SGM LEKTRA Pmag User manual

Pmag GB

Pmag

Electromagnetic flowmeter

Features

• Pipe dimension range: DN10 ÷ DN1000

• Measure range: <0,2m3/h ÷ >30000m3/h

• Fluid conductivity: >5

S/cm

• Sensor material: SS321

• Lining materials: PTFE from DN10 to DN500;

rubber from DN40 to DN1000

• Housing materia: epoxy printing aluminum

• Electrodes materials: SS316; Hastelloy C

• Remote version operating temperature:

<80°C

• Compact version operating temperature:

-20÷75°C

• Accuracy: ±0,5%

• Repeatability: ±0,1%

• Analog outpu: 4÷20mA; max. load 750

• Communication protocol: Modbus (opt.)

• Digital output: 0÷5000Hz

• Pulse output: 24Vdc pull-up

• Alimentazione: 85÷265Vac or 24Vdc

• Consumption: <6W

• Protection compact version: IP67 with 4 cable

gland M16x1,5 for elect. connection

• Protection remote version: IP67/IP68 only pipe

(opt.)

• Display: backlit LCD

forward and reverse flow rate

direct, reverse and net total

General

A complete magnetic flowmeter system consists of two components: the Smag62 microprocessor-based integral-mount

magneti flowmeter transmitter and a flowtube.The flowtube is installed in-line with process piping, either vertically

or horizontally. Coils located on opposite sides of the flowtube create a magnetic field, and conductive liquid moving

through the magnetic field generates a voltage that is detected by two electrodes.The transmitter controls the generation

of the magnetic field and senses the voltage detected by the electrodes. Based on the sensed voltage, the transmitter

calculates a flow rate and produces analog and frequency output signals proportional to this flow rate.

Compactdigitalsystem,forconductiveliquids(>5

S/cm),

even with a limitated content of suspended solids.

Measurement range: from <0,2m3/h to >30000m3/h

Typical measurement accuracy: ±0.5%

Power supply 85÷265Vac or 24Vdc

Page 2 of 24

Pmag62 - Features

1. Features

1.1 Flow Rate Range

Capable of processing signals from fluids that are traveling between to 10 m/s for both forward and reverse flow in all

flowtube sizes..

1.2 Fluid Conductivity

Fluid must have conductivity of at least 5 microsiemen/cm.

1.3 Power Supply

85 ÷ 265Vac or 24Vdc depending on the model.

1.4 Consumption

Typical 6W, max. 8W.

1.5 Ambient Temperature Limits

Operating: -20÷75°C (-4÷167°F).

Storage: -40÷85°C (-40÷185°F).

1.6 Output Signals

4÷20mA: 0÷750 ohm load.

Frequency : 0÷5000 Hz

Pulse: ability to set the pulse width, output H or L status and connect the internal pull-up resistor through JP1

1.7 Reverse Flow

Instantaneous and totalized reverse flow measure.

1.8 Output Testing

Current Source: Transmitter can be commanded to supply a specified current between 4.0 and 20.0 mA.

Frequency Source: Transmitter can be commanded to supply a specified frequency between 0.1 and 10000 Hz.

1.9 Start-up Time

0.5 seconds from zero flow.

1.10 Low Flow Cutoff

Adjustable between 0.0 and 9.9%Qmax. Below selected value, output is driven to the zero flow rate signal level.

1.11 Humidity Limits

0÷100% RH a 65 °C (150 °F), senza condensazione.

1.12 Damping

Adjustable between 0.1 and 99 seconds.

2. TECHNICAL DATA

2.1 Accuracy

System accuracy is ±0.5% of rate from 0.2 to 10 m/s.

2.2 Repeatability

± 0,1% of reading

2.3 Response Time

0.2 seconds maximum.

2.4 Stability

±0.1% of rate over six months.

Page 3 of 24

Pmag - Features

005NDot3NDmorfegnarwolF

)dradnats.nim01ND(

0002NDot006NDmorfegnarwolF

)0001ND.xamdradnats(

3. FLOW TABLES

Page 4 of 24

Pmag - Features

4. DIMENSION

4.1 Compact version

ND .P )mm(eziseniltuO )mm(ezisegnalF

thgieW

)mm( )aPM( a b c e D D

0

n A )gK(

01 0.4 002 243 09 01 06 4 41 6

51 0.4 002 243 59 51 56 4 41 6

02 0.4 002 243 501 02 57 4 41 6

52 0.4 002 023 511 52 58 4 41 7

23 0.4 002 043 041 23 001 4 81 9

04 0.4 002 743 051 04 011 4 81 01

05 0.4 002 063 561 05 521 4 81 21

56 3.1 002 593 581 56 541 4 81 71

08 6.1 002 593 002 08 061 8 81 71

001 6.1 052 504 022 001 081 8 81 22

521 6.1 052 514 052 521 012 8 81 42

051 6.1 003 574 582 051 042 8 22 53

002 0.1 053 335 043 002 592 8 22 54

052 0.1 054 785 593 013 052 053 21 32 48

003 0.1 005 756 544 013 003 004 21 32 201

053 0.1 055 747 505 054 053 064 61 32 321

004 0.1 006 197 565 054 004 515 61 62 741

054 0.1 006 718 516 054 054 565 02 62 212

005 0.1 006 798 076 054 005 026 02 62 902

006 0.1 006 869 087 016 006 527 02 03 252

007 0.1 007 0701 598 016 007 048 42 03 253

008 0.1 008 7611 5101 016 008 059 42 53 264

009 0.1 009 7621 5111 007 009 0501 82 53 055

0001 0.1 0001 7731 0321 007 0001 0611 82 53 086

Page 5 of 24

Pmag - Features

4.2 Remote version

ND .P )mm(eziseniltuO )mm(ezisegnalF

thgieW

)mm( )aPM( a b c e D D

0

n A )gK(

01 0.4 002 542 09 01 06 4 41 4

51 0.4 002 542 59 51 56 4 41 4

02 0.4 002 542 501 02 57 4 41 4

52 0.4 002 322 511 52 58 4 41 5

23 0.4 002 342 041 23 001 4 81 7

04 0.4 002 052 051 04 011 4 81 8

05 0.4 002 362 561 05 521 4 81 01

56 3.1 002 892 581 56 541 4 81 51

08 6.1 002 892 002 08 061 8 81 51

001 6.1 052 803 022 001 081 8 81 02

521 6.1 052 813 052 521 012 8 81 22

051 6.1 003 773 582 051 042 8 22 33

002 0.1 053 534 043 002 592 8 22 34

052 0.1 054 094 593 013 052 053 21 32 28

003 0.1 005 065 544 013 003 004 21 32 001

053 0.1 055 946 505 054 053 064 61 32 121

004 0.1 006 396 565 054 004 515 61 62 541

054 0.1 006 027 516 054 054 565 02 62 012

005 0.1 006 008 076 054 005 026 02 62 702

006 0.1 006 078 087 016 006 527 02 03 052

007 0.1 007 279 598 016 007 048 42 03 053

008 0.1 008 0701 5101 016 008 059 42 53 064

009 0.1 009 0711 5111 007 009 0501 82 53 055

0001 0.1 0001 0821 0321 007 0001 0611 82 53 086

Page 6 of 24

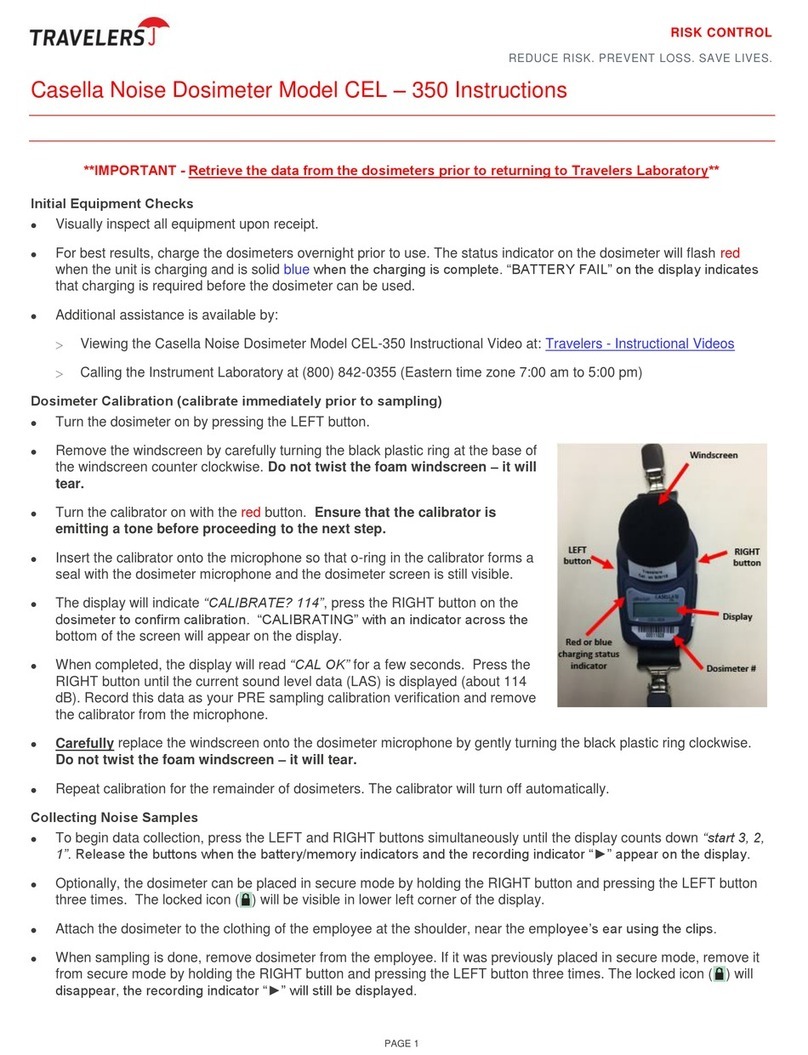

Figure 2-1 PMAG transmitter dimensions

Pmag - Installation

5. INSTALLATION

5.1 Safety measure

Instructions and procedures in this section may require special precautions to ensure the safety of the personnel performing

the operations. Information that raises potential safety issues is indicated by a warning symbol . Please refer to the

following safety messages before performing an operation preceded by this symbol.

5.2 WARNINGS

5.2.1 Explosions could result in death or serious injuryi

- Verify that the operating atmosphere of the flowtube and transmitter is consisten with the appropriate hazardous

locations certifications.

- Do not remove the transmitter cover in explosive atmospheres when the circuit is alive.

- Before connecting a HART-based communicator in an explosive atmosphere, make sure the instruments in the

loop are installed in accordance with intrinsically safe or non-incendive field wiring practices.

- Both transmitter covers must be fully engaged to meet explosion-proof requirements.

5.2.2 Failure to follow safe installation and servicing guidelines could result in death or serious injury

- Make sure only qualified personnel perform the installation.

- Do not perform any service other than those contained in this manual unless qualified.

5.2.3 High voltage that may be present on leads could cause electrical shock

- Avoid contact with leads and terminals.

5.3 PRE-INSTALLATION

There are several pre-installation steps that make the installation process easier. They include identifying the options and

configurations that apply to your application, setting the hardware switches if necessary, and consideration of mechanical,

electrical, and environmental requirements. Please remember that the flowtube liner is vulnerable to handling damage.

Never place anything through the flowtube for the purpose of lifting or gaining leverage.Liner damage can render the flowtube

useless.

5.3.1 Identify Options and Configurations

Standard application of the Pmag includes control of the flowtube coils and one or more following configurations or

options:

- 4÷20 mA Output

- Pulse Output

Be sure to identify the options and configurations that apply to your situation, and keep a list of them nearby during

the installation and configuration procedures.

5.3.2 Mechanical Considerations

The mounting site for the Pmag Integral Mount Transmitter should provide enough room for secure mounting,

easy access to the conduit ports, full opening of the transmitter covers, and easy readability of the local operator

interface (LOI) screen (see Figure 2-1).The LOI can be rotated in 90° increments. This should be performed prior

to installing the magnetic flowmeter system.

Page 7 of 24

5.4 Requirement for electric connection

Before making any electrical connections to the Pmag, consider the following standards and be sure to have proper power

supply, conduit, and other accessories.

5.4.1 Conduit Connections

The Pmag Integral Mount Magnetic Flowmeter Transmitter has 4 M16*1.5 conduit connections.

5.4.2 Transmitter Input Power

The Pmag Transmitter is designed to be powered by voltages ranging 85÷265Vac (50 a 60 Hz), 24Vac or 24Vdc.

5.4.3 DC Power Requirements

Units powered with 24Vdc may draw up to 2 amps of current. As a result, the input power wire must meet certain

gauge requirements.

5.4.4 Disconnects

The supply wires should be connected to the device through an external disconnect or circuit breaker. The disconnect

or circuit breaker should be clearly labeled and located near the transmitter.

5.4.5 Overcurrent Protection

Pmag requires overcurrent protection of the supply lines. Maximum rating of overcurrent devices are as follows:

Pmag - Installation

5.5 ENVIRONMENTAL CONSIDERATIONS

To ensure maximum transmitter life, avoid excessive heat and vibration.Typical problem areas include high-vibration lines

with integrally Mounted transmitters, warm-climate installations in direct sunlight, and outdoor installations in cold

climates. Because the Pmag System requires external power, access to a suitable power source must be ensured.

Overheating will damage the flowtube. Do not encapsulate the flowtube with heating elements

5.6 Mounting

Electric magnetic flow meter has a flanged connector, and meets standard UNI EN 1092-1 ( Ex UNI 2223).

5.7 Environment of the installation

1) The Pmag must by mounted in dry and well ventilated site. Not install the instrument in the place where the water is easily accumulated.

2) The instrument should not be exposed. Shelter is needed where the instrument is installed outside.

3) Vibration should be avoided in the place where the instrument is to be installed.

4) Keep the instrument away from strong magnetic field where big electric motor or transformer are installed.

5) The place where the instrument is installed shall be accessible for maintenance

5.8 Selecting the place for installation

1) The arrow mark on the sensor must be in accordance with the medium flow direction in the pipeline.

2) The sensor must be full with the medium all the time.

3) The straight length of the upstream pipeline must not be less than 5xD, and the downstream 3x3D, where D is the

inner diameter of the pipe, and the middle of the sensor can be a point of the lengths

Page 8 of 24

Pmag - Installation

5.9 Grounding

The grounding of the instrument must be satisfied because the signal the instrument

measured is very weak, only a few milli-voltages, even at its full range. See figure 9

for the grounding position. There are two requirements for grounding:

1) The sensor and the fluid must be equipotential.

2) Special grounding fitting must be assembled when electromagnetic disturbance

is greater. Total section area of the wires for grounding shall be greater than 4mm2

with multicore threads of copper. Grounding wire cannot be connected on electric

motor or common grounding's for all other equipment in case of the influence

occurred from any electric current leakage.

The resistance of grounding shall be less than 10 ohm. See figure 9.

The sensor must be assembled with grounding rings or flanges on its both sides, or a short pipe on which there is an

electrode for grounding when the sensor shall be installed on plastic pipeline or the pipeline has insulated liner.

5.10 Preparation for operation

Strictly check the installment and wirings before it gets into operation!

It shall be pointed out that the instrument, including the sensor and converter has been fully adjusted, calibrated

with actual flow, and inspected under strict measures. All shipped units are certified. No further adjustments

are required when put it into operation. Observing the contents in this manual, to check and analyze any

malfunction

The following steps are to be followed to get the instrument into operation.

1) Make sure that the sensor is completely filled with fluid.

2) Turn on the power supply. One minute late, the value displayed in the indicator will reach some amount, which

means the connections of wires are correct. If the flow direction is wrong, then change the flow direction on the

converter..

3) Zero verification. Shut off the valve tight in downstream first and then the valve in upstream, to let the medium in the

pipeline stops. The displayed value should be 0. The value displayed can be corrected at the converter if the value is

different than 0: ensure that no leaks.

Figure 9

Page 9 of 24

Pmag - Connection

6. ELECTRIC CONNECTION

6.1 Install Conduit

Transmitter junction boxes have n.4 M16*1.5 conduit connections.

Seal unused ports to prevent moisture or other contamination from entering the junction box.

Do not overtighten metal plugs used to seal wiring compartment ports,overtightening can damage the housing.

6.2 Power Connections

To connect power to the transmitter, complete the following steps:

1) Open the power terminal cover.

2) Run the power cable through the conduit to the transmitter.

3) Loosen the terminal cable guard for the input power terminals L and N or + and -.

4) Connect the power cable leads as follows:

For an AC-powered transmitter (fig.2-13):

- Connect AC Ground to a grounding lug.

- Connect AC Neutral to terminal N.

- Connect AC Line to terminal L.

For a DC-powered transmitter (fig.2-13):

- Connect DC Ground to a grounding lug.

- Connect + DC.

- Connect - DC.

6.3 OUTPUT

Satisfy these requirements before attempting to install and operate the Pmag.

6.3.1 Analog output

The loop may be powered from the transmitter itself. Resistance in the loop must be 750ohms or less.

6.3.2 Digital output

The digital output, if set frequency mode generates an output signal from 0 to 5000Hz Max. proportional to flow rate,

if set in pulse mode generates an output signal in relation to totaled volume increasing. The signal is normally used in

conjunction with an external totalizer or control system. complete the following steps to connect the signal cable to

the transmitter:

1) Run the signal cable into the transmitter.

2) Connect the two wires that convey switch closure information to the F+ and F- terminals

6.3.3 RS485 serial output

In models with RS485 option can communicate via Modbus . Connect the serial cable to terminals A + and B-

.Neriw noitcnuF lanimreT

seriw-owT

elbac

4 1.nlioC X

5 2.nlioC Y

seriw-eerhT

elbac

1 1.nedortcelE A

2 dleihS/dnuorG C

3 2.nedortcelE B

6.4 Remote version

To connect the sensor to the transmitter respect the matching cables.:

Page 10 of 24

Pmag - Quick start-up

7. QUICK START-UP

7.1 Transmitter

Check that the analog range of the transmitter matches the analog range in the control system.

7.2 Flowtube

1. For horizontal flow installations, ensure that the electrodes are in a plane such that they remain covered by process

fluid.

2. For vertical or inclined installations, ensure that process fluid is flowing up into the flowtube to keep the electrodes

covered by process fluid.

3. Ensure that the grounding straps on the flowtube are connected to grounding rings, lining protectors, or the adjacent

pipe flanges. Improper grounding will cause erratic operation of the system.

7.3 Process Fluid

1. The process fluid conductivity must be greater than 5 microS.

2. Process fluid must be free of air and gasses.

Completed the mechanical installation and electrical connections, the PMAG is ready to start. May still be necessary

to verify the units ("Units PV" / "Total Units") and the 100% flow value (Qmax (m3 / h) ") in accordance with plant

requirements.

8. LOCAL OPERATOR INTERFACE (LOI)

The LOI option is an operator communications center for the Pmag. Through the LOI, the operator can access any

transmitter function for changing configuration parameter settings, checking totalized values, or other functions.

8.1 SAFETY MESSAGES

Instructions and procedures in this section may require special precautions to ensure the safety of the personnel performing

the operations. Information that raises potential safety issues is indicated by a warning symbol: .

Please refer to the following safety messages before performing an operation preceded by this symbol.

8.2 WARNINGS

Explosions could result in death or serious injury

- Verify that the operating atmosphere of the flowtube and transmitter is consistent with the appropriate hazardous

locations certifications.

- Do not remove the transmitter cover in explosive atmospheres when the circuit is alive.

- Before connecting a HART-based communicator in an explosive atmosphere, make sure the instruments in the loop

are installed in accordance with intrinsically safe or non-incendive field wiring practices.

- Both transmitter covers must be fully engaged to meet explosion-proof requirements.

Failure to follow safe installation and servicing guidelines could result in death or serious injury

- Make sure only qualified personnel perform the installation.

- Do not perform any service other than those contained in this manual unless qualified

High voltage that may be present on leads could cause electrical shock

- Avoid contact with leads and terminals

8.3 LOI FEATURES

The LOI option contains a four-line, 16-character liquid

crystal display (LCD) that is back-lit and visible from

any angle. There are four touch keys on the pad,

and a infrared decoder to receive keys that on the

remote encoder.Table 3-1 lists and details the

functions of the LOI keys.

Page 11 of 24

8.4 LOI ROTATION

Each magnetic flowmeter installation is different from application to application; therefore, the LOI display can be rotated to

accommodate various setups using the following procedure:

1. Remove power from the transmitter

2. Unscrew and remove the LOI cover. Do not remove the cover in explosive atmospheres when the circuit is

alive.

3. Unfasten the 4 screws that attach the LOI assembly to the main circuit assembly.

4. Carefully remove the LOI assembly by pulling it away from the transmitter.

5. Position the LOI in a preferred 90° rotation.

6. Fasten the 4 screws that attach the LOI to the main circuit assembly.

7. Replace the LOI cover

8.5 DATA ENTRY

The LOI keypad has no numerical keys. Enter numerical data using the following procedure:

1. Access the appropriate function.

2. Use to highlight the digit you want to enter or change.

3. Use or to change the highlighted value.

For numerical data, or toggles through the digits 0÷9,decimal point; For alphabetical data, they toggle through

the letters of the alphabet A-Z, digits 0÷9, and the symbols &, +, -, *, /, $, @, %, and the blank space ( or is

also used to toggle through pre-determined choices that do not require data entry.).

4. Use to highlight and change other digits you want to change.

5. Press to confirm the insertion of data.

Pmag - Setting

Page 12 of 24

8.7 LOI MENU

Press the key from run mode: the display will show the list of configuration menu as

shown here next.

Press the or keys to select the desired menu, then press the key to access

Pmag - Setting

8.6 DISPLAY PAGE

The Pmag has three pages to display data and status, press or to change page

If there is no alarm,

this page will not appear

Page 12 of 24

Page 13 of 24

Pmag - Setting

PV Units variable specifies the format in which the flow rate will be displayed.

Default: m3/h. Range: L/s; m3/s; G/s; L/m; m3/m; G/m; L/h; m3/h; G/h.

Press the key from run mode: the display will be as shown here next.

With or select the unit.

Press to confirm, the display will be as shown here next.

press the key to exit and confirm the selection; press the key to exit and delete

the selection.

8.7.1.2 - PV Decimal

PV Decimal specifies how many decimals are displayed after the decimal point.

Default: 3

Range: 1÷3

Press the key from run mode: the display will be as shown here next.

With or select the decimal number places to display.

Press to confirm, the display will be as shown here next.

press the key to exit and confirm the selection; press the key to exit and delete

the selection.

8.7.1.3 - Total Units

Total Units specifies the counter display unit

Default: m3

Range: L, Litri; m3, Metri cubi; G, galloni

Press the key from run mode: the display will be as shown here next.

With or select the counter display unit

Press to confirm, the display will be as shown here next.

press the key to exit and confirm the selection; press the key to exit and delete

the selection.

8.7.1.4 - Total Decimal

Total Decimal specifies how many decimals are displayed after the decimal point.

Default: 3

Range: 1÷3

8.7.1 Basic Configuration (Basic)

Press the key from run mode: the display will be as shown here next, then press

to enter the "Basic" menu

Press the or keys to select the desired function and press the key to access

8.7.1.1 - PV Units

Page 14 of 24

8.7.1.5 - Damping (s)

Damping(S) sets the delay time in seconds for changes in reading. It 'used to mitigate

the fluctuations in flow measurement.

Default: 1; Range: 0.1÷99.9

Press the key from run mode: the display will be as shown here next.

With or change the digit, with moves the cursor.

Press to confirm, the display will be as shown here next.

press the key to exit and confirm the selection; press the key to exit and delete

the selection.

8.7.2 System Configuration (System)

Press the key from run mode, then press the key to select "System" and press

the button to enter.

Press the or keys to select the desired function and press the key to access

To access the menu "System" may need to enter the correct password.

The default password: 0100

After entering, you can change the password

Note: If forget password can not access the menu.

8.7.2.1 - Language

Allows menu language selection.

Default: English

Press the key from run mode: the display will be as shown here next.

Press to confirm, the display will be as shown here next.

press the key to exit and confirm the selection; press the key to exit and delete

the selection.

8.7.2.2 - Signal

Press the key to enter the submenu "Signal"

Press the key from run mode: the display will be as shown here next.

With or select the decimal number places to display.

Press to confirm, the display will be as shown here next.

press the key to exit and confirm the selection; press the key to exit and delete

the selection.

Pmag - Setting

Page 15 of 24

8.7.2.2.1 - Qmax (m3/h)

Set the flow measurement 100%. This value adjusts the analog output end scale

(20mA) and the frequency output end scale.

The range is related to the sensor DN.

Press the key from run mode: the display will be as shown here next.

With or change the digit, with moves the cursor.

Press to confirm, the display will be as shown here next.

press the key to exit and confirm the selection; press the key to exit and

delete the selection.

8.7.2.2.2 - LowCutoff %

Low Cutoff specifies the Qmax% value below which the instantaneous flow

measurement reading (direct or reverse) and the outputs are forced to zero.

Default: 0.0 Range: 0.0÷9.9

Press the key from run mode: the display will be as shown here next.

With or change the digit, with moves the cursor.

Press to confirm, the display will be as shown here next.

press the key to exit and confirm the selection; press the key to exit and

delete the selection.

8.7.2.2.3 - Max Limit %

When the measure variation is lower than Max Limit%, or higher but with a lower time period

than that set in Limit Time (s), the measure is not detected. When the measure variation is

higher than Max Limit% and with a higher time period than that set in Limit Time (s), the

measure is detected. Default: 0.0; Range: 0.0÷9.9

Press the key from run mode: the display will be as shown here next.

With or change the digit, with moves the cursor.

Press to confirm, the display will be as shown here next.

press the key to exit and confirm the selection; press the key to exit and

delete the selection.

8.7.2.2.4 - Limit Time (s)

Sets the time limit used by the function Max Limit%.

Default: 00.0

Range: 00.0÷99.9

Press the key from run mode: the display will be as shown here next.

With or change the digit, with moves the cursor.

Press to confirm, the display will be as shown here next.

press the key to exit and confirm the selection; press the key to exit and

delete the selection.

Pmag - Setting

Page 16 of 24

8.7.2.2.5 - Direction

This parameter enables the flow direction measurement

Default: Fwd (forward)

Range: Fwd (forward); Rev (reverse); Bid. (bidirectional)

Press the key from run mode: the display will be as shown here next.

With or select the parameter setting.

Press to confirm, the display will be as shown here next.

press the key to exit and confirm the selection; press the key to exit and

delete the selection.

8.7.2.2.6 - Indication

Set what is the positive flow direction compared to the arrow on the sensor.

Default: Fwd (forward)

Range: Fwd (forward); Rev (reverse)

Press the key from run mode: the display will be as shown here next.

With or select the parameter setting.

Press to confirm, the display will be as shown here next.

press the key to exit and confirm the selection; press the key to exit and

delete the selection.

8.7.2.3 - Pulse Output

Press the key to enter the submenu “Pulse Output” .

8.7.2.3.1 - Freq Max (Hz)

Sets the maximum frequency in relation to Qmax. The digital output is active as a

frequency output only when the parameter "Liter / Pulse" is set to 0.0.

Default: 2000.0; Range: 100.0÷5000.0

Press the key from run mode: the display will be as shown here next.

With or change the digit, with moves the cursor.

Press to confirm, the display will be as shown here next.

press the key to exit and confirm the selection; press the key to exit and

delete the selection.

8.7.2.3.2 - Liter/Pulse

Set the volume per pulse. When this parameter is set to 0.0, the digital output is

active as a frequency output (see "Max Freq (Hz)").

Default: 0.0; Range: 0.0055÷max. according to the DN

Press the key from run mode: the display will be as shown here next.

With or change the digit, with moves the cursor.

Pmag - Setting

Page 17 of 24

Press to confirm, the display will be as shown here next.

press the key to exit and confirm the selection; press the key to exit and

delete the selection.

8.7.2.3.3 - Pulsewidth (ms)

Sets the pulse width in ms.

Default: 000.0;

Range: 0000.0÷1000.0

Press the key from run mode: the display will be as shown here next.

With or change the digit, with moves the cursor.

Press to confirm, the display will be as shown here next.

press the key to exit and confirm the selection; press the key to exit and

delete the selection.

8.7.2.3.4 - Pulse Level

Sets the pulse output energy level. When set LOW the pulse count is low, when set

HIGH, the pulse count is high.

Default: Active L (LOW); Range: Active L (LOW) ÷ Active H (HIGH)

Press the key from run mode: the display will be as shown here next.

With or select the parameter setting.

Press to confirm, the display will be as shown here next.

press the key to exit and confirm the selection; press the key to exit and

delete the selection.

8.7.2.4 - RS485 Output

Press the key to enter the submenu “RS485 Output” .

8.7.2.4.1 - RS Protocol

Sets the RS485 output communication protocol.

Default: MOD-BUS RTU

Range: MOD-BUS RTU ÷ MOD-BUS ASC

Press the key from run mode: the display will be as shown here next.

With or select the parameter setting.

Press to confirm, the display will be as shown here next.

press the key to exit and confirm the selection; press the key to exit and

delete the selection.

8.7.2.4.2 - Baud Rate

Sets the RS485 output Baud Rate.

Default: 9600

Range: 1200 - 2400 - 4800 - 9600

Pmag - Setting

Page 18 of 24

Pmag - Setting

Press the key from run mode: the display will be as shown here next.

With or select the parameter setting.

Press to confirm, the display will be as shown here next.

press the key to exit and confirm the selection; press the key to exit and

delete the selection.

8.7.2.4.3 - Data Bit

Sets the RS485 output Data Bit.

Default 8

Range: 8 - 7

Press the key from run mode: the display will be as shown here next.

With or select the parameter setting.

Press to confirm, the display will be as shown here next.

press the key to exit and confirm the selection; press the key to exit and

delete the selection.

8.7.2.4.4 - Parity

Sets the RS485 output Parity.

Default: NONE

Range: EVEN; ODD; NONE

Press the key from run mode: the display will be as shown here next.

With or select the parameter setting.

Press to confirm, the display will be as shown here next.

press the key to exit and confirm the selection; press the key to exit and

delete the selection.

8.7.2.4.5 - Stop Bit

Sets the RS485 output Stop Bit.

Default: 1

Range: 1 - 2

Press the key from run mode: the display will be as shown here next.

With or select the parameter setting.

Press to confirm, the display will be as shown here next.

press the key to exit and confirm the selection; press the key to exit and

delete the selection.

8.7.2.4.6 - Dev Address

Set the unity UID in RS485 network

Default: 001

Range: 001÷999

Page 19 of 24

Pmag - Setting

Press the key from run mode: the display will be as shown here next.

With or select the parameter setting.

Press to confirm, the display will be as shown here next.

press the key to exit and confirm the selection; press the key to exit and

delete the selection.

8.7.2.5 - Total Set

Press the key to enter the submenu “Total Set” .

8.7.2.5.1 - Password

To access the menu "Total Set" may need to enter the correct password.

The default password: 0020

After entering, you can change the password

Note: If forget password can not access the menu.

8.7.2.5.2 - Clear Total

Reset totalizer

Default: NO

Range: NO - YES

Press the key from run mode: the display will be as shown here next.

With or select the parameter setting.

Press to confirm, the display will be as shown here next.

press the key to exit and confirm the selection; press the key to exit and

delete the selection.

8.7.2.5.3 - FWD Preset

Predetermines the positive totalizer value

Default: 0000000000

Range: 1÷9999999999

Press the key from run mode: the display will be as shown here next.

With or change the digit, with moves the cursor.

Press to confirm, the display will be as shown here next.

press the key to exit and confirm the selection; press the key to exit and

delete the selection.

Page 20 of 24

8.7.2.5.4 - REV Preset

Predetermines the negative totalizer value

Default: 0000000000

Range: 1÷9999999999

Press the key from run mode: the display will be as shown here next.

With or change the digit, with moves the cursor.

Press to confirm, the display will be as shown here next.

press the key to exit and confirm the selection; press the key to exit and

delete the selection.

8.7.2.6 - Load Setting

Load factory settings.

Default: NO Range: YES - NO

Press the key from run mode: the display will be as shown here next.

With or select the parameter setting.

Press to confirm, the display will be as shown here next.

press the key to exit and confirm the selection; press the key to exit and

delete the selection.

8.7.3 Calibrations (Calibration)

Press the key from run mode, then press the key to select "Calibration" and

press the button to enter.

8.7.3.1 - Zero Trim

Zero flow measurement calibrate. The sensor must be full and the flow stopped.

Default: NO Range: YES - NO

Press the key from run mode: the display will be as shown here next.

With or select the parameter setting.

Press to confirm, the display will be as shown here next.

press the key to exit and confirm the selection; press the key to exit and

delete the selection.

8.7.3.2 - Tube Trim

Press the key to enter the submenu “Tube Trim” .

8.7.3.2.1 - Full Trim

Performs a full pipe recognition self calibration.

Default: NO

Range: NO - YES

Pmag - Setting

This manual suits for next models

1

Table of contents

Other SGM LEKTRA Measuring Instrument manuals

SGM LEKTRA

SGM LEKTRA MUXM User manual

SGM LEKTRA

SGM LEKTRA FLOWMETER User manual

SGM LEKTRA

SGM LEKTRA RPmag Guide

SGM LEKTRA

SGM LEKTRA Transit Time SGM-200H Guide

SGM LEKTRA

SGM LEKTRA RPmag Guide

SGM LEKTRA

SGM LEKTRA SGM-101H Guide

SGM LEKTRA

SGM LEKTRA SGM-101F Guide

SGM LEKTRA

SGM LEKTRA SGM-100F User manual