EC

Low Voltage: 2006/95/EEC

Electromagnetic Compatibility: 2004/108/EEC

General applicable standards:

Electrical Safety: IEC EN60335-1 + IEC EN60335-2-103

Electromagnetic Compatibility - Emissions: CEI EN61000-6-3

Electromagnetic Compatibility - Immunity: CEI EN61000-6-

Apart from the legislation mentioned above, you are also reminded to comply with the following standards during the

installation phase.

General applicable standards:

Safety of electrical systems in non-specialised environments: CEI 64-8 V2

Specific product standards applicable:

Safety in the use of power-operated doors - requirements: UNI EN12453

Safety in the use of power-operated doors - testing methods: UNI EN12445

SERAI products enable users to build systems which comply with these standards. This is extremely important as

THE INSTALLER IS LIABLE FOR THE SYSTEM AND FOR ENSURING ITS OPERATION COMPLIES WITH

LEGAL PROVISIONS.

This handbook must be read in full before proceeding with the installation of the various parts of thesystem.

The installation of the mechanical end stops for gate opening and closure is necessary for system safety purposes

and therefore this operation must be performed before proceeding with the installation of the control unit.

SINCE 1965

ERAIS

GATE AUTOMATION DIVISION

INSTALLATION MANUAL

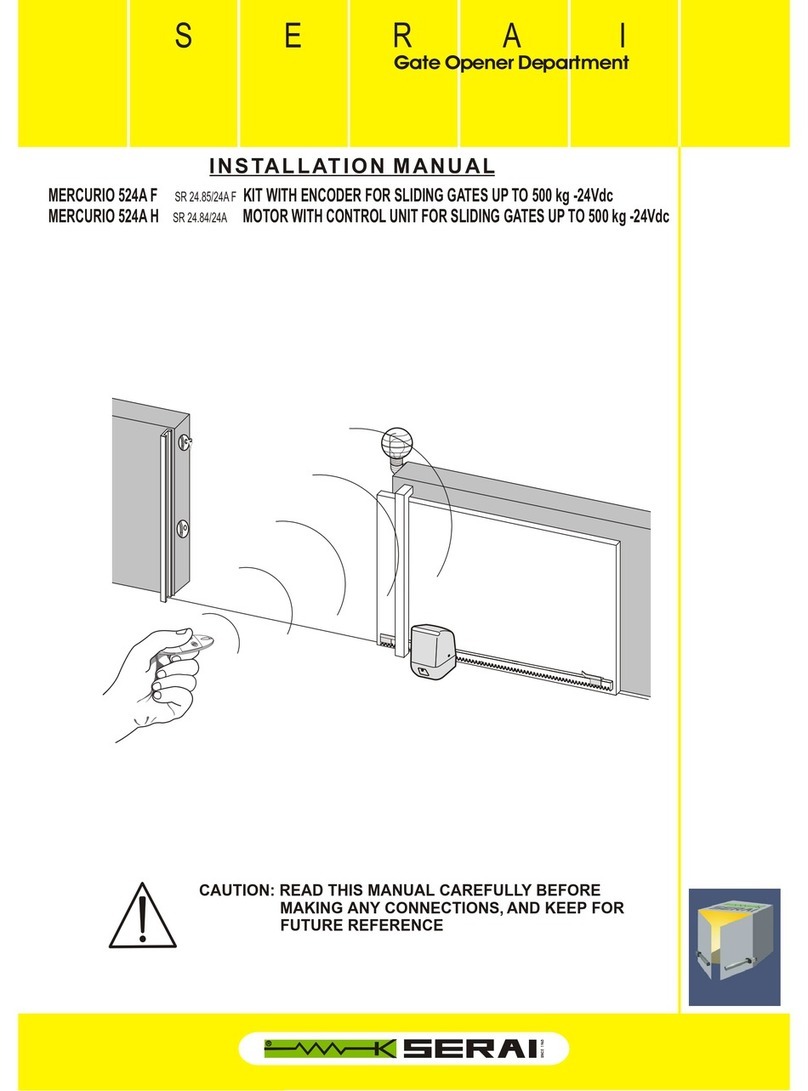

KIT/30 F - SR 03.32 F - KIT WITH 2 MOTORS FOR SWING GATES UP TO 3.0 + 3.0 METERS AND

300 kg PER LEAF - 230 Vac

KIT/39 F - SR 02.39 F - KIT WITH 2 MOTORS FOR SWING GATES UP TO 2.0 + 2.0 METERS AND

200 kg PER LEAF - 230 Vac

DAL 1965

Pag. 2/18

LATERAL VIEW

60 mm 60 mm

280 mm

860 mm (MT/30/2)

660 mm (MT/38/1)

115 mm

80 mm

Attenzione!

Limitedi corsa. Non superare

Caution!

Limitof stroke. Do not exceed

Attenzione!

Limitedi corsa. Non superare

Caution!

Limitof stroke. Do not exceed

VIEW FROM BELOW

950 mm (MT/30/2)

750 mm (MT/38/1)

KIT/30F KIT/39F

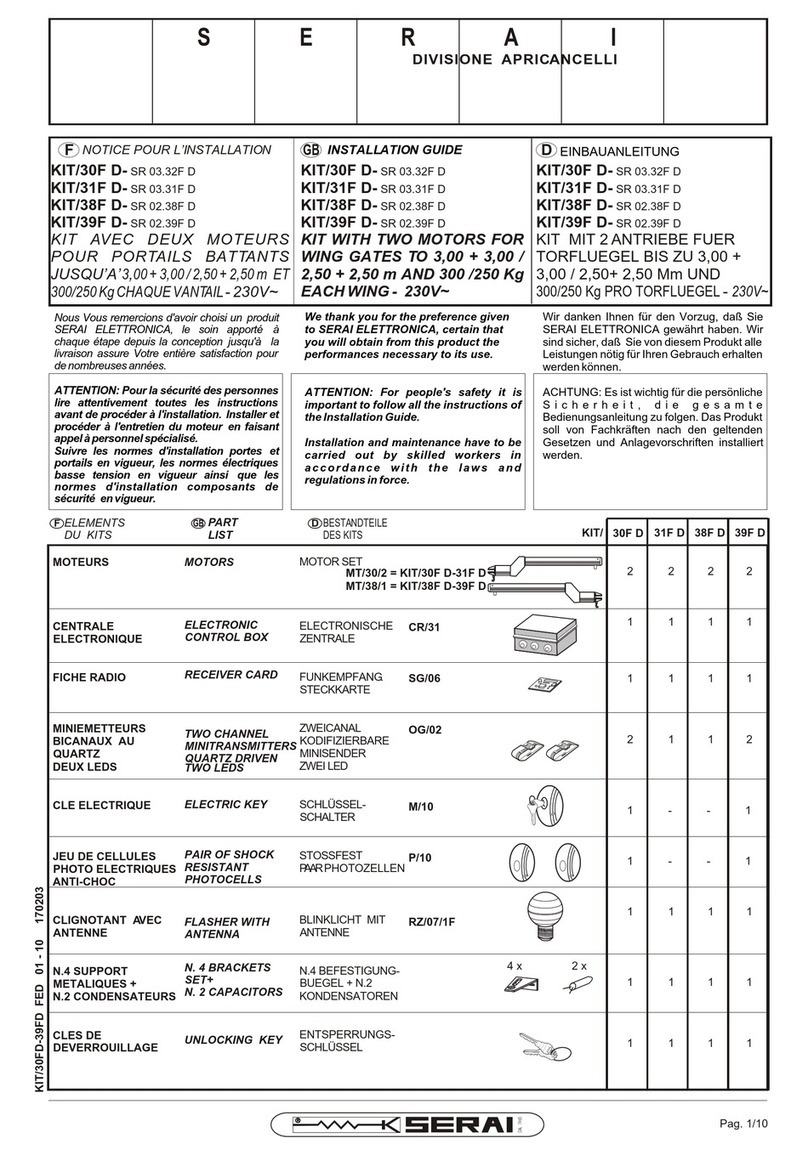

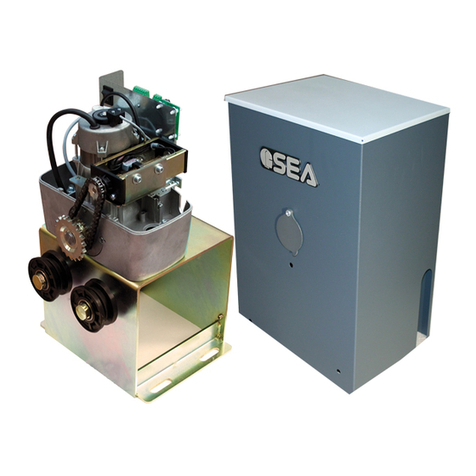

COMPONENTS OF KIT

4 x 2 x

2 2

1 1

2 1

1 1

1 1

1 1

1 1

1 1

1 1

Motors

MT/30/2 = KIT/30F

MT/38/1 = KIT/39F

CR/41 Electronic control unit

with built-in receiver

OG/62 2-channel

minitransmitter with

marsupium support

M/10 Electric key

P/10 Pair of impact-resistant

photocells

RZ/20 F Flashing light with built-

in antenna, without

internal circuit for

flashing

RZ/99 L-shaped holder

N. 4 BRACKETS SET+

N. 2 CAPACITORS

UNLOCKING KEY

OVERALL DIMENSIONS OF GEARMOTOR

KIT/30-39F I E

DAL 1965

Pag. 3/18

1

230V

3 x 1,5

4 x 0,5

2 x 0,5

4 x 0,5

4 x 1,5

4 x 1,5

2 x 0,5

3 x 0,5

RG58 2 X 1,5

1

2

4

55

3

6

MT/30/2 MT/38/1

Power supply 230 V~ ±10% 50/60 Hz 230V~ ±10% - 50/60 Hz

Max. leaf length 3,00 m 2,00 m

Max. leaf weight 300 kg 200 kg

Max. opening angle 110° 110°

Max. absorption 1,6 A 1,6 A

Power 150 W 150 W

Max. torque 180 Nm 120 Nm

Max. thrust 1200 N 1200 N

Angular speed 0,09 rad/s 0,11 rad/s

Opening time for 90° 17 s 17 s

Motor force adjusted: via power supply voltage control

Capacitor 12,5µF 12,5µF

Motor thermal protection 150° 150°

Protection rating IP55 IP55

Operating temperature -20°C ÷ +60°C -20°C ÷ +60°C

Dimensions 950 x 115 x 80 mm 750 x 115 x 80 mm

Weight 9 kg 7,5 kg

4 M/10 electric key

5 Pair of P/10 photocells

6 RZ/20 F Flashing light with antenna

SYSTEM TYPE

1 MT/30/2, MT/38/1 gearmotor

2 CR/41 electronic control unit with built-in receiver

3 OG/62 2-channel minitransmitter

Advice for wiring up in non-specialised environments.

1. Fit an omnipolar switch upstream of the system, choosing one with a gap of at least 3mm between the contacts. Or,

alternatively, use a 10Athermal magnetic circuit breaker.

2. Always make connections, of any type, with the system disconnected from the power supply, i.e. with the main switch

set to OFF (symbol “0”). The control unit, in particular, must never be connected to the power supply either during the

wiring up, or when fitting any expansion boards.

3. The following cables must be used for installation of the system:

22

- for the control unit, motor and electric lock power supplies: 1.5mm section for lengths of up to 19m, 2.5mm section

for lengths of up to 31m,

22

- for the flashing light: 0.75mm section for lengths of up to 3m, 1.5mm section for lengths of up to 19m,

- for the low voltage and current lines, (e.g. for the photocells, control buttons, electromechanical key, sensitive

22

edges and other safety devices: 0.5mm section for lengths of up to 50m, 0.75mm section for lengths of up to 100m.

4. Wire up the earth connection in compliance with legal provisions.

GEARMOTOR TECHNICAL SPECIFICATIONS

The technical data refer to an ambient temperature of 25°C with intermediate force setting.

Lower operating temperatures or higher stress levels could require increased force settings. The opposite applies

for higher temperatures or lower stress levels.

KIT/30-39F I E

DAL 1965

Pag. 4/18

PILLAR

HINGE

GATE

A

60 mm 60 mm

280 mm

860 mm (MT/30/2)

660 mm (MT/38/1)

115 mm

80 mm

Attenzione!

Limitedi corsa. Non superare

Caution!

Limitof stroke. Do not exceed

Attenzione!

Limitedi corsa. Non superare

Caution!

Limitof stroke. Do not exceed

Fig. 3

950 mm (MT/30/2)

750 mm (MT/38/1)

Fig. 2

Fig. 1

BEFORE INSTALLING THE MOTORS

1- Ensure perfect right angles of the gate hinges to

enable totally smooth and balanced swing gate

movement. Otherwise the motor may be damaged

when subject to much higher levels of resistance with

respect to those specified for intended use.

2- In the maximum gate opening and closing positions,

check that two sturdy travel stops are anchored to the

ground to block the gate leafs at the end of travel Fig.

2 -. Otherwise install as necessary.

3- Ensure that the distance between the gate hinge and

post surface, marked A in fig. 2, is:

- less than 130 mm for an opening angle of 90°

- less than 110 mm for an opening angle of 100°

- less than 80 mm for an opening angle of 110°

4- The motor is supplied with the mobile pin (PM) - Fig. 3

- in the correct position for installation. However,

ensure that the distance of the mobile pin from the rear

connection point is:

- 860 mm for motors MT/30/2.

- 660 mm for motors MT/38/1.

Any distance greater than the specified value may

cause shutdown of the motor shortly before the gate

reaches the closing end stop; shorter distances will

cause a smaller opening angle than that required.

WARNING:

NEVER EXCEED THE PIN

STROKE LIMITS AS

INDICATED ON THE MOTOR

Attenzione!

Limite di corsa. Non superare

Caution!

Limit of stroke. Do not exceed

OPENING

AND CLOSING

END STOP

LATERAL VIEW

VIEW FROM BELOW

KIT/30-39F I E

DAL 1965

Pag. 5/18

Fig. 6

OPENINGANGLE 90° OPENINGANGLE 100° OPENINGANGLE 110°

B C B C B C

180 105

170 115 160 95

160 118 150 105 130 120

150 130 140 120 120 130

140 140 130 130 110 140

130 150 120 135 110 150

120 160 110 145

110 167 100 155

100 176 90 165

90 185

Warning: to ensure correct gate movement, use values in the shaded band.

The gate opening (or closing) time varies according to the selected values B and C.

C

90 mm

PM

PM

90 mm

580 mm (MT/30/2)

380mm (MT/38/1)

B

C

860 mm (MT/30/2)

660mm (MT/38/1)

B

PM

Fig. 5Fig. 4

5) Choose the opening angle and calculate distances B and C, -Fig. 4 Fig. 5 and table for bracket positioning. The

values in the grey band are recommended. The brackets can be resized (shortened or lengthened) according to

assembly requirements, and observing distances B and C.

N.B. In the case of outward opening, the overall working area of the gate is reduced due to the dimensions of the

motors. In this case installation of the motors on the upper section of the gate is recommended.

IMPORTANT : Failure to observe distances B and C specified in the table will mean that the gate starts

movement suddenly with excessive oscillations which could lead to damage to the brackets and motor.

PROVISIONAL MOTOR INSTALLATION

6- Close the gate completely. Provisionally fix the rear

bracket - Fig. 6 onto the gate post by welding or by

means of screws + plugs, observing distances B and

C. Provisionally fix the motor to the rear bracket, As

shown in Fig. 6.

7- Move the motor up against the closed leaf to

determine the front bracket welding point. Move the

motor away from the leaf.

Provisionally fix the front bracket to the gate,

observing the distance and travel limits of the mobile

pin. Insert the mobile pin in the front bracket fig. 7

then secure by means of the nut.

BRACKET POSITIONING FOR INWARD OPENING BRACKET POSITIONING FOR OUTWARD OPENING

INWARD OPENING

OUTWARD OPENING

KIT/30-39F I E

Fig. 7

DAL 1965

Pag. 6/18

Fig. 9

Fig. 8

MOTOR INSTALLATION

ON LEFT GATE WING

Fig. 10

Fig. 11

Fig. 12 Fig. 13

!!

Fig. 14 Fig. 15

8- Level the motor and tighten all screws and bolts

fully down. Fig. 8.

9- With the aid of a 17 mm wrench, turn the half-nut

on the mobile pin through half a turn to release

the motors. Fig. 9.

Check that movement is smooth. Return the

half nut of the mobile pin to the original

position. Close the gate: the motor blocks

when the gate reaches the closing end stop.

FINAL INSTALLATION

10- Remove the motor from the brackets. Weld the

front bracket in its final position. Fix the rear

bracket in its final position. Fig. 10.

11- Refit the motor.

12- Mount the lever release mechanism, as shown in

fig. 11. Remove the blank-out disk on the right

(marked internally with D) for the right leaf, and

remove the blank-out disk on the left (marked

internally with S) for the left leaf. In the hole,

insert the key block with protection cover.

Secure the hook-shaped pawl by means of the

relative nut onto the square pin of the key block.

Close the half nut of the mobile pin between the

two half-housings and secure by means of the

relative screws.

MOVING THE GATE MANUALLY IN THE EVENT

OF A POWER FAILURE

- Use the key and release lever as shown in fig.

12.

- Keeping the mobile pin released by means of the

release lever, open manually - Fig.13 -.

- To restore the gate block, simply return the

release lever and gate to the positions prior to

release, pushing the gate until it engages -

Fig.14 -.

- Return the key to the initial position to remove -

Fig. 15.

MOTOR INSTALLATION

ON RIGHT GATE WING

KIT/30-39F I E

CR/41 CONTROL UNIT INSTALLATION

Position the equipment in the vicinity of the gate, to minimise the length of cables for connection to the rest of the

system.

For further protection against atmospheric agents, position the control unit under a canopy or for improved

protection in an enclosure also fitted with two lateral walls. The equipment should also be installed at a height of at

least 1.5 meters, to keep it out of the reach of children.

CONTROL UNIT POSITIONING

The control unit leaves the factory with the cover positioned for opening from the left-hand side.

To invert the cover opening side, proceed as follows:

WARNING: This operation must be performed before

fixing the enclosure to the wall.

Insert a slotted screwdriver in the hinge fixture slot at the rear

of the base and lever the hinge connection tooth while pulling

the cover up to remove. (see Fig. 1)

Fig.1

Insert a slotted screwdriver in the hinge fixture slot on the front

of the cover and lever off the hinge connection tooth while

pulling up the hinge. (see Fig. 2)

Fig.2

Refit the hinges on the right side of the base, inserting

them in the relative seats with the connection teeth

facing the interior of the enclosure, until they click into

place (see Fig. 3).

Fig.3

SETTING THE COVER FOR OPENING TO RIGHT

!

Page 7/18

SINCE 1965

KIT/30-39F I E

CABLE INLET

For cable routing, the lower section of the enclosure is equipped with seats for cable clamps PG11 and PG 13.5 to

be punched out when required.

!

Cable routing

CAUTION: Close all inlets securely to prevent the penetration of

insects which may damage the control unit.

WALL-MOUNTING THE CONTROL UNIT

Ø 6 ÷ 8 mm

Position the equipment in the vicinity of the gate, so

that the length of the cables for connection to the rest

of the system are as short as possible.

Secure the control unit with the cable routing holes

facing downwards.

Page 8/18

NO NO YES

OPENING AND CLOSING THE BOX

When opening the box, ensure that the hinges protrude

sufficiently from the guide on the base to ensure that the cover

remains open without obstructing control unit wiring operations.

Always accompany the cover when closing until it returns

completely inside the hinges, taking care that the seal is inserted

correctly. Close the cover with the relative screws.

Advice for wiring up in non-specialised environments.

1. Fit an omnipolar switch upstream of the system, choosing one with a gap of at least

3mm between the contacts. Or, alternatively, use a 10A thermal magnetic circuit

breaker switch.

2. Make all types of connection with the system disconnected from the power, i.e. with the

main switch set to OFF (symbol “0”). The control unit, in particular, must never be

connected to the power supply either during the wiring up, or when fitting any expansion

cards.

3. The following cables must be used for installation of the system:

2

- for the control unit, motor and electric lock power supplies: 1.5mm section for lengths

2

of up to 19m, 2.5mm section for lengths of up to 31m,

22

- for the flashing light: 0.75mm section for lengths of up to 3m, 1.5mm section for

lengths of up to 19m,

- for the low voltage and current lines, (e.g. for the photocells, control buttons,

2

electromechanical key, sensitive edges and other safety devices: 0.5mm section for

2

lengths of up to 50m, 0.75mm section for lengths of up to 100m.

4. Wire up the earth connection in compliance with legal provisions.

SINCE 1965

KIT/30-39F I E

Page 9/18

SINCE 1965

KIT/30-39F I E

OPEN

CLOSE

COMMON

FLASHING LIGHT

230V~

COURTESY LIGHT

230V~

OPEN

CLOSE

COMMON

PED

CLOSING

PHOTOCELL

RECEIVERTRANSMITTER

RECEIVERTRANSMITTER

PEDESTRIAN

ELECTRIC LOCK

TYPE SERAI M/83/1

WIRING DIAGRAM

OP. DELAY

DISCONNECT THE POWER

SUPPLY BEFORE WORKING

ON THE WIRING

TERMINALS CONNECTIONS DESCRIPTION

POWER SUPPLY Card power supply input 230V~ ±10% 50/60 Hz

FLASHING LIGHT Flashing light power output (230Vac-max 50W) to use with flashing light without

internal electronics -type SERAI RZ/20 F-.

COURTESY LIGHT Courtesy light output (230Vac-max 100W): active for 90 seconds after STOP

MOTOR M1 M1 motor power output (14=Common, 15=Opening, 16=Closing) for single leaf or

pedestrian access (connected to electric lock)

PHOTOCELL

POWER SUPPLY 24Vac power output (max 500mA) for accessories such as photocells

OPENING

PHOTOCELL /

SENSITIVE EDGE

DO NOT USE Short circuit on common with jumpers.

CLOSING

PHOTOCELL

PEDESTRIAN

CONTROL

Pedestrian control input (NO contact). With DIP1 SW1 set to OFF only the leaf

connected to M1 opens. With DIP1 SW1 set to ON the single leaf opens for 7s.

STOP BUTTON

Stop command input (NC contact); when pressed, blocks motor operation;

if pressed during gate open pause time cancels automatic

re-closure.

START

CONTROL

Start command input (NO contact) controls opening and closing in step-step

mode.

Input for photocell active during closure only (NC contact). if obscured

during closure, the gate stops and then opens again.

INPUT

COMMON

Input common terminals.

MOTOR M2 M2 motor power output (17=Common, 18=Opening, 19=Closing) for motor

delayed on opening (2-leaf gates)

ELECTRIC LOCK

COMMAND

12Vac 15VA max output for the direct command electric lock SERAI M/83/1. To

reduce the noise it is possible to add a bridge rectifier as per diagram *

BUILT-IN

RECEIVER

ANTENNA

Input for antenna connection for built-in receiver. (23=SHEATH,

24=ANTENNA)

GATE OPEN

INDICATOR

LIGHT

24Vdc output (28 +, 29 -) max 50mA for gate open indicator connection.

WARNING: to connect indicator lights with consumption of more

than 50mA use a suitable supplementary external relay

21 - 22

11 - 12

12 - 13

14 - 15 - 16

26 - 27

6

8 - 9

5

2

4

3

1 - 7 - 10

17 - 18 - 19

25 - 26

23 - 24

28 - 29

20 DO NOT USE

SUPPLEMENTARY

RELAY

24Vdc - max 50mA

2928

INDICATOR

LIGHT

INDICATOR LIGHT

POWER SUPPLY

OPENING PHOTOCELL

(or SENSITIVE EDGE)

With DIP4 SW2 set to OFF: input for photocell active during both closure and

opening (NC contact). If obscured during opening, the gate stops, and resumes

opening as soon as the photocell is free. If obscured during closing, the gate

stops, and re-opens as soon as the photocell is free.

With DIP4 SW2 ON: Sensitive edge input (NC contact); inverts movement by 10 cm.

FUSES:

F1 = T1,6A 250V~

-slow acting-

-ACCESSORIES 24V-

F2 = 5A 250V~

-istant-

-POWER SUPPLY 230V-

F1F1

F2F2

ON

SW1 SW2

345 6 78

SOG/4

POWER

+

-

ON

PED START STOP FOTO FOTO AP FINE CH FINE AP

DL9

DL8

DL10

1 2 910 11 121314 1516171819 20 21 22

272526

2324

230Vac ±10%

50/60Hz

FN

M2M1

NC

NC

NC

NC

NA

NC

NA

START

STOP

24 Vac

SET BREAK WORK

A B C

Com

+24

spia

12Vac

RX

2829

+ -

230Vac

BRIDGE RECTIFIER

SUPPLEMENTARY

RELAY

12Vac

TRANSFORMER

230/12Vac

-SERAI TR/01-

F

N

ELECTRIC LOCK NOISE REDUCTION

To reduce the noise of the electric lock it is possible to

add an ordinary bridge rectifier 50V 4A connected as per

below indicated diagram

230Vac

12Vdc

12Vac

12Vac

*

~

ELECTRIC LOCK

TYPE SERAI M/83/1

SW1= Microswitches for control

unit setting - see

microswitch settings -

A= Button to enter programming

mode (SET)

B= Button for time programming

(BREAK)

C= Button for time programming

(WORK)

POWER= Trimmer for motor

force adjustment

SW2= Microswitches for control

unit setting - see

microswitch settings -

Page 10/18

!WARNING: the considerable

differences in temperature between

summer and winter can cause

differing rates of expansion in all

materials, including those used in the

building of our motors. That is why

we recommend you check the impact

force setting at the start of winter and

summer.

EARTH CONNECTION BETWEEN MOTOR AND HOME SYSTEM

ELECTRIC CONNECTIONS OF MOTOR

Connect the motors to the electronic control unit by means of cables

2

with a section of 1.5 mm . Observe terminal connections as follows:

SKY BLUE : Common

BLACK : Open/Close - Capacitor

BROWN : Open/Close - Capacitor

YELLOW/GREEN : Earth

Observe the following:

- Connect the motor earth (yellow-green cable) to an efficient ear-

thing system.

- Fit an omnipolar switch upstream of the system, choosing one with

a gap of at least 3mm between the contacts.

MOTOR FORCE ADJUSTMENT

The motor force is adjusted by varying the power supply voltage via the “Power” potentiometer on the SERAI

CR/41 control unit.

In any event, installation must be in full observance with current standards governing power-operated gates;

remember that the installer is responsible for the system and operation in compliance with

standards.

MOTOR

YELLOW-GREEN

CABLES

CONNECTION

TERMINAL

230V POWER SUPPLY

CABLE

MOTOR 2

CABLE

MOTOR 1

CABLE

HOME SYSTEM

YELLOW-GREEN

CABLE

SINCE 1965

YELLOW/GREEN =

GROUND

SKY BLUE =

COMMON

BLACK =

OPEN/CLOSE

BROWN =

OPEN/CLOSE

SI 12,5 µF

450V

NO

KIT/30-39F I E

F1F1

F2F2

ON

SW1 SW2

345 6 78

SOG/4

POWER

+

-

ON

PED START STOP FOTO FOTO AP FINE CH FINE AP

DL9

DL8

DL10

1 2 910 11 121314 1516171819 20 21 22

272526

2324

SET BREAK WORK

A B C

Com

+24

spia

RX

2829

THE MOTORS MT/30/2 AND MT/38/1 ARRIVING AGAINST THE STOP BLOCK WHILE

SLOWING DOWN ARE SUBJECTED TO VIBRATIONS – NOT DAMAGING – BUT THAT

MIGHT CAUSE SOME NOISE.

IN ORDER TO AVOID THE NOISE:

DEACTIVATE THE SLOWING DOWN FUNCTION – DIP2 SW2 IN ON, PAGE 11-, IN THIS

CASE THE LEAF ARRIVES AGAINST THE STOP BLOCK AT NORMAL SPEED

!ATTENTION !

Page 11/18

SETTINGS OF EACH MICROSWITCH

MICROSWITCH

SETTINGS DESCRIPTION OF OPERATION

OPERATION

- Single leaf logic: only the output indicated with M1 is activated

- Two-leaf logic: both outputs M1 and M2 are activated (M2 leaf

delayed on opening)

GATE

CONFIGURATION

1 2 3

ON

4 1 2 3

ON

4

1 2 3

ON

4 1 2 3

ON

4

DECELERATION

SPEED SETTING

1 2 3

ON

4 1 2 3

ON

4

1 2 3

ON

4 1 2 3

ON

4

- High deceleration speed

- Low deceleration speed

- Final closure stroke active: at the end of the closing cycle, full

power is applied for 2s to the motors to improve electric lock

closure.

- Final closure stroke not active.

FINAL CLOSURE

STROKE

- Release stroke activated: the electric lock is activated during a

brief phase of closure against the stops, and is deactivated shortly

after start-up of M1.

- Release stroke deactivated: the electric lock is activated shortly

before start-up of M1, and is deactivated shortly after start-up of

M1

1 2 3

ON

4 1 2 3

ON

4

1 2 3

ON

4 1 2 3

ON

4

1 2 3

ON

4 1 2 3

ON

4

1 2 3

ON

4 1 2 3

ON

4

ELECTRIC LOCK

RELEASE STROKE

!

WARNING: Microswitches must only be adjusted when the control unit is disconnected from the

power supply; any new microswitch settings are applied on subsequent start-up.

After making new settings on microswitches, we recommend repeating the work time programming

procedure (see control unit programming).

!

WARNING:

During deceleration, the force is reduced and therefore the speed depends on the characteristics

of the motor and gate. AN EXCESSIVELY LOW DECELERATION SPEED COULD PREVENT

SMOOTH LEAF MOVEMENT IF NECESSARY, DISABLE BY MEANS OF DIP2 OF SW2.

SW1 SW2

1 2 3

ON

4 1 2 3

ON

4

1 2 3

ON

4 1 2 3

ON

4

START-UP

TORQUE

1 2 3

ON

4 1 2 3

ON

4

1 2 3

ON

4 1 2 3

ON

4

DECELERATION

SETTINGS

- Deceleration deactivated.

- Deceleration activated.

- Start-up torque activated: on start-up motors are powered up at

the maximum voltage for 2s.

RECOMMENDED ABOVE ALL IN WINTER

- Start-up torque deactivated: on start-up motors are powered up at

the voltage set by means of the potentiometer.

WARNING: in this case there may be difficulties with start-

up above all if a low force level is set

!

SINCE 1965

KIT/30-39F I E

ATTENTION: The motors MT/30/2 and MT/38/1 arriving against the stop block while slowing

down are subjected to vibrations – not damaging – but that might cause some noise.

In order to avoid the noise:

deactivate the slowing down function – dip2 SW2 in ON-, in this case the leaf arrives against

the stop block at normal speed

!

Page 12/18

STEP-STEP

FUNCTION

DISABLED

DURING

OPENING

- A start command sent during closing causes the gate to stop for

2” and subsequent automation re-opening.

- A start command sent during opening is ignored, while during the

gate open pause causes closure.

DURING

CLOSURE

2 s

start start

start

start

DURING

OPENING

DURING

CLOSURE

COMMAND SENT

DURING

GATE MOVEMENT

MICROSWITCH

SETTINGS DESCRIPTION OF OPERATION

OPERATION

1 2 3

ON

4 1 2 3

ON

4

1 2 3

ON

4 1 2 3

ON

4

- A start command sent during closing causes the gate to stop for

2” and subsequent automation re-opening.

2 s

start

STEP-STEP

FUNCTION

ENABLED

SW 2SW 1

INPUT OF OPENING

PHOTOCELL

OR

SENSITIVE EDGE

1 2 3

ON

4 1 2 3

ON

4

1 2 3

ON

4 1 2 3

ON

4

LED SIGNALS

LED

FINE CH

FINE AP

FOTO AP

FOTO

STOP

PED

START

ON OFF

FUNCTION

Internal photocell

External photocell

STOP button

PEDESTRIAN button

Open/Close button

Opening photocell free

of obstacles

Closing photocell free

of obstacles

Stop button in normal status

Pedestrian button pressed

Open/Close button pressed

Connection between terminals

8-10 OK No jumper between terminals 8-10

Opening photocell obscured

(presence of obstacle)

Closing photocell obscured

(presence of obstacle)

Stop button pressed

Pedestrian button in normal status

Open/Close button in normal status

DL10 Programming Indicates the various programming phases

DL8 M2 motor control Brightness varies depending

on the M2 motor control

voltage

M2 Motor not powered

DL9 M1 motor control Brightness varies depending

on the M1 motor control

voltage

M1 Motor not powered

Connection between terminals

9-10 OK

No jumper between terminals 9-10

- Sensitive edge function activated: the input on terminal 6 both on

opening and closing inverts movement by 10cm.

- Opening photocell function activated: connect the photocells to

terminal 6; if obscured during opening, the gate stops, and resumes

opening as soon as the photocell is free. If obscured during closing,

the gate stops, and re-opens as soon as the photocell is free.

SINCE 1965

- A start command sent during opening causes the gate to stop.

- A subsequent start command closes the gate.

KIT/30-39F I E

Page13/18

CONTROL UNIT PROGRAMMING

It is important to follow the programming step by step; in the event of errors during this stage, a new programming

session must be performed, in which case the new data will replace the previous data.

To quit an incorrect programming session, switch the control unit off then on again.

Before proceeding with the programming, check that the system is equipped with all the electrical and safety

devices (buttons, photocells, flashing lights, etc.), and that these are all connected.

Ensure they all operate correctly:

All the indicator LEDs for the NC inputs (stop, photocells, etc.) are lit.

All the indicator LEDs for the NO inputs (start, pedestrian) are off.

In the event of faults, ascertain and remove the cause.

WARNING: Any unused normally closed (NC) inputs must be jumpered.

WORK AND DECELERATION TIME PROGRAMMING FOR TWO-LEAF GATES (DIP1 SW1 OFF)

With the control unit powered and the gate closed, press the A (SET) key once to enter the programming mode.

The DL10 LED starts flashing to indicate that the control unit is in the programming mode.

Wait for a time interval equal to the offset to be applied to motor M2 in the opening phase (max. 15s),

then press the key B (BREAK) once to start the opening phase of motor M2

(start up automatically after 15s).

While both leafs are opening, set the motor power by means of the POWER potentiometer.

WARNING: - If the POWER potentiometer is set too low, the gate may not open. We

recommend setting POWER starting from the MAXIMUM value and gradually

moving down to the minimum value.

- The considerable differences in temperature between summer and winter can

cause differing rates of expansion in all materials, including those used in the

building of our motors. That is why we recommend you check the impact force

setting at the start of winter and summer.

WARNING: - If one or more parameters are altered, programming must be repeated from the

beginning.

- In the programming procedure, deceleration has only been set in the closing

phase, but is implemented also during the opening phase.

Press the key C (WORK) once to start the opening phase of motor M1 (M2 remains stationary).

When the leaf connected to M1 reaches the opening stop, let a few seconds pass (max. 3-4s) and then press

key C (WORK) once. Motor M1 is shut down.

When the leaf connected to M2 reaches the opening stop, let a few seconds pass (max. 3-4s) and then press

key B (BREAK) once. Motor M2 is shut down.

When the leafs are completely open and the motors are not powered, press the key B (BREAK) once to start

the closure phase of motor M2 (M1 remains stationary).

Wait for a time interval equal to the offset to be applied to motor M1 in the closing phase (max. 15s),

then press the key C (WORK) once to start the closing phase of motor M1

(start up automatically after 15s).

At the point in which motor M2 should start deceleration (at least 50cm before the stop is recommended) press

the key B (BREAK). The motor M2 slows down.

WARNING: skip this point if deceleration is disabled (DIP2 SW2 ON)

At the point in which motor M1 should start deceleration (at least 50cm before the stop is recommended) press

the key C (WORK). The motor M1 slows down.

WARNING: skip this point if deceleration is disabled (DIP2 SW2 ON)

When the leaf connected to M2 reaches the closing stop, let at least 5 seconds pass and then press key B

(BREAK) once. Motor M2 is shut down.

When the leaf connected to M1 reaches the closing stop, let at least 5 seconds pass and then press key C

(WORK) once. Motor M1 is shut down and the control unit automatically exits the programming phase and is

ready for normal operation.

SINCE 1965

KIT/30-39F I E

Page 14/18

With the control unit powered and the gate closed, press the A (SET) key once to enter the programming mode.

The DL10 LED starts flashing to indicate that the control unit is in the programming mode.

While the leaf is opening, set the motor power by means of the potentiometer POWER.

WARNING: - If the POWER potentiometer is set too low, the gate may not open. We

recommend setting POWER starting from the MAXIMUM value and gradually

moving down to the minimum value.

- The considerable differences in temperature between summer and winter can

cause differing rates of expansion in all materials, including those used in the

building of our motors. That is why we recommend you check the impact force

setting at the start of winter and summer.

WARNING: - If one or more parameters are altered, programming must be repeated from

the beginning.

- In the programming procedure, deceleration has only been set in the

closing phase, but is implemented also during the opening phase.

Press the key C (WORK) once to start the opening phase of motor M1.

When the leaf reaches the opening stop, let a few seconds pass (max. 3-4s ) and then press key C (WORK)

once. Motor M1 is shut down.

With the leaf completely open and motor not powered, press the key C (WORK) once to start the closing

phase.

At the point in which motor M1 should start deceleration (at least 50cm before the stop is recommended) press

the key C (WORK). Motor M1 slows down.

WARNING: skip this point if deceleration is disabled (DIP2 SW2 ON)

When the leaf reaches the closing stop, let at least 5 seconds pass and then press key C (WORK) once. Motor

M1 is shut down and the control unit automatically exits the programming phase and is ready for normal

operation.

GATE OPEN PAUSE TIME PROGRAMMING (AUTOMATIC RECLOSURE)

With the control unit powered and the gate closed, press the A (SET) key once to enter the programming

mode. The DL10 LED will start flashing, indicating that the control unit has entered the programming

stage.

Press the key B (BREAK) once, keeping it pressed until the flashing light comes on; the control unit will

start the gate open pause count, which is indicated by the light flashing intermittently.

Once the desired time has lapsed, press the key B (BREAK) again; the control unit will automatically store

the amount of time between the two times the key B (BREAK) was pressed. It then quits the programming

phase and switches to standard operation mode.

If the key B (BREAK) is not pressed a second time within 120s, the control unit quits the programming,

memorising the maximum time as 120s.

ACTIVATING AUTOMATIC RECLOSURE (max time settable: 120s)

Press the key B (BREAK) and keep it pressed until the DL10 LED switches off.

The control unit quits the programming phase and switches to standard operation mode.

This operation deactivates the automatic reclosure function.

DEACTIVATING AUTOMATIC RECLOSURE

With the control unit powered and the gate closed, press the A (SET) key once to enter the programming

mode. The DL10 LED will start flashing, indicating that the control unit has entered the programming

stage.

WORK AND DECELERATION TIME PROGRAMMING FOR SINGLE LEAF GATES (DIP1 SW1 ON)

SINCE 1965

KIT/30-39F I E

RADIO CONTROL CODE LEARNING

The electronic board incorporates a 433.92 MHz 2-channel radio receiver which allows remote gate control via

either the OG/02 and OG/04 series microswitch-operated radio controls, or the self-learning radio controls from the

following series: OG/62, OG/64, OG/28, OG/48, OG/52, OG/54, OG/82/1 and OG/84. Both channels are used

solely for gate control; more specifically, channel 1 of the radio receiver serves for the start function, while channel

2 is used for the pedestrian function.

ERASURE OF STORED CODES

All the radio codes stored in the memory can be erased by pressing the A (SET) key, and keeping it pressed until

the DL10 LED switches off (approx. 10s) without sending any radio codes during this time.

!WARNING: - a mini transmitter must be programmed before it is used.

- the maximum number of codes that can be stored is 32 for the open/close control

+ 32 for the pedestrian control (no other combinations, e.g. 40 open/close

+ 24 pedestrian etc, are possible) . Let's have a look at two examples of storable

codes:

- example A: 32 self-learning mini transmitters from the following series: OG/62,

OG/64, OG/28, OG/48, OG/52, OG/54, OG/82/1 and OG/84 as the start

control (e.g. left-hand button) + 32 self-learning mini transmitters from

the following series: OG/62, OG/64, OG/28, OG/48, OG/52, OG/54,

OG/82/1 and OG/84 as the pedestrian control (e.g. right-hand button)

- example B: 31 self-learning mini transmitters from the following series: OG/62,

OG/64, OG/28, OG/48, OG/52, OG/54, OG/82/1 and OG/84 as the start

control (e.g. left-hand button) + 1 OG/02 or OG/04 series microswitch-

operated mini transmitter as the start control (there is no need to store

the other OG/02 and OG/04 transmitters, simply set the microswitches in

the same sequence as the one already stored) + 31 self-learning mini

transmitters from the following series: OG/62, OG/64, OG/28, OG/48,

OG/52, OG/54, OG/82/1 and OG/84 as the pedestrian control (e.g. the

right-hand button) + 1 OG/02 or OG/04 microswitch-operated mini

transmitter as pedestrian control (there is no need to store the other

OG/02 and OG/04 transmitters, simply set the microswitches in the same

sequence as the one already stored)

!

Page 15/18

START CODE LEARNING

- With the control unit powered and the gate closed, press the A (SET) key once to enter the programming mode.

The DL10 LED starts flashing to indicate that the control unit is in the programming mode.

- Press the button on the mini transmitter (e.g. the left-hand one) to serve as the start control, and keep it pressed

until the DL10 LED switches off. The control unit stores the radio code received and automatically quits the

programming phase, switching to the standard operation mode.

PEDESTRIAN CODE LEARNING

- With the control unit powered and the gate closed, press and hold down the A (SET) key to enter the

programming mode. The DL10 LED starts flashing to indicate that the control unit is in the programming mode.

- Keeping A (SET) pressed, press the button on the mini transmitter (e.g. the right-hand one) to serve as the

pedestrian control, and keep the two buttons pressed until the DL10 LED switches off. The control unit stores the

radio code received and automatically quits the programming phase, switching to the standard operation mode.

- Repeat the procedure if several mini transmitters have to be stored.

12 34 56 78910

123 45 67 8 910

!

MODIFYING THE FACTORY

SETTING TO PREVENT

UNWANTED COMMANDS

MICROSWITCH CONFIGURATION (FOR OG/02 AND OG/04 MINI TRANSMITTERS ONLY)

These instructions only apply if the OG/02 and OG/04 series microswitch-operated mini transmitters are fitted.

Before performing the code learning procedure on the receiver, the factory configuration of the microswitches must

be modified to prevent unwanted commands

WARNING: before proceeding with the mini transmitter programming or erasure phase,

disconnect the antenna to prevent the receiver acquiring other signals during these phases

which could impair automation operation. Reconnect the antenna once the procedures are

complete.

SINCE 1965

KIT/30-39F I E

CR/41 CONTROL UNIT TECHNICAL SPECIFICATIONS

Power supply: 230Vac ±10% 50/60Hz

Motor power supply: 2 single-phase motor, 230Vac, 200W+200W

Power supply for accessories: 24Vac, 500mA

Flashing light power supply: 230Vac, max 50W

Courtesy light power supply: 230Vac, max 100W

Electric lock power supply: 12Vac 15VA

Motor work time setting: from 0 to 120s

Pause time setting: from 4 to 120s

Offset level on opening and closing: from 0 to 15s

Operating temperature: -20°C ÷ +70°C

Protection rating: IP54

Dimensions (H x L x D) and weight: 270x212x118mm, 1.7Kg

Page 16/18

EXPANDING THE NUMBER OF MINI TRANSMITTERS

If the 32 mini transmitters storable in the built-in receiver are not sufficient, they can be increased by fitting the SOG/4A

receiver (which takes the number of mini transmitters up to 40), with the optional addition of the SOG/2A expansion bo-

ard (which takes the number of mini transmitters up to 794).

After fitting the SOG/4A receiver, all the codes stored in the built-in receiver must be erased and all the mini tran-

smitters on the new SOG/4A receiver reprogrammed (see specific instructions). The antenna must be moved

from the terminal on the control unit to the terminal on the SOG/4A.

SINCE 1965

KIT/30-39F I E

nd

2 CHANNEL

OUTPUT:

AUXILIARY

CONTROL

ANTENNA

NC

C

NO

Channel 2 output (relay

contact)

Max. applicable voltage =

24Vac/dc

Max. applicable current = 1A

ELECTRIC LOCKS

LIGHTS

OTHER AUTOMATIONS

OTHER

FIT THE

SOG/4A

RECEIVER

st

1 CHANNEL

OUTPUT:

CONTROL UNIT

START CONTROL PEDESTRIAN CONTROL

ON CR/41 -TERMINALS 1-2-

DISCONNECT THE POWER

SUPPLY BEFORE WORKING

ON THE WIRING

NONC

F1F1

F2F2

ON

SW1 SW2

345 6 78

SOG/4

POWER

+

-

ON

PED START STOP FOTO FOTO AP FINE CH FINE AP

DL9

DL8

DL10

1 2 910 11 121314 15161718 19 20 21 22

272526

2324

SET BREAK WORK

A B C

Com

+24

spia

RX

2829

Page 17/18

90 mm

70 mm

TX RX

h MIN h MIN

h = 40 cm

MIN

l = 10 m

MAX

l

MAX

RX TXTX RX

RX RXTX TX

NO OK

PHOTOCELL TECHNICAL SPECIFICATIONS

Operating range

- outdoor ................. 10 m

- indoor ................... 20 m

Power supply ......... 24 V~ ±10%

TX absorption ........ 55 mA a 24 V-;

67 mA a 24 V~

RX absorption ........ 15 mA a 24 V-;

25 mA a 24 V~

Ø 6mm

Ø 3.5mm

P/10 PHOTOCELLS

NO OK

RECEIVER TRANSMITTER

POWER SUPPLY

RELAY

OUTPUT POWER SUPPLY

ALIGNMENT

RX TX

LED

CONNECTIONS

The cable routing hole must be sized exactly for the cable

to be passed through and no more

Relay output............ 1A 24 V~

Temperature............ -10° ÷ +60°C

Dimensions..............70 x 40 x 90 mm

Weight......................120 g

RX RX

THE CONTACT POSITION

REFERS TO WHEN THE RECEIVER

IS ENERGIZED

40 mm

POSITIONDIMENSIONS

INSTALLATION

RX

SPHERICAL ORANGE LAMP WITH BUILT-IN 433.92 MHz ANTENNA - 230 V~ RZ/20 F

!

RZ/99 SR 10.99

L-SHAPED

HOLDER

NO

2 x 0.75 mm²

POWER SUPPLY

RG58

ANTENNA

CS/07 SR12.07

OPTIONAL CABLE

CONNECTIONS

!

WARNING:

WE RECOMMEND YOU POSITION THE POWER SUPPLY CABLE INSIDE A CONDUIT WHICH IS NOT ACCESSIBLE

BY THE USER.

HOWEVER, IF SOME PARTS REMAIN ACCESSIBLE, THESE MUST HAVE DOUBLE INSULATION TOWARDS THE

USER. CABLE CLAMPS MUST ALSO BE USED TO AVOID TEARING OF THE CABLE.

230Vca

230Vca

WHEN REPLACING LIGHT

BULBS, ALWAYS USE

230 V MIN. 25W

PEAR BULBS

SINCE 1965

KIT/30-39F I E

TROUBLESHOOTING GUIDE

PROBLEM CAUSE SOLUTION

The gearmotor

is not working

No power supply

to motors

Check voltage presence on motor power supply input

terminals

Ensure that the power cable is not detached and is intact

(cable replacement must be carried out by an authorised

technician)

Check the control unit fuses

No power supply

to control unit

Check the mains fuse and presence of mains power voltage

Motor thermal protection

activated

Leave the motor stationary for at least 10-15 minutes and then

check operation again

The gate

does not

complete

its travel

Gate blocked Ensure that there are no obstacles by moving the gate manually.

Remove any obstacles if present.

Unsuitable bracket

position

The brackets are not positioned according to values A, B,

and C

The gate is slow

and start-up

is problematic

Capacitor failure Measure the capacitor capacity and replace

if necessary

Incorrect motor force

setting

Repeat programming, increasing the motor force by means

of the potentiometer “Power”

Incorrect work

times

Repeat the work time programming

Start-up torque

deactivated

Check the relative microswitch on the board

Incorrect deceleration

settings

Ensure that the set deceleration speed is sufficient to move

the gate; if necessary disable deceleration

(dip2 SW2 set to ON)

KIT/30-39F I E 10 18 110607 - A4Vf/r - IS KIT30F-IS-E

The remote

control range

is reduced

Unsuitable antenna

connection

Check that the antenna is connected correctly to

terminals 23 and 24

External antenna

required

To permit maximum reception distance, replace the

internal antenna on the flashing light with an external

one (SERAI OG/50 -SR 25.50)

SOG/4A receiver

in use

Replace the built-in receiver with the SOG/4A

card

ELETTRONICA PADOVA

I

SINCE 1965

MADE IN ITALY

VIA ENRICO FERMI, 22

35020 LEGNARO - PADOVA

I T A L I A

PHONE +39 049 79 08 58

FAX +39 049 88 30 529

E-MAIL [email protected]

WEB www.serai.com

TERMS OF GUARANTEE

The company reserves the right to make modifications to the equipment without prior notice thereof. SERAI products are covered by a standard guarantee with a term of 24 months.

Coverage starts on the date on which the tax document constituting proof of purchase is issued and guarantee services shall be provided on the company's premises at Legnaro - PD -

or at the Authorised Service Centres. Carriage costs shall be borne by the Customer.

CE CONFORMITY DECLARATION

SERAI spa declares that the product KIT/30F, KIT/39F has been desifned and manufactured according to the above mentioned directives and standards

WEEE DIRECTIVE 2002/96/EC

This appliance was manufactured after 13/08/2005. To protect the environment: when the equipment is no longer needed, take it to a special WEEE (Waste Electric and

Electronic Equipment) collection centre. Do not dispose of it with normal household waste.

This manual suits for next models

1

Table of contents

Other Serai Gate Opener manuals