SGM LEKTRA SGM-101F Guide

SGM-101F

transit time ultrasonic flowmeter

technical documentation EN Rev. B

Page 2 of 60

SGM-101F - contents

CONTENTS

1-WARRANTY

2-PRODUCT

3-FEATURES

4-DIMENSIONS

5-PIPE SPECIFICATIONS

6-TRANSDUCERS POSITIONING

7-INSTALLATION

8-ELECTRICAL CONNECTIONS

9-CONFIGURATION

10-PROGRAMMING MENU

11-MAIN PARAMETERS DESCRIPTION

12-TROUBLESHOOTING

13-COMMUNICATION PROTOCOL

14-NOTE

15-FACTORY TEST AND QUALITY CERTIFICATE

page 3

page 4

page 6

page 7

page 10

page 11

page 15

page 24

page 28

page 33

page 51

page 55

page 56

page 57

page 60

Page 3 of 60

SGM-101F - warranty

Products supplied by SGM LEKTRA are guaranteed for a period of 12 (twelve) months from delivery date

according to the conditions specified in our sale conditions document.

SGM LEKTRA can choose to repair or replace the Product.

If the Product is repaired it will maintain the original term of guarantee, whereas if the

Product is replaced it will have 12 (twelve) months of guarantee.

The warranty will be null if the Client modifies, repair or uses the Products for other purposes than the normal

conditions foreseen by instructions or Contract.

In no circumstances shall SGM LEKTRA be liable for direct, indirect or consequential or other loss or damage

whether caused by negligence on the part of the company or its employees or otherwise howsoever arising out

of defective goods.

1-WARRANTY

Page 4 of 60

SGM-101F - product

2-PRODUCT

1. SGM-101F

2. Wall mounting Kit

3. protection trasparent cover

4. Transducers

5. Transducers cables

6. Skintop

7. Heat counter connector (opz.)

3

2

1

5

4

6

7

2.1 IDENTIFICATION

Each meter has an adhesive identification plate on which are the meter main data. The following picture describes the

information and data on the identification plate.

1. Product code 3. Serial number2. Power supply

SGM-101FWATL-1NA

230Vdc 50-60Hz

FU0101600357

2

3

1Mod.

P.S.

S.N.

Page 5 of 60

SGM-101F - product

Pipe

diameter

ș

Upstream

transducer

Downstream

transducer

T2

T1

Wall

thickness

D

VLQș

¨7

77

V=

Forward

direction

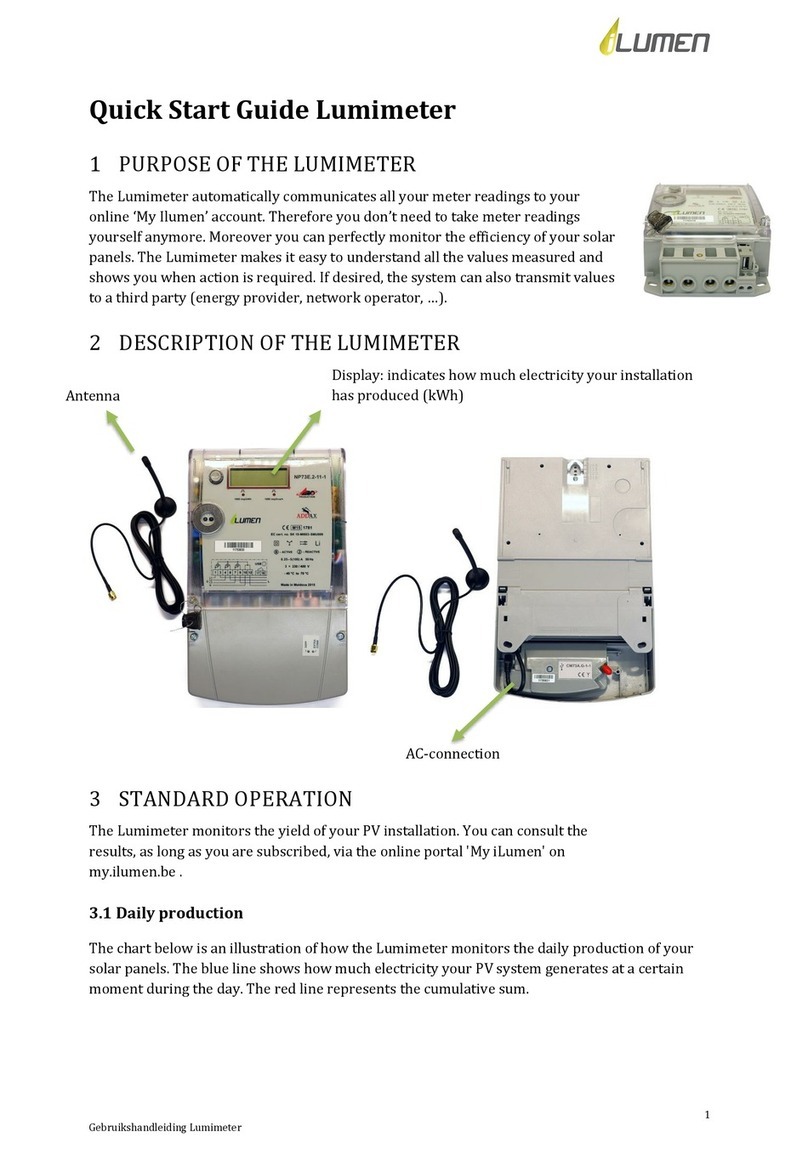

2.2 WORKING PRINCIPLE

The SGM-101F is composed by a digital converter and two clamp-on or insertion type ultrasonic transducers.

The instrument calculates the instantaneous flow rate value by measuring the flight time difference of the ultrasonic pulses.

- Compact system for conductive and non-conductive fluids, even with the suspended material presence (<10g/l; <Ø1mm)

- Measuring ranges from <0,2m3/h to >30000m3/h

- Applicable to various pipes materials (eg. SS316, copper, plastic, etc.), with or without an inner lining.

- Power supply 24Vac; 115Vac; 230Vac.

The meter is designed to measure the fluid velocity inside a pipe.

The clamp-on transducers models allow an easy installation.

The transit time flow meter uses two ultrasonic transducers that work as transmitters and receivers.

They are installed externally to the pipe at a specific distance from each other.

They can be installed at V mode (2 sonic section), at W mode (4 sonic section) or at Z mode (1 sonic section).

The installation method choice depends on the pipe and the fluid characteristics.

The SGM-101F measures the transit time via the two transducers that alternatively transmit and receive a sound pulses

sequence.

The difference in the measured transit time is directly related to the fluid velocity in the pipe.

θ= sonic section angle

D = pipe internal diameter

T1 = sound transit time from the upstream transducer to the transducer downstream

T2 = sound transit time from the downstream transducer to the transducer upstream

∆T = T2-T1

Page 6 of 60

3-FEATURES

SGM-101F - features

Pipe dimension range

DN20 ÷ DN4000

Transmitter protection class

IP66

Transducer protection class

IP68

Display

backlighted 2x20 alphanumeric digit

Keypad

4 keys

Housing material

painted aluminium

Displayed data

instantaneous flowrate; flow totalizer

Mounting

wall

Analog Output

Sel. 4÷20mA o 0÷20mA

Accuracy

±1%

Repeatability

±0,2%

Linearity

±0,5%

Basic measurement period

500ms

Serial port

RS485

Communication protocol

MODBUS RTU or ASCII+ (opz.)

Data logger

on SD card (opt.) or via MODBUS

Programmable frequency output

0÷5000Hz

Relay output

n.1 for pulse totalizer or alarm

Medium speed range

±12m/s

Unit working temperature

-20÷60°C

Ambient humidity

non condensing 85% RH (40°C)

Tasducer working temperature

TS-2 / TM-1 / TL-1 -30 ÷ +90°C; TS2H / TM1H -30 ÷ +160°C; TC-1/ TLC2 -40 ÷ +160°C

PT100 sensors working temperature

-40°C +160°C

Tasducer cable std. length

5mt

PT100 sensor cable std. length

15mt

Powers

24Vac; 115Vac; 230Vac.

Dimensions

200x120x77mm

Weight without sensors

1Kg

Page 7 of 60

SGM-101F - dimensions

4-DIMENSIONS

180

179

215

120

138

157

74

Ø8

Ø8

4

80

132,5

4.1 SGM-101F MECHANICAL DIMENSIONS

Transducer Type Features

TS-2

Dimensions

67mm 28mm

32mm

Pipe Ø range 20÷100mm (¾” ÷ 4”)

Temperature -30 ÷ +90°C

Menu 23 >19. CLAMP-ON TS-2

4.2 TRANSDUCERS DIMENSIONS AND FEATURES

Page 8 of 60

SGM-101F - dimensions

Transducer Type Features

TS2H

Dimensions

67mm 28mm

32mm

Pipe Ø range 20÷100mm (¾” ÷ 4”)

Temperature -30 ÷ +160°C

Menu 23 >19. CLAMP-ON TS-2

TM-1

Dimensions

89mm 42mm

44mm

Pipe Ø range 50÷700mm (2” ÷ 40”)

Temperature -30 ÷ +90°C

Menu 23 >16. CLAMP-ON TM-1

TM1H

Dimensions

89mm 42mm

44mm

Pipe Ø range 50÷700mm (2” ÷ 40”)

Temperature -30 ÷ +160°C

Menu 23 >16. CLAMP-ON TM-1

TL-1

Dimensions

123mm 57mm

54mm

Pipe Ø range 300÷4000mm (3” ÷ 160”)

Temperature -30 ÷ +900°C

Menu 23 >20. CLAMP-ON TL-1

Page 9 of 60

SGM-101F - dimensions

Transducer Type Features

TC-1

(standard)

Dimensions

90mm

147mm

190mm

Pipe Ø range 80÷4000mm (3” ÷ 160”)

Temperature -40 ÷ +160°C

Max pressure 1.6Mpa (16bar)

Menu 23 >17. INSERZ. TC-1

TLC2

(for

non-metallic

pipes)

Dimensions 165mm

287mm

330mm

Pipe Ø range 80÷4000mm (3” ÷ 160”)

Temperature -40 ÷ +160°C

Max pressure 1.6Mpa (16bar)

Menu 23 >21. INSERZ. TLC-2

PT100

(With brass

plate)

Dimensions

Ø3

185

CONNECTOR 4 WIRES CABLE M12

Temperature -40 ÷ +160°C

Page 10 of 60

SGM-101F - dimensions / pipe specifications

5-PIPE SPECIFICATIONS

5.1 OUTSIDE PIPE DIAMETER

In the event that an appropriate instrument to measure the pipe outer diameter is not available

(programming in M11), proceed as follows:

- use a rope or paper tape or sheet

- wrap the pipe with rope or paper tape or sheet and mark the circumference point

- measure the length corresponding to the pipe circumference

- enter the measured value to “Pipe Outer Perimeter” menu (M10), SGM-101F will automatically calculate

the correct pipe diameter value

5.2 PIPE THICKNESS

Value measured on site using an appropriate tool (caliper, ecc.), or from the technical data of the hydraulic

circuit (programming in M12). In the presence of tubes without inner lining, is possible to use the SGM-100T thi-

ckness gauge.

5.3 PIPE MATERIAL

Value detectable on site, or from the technical data of the hydraulic circuit (programming in M14).

5.4 INNER LINING MATERIAL

Value detectable on site, or from the technical data of the hydraulic circuit (programming in M15).

5.5 INNER LINING THICKNESS

Value measured on site using an appropriate tool (caliper, ecc.), or from the technical data of the hydraulic

circuit (programming in M16).

Transducer Type Features

PT100 Dimensions

185

Ø5

100

¼" G

Temperature -40 ÷ +160°C

PT100 Dimensions

185

Ø5

50

¼" G

Temperature -40 ÷ +160°C

Page 11 of 60

6.1 INSTALLATION CHECK-UP

The signal power and quality (Q) can be checked through the installation check-up and it’s possible to make the

comparison of the measured flight time by the measuring range depending on the pipe diameter.

6.1.1 Signal reception power - M90

The signal power, displayed to the menu M90 with UP and DN, is indicated by a three-digit number.

[00.0] means missing signal and [99.9] indicates the maximum measurable value.

Although the instrument is working properly with a signal power between 50.0 and 99.9, it is always

recommended to try to get a value as high as possible using the following methods:

1) Select the most favorable installation position.

2) Clean the pipe outer surface and apply more coupling grease.

3) Move the transducers both vertically and horizontally while doing the signal reception control.

Mechanically lock the transducers when the detected power has reached its maximum value

(always checking that the distance between the two transducers is equal to that indicated in the menu M25)

6.1.2 Signal quality (Q) - M90

Better the signal quality (Q value higher), better will be the ‘SNR and consequently the accuracy.

In normal operating conditions the Q value, displayed to the menu M90, is between 60 and 90.

In the case of a lower value, check:

1) Any interference with other instruments.

2) The transducers coupling with the pipe surface (clean the pipe or add more coupling grease).

3) The mounting position on the pipe.

6.1.3 Total transit time and Delta Time - M93

The numbers shown in the M93 are called total transit time and delta time.

These values are fundamental to calculate the flow rate inside the pipe.

The total transit time should remain stable or in any case subject to minimal variations.

If the delta time fluctuates above 20% means that there are problems with the transducers installation.

6.1.4 Time ratio between the Measured Total Transit Time and the Calculated Time - M91

The value should be in the range 100±3%. If the value exceeds this range check:

1) That the parameters have been entered correctly.

2) That the distance between the two transducers is the same as indicated in the menu M25.

3) That the transducers are installed in the right direction.

4) That the positioning point was chosen in an appropriate manner and that the pipe has not changed shape.

5) Inside the pipe there are no deposits.

SGM-101F - dimensions / pipe specifications

6-TRANSDUCERS POSITIONING

Page 12 of 60

SGM-101F - transducers positioning

6.2 POSITIONING TYPE SELECTING

The transducers positioning type selection, Z-Mode, or V-Mode or W-Mode, is a function of measuring pipe DN:

DN20÷50 - recommended installation: W (small pipe)

DN50÷250 - recommended installation: V

DN250÷4000 - recommended installation: Z

6.3 MARKING POSITIONING

After the pipe parameters and transducers positioning type programming, the conversion unit automatically

calculates the mounting axial distance between the two transducers: M25, Transducer Spacing.

The M25 value is used to mark out on the pipe the exact transducers positioning.

6.4 MARKING TOOLS

To mark the transducers positioning points on the pipe surface are sufficient simple, but at the same time

effective, tools:

- a paper tape with a minimum width of 50mm.

- a pencil or a thin tip pen

- a meter

6.5 MARKING METHODS

6.5.1 Z type positioning

For a correct transducers positioning, proceed as follows:

1) wrap the pipe with the paper tape making sure that the edges are perfectly overlapping

With the pencil, draw the “C” circle on the pipe and, at the same time mark on the paper the

circumference measured point.

C

2) Remove the paper tape, cut it at the marked point and fold in half the portion corresponding to

the circumference. Then place the folded sheet on the top of the pipe.

The vertex of the sheet (point A) is the mounting position of the first transducer.

A

Page 13 of 60

SGM-101F - transducers positioning

4) From point B draw the straight line “D” parallel to the pipe axis and equal to the value, showed in M25,

previously calculated to identify point “E”.

D

A

B

E

5) Points “A” and “E” are the mounting positions of the transducers.

A

E

3) Identify the point “B” positioned at 180° degrees from point “A”

A

B

Page 14 of 60

SGM-101F - transducers positioning

6.5.2 V and W type positioning

For a correct transducers positioning, proceed as follows:

1) Identify point “A”, which will be the mounting position of the first transducer.

A

2) From point “A” draw a straight line “S” parallel to the pipe axis, and equal to the value, showed in M25,

previously calculated to identify point “E”.

A

B

Page 15 of 60

SGM-101F - transducers positioning

3) Point “A” and “E” are the mounting positions of the transducers.

A

E

6.6 PIPE SURFACE CLEANING

Clean the pipe surface with a sander, removing any trace of rust, paint, coating, pipe outer coating or else.

The treated area must be extended, according to the transducers model, at least as shown in the following table:

A

B

TS-2 TM-1 TL-1

A70mm 90mm 140mm

B40mm 55mm 80mm

6.7 CLAMP-ON TRANSDUCERS FIXING

1) On the transducer lower surface apply a thick layer of acoustic coupling grease .

2) Fix the transducer on the pipe surface at the transducer installation point, already cleaned.

3) Securely fasten the transducers on the pipe with the supplied steel hose clamps.

WARNING - do not overtighten in order to avoid damages to the transducers.

Page 16 of 60

SGM-101F - installation

7-INSTALLATION

7.1 MEASURING POINT SELECTION

The transducers must be mounted on a pipe section which allows to respect the minimum distance between

the element of resistance to flow, such as curves or derivations, and the measuring point.

See the following table.

Flow resistance element Upstream side Downstream side

90° curves

15 x DN 5 x DN

T junction

40 x DN 5 x DN

Adaptors

18 x DN 5 x DN

Valves

40 x DN 5 x DN

Pumps

20 x DN

P

Page 17 of 60

SGM-101F - installation

In the event that the minimum values shown in previous table 4 can not be met, it is necessary to adopt every

precautions to mitigate the flow turbulence and improve the homogeneity of the flow velocity in the pipe.

One of the best device is the transducers upstream installation of a fluid threads rectifier, which allows to have a

straight section length of the pipe less than indicated.

The pipe where the transducers are placed must have the following characteristics:

- smooth surface without rust or other surface deterioration;

- circular cross section

The ideal points for the transducer positioning are:

- hydraulic circuit lowest point (a);

- vertical pipes with the upward flow (b);

- inclined pipes with the upward flow (c);

- vertical open drain pipes with a section restriction to avoid sudden pipe emptying during flow measurement (d)

a

b

c

Restriction

d

In the case of a horizontal pipe, the transducers positioning should be between ± 45 ° relative to the horizontal

center line of the pipe. This is to avoid that any air bubbles can interfere with the flow velocity detection,

Furthermore, in the case of buried pipe must observe the following measures:

with insertion type transducers L>540mm; with clamp-on type transducers L>400mm.

LL

H 200mm

45°

45°

Page 18 of 60

SGM-101F - installation

The transducers positioning points to be avoided are:

- vertical pipes with the downward flow, because they may not be completely filled with fluid.

- inclined pipes with the downward flow, because they may not be completely filled with fluid.

- the transducers must never be placed in the highest point of the concerned hydraulic circuit, because there

is greater chance that in that pipeline section will create air pockets.

- vertical open drain pipes without a section restriction to avoid sudden pipe emptying during

flow measurement.

7.2 POSITIONING DISTANCE

The value (calculated automatically by the system) shown in menu M25 refers to the “Lout” mounting distance

between the two transducers, as shown in the following figures.

Lout Lout

Page 19 of 60

SGM-101F - installation

7.3 V INSTALLING

Is the installation method for pipes with diameters in the DN50÷250 range.

Upstream

transducer

Downstream

transducer

Forward ow

direction

7.4 Z INSTALLING

Is the installation method for pipes with diameters in the DN300÷4000 range.

Upstream

transducer

Downstream

transducer

Forward ow

direction

7.5 W INSTALLING

Is the installation method for pipes with diameters in the DN20÷50 range.

Upstream

transducer

Downstream

transducer

Forward ow

direction

Page 20 of 60

SGM-101F - installation

7.6 INSERTION TRANSDUCER INSTALLATION

Steps required for proper installation:

1 - with encased pipe, check that there is the minimum space required for the transducers installation.

2 - with encased pipe, check that the free section length of the pipe is the minimum required.

540

Min. distance

from wall

540

Min. distance

from wall

ø Pipe

Distance

transducer

Distance between the transducer + 200mm.

Transducer Pipe Transducer

3 - Procuring the necessary equipment for drilling the pressure pipes .

4 - Set the pipe parameters: in the menu M23 choose the option 17 or 21 (TC-1 or TLC-2 insertion transducer);

in the menu M24 choose 1. (Z installation) and in the menu M25 check the positioning distance.

5 - Determine the best location for installation on pipe .

6 - Installing the ball valve base.

Metallic pipe Non-metallic pipe

Valve base

welded to the pipe Metal band

Table of contents

Other SGM LEKTRA Measuring Instrument manuals

SGM LEKTRA

SGM LEKTRA FLOWMETER User manual

SGM LEKTRA

SGM LEKTRA SGM-101H Guide

SGM LEKTRA

SGM LEKTRA SGM-100F User manual

SGM LEKTRA

SGM LEKTRA RPmag Guide

SGM LEKTRA

SGM LEKTRA RPmag Guide

SGM LEKTRA

SGM LEKTRA MUXM User manual

SGM LEKTRA

SGM LEKTRA Pmag User manual

SGM LEKTRA

SGM LEKTRA Transit Time SGM-200H Guide