sewerin miniLec 4 User manual

Operating

Instructions

Measurable success by Sewerin equipment

Congratulations. You have chosen a quality instrument manufactured

by Hermann Sewerin GmbH.

Our equipment will provide you with the highest standards of perform-

ance, safety and efciency. They correspond with the national and in-

ternational guide-lines.

Please read and understand the following operating instructions before

using the equipment; they will help you to use the instrument quickly and

competently. If you have any queries we are available to offer advice

and assistance at any time.

Yours

Hermann Sewerin GmbH

Robert-Bosch-Straße 3

33334 Gütersloh, Germany

Tel.: +49 5241 934-0

Fax: +49 5241 934-444

www.sewerin.com

info@sewerin.com

SEWERIN SARL

17, rue Ampère – BP 211

67727 HOERDT CEDEX, France

Tél. : +33 3 88 68 15 15

Fax : +33 3 88 68 11 77

www.sewerin.fr

sewerin@sewerin.fr

Sewerin Ltd

Hertfordshire

UK

Phone: +44 1462-634363

www.sewerin.co.uk

info@sewerin.co.uk

SEWERIN IBERIA S.L.

Centro de Negocios “Eisenhower”

Avenida Sur del Aeropuerto

de Barajas 28, Of. 2.1 y 2.2

28042 Madrid, España

Tel.: +34 91 74807-57

Fax: +34 91 74807-58

www.sewerin.es

info@sewerin.es

Sewerin Sp.z o.o.

ul. Twórcza 79L/1

03-289 Warszawa, Polska

Tel.: +48 22 675 09 69

Tel. kom. +48 501 879 444

www.sewerin.pl

info@sewerin.pl

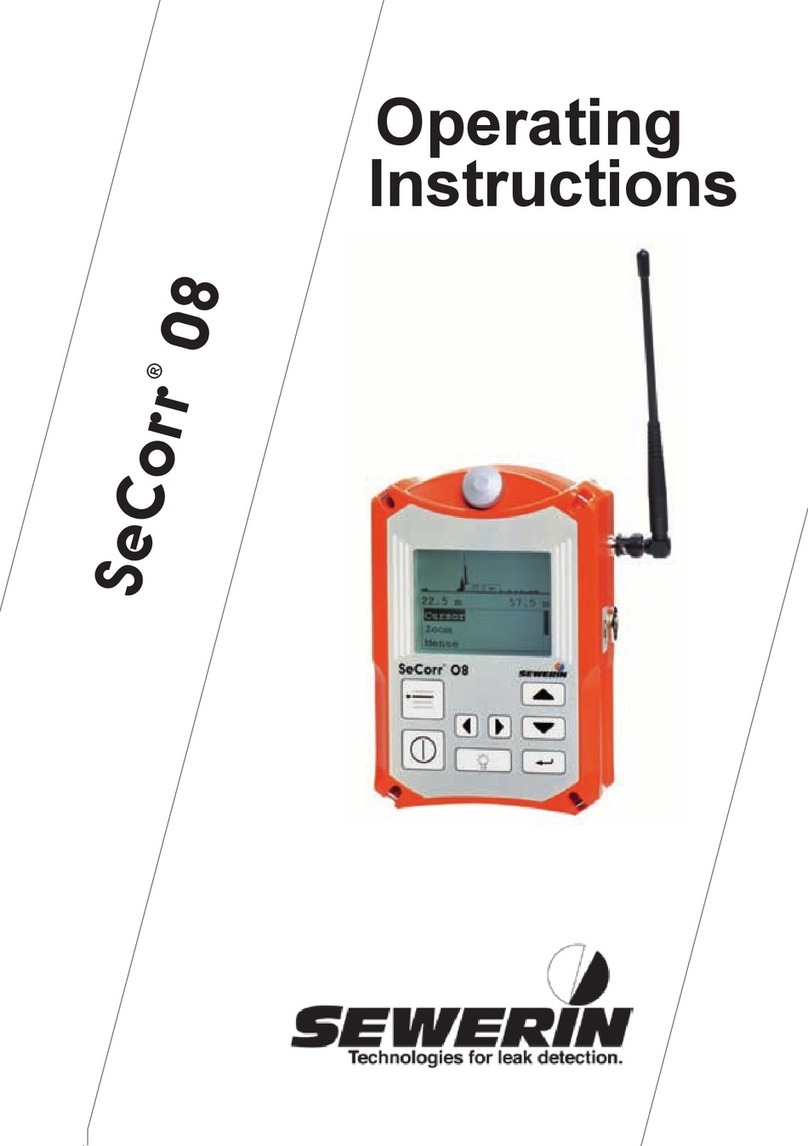

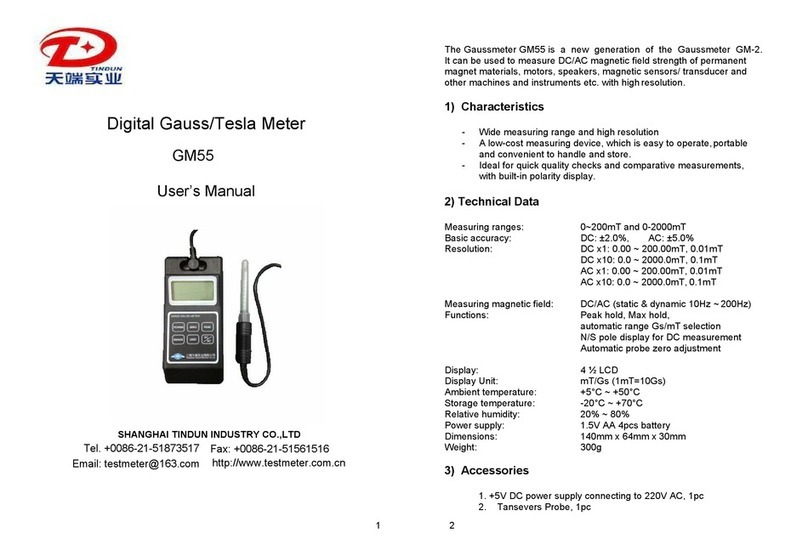

Illustration MiniLec 4 with full equipment (version HP)

Inlet for prelimi-

nary test

Inlet for

Main test,

Test of working

order and

Regulator

inspections

Buzzer

Keyboard

Outlet for Test of

working order

Suspension

Signal light/

infrared interface

LCD

Charging contacts

Overview

Operating keys

Switching the instrument on/off

(keep pressed for approx. 3 seconds)

Entries/conrming a selection (short pressing)

Changing between the operating menus

Selection of menu items

LCD

Test mode Type of gas

Battery state Flow rate

Unit

Pressure Unit

Operating Instructions

26.10.2016 – V3.XXX – 103999 – en

MiniLec® 4

Symbols used

CAUTION!

This symbol refers to important safety instructions.

Adhere strictly to these instructions to avoid material

damages!

Note:

This symbol refers to information and useful tips

which are exceeding the basic operating proce-

dures.

CAUTION! Danger of injuries!

This symbol refers to important safety instructions.

Adhere strictly to these instructions to avoid

injuries!

I

Contents Page

1 General information ................................................................1

1.1 Warranty....................................................................................1

1.2 Application purpose...................................................................2

1.3 Intended usage .........................................................................2

1.4 General safety instructions........................................................3

2 Equipment................................................................................4

2.1 Connections ..............................................................................4

2.2 Visual and audible signals.........................................................5

2.3 Infrared interface .......................................................................6

3 Operation .................................................................................7

3.1 Measuring mode .......................................................................7

3.1.1 General information regarding the measuring mode..............7

3.1.1.1 Switching on the device ......................................................7

3.1.1.2 User menu.........................................................................10

3.1.2 Setting the zero point ........................................................... 11

3.1.3 Test of working order............................................................12

3.1.3.1 Preparations......................................................................12

3.1.3.2 Execution ..........................................................................13

3.1.3.3 Analysis of working order..................................................14

3.1.4 Main test...............................................................................15

3.1.4.1 Preparations......................................................................15

3.1.4.2 Execution ..........................................................................16

3.1.5 Preliminary test ....................................................................17

3.1.5.1 Preparations:.....................................................................18

3.1.5.2 Execution ..........................................................................18

3.1.6 Regulator inspection ............................................................20

3.1.6.1 Preparations......................................................................20

3.1.6.2 Execution ..........................................................................20

3.1.6.3 Dynamic pressure .............................................................22

3.1.6.4 Static pressure ..................................................................22

3.1.6.5 Reaction pressure inspection............................................23

3.1.6.6 Zero shut-off......................................................................23

3.1.6.7 Low-pressure cut-off valve (Low ow safe).......................23

3.1.7 Start measurement/Stop measurement/Store......................24

3.1.8 Protocols ..............................................................................25

II

Contents Page

3.2 Extended settings ...................................................................27

3.2.1 Access..................................................................................27

3.2.2 Procedure.............................................................................29

3.2.3 Info menu .............................................................................31

3.2.3.1 Adjustment menu ..............................................................31

3.2.3.2 System menu ....................................................................32

3.2.3.3 Hardware menu.................................................................33

3.2.3.4 Parameters menu..............................................................35

3.2.3.5 Memory menu ...................................................................35

4 Charging and battery operation...........................................36

4.1 Operation with rechargeable nickel metal hydride

accumulators (NiMH) ..............................................................36

4.2 Operation with non-rechargeable alkaline batteries................39

5 Maintenance ..........................................................................40

5.1 Functional test/inspection........................................................40

5.2 Check to ensure the indication accuracy and leak-tightness

of the device ............................................................................40

5.3 Adjustment ..............................................................................41

5.4 Maintenance and repair ..........................................................41

6 Errors .....................................................................................42

7 Appendix................................................................................43

7.1 Equipment and permissible ranges of use ..............................43

7.2 Sensors ...................................................................................44

7.3 Connection and application options ........................................45

7.4 Entering a user name..............................................................50

7.5 Delivery variants and accessories...........................................52

7.5.1 Delivery variants...................................................................52

7.5.2 Accessories..........................................................................53

7.6 Declaration of conformity ........................................................58

7.7 Advice on disposal ..................................................................59

7.8 Terminology and abbreviations ...............................................60

8 Index.......................................................................................61

1

1 General information

1 General information

1.1 Warranty

To ensure proper functioning and safety, it is required to observe

the following notes.

Hermann Sewerin GmbH is not liable for damage caused by failure

to comply with these notes. The guarantee and liability conditions

of the sales and delivery conditions of Hermann Sewerin GmbH

are not extended by the following notes.

zThis product may only be taken into operation after reading

thoroughly the accompanying operating instructions.

zThis product may only be taken into operation by sufciently

qualied staff who is familiar with the legal requirements (in

Germany: TRGI).

zThis product may only be used as set forth in these operating

instructions.

zThis product is exclusively destined for industrial and com-

mercial applications.

zRepairs may only be performed by qualied experts or appro-

priately trained staff.

zModications and conversions may only be carried out with prior

written consent of Hermann Sewerin GmbH. The manufacturer

is not liable for damage resulting from arbitrary modications

of the product.

zOnly accessories manufactured by Hermann Sewerin GmbH

may be used in conjunction with the product.

zOnly spare parts which are approved by Hermann Sewerin

GmbH may be used for repairs.

zOnly approved or recommended battery types may be used.

zTechnical changes within the scope of further development

reserved.

Apart from the notes and instructions included in these operating

instructions, adhere also strictly to all generally valid safety and

accident prevention rules!

2

1 General information

1.2 Application purpose

MiniLec 4 is an electronic instrument for measuring the pressure

and the ow rate of low-pressure gas installations.

Apart from performing measurements, the instrument also permits

to store and record measurement data.

Note:

These operating instructions describe the function-

alities of rmware version 2.XXX.

Subject to changes!

The descriptions always refer to the default settings

of the instrument.

1.3 Intended usage

The instrument can be used for the following purposes:

zServiceability determinations (i. e. tests of working order) ac-

cording to DVGW worksheets G 600 (TRGI 2008) and G 624

[DGWV: German Technical and Scientic Association for Gas

and Water].

zMain tests according to DVGW worksheets G 600 (TRGI 2008)

and G 624.

zPreliminary tests according to DVGW worksheets G 600 (TRGI

2008) and G 624.

zRegulator inspections according to DVGW worksheets G 459-2

and G 495.

3

1 General information

1.4 General safety instructions

zThe MiniLec 4 instrument is constructed in accordance with the

European Ex protection standards CENELEC and ATEX 100a.

zThe instrument may only be used with the following gasses:

– Air

–Natural gas

– Methane (CH4)

–Propane (C3H8)

–Butane (C4H10)

– Town gas (TGas)

–Hydrogen (H2)

Note:

The instrument is prepared ex works for detecting

methane (CH4) as test gas. Measurements with air

or natural gas are also carried out with this setting.

It is not required to change the type of gas.

zIt is required to use supply tubes with hydrophobic lters to

protect the ow rate sensor (applies to Test of working order

[i. e. serviceability determinations] and Main test).

zThe maximum operating pressure must not be exceeded:

– Test mode Test of working order: max. 200 mbar

– Test mode Main test: max. 200 mbar

– Test mode Preliminary test: max. 2 bar

– Test mode Regulator inspection max. 200 mbar

zThe permissible operating temperature is -10 °C to +40 °C.

zThe permissible storage temperature is -20 °C to +70 °C.

zThe permissible humidity is 0% RH to 90% RH, non-condens-

ing.

zThe permissible ambient pressure is 860 hPa to 1100 hPa.

4

2 Equipment

2 Equipment

The instrument can be delivered in two versions:

zVersion HP (full equipment),

suitable for Preliminary test, Main test, Test of working order

(serviceability determinations) and Regulator inspection

zVersion LP (basic equipment),

suitable for Main test, Test of working order and Regulator

inspection.

2.1 Connections

CAUTION!

Only members of staff who are familiar with the legal

requirements (in Germany: TRGI) are permitted to

connect and operate the instrument.

The instrument can be connected to the gas installation with the

help of three quick-release connections (see illustration in the

appendix):

zInlet for Main test, Test of working order and Regulator inspec-

tion

zInlet for Preliminary test (not available for the LP version)

zOutlet for Test of working order.

Note:

The quick-release connections allow only are de-

signed in such a way that they allow only to con-

nect tubes which are suitable for the appropriate

test mode.

5

2 Equipment

2.2 Visual and audible signals

MiniLec 4 is equipped with two signalling instruments:

zred signal light on top of the instrument

zbuzzer at the front panel of the instrument.

Note:

These signalling instruments cannot be switched off.

Every touch of a key is conrmed by an audible signal:

zvery long tone indicates an error message

zlong tone switching off, menu change

zshort tone switchingon, conrming the selection,

navigation within a menu

6

2 Equipment

Receiving instrument

2.3 Infrared interface

The instrument is provided with an infrared interface (IrDA 1.0)

which can be used to transmit the readings to a PC or other in-

struments (e. g. printer, pocket PC, organizer). It is located on

the outer surface of the instrument, below the red signal light.

To ensure an optimum data transmission, you need to align

the MiniLec 4 instrument with the relevant interface of the PC,

printer, etc.

The following illustration shows how the instruments are properly

aligne:

7

3 Operation

3 Operation

The operation of the instrument is divided into two sections:

zMeasuring mode (see section 3.1)

Measurements are carried out in the measuring mode. The User

menu can be used to change the test mode, to store measure-

ment data and to call up protocols.

zExtended settings (see section 3.2)

The extended settings permit to change default measurement

settings and further instrument settings (such as “Adjustment”,

“System”, “Hardware”, etc.). It is not possible to carry out a

measurement when the extended settings are opened.

3.1 Measuring mode

3.1.1 General information regarding the measuring mode

3.1.1.1 Switching on the device

The instrument is switched off.

zPress the key for approx. three seconds.

The instrument is switched on. The two following start displays

appear:

Start display

Indication of:

- Instrument type (MiniLec)

- Firmware version (V3.000)

- Installed sensors

(10 l/h, 200 mbar, 2.00 bar)

Date/time

Indication of:

- Date (15.05.2008)

- Time (10:10)

- User data (example)

l/h

mbar

bar

10

200

2.00

MiniLec

V3.000

15.05.2008 10:10

City Council

Frank Smith

Leakage Delivery

8

3 Operation

The instrument enters the pre-set test mode.

Note:

The test mode to be enabled immediately after the

start-up can be changed in the extended settings

(see section 3.2). As default, the mode Test of

working order is set.

The following display data depend on the testing mode.

Test of working order

Measuring range

Indication of the test mode,

including information on the sen-

sors’ measurement range

Parameters

Indication of the measuring

specications, corresponding to

the selected test mode

Measuring data

Indication of measurement val-

ues

Working order

0...10 l/h

0..200 mbar

WO < 1.0 l/h

LWO 5.0 l/h<

NWO 5.0 l/h

≥

<

≥

W

CH4

0.0

Il/h

0.0 mbar

9

3 Operation

Main test

Measuring range

Indication of the test mode,

including information on the sen-

sors’ measurement range

Parameters

Indication of the measuring

specications, corresponding to

the selected test mode

Measuring data

Indication of measurement val-

ues

Preliminary test

Measuring range

Indication of the test mode,

including information on the sen-

sors’ measurement range

Parameters

Indication of the measuring

specications, corresponding to

the selected test mode

Measuring data

Indication of measurement val-

ues

While these displays are indicated, no entry is possible. If the

display Measuring data appears, the instrument has entered

the Measuring mode.

Main test

0..200 mbar

Meas.time 10 min

result WO

dp < 0.1 mbar

M

0.0

mbar

Pre test

0..2.00 bar

Batterie

Meas.time 10 min

result WO

dp <3mbar

P

0.000

barm

10

3 Operation

3.1.1.2 User menu

The measuring mode permits to use the following functions:

zZero point correction

zSelection of the test mode

zStart meas. resp. Store

zProtocols.

These functions can be called up via the User menu:

zPress the or key for approx. two seconds.

The User menu appears:

Zero point

Working order

Main test

Pre test

Regulator ins

Start meas.

Protocols

Exit

If the measurement time for the test of working order is zero, the

user menu displays the menu item Store instead of the menu

item Start meas..

The functions of the User menu are described in the chapters

3.1.2 to 3.1.8.

To change between the menu items:

zYou can move up or down in the menu by pressing the appro-

priate or arrow key.

zConrm the selection by pressing the key.

If the selection is not conrmed, the display returns to the mea-

suring mode after a couple of seconds.

11

3 Operation

3.1.2 Setting the zero point

Before the measurements are started, the instrument can be

adjusted to the ambient conditions by setting the zero point. At

that time, no tubes should be attached to the instrument. If the

zero point is incorrectly set, other values than zero are indicated

on the display after switching on the instrument.

Note:

The zero point must be set for every individual test

mode.

Perform the following steps to set the zero point of the instrument:

zPress the or key for approx. two seconds.

zUse the or keys to select the menu item.

zConrm the selection with the key.

The instrument returns to the Measuring mode. The display

shows zero.

12

3 Operation

3.1.3 Test of working order

CAUTION!

Test of working order (i. e. serviceability determina-

tions) may only be carried out by sufciently qualied

members of staff who are familiar with the prevailing

national regulations (in Germany, for example: TRGI).

All relevant safety procedures and accident preven-

tion regulations have to be taken into account.

Test of working order are carried out to determine and evaluate

the operational safety of low-pressure gas installations. A built-in

ow rate sensor is used to measure the amount of gas which is

streaming into the gas installation over a dened period of time

(leakage rate).

3.1.3.1 Preparations

There are different ways to install the instrument in the supply

system (see section 7.4):

–Flow measuring principle (at the location of the gas meter)

– Measuring principle of the return ow (at an arbitrary place of

the pipe)

–Check of non-metered pipes

–etc.

zSwitch the instrument on.

zConnect the instrument to the supply system. Use the corre-

sponding quick-release connections for this which are installed

on the instrument.

zApply the required testing pressure.

zCheck whether a Wfor the testing mode Test of working order

is visible in the upper left section of the display. If necessary,

adjust the testing mode Working order (see section 3.1.1.2).

Table of contents

Other sewerin Measuring Instrument manuals

sewerin

sewerin UT 9000 User manual

sewerin

sewerin SR2-EX-P User manual

sewerin

sewerin VARIOTEC 480 EX User manual

sewerin

sewerin SeCorrPhon AC 200 User manual

sewerin

sewerin EX-TEC Combi User manual

sewerin

sewerin COMBIPHON User manual

sewerin

sewerin Stethophon 04 User manual

sewerin

sewerin FLIS-EX User manual

sewerin

sewerin Multitec 540 User manual

sewerin

sewerin EX-TEC PM 4 User manual