sewerin EX-Tec HS 680 User manual

03.06.2019 a – 105734 – en

EX-TEC®HS 680/660/650/610

Operating Instructions

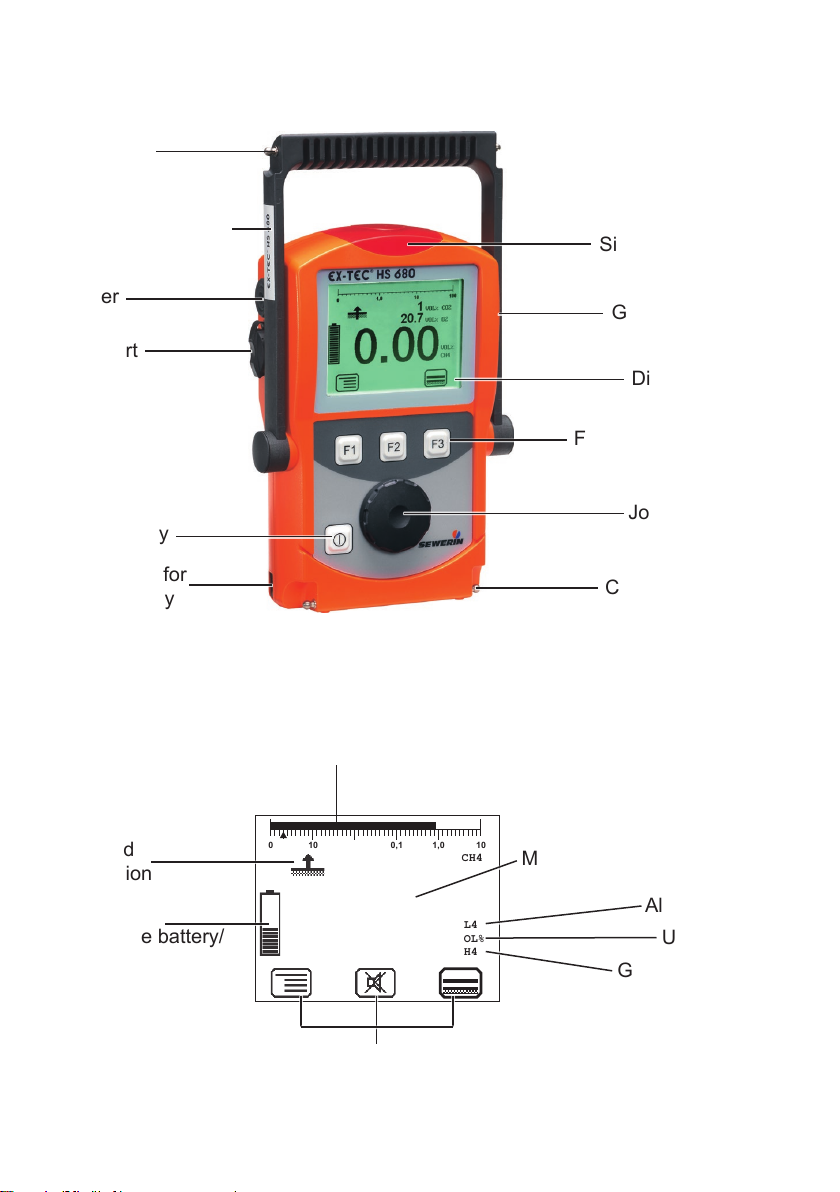

Connector

Buzzer

USB port

ON/OFF key

Connection for

power supply

Signal light

Gas input

Function keys

Jog dial

Connector

Display

CH4

AL4

VOL%

CH4

0,1 1,0

010 100 10

0.90

Measurement value

Capacity

disposable battery/

rechargeable battery

Selected

application

Bar display

Alarm

Unit

Gas type

Current assignment of

function keys F1 – F3

Supporting bracket

Fig. 1: EX-TEC HS 680 device overview

Fig. 2: EX-TEC HS 680 display

EX-TEC®HS 680/660/650/610

General

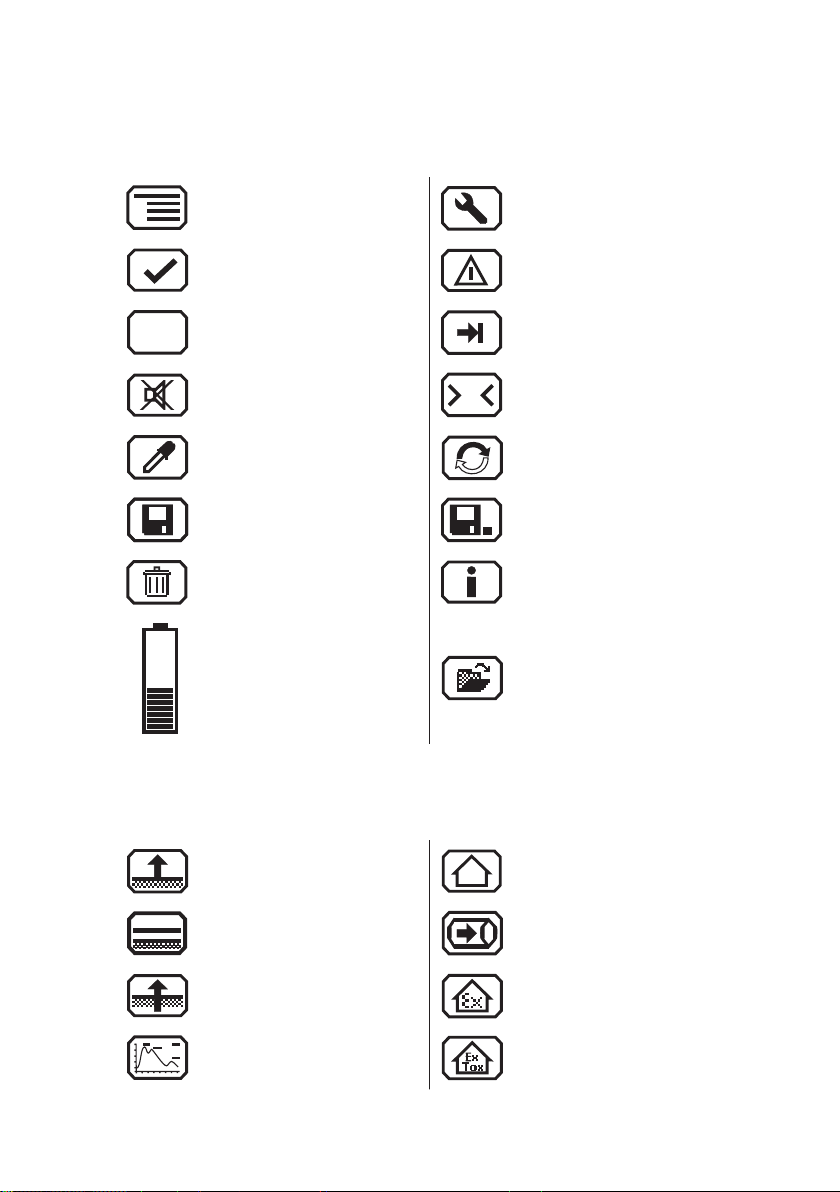

Menu Fault

OK Carry out device inspection

Esc

Cancel Tab (jump to next input

eld)

Buzzer o

0

Set zero point

Take sample Purge

Save Stop measurement

Delete Information

Capacity disposable bat-

tery/rechargeable battery

Open stored comment

Open stored inspector

Applications

Inspection above ground Structure

Plants Gas measuring

Measuring in bar holes Warning %LEL

Ethane analysis Warning ExTox

Display symbols

Information about this document

The warnings and notes in this document mean the following:

ADANGER!

Risk of personal injury. Will result in serious injury or

death.

AWARNING!

Risk of personal injury. Can result in serious injury or

death.

ACAUTION!

Risk of personal injury. Can result in injury or a risk to

health.

Notice!

Risk of damage to property.

Note:

Tips and important information.

Numbered lists (numbers, letters) are used for:

●Instructions that must be followed in a certain order

Lists with bullet points (point, dash) are used for:

●Lists

●Instructions that only involve one step

Numbers between forward slashes /.../ refer to the referenced doc-

uments.

I

Contents Page

1 General.....................................................................................1

1.1 Warranty....................................................................................1

1.2 Purpose.....................................................................................2

1.3 Intended use .............................................................................3

1.4 General safety information ........................................................4

1.5 Allocation of tasks to applications .............................................5

2 Features ...................................................................................6

2.1 Visual and audible signals.........................................................7

2.2 Sensors .....................................................................................8

2.3 Explosion protection..................................................................9

2.3.1 Passive explosion protection..................................................9

2.3.2 Active explosion protection ..................................................10

3 Operation ............................................................................... 11

3.1 General information on operation............................................ 11

3.1.1 Keys and jog dial.................................................................. 11

3.1.2 Selecting/exiting menus and menu items.............................12

3.1.3 Switching the device on .......................................................12

3.1.4 Selecting/changing the application.......................................14

3.1.5 Dierences between measuring mode and settings mode ..15

3.2 Measuring mode .....................................................................15

3.2.1 Accessing the menu (measuring mode menu structure)......16

3.2.2 Zero point .............................................................................17

3.2.3 Inspection above ground......................................................18

3.2.4 Plants ...................................................................................19

3.2.5 Measuring in bar holes.........................................................20

3.2.6 Ethane analysis ...................................................................21

3.2.6.1 General information on ethane analysis............................22

3.2.6.2 Purging the detector..........................................................24

3.2.6.3 Carrying out an ethane analysis........................................25

3.2.6.4 Evaluating an ethane analysis ..........................................26

3.2.7 Structure...............................................................................29

3.2.8 Gas measuring.....................................................................30

3.2.9 Warning %LEL ....................................................................31

3.2.10 Warning ExTox .....................................................................32

3.2.11 Settings ................................................................................33

3.2.12 Start/stop/save a measurement ...........................................33

3.2.13 Protocols ..............................................................................35

II

Contents Page

3.2.14 Device inspection .................................................................36

3.2.15 Gas type CxHy .....................................................................36

3.2.16 Device information ...............................................................37

3.3 Settings ...................................................................................37

3.3.1 Opening settings ..................................................................37

3.3.2 Settings menu structure .......................................................39

3.3.3 Adjustment ...........................................................................40

3.3.4 System .................................................................................42

3.3.5 Alarms ..................................................................................44

3.3.6 Date/time..............................................................................44

3.3.7 Memory ................................................................................44

4 Power supply.........................................................................46

4.1 Suitable disposable/rechargeable battery types .....................46

4.2 Operation with rechargeable batteries ....................................47

4.2.1 Charging...............................................................................48

4.2.2 Rechargeable battery maintenance .....................................49

4.3 Battery alarm...........................................................................49

4.4 Replacing disposable/rechargeable batteries .........................50

5 Maintenance ..........................................................................51

5.1 Device inspection ....................................................................51

5.1.1 General information on the device inspection ......................51

5.1.1.1 Scope................................................................................51

5.1.1.2 Frequency .........................................................................52

5.1.1.3 Documentation..................................................................53

5.1.1.4 Integrated device inspection .............................................53

5.1.1.5 Order.................................................................................54

5.1.1.6 Test gases for the device inspection .................................54

5.1.2 Performing the device inspection .........................................56

5.1.2.1 Accessing the device inspection .......................................56

5.1.2.2 Concluding the device inspection......................................57

5.1.3 Testing the general status ....................................................58

5.1.3.1 Housing.............................................................................58

5.1.3.2 Signals ..............................................................................59

5.1.3.3 Probe.................................................................................59

5.1.3.4 Filter ..................................................................................59

5.1.3.5 Pump.................................................................................59

5.1.4 Testing indication accuracy with supply of fresh air .............60

5.1.5 Testing indication accuracy with supply of test gas..............60

III

Contents Page

5.2 Adjustment ..............................................................................62

5.2.1 Scope ...................................................................................62

5.2.2 Test gases for the adjustment ..............................................63

5.2.3 Special features of adjustment with gas mixture..................64

5.2.4 Preparation...........................................................................65

5.2.5 Performing the adjustment ...................................................65

5.2.5.1 Adjusting the zero point.....................................................66

5.2.5.2 Adjusting the sensitivity.....................................................66

5.2.6 Carrying out an oxygen adjustment .....................................68

5.2.6.1 Adjusting the zero point for oxygen...................................68

5.2.6.2 Adjusting the sensitivity for oxygen...................................69

5.3 Servicing .................................................................................69

6 Faults......................................................................................70

7 Appendix................................................................................71

7.1 Specications and permitted operating conditions..................71

7.2 Alarms .....................................................................................72

7.2.1 Features ...............................................................................72

7.2.2 Occupational exposure limits (OEL) and excess factors

(STEL and LTEL)..................................................................75

7.2.3 Alarm thresholds (factory settings).......................................75

7.2.4 Setting ranges for gas types ................................................76

7.3 Limit values for the device inspection .....................................77

7.4 Memory capacity .....................................................................78

7.5 Sensors ...................................................................................79

7.5.1 Infrared sensors (IR) ............................................................79

7.5.1.1 Methane CH4, propane C3H8, butane C4H10 for

Warning %LEL and Warning ExTox ..................................79

7.5.1.2 Methane CH4, propane C3H8for gas measuring ...............80

7.5.1.3 Carbon dioxide CO2for warning ExTox.............................80

7.5.1.4 Carbon dioxide CO2for measuring in bar holes................81

7.5.2 Electrochemical sensors (EC)..............................................81

7.5.2.1 Oxygen O2........................................................................81

7.5.2.2 Carbon monoxide CO .......................................................82

7.5.2.3 Hydrogen sulphide H2S.....................................................83

7.5.3 Gas-sensitive semiconductor ...............................................83

7.6 Technical information ..............................................................84

7.6.1 Identication sticker (back of device) ...................................84

7.6.2 Cleaning ...............................................................................84

IV

Contents Page

7.6.3 Electrostatic charge..............................................................84

7.7 Accessories and consumables................................................85

7.8 Declaration of conformity ........................................................86

7.9 Inspection protocols ................................................................87

7.9.1 Test with individual gases.....................................................87

7.9.2 Test with gas mixture............................................................89

7.10 Advice on disposal ..................................................................91

7.11 Terminology and abbreviations ...............................................92

7.12 Referenced documents ...........................................................93

8 Index.......................................................................................94

1

1 General

1 General

1.1 Warranty

The following instructions must be complied with in order for any

warranty to be applicable regarding functionality and safe opera-

tion of this equipment. This product must only be commissioned

by qualied professionals who are familiar with the legal require-

ments (Germany: DVGW).

●Read these operating instructions prior to operating the product.

●Use the product only as intended.

●Repairs and maintenance must only be carried out by special-

ist technicians or other suitably trained personnel. Only spare

parts approved by Hermann Sewerin GmbH may be used when

performing repairs.

●Use only suitable battery types, otherwise the device will not

be explosion-proof.

● Changes or modications to this product may only be carried

out with the approval of Hermann Sewerin GmbH.

●Use only Hermann Sewerin GmbH accessories for the product.

Hermann Sewerin GmbH shall not be liable for damages resulting

from the non-observance of this information. The warranty con-

ditions of the General Terms and Conditions (AGB) of Hermann

Sewerin GmbH are not aected by this information.

In addition to the warnings and other information in these Oper-

ating Instructions, always observe the generally applicable safety

and accident prevention regulations.

The manufacturer reserves the right to make technical changes.

2

1 General

1.2 Purpose

The EX-TEC HS 680 and the models 660, 650 and 610 are hand-

held measuring devices which can be used for all gas pipeline

testing applications.

The devices are designed for professional industrial use and

require the necessary specialist knowledge for working in gas

pipelines. Sample applications are described in /3/.

All devices are tted with infrared sensors for measuring hydro-

carbons CXHYand carbon dioxide CO2as standard. Models 680

and 660 also feature a gas-sensitive semiconductor.

Models 680 and 660 can be optionally tted with a detector for

ethane analysis to help you safely distinguish between natural

gas and swamp gas.

All devices can also be individually tted with electrochemical

sensors.

The infrared sensors operate on the principle of absorption via

infrared-active gases, and the electrochemical sensors operate

on the electrochemical cell principle. The gas-sensitive semi-

conductor reacts to changes in conductivity brought about by

reducible gases.

Note:

These operating instructions describe the EX-TEC HS 680 with

all additional equipment (rmware version 2.XXX). All descrip-

tions refer to the device as delivered (factory settings) and apply

to all device versions. The manufacturer reserves the right to

make changes.

3

1 General

1.3 Intended use

This device is intended for professional residential and commer-

cial use including small rms and commercial operations. The

appropriate specialist knowledge is required to operate the device.

The device may only be used to measure the following gases

(depending on the device model and additional equipment):

●Methane CH4/propane C3H8/butane C4H10

●Carbon dioxide CO2

●Oxygen O2

●Hydrogen sulphide H2S

●Carbon monoxide CO

The device must not be used for:

●Gas analysis of technical processes

●Monitoring liquids

The device can be used up to a temperature of 40 ºC. However,

high temperatures reduce the lifetime of the sensors and re-

chargeable batteries.

If a device with an electrochemical sensor is exposed to gas

concentrations above the measuring range limit, this can reduce

the lifetime of the sensor.

4

1 General

1.4 General safety information

●The device has been tested to ensure that it is explosion-proof

in accordance with European standards (CENELEC).

●The device must only be switched on with fresh air.

●Do not use this device in oxygen-enriched atmospheres, oth-

erwise it will not be explosion-proof.

● Only probe hoses with a hydrophobic lter may be used.

Exception:

If the probe has a built-in hydrophobic lter, the hose does not

require any other lters.

●The device must only be tested and adjusted with test gases

in well ventilated rooms or in the open air. Test gases must be

handled in a professional manner.

●Always carry out a device inspection (see section 5.1) after

the device has suered an impact (for example, if dropped

accidentally).

●The device complies with the limits of the EMC directive. Always

observe the information in the manuals of (mobile) radio equip-

ment when using the device close to (mobile) radio equipment.

Note:

Follow the advice regarding explosion protection (see section 2.3).

5

1 General

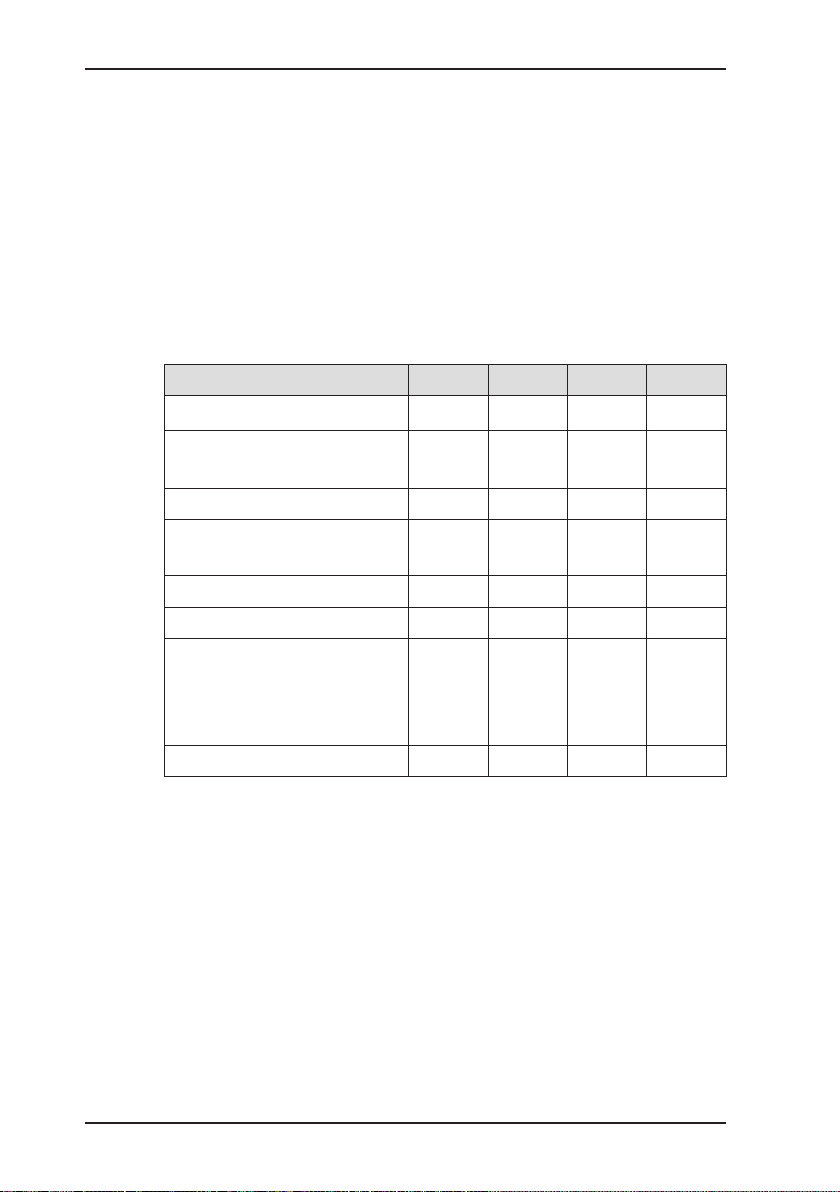

1.5 Allocation of tasks to applications

The table is designed to help you decide which application to

choose for which activity (in accordance with /3/).

Location Activity Application

Gas lines, gas systems, … ●Measuring the gas concentration

– Purging (to demonstrate purity or absence of gas,

e.g. when commissioning/decommissioning gas systems)

Gas measuring

Buried gas lines ●Measuring very low gas concentrations:

– Ground

– Gas line

– Possible leakage points

Inspection

above ground

●Distinguishing between natural gas and swamp gas Ethane analysis

Gas lines, gas systems, …

in houses, enclosed spaces

and shafts

●Warning against explosive gas concentrations through work

area monitoring

Warning %LEL

●Warning against explosive and toxic gases through work area

monitoring

Warning ExTox

In the ground ●Measuring the gas concentration to:

– Determining gas dispersion (detection limit)

– Classify leaks

– Locating a probable gas escape (repair point)

– Preventing possible dangers

Measuring in

bar holes

Poorly accessible gas pipes,

systems

●Measuring very low gas concentrations

●Locating the source of gas

●Finding leaks

Plants

In the house ●Measuring very low gas concentrations

●Locating the source of gas

●Finding leaks at internal connections

Structure

6

2 Features

2 Features

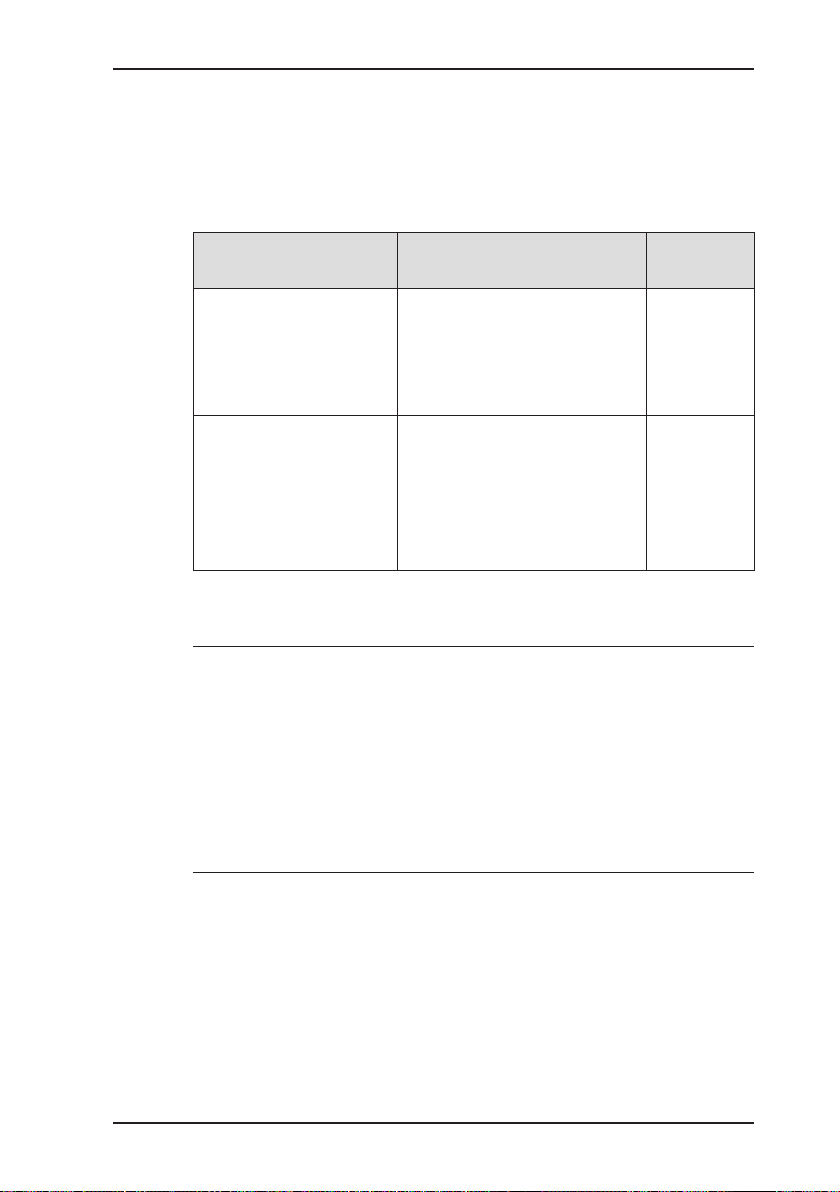

The device comes in four models:

EX-TEC HS 680

EX-TEC HS 660

EX-TEC HS 650

EX-TEC HS 610

The models are suitable for the following applications:

Application HS 680 HS 660 HS 650 HS 610

Inspection above ground × ×

Measuring in bar holes

O2

×

○

×

○

×

○

×

○

Plants × ×

Structure

CO

×

○

×

○

Gas measuring × × × ×

Warning %LEL × ×

Warning ExTox

CO

H2S

O2

×

○

○

○

×

○

○

○

Ethane analysis ○ ○

× standard ○ optional

7

2 Features

2.1 Visual and audible signals

The device features two alarms:

● Signal light on top of device (visual signal)

● Buzzer on side of device (audible signal)

The signals indicate alarms and faults. The device also emits

signals when it is switched on and o.

If this symbol appears on the display, the audible signal

can be switched o.

When an audible signal has been switched o it cannot

be switched back on while the concentration level re-

mains above the alarm threshold.

This symbol appears at the top left of the display as soon

as the audible signal has been switched o. It disappears

automatically if the level falls below the alarm threshold.

Operating signal

When using the Warning %LEL and Warning ExTox applications,

the device emits a visual and audible signal at regular intervals.

This indicates that the device is working properly.

Alarm

The device can monitor several gases at the same time. If the

measured gas concentration of one or more gases exceeds spec-

ied limit values (alarm thresholds) the device gives a warning. It

emits both audible and visual signals, which are clearly dierent

from the operating signal.

AWARNING! Risk to life from dangerous gas concen-

trations

An alarm always indicates danger.

●Take all necessary measures for your own safety and

the safety of others immediately.

There is detailed information on alarms in section 7.2.

8

2 Features

2.2 Sensors

The device features three types of sensor:

● Gas-sensitive semiconductor (SC)

● Infrared sensor (IR)

● Electrochemical sensor (EC)

Application Gas Measuring range Sensors

Inspection above

ground

CH41 ppm – 10 % vol. SC, IR

Plants CH41 ppm – 100 % vol. SC, IR

Measuring in bar

holes

CH40.0 – 100 % vol. IR

CO20 – 30 % vol. IR

O20 – 25 % vol. EC

Ethane analysis CH4--- Gas chroma-

tograph, SC

C2H6

C3H8

Structure CH41 ppm – 100 % vol. SC, IR

CO 0 – 500 ppm EC

Gas measuring CH40.0 – 100 % vol. IR

Warning %LEL and

warning ExTox

CH40 – 100% LEL IR

CO 0 – 500 ppm EC

CO20 – 5 % vol. IR

O20 – 25 % vol. EC

H2S 0 – 100 ppm EC

9

2 Features

2.3 Explosion protection

2.3.1 Passive explosion protection

The device is assigned to the following explosion-proof groups:

Explosion-proof

group

For the following

atmospheres

When

using

II2G Ex d e ib IIB T4 Gb – Methane CH4

– Propane C3H8

– Butane C4H10

– Hydrogen sulphide H2S

– Carbon monoxide CO

Device

without

carrying

bag TG8

II2G Ex d e ib IIC T4 Gb – Methane CH4

– Propane C3H8

– Butane C4H10

– Hydrogen sulphide H2S

– Carbon monoxide CO

– Hydrogen H2

Device

with

carrying

bag TG8

EC type-examination certicate: TÜV 07 ATEX 553353 X

ADANGER! Risk of explosion from sparks

●Only ever open the battery compartment outside of

explosive areas.

●Only ever charge the device outside of explosive areas.

●Only use the USB port outside of explosive areas.

●Use only suitable battery types.

●When working with hydrogen, always use the TG8 car-

rying bag for the device.

10

2 Features

2.3.2 Active explosion protection

The functional safety test applies to:

Applications: Warning %LEL

Warning ExTox

Gas types: Measuring range:

– Methane CH40 – 100% LEL

– Propane C3H80 – 100% LEL

Gases: Measuring range: As per:

– Oxygen O20 – 25 % O2/7/

– Carbon dioxide CO20 – 5 % CO2/5/

– Carbon monoxide CO 0 – 500 ppm CO /5/

– Hydrogen sulphide H2S 0 – 100 ppm /5/

Tested accessories: – Test set SPE VOL

– Flexible hand probe, 1 m

– Floating probe 2 m / 6 m

Type examination

Testing institute: DEKRA EXAM GmbH

Certicates: PFG 08 G 002 X

BVS 09 ATEX G 001 X

The following points were not part of the type examination:

●Saving measurement data (see section 3.2.12)

●Saving protocols from the integrated device inspection (see

section 5.1.1.4)

●Disposable alkaline batteries for the power supply (see sec-

tion 4.1)

11

3 Operation

3 Operation

3.1 General information on operation

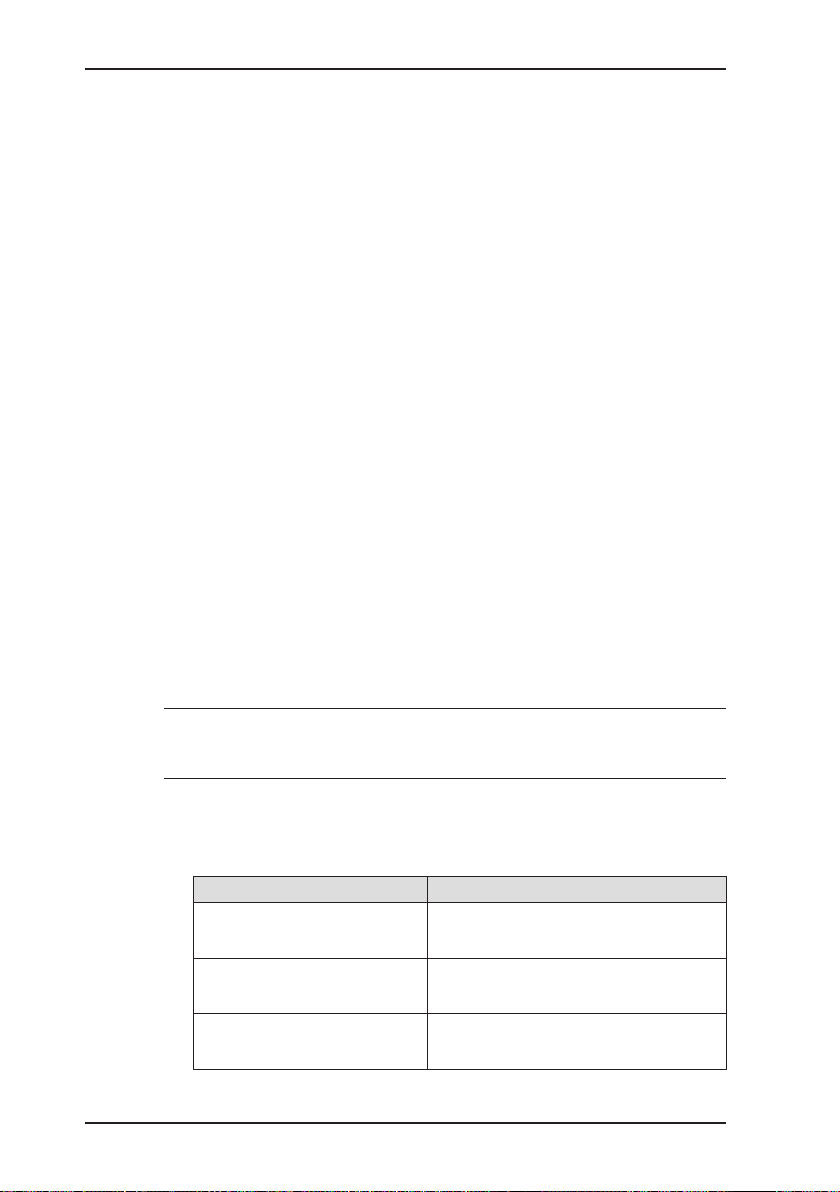

3.1.1 Keys and jog dial

The ON/OFF key is the only control on the device that does not

change its function.

When switched on, the device is operated using the jog dial and

function keys to navigate the display.

Control Action Function

ON/OFF key Press ●Switches the device on

● Switches the device o

Function keys

F1, F2, F3

Press ●Variable

●As indicated on the display at

the bottom of the screen

●Function keys may also have

no function assigned in some

cases

Jog dial Turn ●Selects functions, settings,

measurement data, etc.

● Modies values

Press ●Opens the next program lev-

el (for example, menu item,

function, measurement data,

selectable values)

●Accepts values

12

3 Operation

3.1.2 Selecting/exiting menus and menu items

Functions, applications and settings etc. are selected via the

main menu (for short: Menu). This menu has submenus and

menu items. Refer to section 3.2.1 for information on accessing

the menu.

Selecting submenus/menu items

Submenus and menu items are selected and opened using the

jog dial and/or the function keys.

In measuring mode the name of the selected application is in-

dicated by the symbol at the top left of the display. You can nd

detailed information on selecting and switching applications in

section 3.1.4.

Exiting menus/menu items

There are generally two ways to exit open menus/menu items

and return to the next level up:

●Press Esc

●Select Back from the menu

3.1.3 Switching the device on

Note:

Always switch the device on with fresh air.

1. Press the ON/OFF key. The device switches on.

The switching on process involves an internal check.

Process Test purpose

Buzzer emits audible

signal.

Is the audible signal working?

Signal light gives visual

signal.

Is the visual signal working?

Display is inverted. Are there pixels missing from the

display?

This manual suits for next models

3

Table of contents

Other sewerin Measuring Instrument manuals

sewerin

sewerin SR2-EX-P User manual

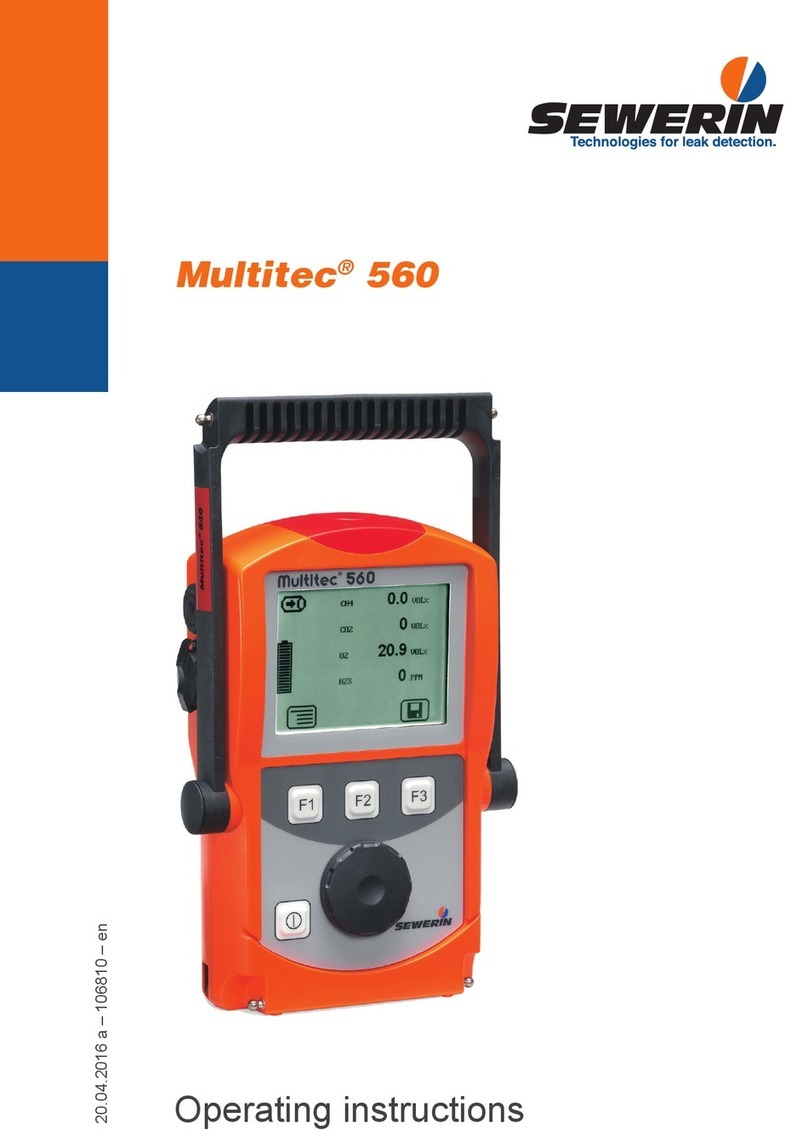

sewerin

sewerin Multitec 560 User manual

sewerin

sewerin Multitec 540 User manual

sewerin

sewerin COMBIPHON User manual

sewerin

sewerin SPE 2 User manual

sewerin

sewerin FLIS-EX User manual

sewerin

sewerin EX-TEC PM 4 User manual

sewerin

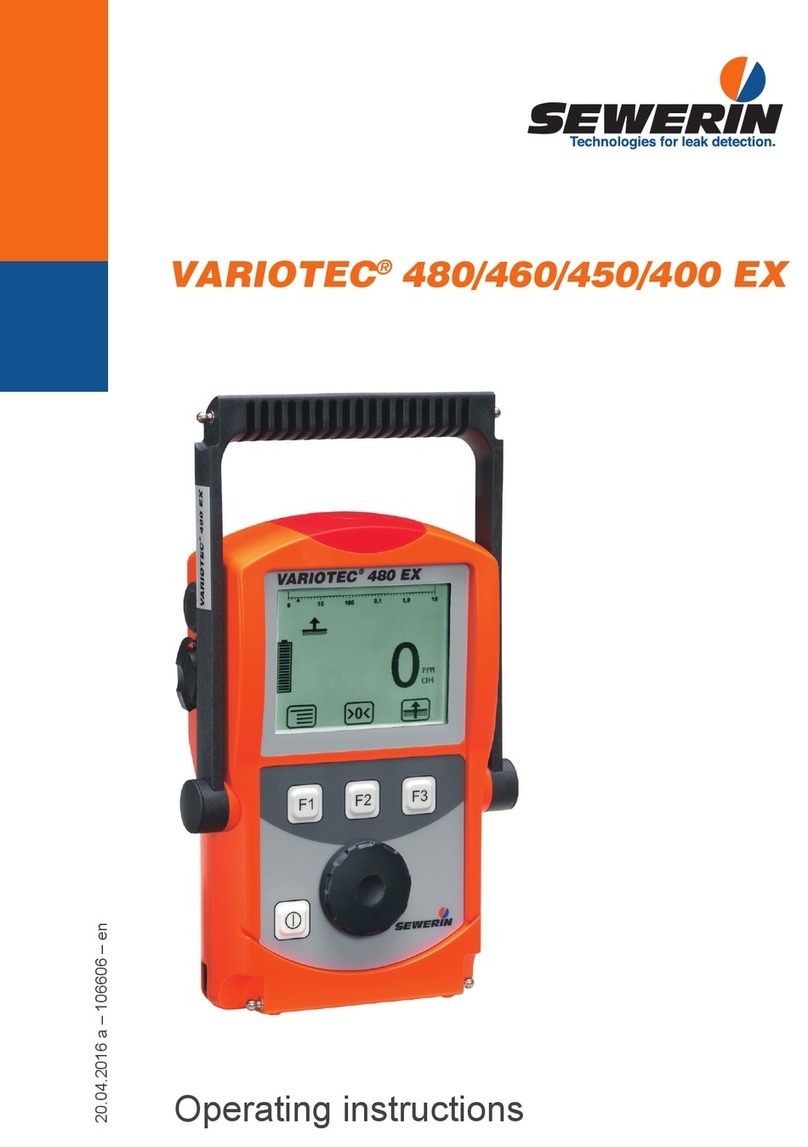

sewerin VARIOTEC 480 EX User manual

sewerin

sewerin Multitec 545 User manual

sewerin

sewerin Stethophon 04 User manual