sewerin COMBIPHON User manual

12.09.2017 a – 107543 – en

COMBIPHON®

Operating Instructions

COMBIPHON®system

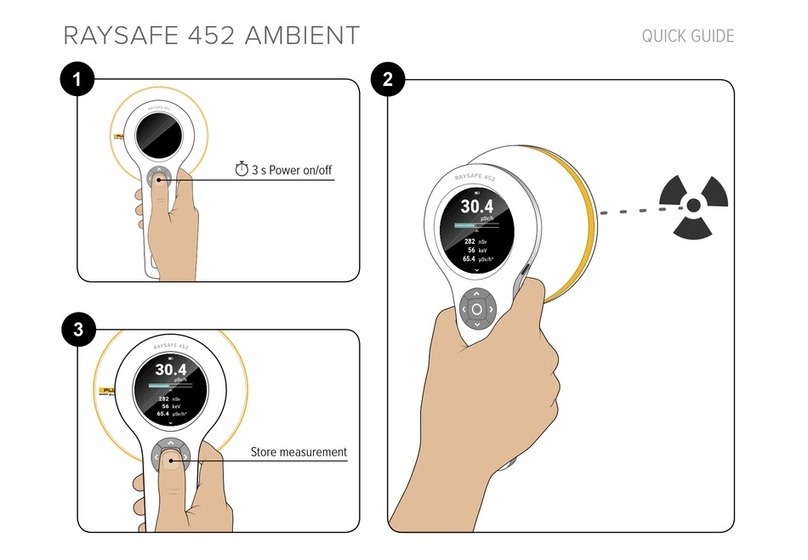

Fig. 1: CG 50 generator in case with accessories

Fig. 2: Ports on case

AC/DC adapter L

Tapper

Remote control

CG 50 generator

Oscillator port

Power port

CG 50 generator

Fig. 3: CG 50 generator – displays and controls

* Intensity setting for tapper only.

Stopper LED

Frequency LED

Frequency adjuster

Tapper LED

Battery LED

On/o and

intensity adjuster*

Information about this document

Warnings and notes in this document mean the following:

NOTICE!

Risk of damage to property.

Note:

Tips and important information.

Enumerated lists (numbers, letters) are used for:

●Instructions that must be followed in a certain order

Lists with bullet points (point, dash) are used for:

●Lists

●Instructions that only involve one step

Contents │ I

1 Introduction .............................................................................1

1.1 Warranty....................................................................................1

1.2 Purpose.....................................................................................2

1.3 Intended use .............................................................................2

1.4 General safety information ........................................................2

2 COMBIPHON system ..............................................................4

2.1 System components (overview) ................................................4

2.2 Power supply to the system ......................................................4

3 CG 50 generator ......................................................................6

3.1 Controls and displays................................................................6

3.2 Switching the generator on and o............................................6

4 Locating with the tapper.........................................................7

4.1 Using the tapper to locate pipes................................................7

4.2 After location .............................................................................8

5 Locating pipelines with the stopper......................................9

5.1 Functional principle ...................................................................9

5.2 Using the stopper to locate pipes............................................10

5.3 After location ........................................................................... 11

5.4 Cleaning the stopper ...............................................................12

6 CG 50 generator with remote control (optional) ................14

6.1 Operating the tapper with the remote control..........................14

6.2 Operating the stopper with the remote control ........................15

7 Troubleshooting ....................................................................16

7.1 Problems with the CG 50 generator........................................16

7.2 Problems with the tapper ........................................................16

7.3 Problems with the stopper.......................................................16

8 Appendix................................................................................18

8.1 Technical data .........................................................................18

8.1.1 CG 50 generator ..................................................................18

8.1.2 Tapper ..................................................................................19

8.1.3 Stopper (optional).................................................................19

8.1.4 AC/DC adapter L..................................................................19

II │ Contents

8.1.5 Remote control (optional).....................................................19

8.2 Accessories.............................................................................19

8.3 Declaration of conformity ........................................................19

8.4 Advice on disposal ..................................................................20

9 Index.......................................................................................21

1 Introduction │ 1

1 Introduction

1.1 Warranty

The instructions below must be complied with in order for any

warranty to be applicable regarding functionality and safe oper-

ation of this equipment. This product must only be commissioned

by qualied professionals.

●Read these operating instructions prior to operating the prod-

uct.

●Use the product only as intended (Section 1.3).

●Repairs and maintenance must only be carried out by special-

ist technicians or other suitably trained personnel. Only spare

parts approved by Hermann Sewerin GmbH may be used

when performing repairs.

● Changes or modications to this product may only be carried

out with the approval of Hermann Sewerin GmbH.

●

Use only Hermann Sewerin GmbH accessories for the product.

Hermann Sewerin GmbH shall not be liable for damages result-

ing from the non-observance of this information. The warranty

conditions of the General Terms and Conditions (AGB) of Her-

mann Sewerin GmbH are not broadened by this information.

In addition to the warnings and other information in these Oper-

ating Instructions, always observe the generally applicable safety

and accident prevention regulations.

The manufacturer reserves the right to make technical changes.

2 │ 1 Introduction

1.2 Purpose

COMBIPHON is a system used to mechanically cause pipelines

to vibrate. The vibrations generate noises which can be located

acoustically (e.g. using the AQUAPHON or AquaTest T10 sys-

tem).

The COMBIPHON system is ideal for locating pipelines made of

plastic, bre cement and metal.

1.3 Intended use

The COMBIPHON system is intended for professional industrial

and commercial use. The appropriate specialist knowledge is

required to operate the system.

Only use the COMBIPHON system for the application specied

in section 1.2.

1.4 General safety information

The COMBIPHON system was manufactured in accordance with

all binding legal and safety regulations. It corresponds to the

state of the art and complies with conformity requirements. The

product is safe to operate when used in accordance with the in-

structions provided.

If you handle the product improperly or not as intended, the prod-

uct may present a risk to persons and property. For this reason,

always observe the following safety information.

Risk of personal injury (health risk)

●Proceed with extreme caution in the vicinity of electrical lines.

●Do not use the COMBIPHON system in the case of damage

or faults.

1 Introduction │ 3

Hazards for the product and other property

●Avoid damage, strong shocks, constant moisture and dirt.

●Before using the device, always check that the system com-

ponents are in good working order. Never use damaged or

defective components.

●

Dirty contacts and moisture can result in functional disturbanc

-

es. Clean and dry the electrical connections if necessary.

●Handle the system carefully and safely both during transport

and when working.

●

Observe the permitted operating and storage temperatures

(page 18).

4 │ 2 COMBIPHON system

2 COMBIPHON system

2.1 System components (overview)

COMBIPHON is a modular system. The main system compo-

nents are as follows:

●CG 50 generator (permanently installed in case)

●Tapper

Oscillator for use with water or gas pipes

●Stopper (optional)

Oscillator for use with water mains

●AC/DC adapter L

for operating and charging the CG 50 generator

2.2 Power supply to the system

There are various power supply options available for the CG 50

generator:

●external power source (100 –240 V)

−AC/DC adapter L

−12 V battery via vehicle cable L (accessory)

●

Pb battery (rechargeable lead acid battery), built-in and sealed

The CG 50 generator automatically starts charging / trickle charg-

ing when it is connected to an external power source. In trickle

charge mode, the battery is constantly monitored and recharged

when necessary.

Note:

SEWERIN recommends always connecting the CG 50 generator

to an external power source, even when it is not in use. This will

prevent harmful deep discharge of the battery and also means

that the CG 50 generator is always ready for use.

2 COMBIPHON system │ 5

If the battery voltage drops below 10 V and there is no external

power supply, the CG 50 generator will switch to standby mode.

In standby mode the current is less than 7 mA, and all the LEDs

will go out.

6 │ 3 CG 50 generator

3 CG 50 generator

The CG 50 generator is permanently integrated in the case and

cannot be removed (g. 1).

There is an optional remote control available for the CG 50 gen-

erator.

3.1 Controls and displays

For an overview including the names of all the controls and dis-

plays, see the front cover ap (g. 3). The frequency and intensity

of the signal used for the location process are set using the knobs

on the CG 50 generator.

The LEDs on the control panel indicate the following operating

statuses:

LED Colours Signal Operating status

Tapper red constant tapper connected

Stopper red constant stopper connected

Disposable

battery

green constant generator switched on

ashing battery charging

double ashing trickle charge

red ashing undervoltage

Frequency red ashing generator generating

pulse

3.2 Switching the generator on and o

The CG 50 generator is switched on and o using the on/o knob.

● Turn the on/o knob to the right until you overcome the slight

resistance. The generator is switched on.

● Turn the on/o knob to the far left until you overcome the slight

resistance. The generator is switched o.

4 Locating with the tapper │ 7

4 Locating with the tapper

The tapper causes pipelines to vibrate, which enables the line

to be located.

For the location process itself an appropriate system for acoustic

leak detection must be used (e.g. AQUAPHON system).

The tapper can be used with gas and water pipes up to 120 mm

in diameter.

Fig. 4: Tapper, attached to a house service connection

4.1 Using the tapper to locate pipes

Proceed as follows to use the tapper to locate pipes:

1. Attach the tapper to the line.

a) To do this, place the fastening chain around the pipeline.

b) Hook the fastening chain onto the tapper.

c) Using the knob on the tapper, tighten the fastening chain

until the tapper is securely positioned.

2.

Connect the connection cable of the tapper to the CG 50 gen-

erator.

3. Switch on the CG 50 generator.

4. Start up the system to be used for acoustic leak detection.

8 │ 4 Locating with the tapper

5.

To optimally adjust the pulses to the individual conditions,

initially turn the intensity adjuster and frequency adjuster to-

wards the centre.

6. Start locating the pipeline.

●

While doing so, gradually adjust the intensity and frequency

of the emitted pulses on the CG 50 generator until they suit

the local conditions.

−

Take into account the type of ground surface, the soil

density and possible background noise.

−Do not set the intensity and frequency too high if you are

locating a pipeline close to the tapper. Vibrations can, for

example, travel along the walls of buildings and make

location dicult.

7. Mark the course of the located line.

4.2 After location

Once you have nished your location work:

1. Switch o the CG 50 generator.

2.

Disconnect the connection cable of the tapper from the CG 50

generator.

3. Disconnect the tapper from the pipeline.

4. Clean and dry the tapper before storing it in the case.

NOTICE! Equipment damage possible

Moisture in the case can eventually lead to equipment damage:

●

Leave the case open in a dry environment until it has fully

dried out.

5 Locating pipelines with the stopper │ 9

5 Locating pipelines with the stopper

The stopper is an optional accessory for the COMBIPHON sys-

tem. The stopper is designed for use on water mains.

The stopper can be connected to:

●DIN above-ground hydrants

●DIN underground hydrants in conjunction with a standpipe

Fig. 5: Stopper on standpipe

5.1 Functional principle

When water is withdrawn from a hydrant, the water column is set

in motion. The stopper slows down the water column at intervals.

This generates noises that travel along the line and can be locat-

ed even at long distances.

For the location process itself, an appropriate system for acoustic

water leak detection must be used (e.g. AQUAPHON system).

Intensity adjuster

Standpipe

Shut-o valve

Manometer

Stopper

10 │ 5 Locating pipelines with the stopper

5.2 Using the stopper to locate pipes

Note:

This section explains how to use the stopper at an underground

hydrant with a standpipe. If the hydrant is above ground, connect

the stopper directly.

Proceed as follows to use the stopper to locate pipes:

1. Connect the standpipe with ushing adapter to the hydrant.

2. Rinse the hydrant/pipeline to remove any dirt from the stop-

per. To do this, open the shut-o valves on the hydrant and

the standpipe. As soon as the water runs totally clear, close

the shut-o valves. The hydrant/pipeline is now rinsed.

3. Take the ushing adapter o the standpipe.

4. Connect the stopper to the standpipe.

5.

Always turn the intensity adjuster on the stopper (g. 5) all the

way to the right initially (lowest intensity).

6.

Connect the connection cable of the stopper to the CG 50

generator.

7. Open the shut-o valves on the hydrant and the standpipe.

8. Switch on the CG 50 generator.

9.

Start up the system to be used for acoustic leak detection and

start the locating process.

10.

Carefully adjust the pulse to the local conditions. Take into

account, for example, the ground surface, soil density and

background noise.

●

To strengthen the pulse, gradually turn the intensity adjuster

on the stopper to the left.

●

Use the frequency adjuster on the CG 50 generator to

change the frequency of the pulse.

11.Mark the course of the located line.

5 Locating pipelines with the stopper │ 11

5.3 After location

Once you have completed the location process:

1. Switch o the CG 50 generator.

2. Close the shut-o valve on the hydrant.

3.

Disconnect the connection cable of the stopper from the

CG 50 generator.

4. Remove the stopper from the hydrant.

If using on an underground hydrant:

a) Remove the stopper from the standpipe.

b) Remove the standpipe from the hydrant.

5. Thoroughly clean the components of the stopper (section 5.4

on page 12).

6. Dry all parts or let them dry naturally.

7. Clean and dry the stopper before storing it.

NOTICE!

Functional disturbances possible as a result of corrosion

To prevent the corrosion of surfaces:

● Make sure the system is as dry as possible when storing it.

●

Only reassemble the stopper when it is dry or immediately

before next use.

12 │ 5 Locating pipelines with the stopper

5.4 Cleaning the stopper

To ensure the functionality of the stopper, thoroughly clean and

dry the stopper after every use.

Fig. 6: Components of the stopper

1 Front with screws, 2 Cylinder with piston,

3 Housing, 4 Intensity adjuster

Proceed as follows:

1. Undo the screws on the front of the stopper using the Allen

key provided.

2. Clean the piston and cylinder.

a) Remove the cylinder.

b)

Carefully pull the piston out of the cylinder, making sure

you keep it straight.

c) Thoroughly rinse the piston and cylinder with low-lime or

distilled water.

d) Thoroughly dry the cylinder and piston.

e)

Carefully insert the piston back into the cylinder. Make sure

that the components do not get jammed.

f) Screw the cylinder back onto the housing.

3. Clean the intensity adjuster.

a)

Undo the screws beside the intensity adjuster using the

Allen key provided.

b) Carefully pull out the intensity adjuster.

c) Pull out the slide gate.

5 Locating pipelines with the stopper │ 13

d)

Thoroughly rinse the intensity adjuster, slide gate and

housing with low-lime or distilled water.

e) Thoroughly dry the intensity adjuster and slide gate. Allow

the housing to air-dry.

f) Re-insert the slide gate and intensity adjuster.

g)

Secure the screws with lock washers again so that they

are equally tight.

The stopper is now clean.

14 │ 6 CG 50 generator with remote control (optional)

6 CG 50 generator with remote control (optional)

The CG 50 generator can also be operated with a remote control.

The remote control is available as an optional accessory.

Fig. 7: Remote control

6.1 Operating the tapper with the remote control

Use the remote control to adjust the intensity of the pulses on the

tapper to the requirements as follows:

●Up key: increases the intensity of the tapper.

●Down key: reduces the intensity of the tapper.

●Pause key: pauses pulses.

●Pause key again: resumes pulse after pause.

Note:

The intensity on the tapper cannot be adjusted with the remote

control to a higher value than that specied by the intensity ad-

juster on the CG 50 generator.

●To be able to set the maximum intensity on the tapper using

the remote control, turn the intensity adjuster on the CG 50

generator all the way to the right.

Up key

Down key

Pause key

Other manuals for COMBIPHON

1

Table of contents

Other sewerin Measuring Instrument manuals

sewerin

sewerin SeCorr 08 User manual

sewerin

sewerin UT 9000 User manual

sewerin

sewerin miniLec 4 User manual

sewerin

sewerin Stethophon 04 User manual

sewerin

sewerin SR2-EX-P User manual

sewerin

sewerin EX-TEC Combi User manual

sewerin

sewerin VARIOTEC 480 EX User manual

sewerin

sewerin Multitec 545 User manual

sewerin

sewerin EX-TEC PM 4 User manual

sewerin

sewerin SPE 2 User manual