sewerin SeCorr 08 User manual

Operating

Instructions

SeCorr® 08

Measurable success by Sewerin equipment

Congratulations.

You have chosen a quality instrument manufactured by Hermann

Sewerin GmbH.

Our equipment will provide you with the highest standards of perfor-

mance, safety and efciency. They correspond with the national and

international guide-lines.

Please read and understand the following operating instructions before

using the equipment; they will help you to use the instrument quickly and

competently. If you have any queries we are available to offer advice

and assistance at any time.

Yours

Hermann Sewerin GmbH

Robert-Bosch-Straße 3

33334 Gütersloh, Germany

Tel.: +49 5241 934-0

Fax: +49 5241 934-444

www.sewerin.com

info@sewerin.com

Sewerin USA LLC

2835 Haddoneld Road

Pennsauken, NJ 08110-1108

Phone: +1 215-852-8355

Fax: +1 856-662-7070

www.sewerin.net

sewerin-usa@sewerin.net

SEWERIN SARL

17, rue Ampère – BP 211

67727 Hoerdt Cedex, France

Tél. : +33 3 88 68 15 15

Fax : +33 3 88 68 11 77

www.sewerin.fr

sewerin@sewerin.fr

Sewerin Ltd

Hertfordshire

UK

Phone: +44 1462-634363

www.sewerin.co.uk

info@sewerin.co.uk

SEWERIN IBERIA S.L.

Centro de Negocios Eisenhower

Avenida Sur del Aeropuerto

de Barajas 24, Ed. 5 Of. 2C

28042 Madrid, España

Tel.: +34 91 74807-57

Fax: +34 91 74807-58

www.sewerin.es

info@sewerin.es

Sewerin Sp.z o.o.

ul. Annopol 3

03-236 Warszawa, Polska

Tel.: +48 22 519 01 50

Fax: +48 22 519 01 51

Tel. kom.+48 501 879 444

+48 608 01 37 39

www.sewerin.com

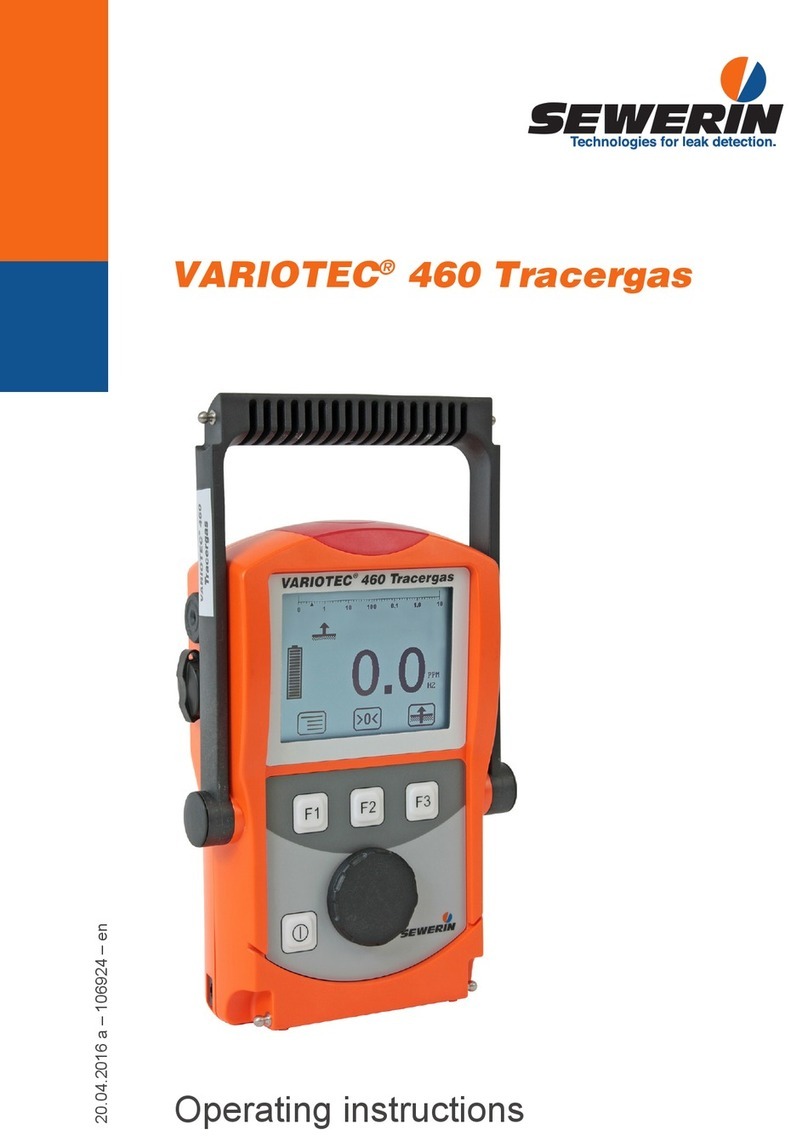

Illustration SeCorr 08

Rotary regulator

Menu key

ON/OFF key

Light key

Central screen

Enter key

Arrow keys

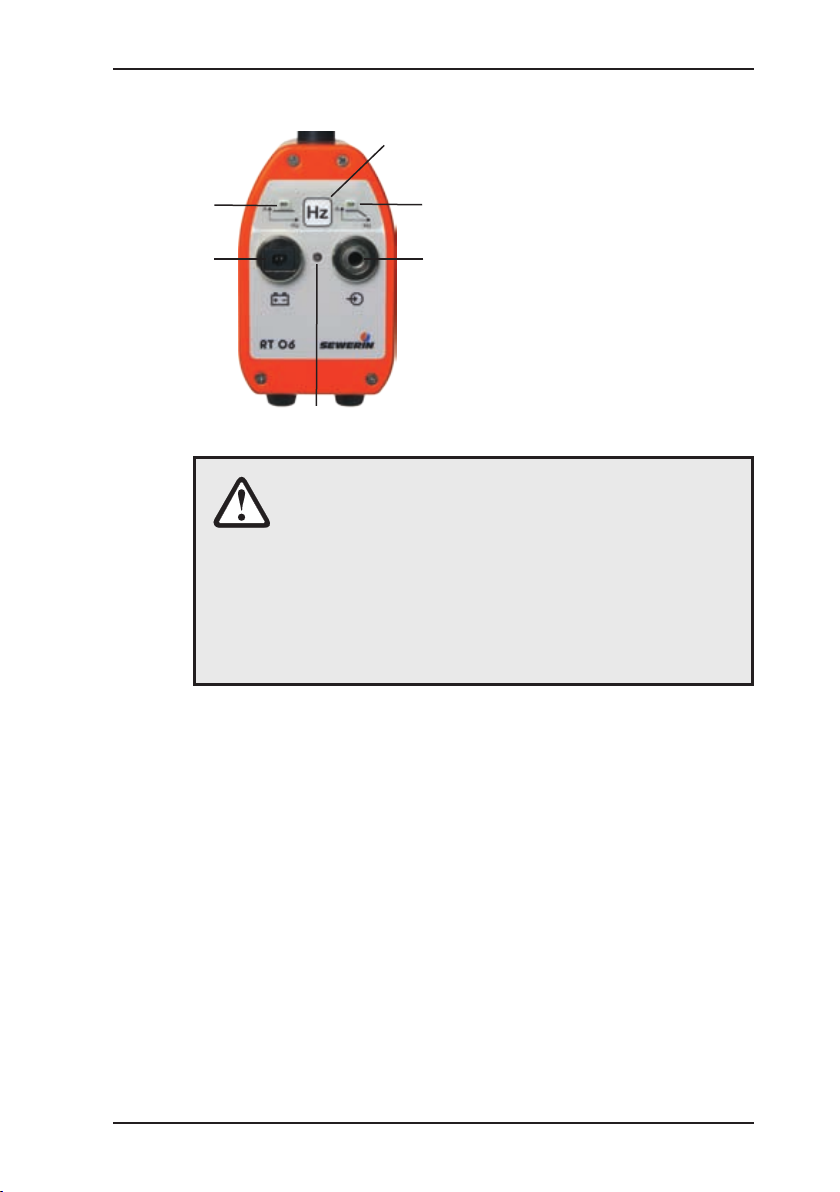

RT 06

A

Hz

A

Hz

Filter key (4)

LED (5), plastic,

low pass

LED (6), metal,

Wideband

Status-LED (1)

Power supply (3) Microphone connection (2)

Illustration RT 06

Operating Instructions

26.04.2010 – V 4.X – 103923 – en

SeCorr® 08

Warranty & Used symbols

Used symbols:

CAUTION!

This symbol is used to indicate dangers which may

either result in hazards for the operators or in severe

damage – or even destruction – of the product.

Note:

This symbol is used to call attention to information

and tips which may be helpful and which are exceed-

ing the basic operating procedures.

The following instructions must be complied with in order for any warranty

to be applicable in respect of the functionality and safe operation of this

equipment.

Hermann Sewerin GmbH accepts no liability for any damages resulting

from failure to observe these instructions. The warranty and liability provi-

sions of the terms of sale and delivery of Hermann Sewerin GmbH are not

affected by the information given below.

The product must only be operated after the relevant operating instruc-z

tions have been read and understood.

The product must only be used for its intended purpose.z

The product is only suitable for use in industrial and commercial ap-z

plications.

Repairs must only be carried out by a specialist technician or by otherz

suitably trained personnel.

Changes or modications to this product must not be carried out with-z

out approval from Hermann Sewerin GmbH. The manufacturer cannot

be held responsible for damages if non-approved modications have

been made.

All repairs must be carried out using replacement parts that have been z

approved by Hermann Sewerin GmbH.

The manufacturer reserves the right to make technical modications in z

the course of further development.

Generally applicable safety and accident-prevention regulations must be

complied with, in addition to the information provided in this manual.

I

Contents Page

1 Function description...............................................................1

1.1 Usage........................................................................................1

2 Use............................................................................................2

2.1 First use ....................................................................................2

2.2 Switching ON/OFF ....................................................................2

2.3 Channel assignment .................................................................3

2.4 Radio transmitter RT 06 ............................................................5

3 Operating elements.................................................................6

3.1 ON/OFF key ..............................................................................6

3.2 Rotary regulator ........................................................................6

3.3 Enter key ...................................................................................7

3.4 Menu key...................................................................................7

3.5 Left/right arrow keys..................................................................7

3.6 Up/down arrow keys..................................................................7

3.7 Light key....................................................................................8

3.8 Adjusting the contrast................................................................8

4 Performing a correlation measurement ................................9

4.1 Entering pipe data .....................................................................9

4.2 Starting a measurement..........................................................10

4.3 Evaluating the result................................................................ 11

4.3.1 Filtering ................................................................................12

4.3.2 Cursor ..................................................................................12

4.3.3 Zoom ....................................................................................13

4.4 Continuing a measurement .....................................................14

5 Measuring the sound velocity..............................................15

5.1 General information.................................................................15

5.2 Performing a measurement.....................................................15

6 Charging equipment .............................................................17

6.1 Battery state ............................................................................18

6.2 Charging process/battery maintenance ..................................19

II

Contents Page

7 Menu.......................................................................................20

7.1 Menu structure ........................................................................20

7.2 Listen.......................................................................................21

7.2.1 AQUAPHON.........................................................................21

7.2.1.1 Display ..............................................................................22

7.2.1.2 Assignment of keys...........................................................23

7.2.1.3 Sensitivity..........................................................................23

7.3 File ..........................................................................................23

7.3.1 Store.....................................................................................23

7.3.2 Open ....................................................................................24

7.3.3 Delete...................................................................................25

7.4 Filtering ...................................................................................25

7.4.1 Automatic ltering.................................................................25

7.4.2 Manual ltering.....................................................................25

7.4.3 Setup....................................................................................28

7.4.3.1 Filter limits.........................................................................28

7.4.3.2 Filter basis.........................................................................28

7.4.3.3 Filtering method ................................................................29

7.5 Measurement method .............................................................29

7.6 Parameter ...............................................................................29

7.6.1 Noise suppression................................................................29

7.6.2 Measuring time.....................................................................31

7.6.3 Summation/average .............................................................31

7.6.4 Mode of curve ......................................................................31

7.6.5 Correlation............................................................................31

7.6.6 Sampling frequency .............................................................32

7.6.7 Table.....................................................................................32

7.6.8 Standard values ...................................................................32

7.7 Components............................................................................33

7.8 Setup.......................................................................................34

7.8.1 Date, time.............................................................................34

7.8.2 Language .............................................................................34

7.8.3 Radio/cable ..........................................................................34

7.8.4 System .................................................................................34

7.8.5 Name....................................................................................35

7.8.6 Service .................................................................................35

8 Methods of optimising measuring results..........................36

8.1 Changing the number of averaging processes .......................36

8.2 Using lters .............................................................................36

III

Contents Page

8.3 Automatic ltering....................................................................37

8.4 Checking the microphone connections ...................................37

8.5 Using accessories ...................................................................37

8.6 Changing the location .............................................................37

8.7 Saving time .............................................................................37

9 Communication with PC.......................................................38

9.1 Requirements..........................................................................38

9.2 Software installation ................................................................38

10 Technical data........................................................................40

11 Accessories ...........................................................................41

12 Error messages .....................................................................42

13 Annexe ...................................................................................44

13.1 EC Declarations of Conformity................................................44

13.2 Advice on disposal ..................................................................44

13.3 History of changes ..................................................................45

14 Index.......................................................................................46

1

1 Function description

1 Function description

1.1 Usage

The correlator SeCorr 08 permits to detect leakage points an

directly buried pressure line systems according to the correla-

tion principle. Sensitive microphones are used to record leakage

noise on accessible installations and ttings. These recordings

are wireless transmitted to the correlator.

SeCorr 08 calculates then the exact leakage position using the

Fast Fourier Transformation (FFT = mathematic algorithm).

Supplementary functions are available to improve e.g., the indi-

cation of leaks, to enter several pipe sections or to measure the

sound velocity.

The RT 06 radio transmitter can be used to measure fully auto-

matically the input level of the microphone and to set the level

control of the amplier to the optimum value. Characteristics and

parameters – such as the used microphone type, the charge state

of batteries and the amplier setting – are wireless transmitted to

the correlator for further evaluation.

Note:

These operating instructions are based on soft-

ware release 4.X, with „X“ standing for any number.

The currently installed software version of your

SeCorr 08 is displayed after switching on the device.

Future releases are subject to change!

2

2 Use

2 Use

2.1 First use

CAUTION!

Before placing SeCorr 08 and RT 06 for the rst

time into service, make sure that all used batteries

are completely charged. If the batteries are only

partially charged, the capacity of the batteries may

be reduced thus leading to shorter operation.

2.2 Switching ON/OFF

Position both piezo micro-z

phones at accessible fitting

parts. If the circular magnet

is screwed on the piezo mi-

crophone, it may be required

to remove the circular, rmly

adhering protective disk from

the magnet.

Plug both microphone con-z

nectors into the sockets of the

radio transmitter RT 06. If you

want to use only one RT 06, it

is required to connect a micro-

phone directly to input 2 of the

SeCorr 08.

On the RT 06, LED 1 must

be lit.

Connect the headphones toz

socket 3 of the SeCorr 08.

Switch on the SeCorr 08 by z

pressing the ON/OFF key for

a couple of seconds.

2

1

3

2 Use

The initial screen is briefly

displayed, containing informa-

tion on the release number of

the software and the battery

capacity.

Then the central screen ap-

pears (see back of cover

page). From this screen, you

can access the individual

menus (menu key) or start the

desired functions.

Keep thezON/OFF key pressed

until the device switches off.

2.3 Channel assignment

Channel 1 Channel 2

Is indicated together

with message

„battery empty“

RT 06-1 RT 06-2

Indication Left Right

Type with one signal

channel

Director connection

of microphone to

SeCorr 08

Radio transmitter 2

(orange)

Type with two sig-

nal channels

Radio transmitter

1 (blue)

Radio transmitter

2 (orange)

Only one radio

transmitter is used

(e. g. in case of a

defect):

Variant 1z

(blue radio trans-

mitter in use)

Radio transmitter 1

(blue)

Direct connection

of microphone to

SeCorr 08

Variant 2z

(orange radio

transmitter in use)

Direct connection

of microphone to

SeCorr 08

Radio transmitter 2

(orange)

3

4

2 Use

During correlation measure-z

ments the noise intensity of

both microphone channels is

indicated to the left- and right-

hand side of the correlation

function.

Note:

The SeCorr 08 version with two transmitters permits

to connect a microphone directly two the SeCorr 08,

e.g., if a radio transmitter is defective (see also sec-

tion 7.8.3).

started

5

2 Use

2.4 Radio transmitter RT 06

The radio transmitter RT 06

can be operated with different

sensors, EM30 microphones

and the HA hydrophone.

It is recommended to use the

active lter ZF01, if interfering

noise is to ltered out or if only

a specic acoustic frequency

range is to be transmitted to

the correlator SeCorr 08.

1

2

3

65

4

CAUTION!

Connect always rst the sensor to the measurement

location (by coupling the microphone to the slide

valve, hydrant, etc.). Then, switch on the RT 06 by

plugging the sensor into socket 2.

This sequence of steps ensures that the automatic

amplication in the RT 06 is quickly and properly

set.

The RT 06 is enabled when the sensor is plugged into socket 2.

Press the lter key 4 generally if plastic pipes are used. The right

LED 5 is lit to indicate the changeover. If this setting is selected,

only the low-pass frequencies are transmitted to the correlator.

This may help to increase the quality of the correlation mea-

surement. If the RT 06 is switched on, all frequencies are always

transmitted; the left LED 6 is lit.

The transport handle on top of the antenna can be used for car-

rying the device.

LED 1 shows the state of the RT 06:

Operation: green

Undervoltage: ashed red

Charging: 1 x ashing green

Buffering: 2 x ashing green

No charging: red (because temperature below 0 °C)

6

3 Operating elements

3 Operating elements

3.1 ON/OFF key

Press this key to switch the de-

vice on or off. Hold it pressed un-

til the SeCorr 08 is activated.

If the key is pressed only shortly,

the currently running function is

stopped (e.g., a correlation in

progress). If you have opened

the menu, you can use the ON/

OFF key to return to the next

higher menu level. Press the key

only shortly.

If a correlation is stopped, the

diagram (correlation function)

can be zoomed in. If any key is

pressed, the display returns to

normal representation.

3.2 Rotary regulator

Turn the Rotary regulator to

move the selection or the cursor

to the left/right or up/down.

You can use the Rotary regulator

to change values in numerical

entry elds (e.g., pipe length).

Press the Rotary regulator once

to change the direction of move-

ment from up/down to left/right or

vice versa.Pressing the Rotary

regulator has the same effect as

pressing the Enter key.

7

3 Operating elements

3.3 Enter key

Press this key to enable the cur-

rently selected function.If you

select „Cancel“ in the menu, the

display returns to the central

screen.

3.4 Menu key

Press this key to open the menu

(see section 7).

3.5 Left/right arrow keys

Press these keys to move to the

left or right within the selected

function. In some menus the

arrow keys can also be used for

selecting options.

You can access the next higher

menu level by pressing the left

arrow key. You can use this func-

tion only if the cursor is set to its

left or right end position.

3.6 Up/down arrow keys

Press these keys to move the

cursor up or down in a menu.

In some menus the Arrow keys

can also be used for selecting

options.

8

3 Operating elements

3.7 Light key

Use this key to switch the il-

lumination on or off. The illu-

mination automatically switch-

es off after a pre-set period

(see section 7.8.4).

3.8 Adjusting the contrast

The contrast of the display is au-

tomatically controlled in relation

to the temperature.

You can adjust the contrast

manually by holding the Light

key pressed while operating the

Up or Down Arrow key at the

same time.

9

4 Performing a correlation measurement

4 Performing a correlation measurement

4.1 Entering pipe data

Before starting a measurement, it is required to enter the pipe

data.

Select option pipe data usingz

the Arrow keys and conrm

your selection with the Enter

key.Then, enter the number of

pipe sections.

Depending on the type of ap-z

plication, select One, Two or

Three pipe sections with the

arrow keys. Conrm your se-

lection with the Enter key.

Enter the pipe length. Use z

the left or right arrow key to

change between the displayed

digits.

You can use the Up/Down z

arrow keys to increase or

reduce the displayed value in

increments.

Confirm the length with thez

Enter key.

In the list, select the materialz

of the pipe section using the

Arrow keys. You can also use

the direct option to enter the

sound velocity manually.

Pay attention to the following: z

The values in the list are ap-

proximate values and may be

subject to inaccuracies (see

section 5.)

In the displayed list, select thez

pipe diameter using Arrow keys.

10

4 Performing a correlation measurement

Note:

Apart from the default application, „Cross cor-

relation“, SeCorr 08 can also be used to perform

automatic correlations („Auto correlation“); refer to

chapter 7.6.5!

4.2 Starting a measurement

Select this function, if a measurement section is measured for

the rst time or if an error occurred during the rst measurement

(transmitter is not switched on, problems during connecting the

microphone, etc.).

Select start with the Arrow z

keys and conrm your selec-

tion with the Enter key.

Use the headphones to check

the measurement trend acous-

tically (safety instructions: see

section 7.2.1).

If necessary, repeat these en-z

tries for the second and third

pipe section.

pipe data

start

continue

A summary of the entered zpipe

data appears on the screen.

Select Start with the Arrow

keys. Press the Enter key.

The correlation measurement

starts.

Start

cancel

100.0 m

steel

125 mm

1280 m/s

11

4 Performing a correlation measurement

Press Cancel to return to thez

main menu.

Depending on the selected

settings (see section 7.6.2)

either 16, 32, 64 or 128 aver-

aging processes (i.e., meas-

urements) are performed.

The display shows the current-

ly performed measurement.

During the measurement, the

correlation function is continu-

ously updated.

The correlation measurement z

can be interrupted any time

by pressing the ON/OFF key

shortly.

An interrupted measurement

can always be resumed.

After the zmeasurement the re-

sult is displayed. The adjacent

illustration shows a correlation

example. The method of dis-

play depends on the setting

selected in the „Filter / Setup“

menu.

4.3 Evaluating the result

The correlation function uses

peaks to indicate where a leak

may be located. The time-delay

difference is displayed on the x

axis in ms (i.e., milliseconds).

The highest peak is automati-

cally highlighted.

pipe data

start

continue

pipe data

start

continue

Table of contents

Other sewerin Measuring Instrument manuals

sewerin

sewerin UT 9000 User manual

sewerin

sewerin EX-TEC PM 4 User manual

sewerin

sewerin EX-TEC Combi User manual

sewerin

sewerin COMBIPHON User manual

sewerin

sewerin EX-Tec HS 680 User manual

sewerin

sewerin Multitec 545 User manual

sewerin

sewerin Stethophon 04 User manual

sewerin

sewerin VARIOTEC 480 EX User manual

sewerin

sewerin SPE 2 User manual

sewerin

sewerin VARIOTEC 460 Tracergas User manual