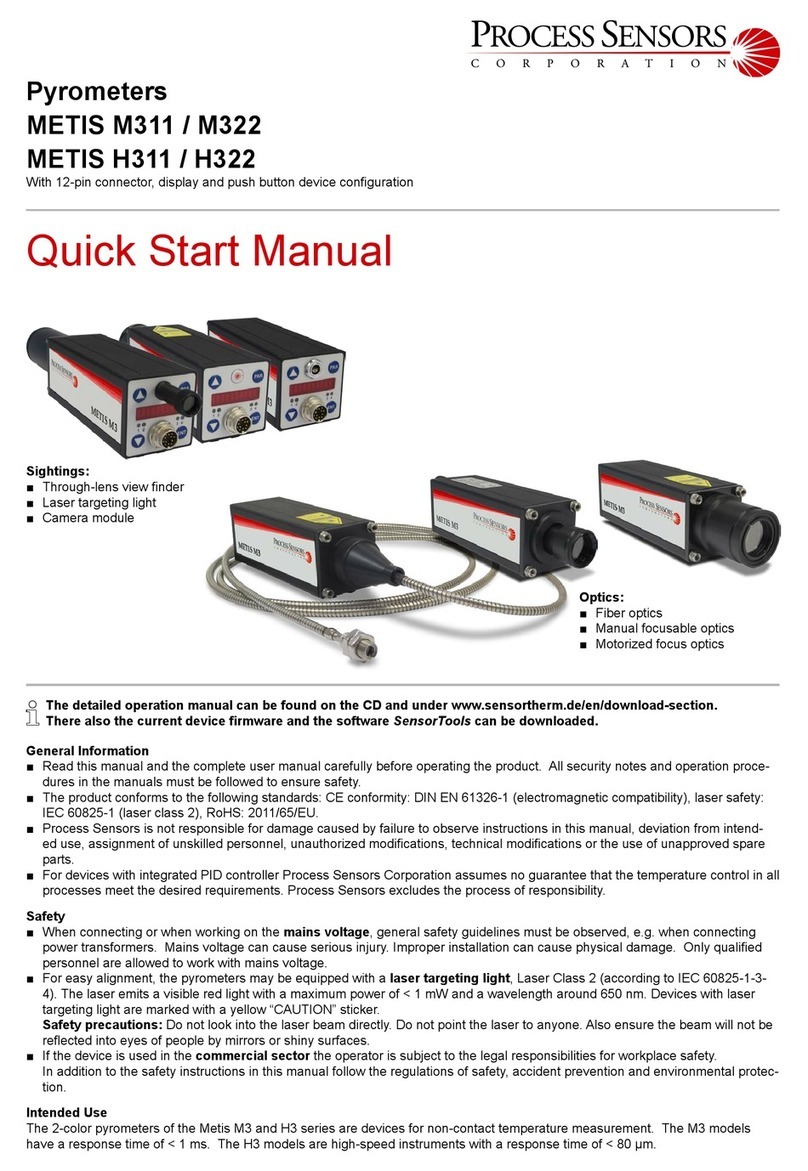

sewerin FLIS-EX User manual

24.01.2023 a – 104163 – en

FLIS-EX

Operating Instructions

Suction intake

Canister holder with

bayonet tting for

storing the hose

Motor protection switch

Exhaust opening

Fig. 1: Side view A

Fig. 2: Side view B

FLIS-EX

Nozzle

Clamping coil

Hose clip with lug

Hose (fabric)

Fig. 3: End of hose with bayonet tting

FLIS-EX

Illustration of warnings in this document

AWARNING!

Risk of personal injury. Could result in serious injury or death.

Contents │ I

1 General.....................................................................................1

1.1 Warranty ....................................................................................1

1.2 Purpose .....................................................................................2

1.3 Intended use .............................................................................2

2 Features ...................................................................................3

3 Operation .................................................................................4

3.1 Preparing the device .................................................................4

3.2 Switching the device on ............................................................5

3.3 Switching o the device.............................................................6

4 Maintenance and servicing ....................................................7

4.1 Visual inspection .......................................................................7

4.2 Cleaning ....................................................................................7

5 Transport, storage, storing the hose.....................................8

6 Appendix..................................................................................9

6.1 Technical data ...........................................................................9

6.2 Explosion protection ..................................................................9

6.3 Accessories .............................................................................10

6.4 Declaration of conformity .......................................................10

6.5 Inspection protocol ..................................................................11

1 General │ 1

1 General

1.1 Warranty

The following instructions must be complied with in order for

any warranty to be applicable regarding functionality and safe

operation of this equipment.

Hermann Sewerin GmbH accepts no liability for any damages

resulting from non-compliance with these instructions. The

warranty and liability provisions of the terms of sale and delivery

of Hermann Sewerin GmbH are not aected by the information

given below.

This product must only be operated after the

relevant operating instructions have been read

and understood.

●

This product must only be commissioned by qualied

professionals who are familiar with the legal requirements

(Germany: occupational health and safety regulations of the

BGI (Chemical Employer's Liability Insurance Association)).

● This product must only be used for its intended purpose.

●

This product is only suitable for use in industrial and commercial

applications.

●Repairs must only be carried out by a specialist technician or

by other suitably trained personnel.

● Changes or modications to this product must not be carried

out without approval from Hermann Sewerin GmbH. The

manufacturer cannot be held responsible for damages or

the explosion protection of the relevant model if unapproved

modications have been made.

● Only accessories supplied by Hermann Sewerin GmbH may

be used with this product.

●

All repairs must be carried out using replacement parts that

have been approved by Hermann Sewerin GmbH.

●

The manufacturer reserves the right to make technical

modications in the course of further development.

Generally applicable safety and accident prevention regulations

must be complied with, in addition to the information provided in

this manual.

2 │ 1 General

1.2 Purpose

Large volumes of CO2 can be released in well shafts and

ventilation and purge shafts as a result of pressure drops. High

concentrations of CO2in respiratory air leads to disorientation,

unconsciousness and death.

SEWERIN's FLIS-EX (FLIS for short) helps ventilate and purge

shafts.

1.3 Intended use

The following work can be performed in shafts with the FLIS:

● ventilating (supplying fresh air)

● purging (extracting harmful gases)

Always observe national regulations for the respective application

when using the FLIS. For example, in Germany please observe

the following:

● DGUV (German Social

Accident Insurance Institu-

tion) regulation 113-004

Working in tanks and conned

spaces

● DGUV provision 22 Accident prevention regulation

for wastewater engineering

plants

● DGUV regulation 103-003 Working in enclosed spaces in

wastewater engineering plants

● DGUV regulation 103-002 District heating distribution

plants

● DGUV principle 313-002 Selection, training and commis-

sioning of experts for measuring

pursuant to BGR 117 – part 1,

DGUV principle 313-002

● DGUV regulation 113-001 Explosion protection regulations

(Ex-RL)

The FLIS must not be used in oxygen-enriched atmospheres.

Otherwise the device will not be explosion-proof.

2 Features │ 3

2 Features

The FLIS has been constructed in accordance with the European

explosion protection standard ATEX 100a and complies with the

CENELEC recommendations.

The FLIS contains the following electrical equipment:

Type

EU type examination

certicate

Fan motor EeeA.. 56./.. PTB 03 ATEX 3004

Motor protection

switch

5823/8 DMT 01 ATEX E153 U

Starting/operating

capacitor

27 ... SEV17 ATEX 0165 X

The FLIS comes with:

● suction hose with cage

●extension hose

●extension hose in canister holder

The cage of the suction hose prevents dirt from getting into the

device (e.g. branches, leaves). Extension hoses do not have a

cage.

The hoses are attached to the FLIS using the bayonet tting and

secured with a buttery nut.

Hoses can be connected to each other. Using more than three

hoses can reduce the air volume of the FLIS.

4 │ 3 Operation

3 Operation

The FLIS can both ventilate and purge shafts. Either of the two

options is selected depending on:

● the type and size of the shaft

● the anticipated gases

●

the regulations of the responsible German Social Accident

Insurance Institution or other legal stipulations

AWARNING!

Risk of poisoning from toxic gases

Shafts may contain harmful toxic gases.

●

When purging, always wait the specied time before

entering the shaft (section 3.2).

●

Always measure the gas concentration before entering.

● Always take a gas measuring device into the shaft with

you, so that you can respond immediately if the suction

capacity of the FLIS is no longer sucient.

● Never switch o the FLIS if there is anyone in the shaft.

3.1 Preparing the device

Regardless of how the FLIS will be used (for ventilating or

purging), it is always prepared for use as follows:

1. Place the FLIS at the edge of the shaft.

− The FLIS must be stable and protected against shocks.

− Make sure that coarse dirt does not get into the FLIS de-

vice.

2. Open the inspection cover.

3. Attach the hoses.

− The table below contains information about the connection

options and the ways in which hoses can be combined.

− Tighten the buttery nuts on the nozzle to ensure a secure

mechanical and electrical contact.

3 Operation │ 5

4. Dangle the hoses in the shaft as follows.

− Ventilate: extension hose

− Purge: suction hose

The cage of the suction hose must be inside the shaft.

Connection options

Type of use Suction intake Exhaust opening

Ventilating 1 × 1 ×

or

2 ×

1 × + 1 × 1 ×

no hose 1 ×

or

2 ×

or

1 × + 1 ×

or

2 × + 1 ×

Purging 1 × no hose

or

1 ×

or

2 ×

1 × + 1 × no hose

or

1 ×

1 × + 2 × no hose

Suction hose Extension hose

6 │ 3 Operation

3.2 Switching the device on

Once you have prepared the device (section 3.1), you can start

to use it.

1. Connect the device outside of the explosive area.

− Do this by connecting the FLIS to the power supply. Switch

on the device at the motor protection switch.

The device starts to ventilate or purge the shaft.

2. Wait for at least 6× the air volume before you start to enter

the shaft.

Air volume (calculating the waiting time)

Before entering the shaft, always ensure that harmful gases

are adequately purged or diluted. The respective waiting time

depends on the power of the fan and the volume of the shaft.

Typical fan power

[m³/min]

Waiting time [min]* for 6-times air vol-

ume in a space volume of

3 m³ 10 m³

3.5 5:30 17:30

* Times rounded up

The waiting time for other space volumes is calculated as follows:

Waiting time = 6-times volume of space

fan power

3.3 Switching o the device

1. Switch o the device at the motor protection switch.

2. Disconnect the device from the power supply.

4 Maintenance and servicing │ 7

4 Maintenance and servicing

The FLIS does not require maintenance. An inspection protocol

is appended for regularly checking the device in accordance with

DIN 60079-17.

4.1 Visual inspection

The FLIS does not have enclosed housing. Therefore, damage

from external inuences are possible.

FLIS

●Check the FLIS for visible outer damage before each use.

●

Always inspect the device when it is powerless (disconnect

the mains plug).

● Never use a faulty device.

● Return faulty devices to the manufacturer for repair.

Hoses

● Check the hoses for mechanical damage.

− Hose fabric free from damage?

−

Lug of hose clip:

ensures contact with nozzle (clamping coil)?

− Replace the damaged hoses.

4.2 Cleaning

● Always disconnect the mains plug before cleaning.

● Clean with a damp cloth. Dry cloths run the risk of electrostatic

charge on the housing surface.

● Remove signicant contamination immediately.

8 │ 5 Transport, storage, storing the hose

5 Transport, storage, storing the hose

Transport and storage

●

Protect the FLIS from mechanical damage during transportation.

Pay attention in particular to the bottom of the device which is

freely accessible.

● Make sure the device is dry when storing.

●

Always wind up the connection cable for transport and storage.

Storing the hose

There are two canister holders built into the FLIS for storing the

hoses. The canister holders have a locking bolt on the open side.

● Secure your hoses to make sure they cannot fall out.

− Do this by allowing the bayonet tting on the end of the hose

to engage in the locking bolt.

6 Appendix │ 9

6 Appendix

6.1 Technical data

Model 230 V~ / 50 Hz

Explosion protection yes

Position of use upright

Protection class without the hoses

tted IP23

Protection class with the hose tted

on the suction side IP43

Air volume when the suction hose

is connected with 2 extension hos-

es (each 2.3 m) approx. 3.5 m3/min

Motor output 120 W / 0.7 A

Sound level when hoses are con-

nected 60 dB (A) / 1 m

Weight 19 kg

Dimensions (W × H × D) 50 × 40 × 40 cm

Cable length 20 m

Permitted operating/storage tem-

perature -15 – 40 °C

Permitted moisture 0 – 90 % r.h.

Permitted atmospheric pressure 860 – 1100 hPa

6.2 Explosion protection

The FLIS-EX is classied in explosion protection group II2G IIC

T4 Gb and is suitable for the following atmospheres:

−Methane CH4

− Propane C3H8

−Butane C4H10

− Hydrogen sulphide H2S

−Carbon monoxide CO

− Hydrogen H2

EU type examination certicate: TÜV 05 ATEX 2766 X

10 │ 6 Appendix

6.3 Accessories

Part Order number

Suction hose with cage ZG03-Z0401

Extension hose ZG03-Z0201

Extension hose in canister holder ZG03-81000

6.4 Declaration of conformity

Hermann Sewerin GmbH hereby declares that the FLIS-EX

230 V fulls the requirements of the following guideline:

● 2014/34/EU

Gütersloh, 2016-04-20

Dr S. Sewerin

(Managing Director)

The complete declarations of conformity can be found online.

6 Appendix │ 11

6.5 Inspection protocol

24.01.2023

1.0

1.1

1.2

1.3

1.4

1.5

2.0

3.0

3.1

3.2

3.3

3.4

4.0

4.1

4.2

4.3

Signature

Equipment test according to BGV A2 (VDE0701/0702):

Insulation resistance > 0.5 Mohms / 500V

Sticker with cleaning instructions is present

Resistance of the electrical connection(with connected

hoses):

– Earthing contact – suction hose (< 100 ohms)

– Earthing contact – venting hose (< 100 ohms)

Test of the protective motor switch:

Block fan roller in switched-off state > switch on: Motor must

switch off automatically after max. 16 seconds

Housing in perfect condition

Mains connection line undamaged

FLIS-EX

INSPECTION PROTOCOL

FAB No. (e. g.: 008 01 xxx)

according to DIN EN 60079-17

Place, date

Check identification plates:

Suction hose undamaged

Extension hose undamaged

Butterfly nut at the connecting pieces runs smoothly and

evenly

– FLIS identification plate is present

General functional check

Visual check (to be performed by the user before starting to work)

Close examination (check of the original state)

Detailed check (to be performed by a specialist, e.g. after maintenance)

– Identification plate of protective motor switch is present

– Identification plate present at the valve unit (with explosion

protection marking)

Mains connection line of type H07RN-F3G

Check all modules for firm seating

Put the device into operation > Check suction effect at the

suction hose

Hermann Sewerin GmbH

Robert-Bosch-Straße 3

33334 Gütersloh, Germany

Tel.: +49 5241 934-0

Fax: +49 5241 934-444

www.sewerin.com

SEWERIN SARL

17, rue Ampère – BP 211

67727 Hoerdt Cedex, France

Tél. : +33 3 88 68 15 15

Fax : +33 3 88 68 11 77

www.sewerin.fr

SEWERIN IBERIA S.L.

Centro de Negocios Eisenhower

Avenida Sur del Aeropuerto

de Barajas 28, Planta 2

28042 Madrid, España

Tel.: +34 91 74807-57

Fax: +34 91 74807-58

www.sewerin.com

Sewerin Portugal, Lda

Rua Sr. Dos Milagres, 16, 2º Esq

3800-261 Aveiro, Portugal

Tlf.: +351 234 133 740

Fax.: +351 234 024 446

www.sewerin.com

Sewerin Sp. z o.o.

ul. Twórcza 79L / 1

03-289 Warszawa, Polska

Tel.: +48 22 675 09 69

Tel. kom.:+48 501 879 444

www.sewerin.com

Sewerin Ltd.

Hertfordshire

UK

Phone: +44 1462-634363

www.sewerin.co.uk

Table of contents

Other sewerin Measuring Instrument manuals

sewerin

sewerin miniLec 4 User manual

sewerin

sewerin UT 9000 User manual

sewerin

sewerin VARIOTEC 480 EX User manual

sewerin

sewerin Multitec 560 User manual

sewerin

sewerin EX-TEC PM 4 User manual

sewerin

sewerin COMBIPHON User manual

sewerin

sewerin EX-Tec HS 680 User manual

sewerin

sewerin Multitec 520 User manual

sewerin

sewerin VARIOTEC 460 Tracergas User manual

sewerin

sewerin Stethophon 04 User manual