SGM LEKTRA Transit Time SGM-200H Guide

SGM-200H

“transit time” ultrasonic flow meter

GB technical documentation Rev. D

Page 2 di 32 www.sgm-lektra.com

SGM-200H - table of contents

TABLE OF CONTENTS

1-WARRANTY

2-PRODUCT

3-TECHNICAL SPECIFICATIONS

4-DIMENSIONS

5-INSTRUMENT PARAMETERS

6-DESCRIPTION OF MAIN PARAMETERS

7-INSTALLATION

8-USE

9-TESTING AND QUALITY CERTIFICATE

page 3

page 4

page 6

page 7

page 11

page 12

page 15

page 28

page 32

Page 3 di 32

www.sgm-lektra.eu

SGM-200H - warranty

SGM LEKTRA S.R.L. undertakes to remedy any fault, defect or absence, occurring within 12 months from the

delivery date, provided that it is attributable to it and has been notified within the prescribed time limit.

SGM LEKTRA S.R.L. can choose whether to repair or replace the defective Products.

The Products replaced under warranty will have an additional 12-month warranty.

The Products repaired under warranty will have a warranty until the original time limit.

The parts of the Products repaired out of warranty will have a 3-month warranty.

The Products are only guaranteed to meet particular specifications, technical characteristics or conditions of use

if this is expressly agreed in the Purchase Agreement or in the documents referred to therein.

The warranty of SGM LEKTRA S.R.L. absorbs and replaces the warranties and responsibilities, both contractual

and non-contractual, originating from the supply such as, for example, compensation for damages,

reimbursement of expenses, etc., both towards the Customer and towards third parties.

The warranty is void in the event of tampering with or improper use of the Products.

1-WARRANTY

Page 4 di 32 www.sgm-lektra.com

SGM-200H - product

2-PRODUCT

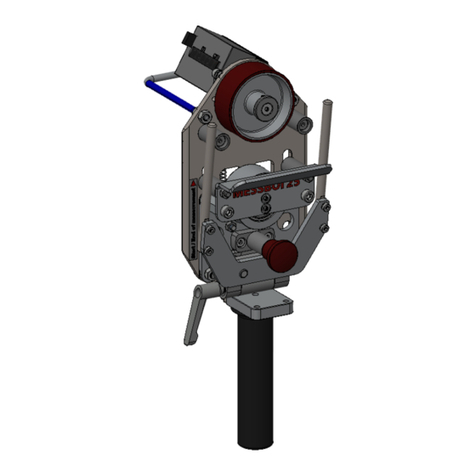

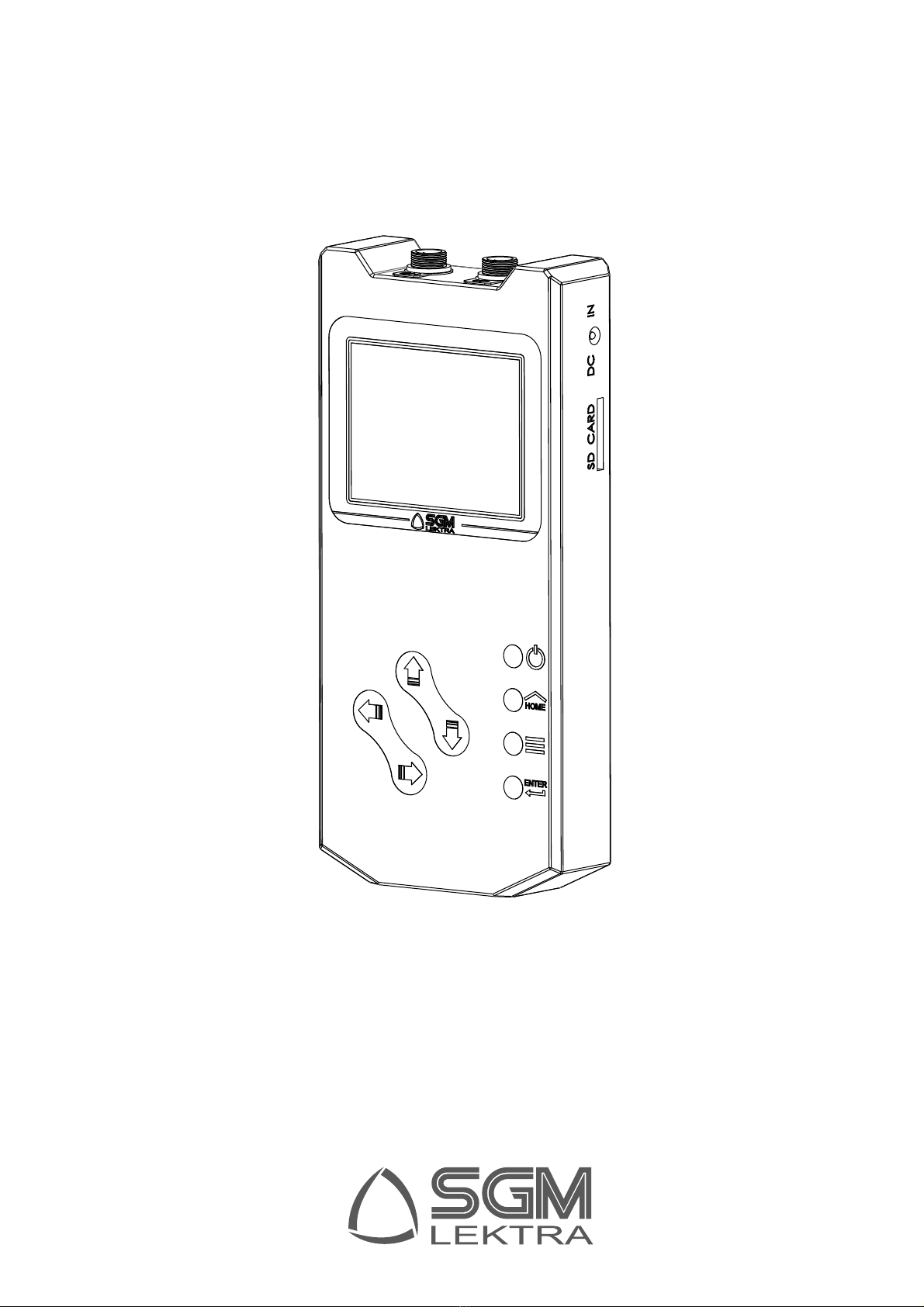

1. Transducer connectors

2. Charging connector

3. SD card

4. “ON” LED

5. “Charging” LED

6. ON/OFF key

7. Main screen key

2.1 IDENTIFICATION

Every instrument has an adhesive identification plate on which the main information about the product is outlined.

The following image describes the information and data on the plate.

1. Product code

2. Serial number

3. Power supply

SGM-200HTM1HD

FU0101600357

3

1Mod.

P. S .

S.N.

Batt. 4,8V 300mA/h

2

10

12

11

13

9

8

7

6

2

3

5

4

1

14

8. Cancel/annul key

9. Confirm key

10. UP

11. DOWN

12. LEFT

13. RIGHT

14. Display

Page 5 di 32

www.sgm-lektra.eu

SGM-200H - prodotto

Diameter

Pipe

ș

Upstream

transducer

Downstream

transducer

T2

T1

Pipe

thickness

D

VLQș

¨7

T1•T2

V=

Towards

direct flow

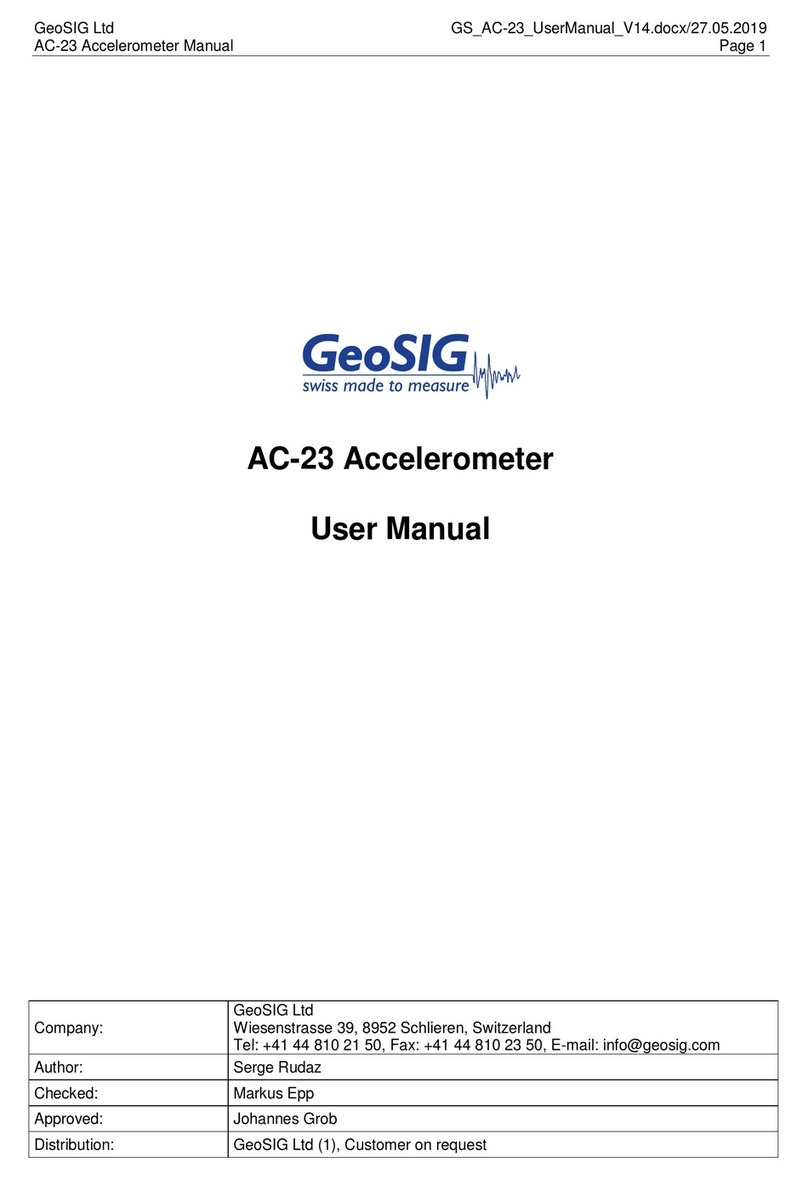

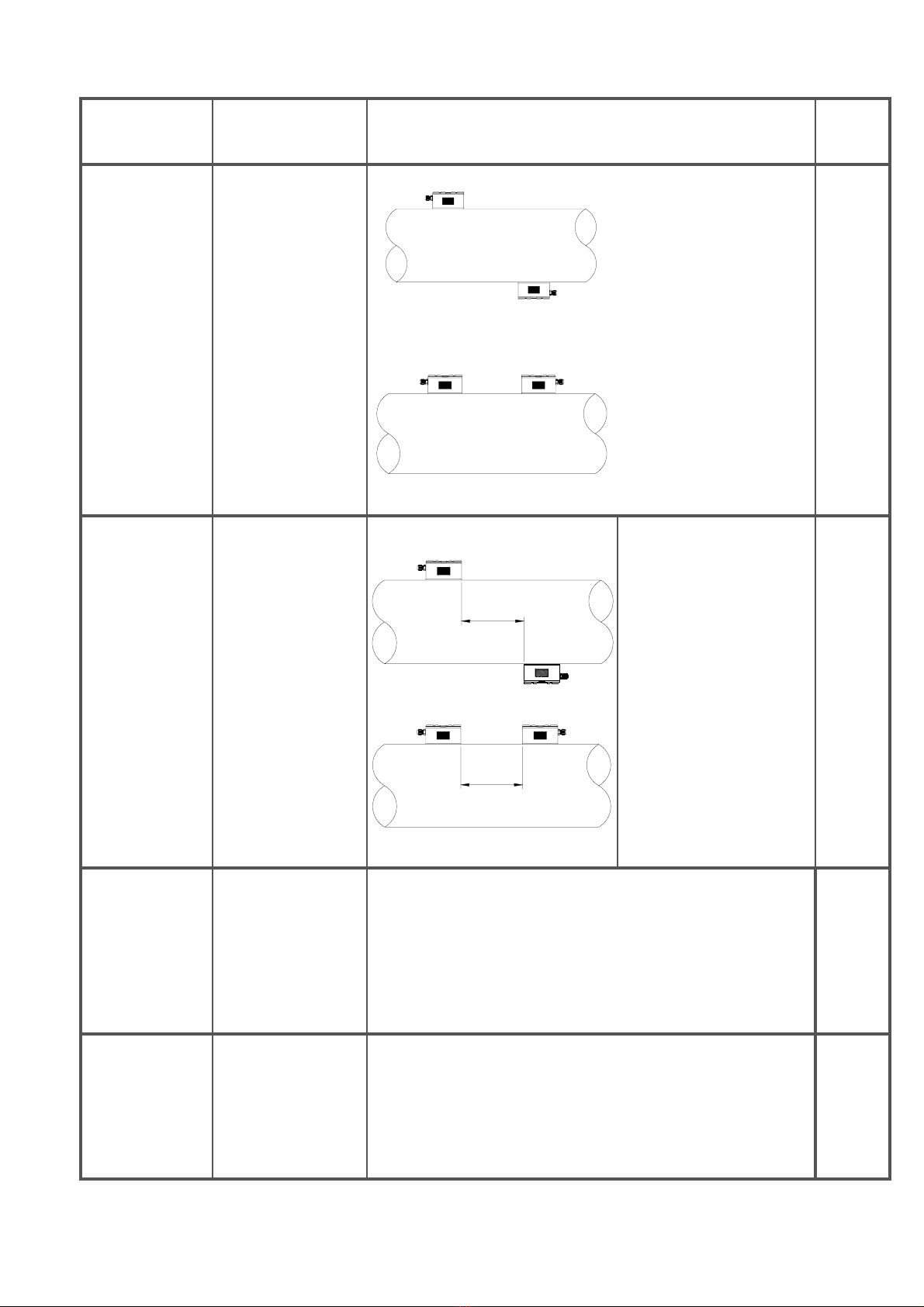

2.2 PRINCIPLE OF OPERATION

The SGM-200H measures the transit time through the two transducers which alternately transmit and receive a

sequence of sound pulses.

The difference in the measured transit time is directly related to the fluid speed in the pipe, as indicated in the

figure below.

When the speed of the fluid in the pipe and its geometry is known, the SGM-200H calculates the instantaneous

flow rate.

“Clamp on” transducers enable an easy installation; they are installed outside the pipe at a specific distance from

each other. They can be installed with V (2 sound tracts), W (4 sound tracts) or Z (1 sound tract) methods.

The choice of installation method depends on the pipe and on the characteristics of the fluid.

θ= angle of the sound path

D = diameter of the pipe

T1 = transit time of sound between upstream and downstream transducers

T2 = transit time of sound between downstream and upstream transducers

∆T = T2 - T1

2.3 GENERAL CHARACTERISTICS

2.3.1 Applications

The SGM-200H has several possible applications. The dimensions of the pipe can vary from 20 to 4000 mm

(0.79 to 157 inches) while liquids can be: ultra-pure, drinking water, chemicals, dirty water, cooling water,

river water, etc.

Since clamp-on transducers are applied externally to the pipe, they are not in contact with the liquid and have

no moving parts, the transmitter does not suffer damage due to wear, scale or pressure.

2.3.2 Data Integrity function

All the configuration values entered by the user are saved in the EE PROM, which is protected by a password

to prevent accidental changes. The transmitter is equipped with a clock for memorising the date and time of the

measurement, and runs on battery power. Should the batteries drain completely, it will be necessary to re-set the

date and time parameters.

Page 6 di 32 www.sgm-lektra.com

3-TECHNICAL SPECIFICATIONS

Display

3.5”, 320x240pixel, 65536 colours; auto switch offafter 10 minutes of inactivity

Data displayed

instantaneous flow rate; flow rate totalisers; instrument parameters

Languages

Italian, English, Chinese

Keyboard

8 keys

Case

ABS

Dimensions

218x103x35mm

Weight

400g

Temperature

-20 ÷ 60°C

Linearity

± 0.5%

Repeatability

± 0.2%

Total accuracy

± 1%

Max liquid speed

12 m/s

Pipe diameter

DN20 ÷ DN4000

Rechargeable Batteries

integrated, Ni-MH, 4x1,2V 300mA/h, 48h autonomy

Battery charger

100÷240Vac; 12Vdc out, 1.25A max current

Consumption

average 100mA, maximum 310mA, in stand by 100uA

Totaliser

7 digits for positive, negative and net

Data logger

On SD or SDHC card with capacities from 512Mb to 32Gb

16GB, they can store data for 10 years

Intervallo di memorizzazione data logger

5s, 10s, 20s, 30s, 60s

Clamp-on transducers

TS-2 type suitable for pipes from 20 to 100mm (-30÷90°C)

TM-1 type suitable for pipes from 50 to 700mm (-30÷90°C)

TL-1 type suitable for pipes from 300 to 4000mm (-30÷90°C)

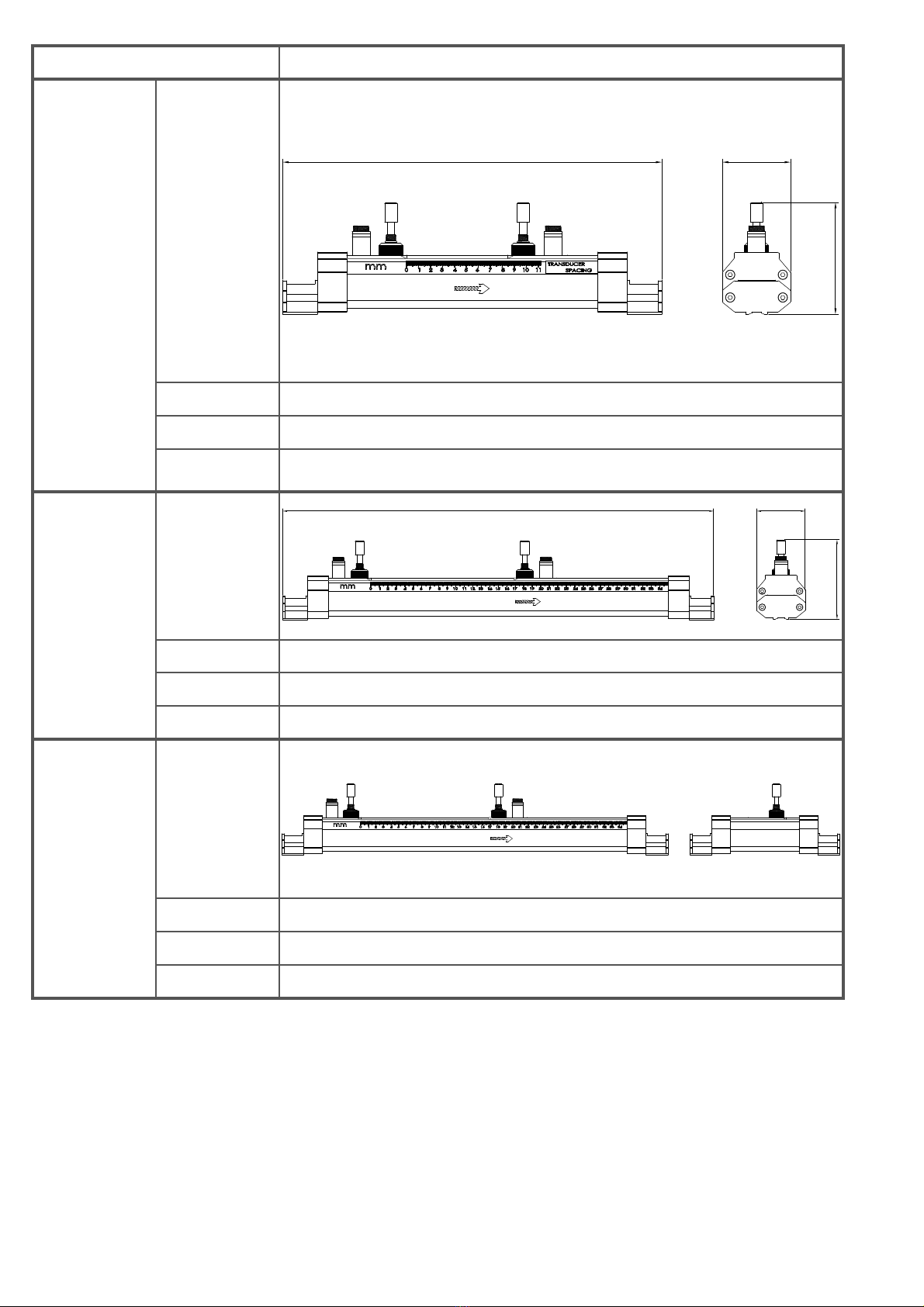

Clamp-on transducers assembled on metric rail

HSNN type suitable for pipes from 20 to 100mm (-30÷90°C)

HMNN type suitable for pipes from 50 to 300mm (-30÷90°C)

HMEN type suitable for pipes from 50 to 700mm (-30÷90°C)

Clamp-on transducers for high temperatures

TS2H type suitable for pipes from 20 to 100mm (-30÷160°C)

TM1H type suitable for pipes from 50 to 700mm (-30÷160°C)

SGM-200H - technical specifications

Page 7 di 32

www.sgm-lektra.eu

SGM-200H - dimensions

4-DIMENSIONS

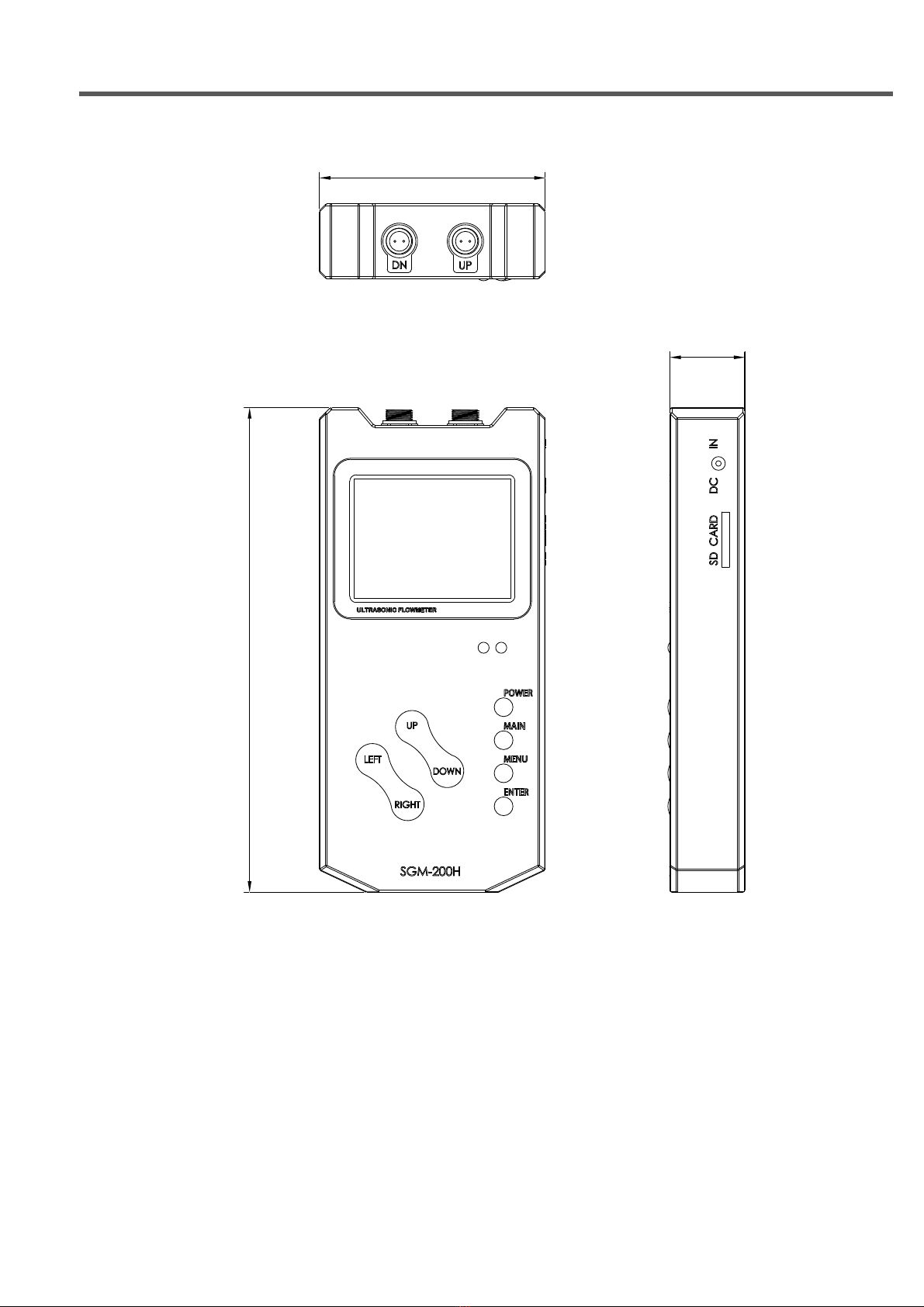

220

34

102,5

4.1 MECHANICAL DIMENSIONS SGM-200H

Page 8 di 32 www.sgm-lektra.com

SGM-200H - dimensions

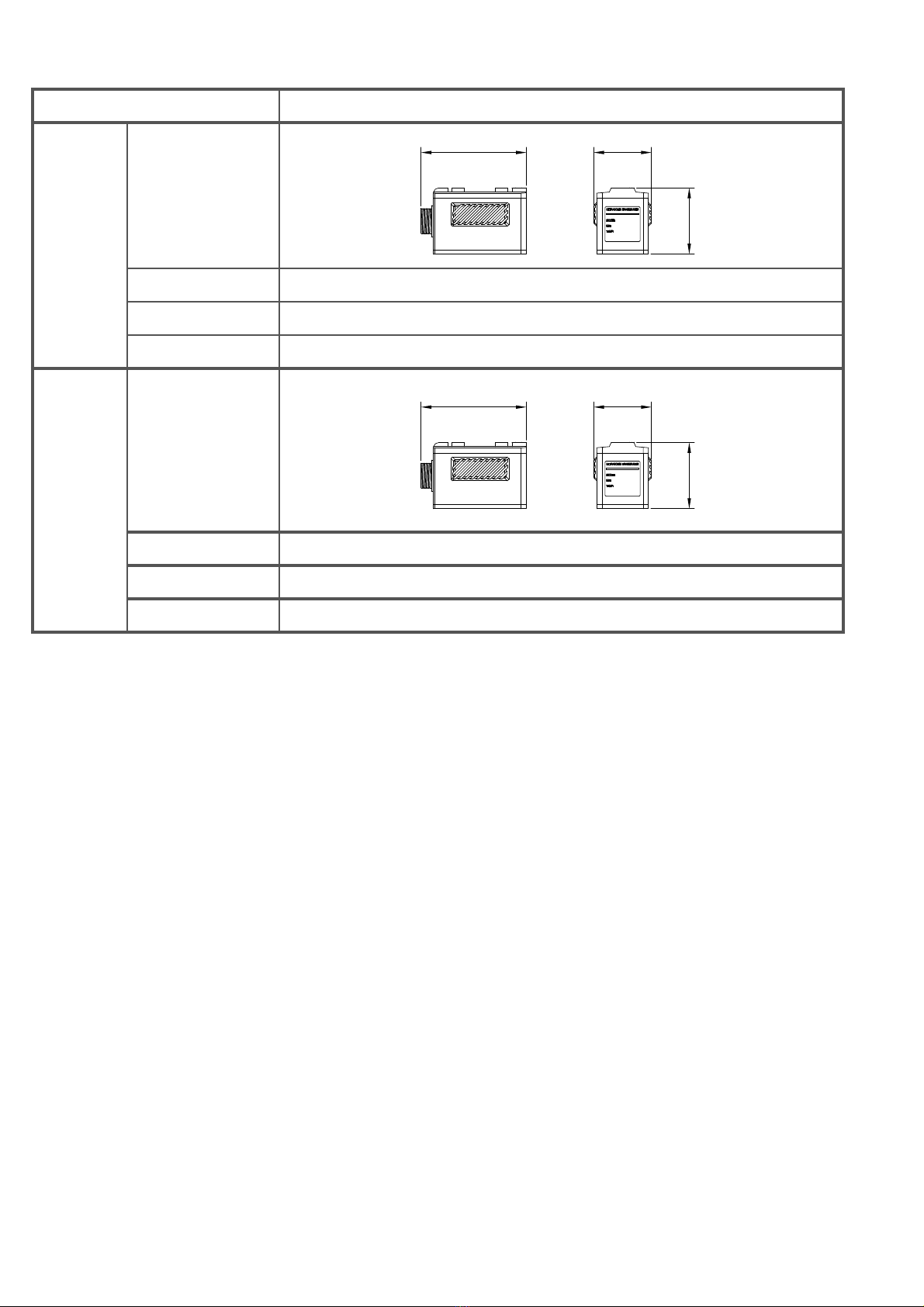

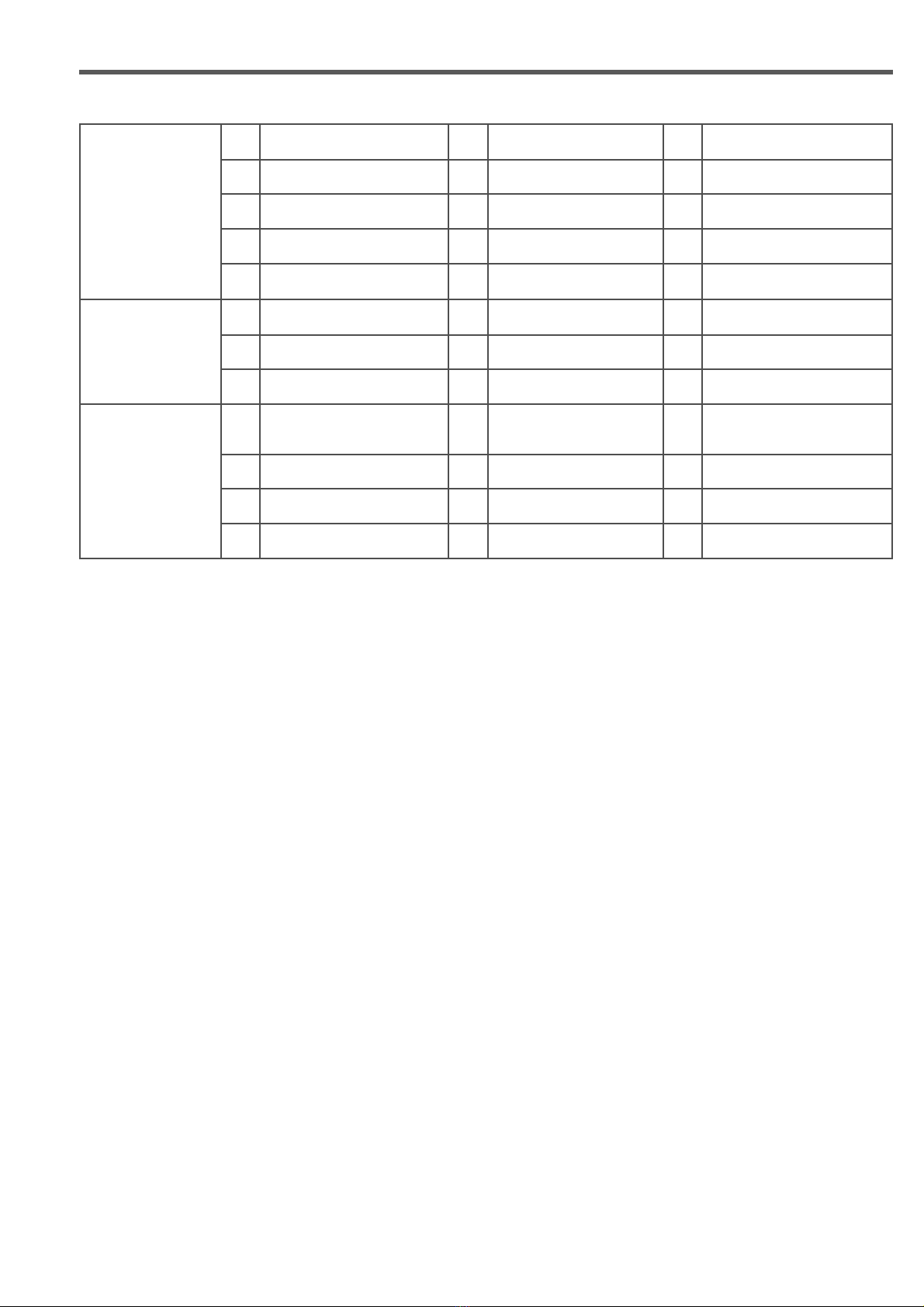

Transducer Model Features

TS-2

Dimensions

51 28

32

Pipe Ø range 20÷100mm (¾” ÷ 4”)

Temperature -30 ÷ +90°C

Parameter 13 >STANDARD S1

TS2H

Dimensions

51 28

32

Pipe Ø range 20÷100mm (¾” ÷ 4”)

Temperature -30 ÷ +160°C

Parameter 13 >STANDARD S1

4.2 DIMENSIONS AND CHARACTERISTICS OF THE TRANSDUCERS

Page 9 di 32

www.sgm-lektra.eu

SGM-200H - dimensions

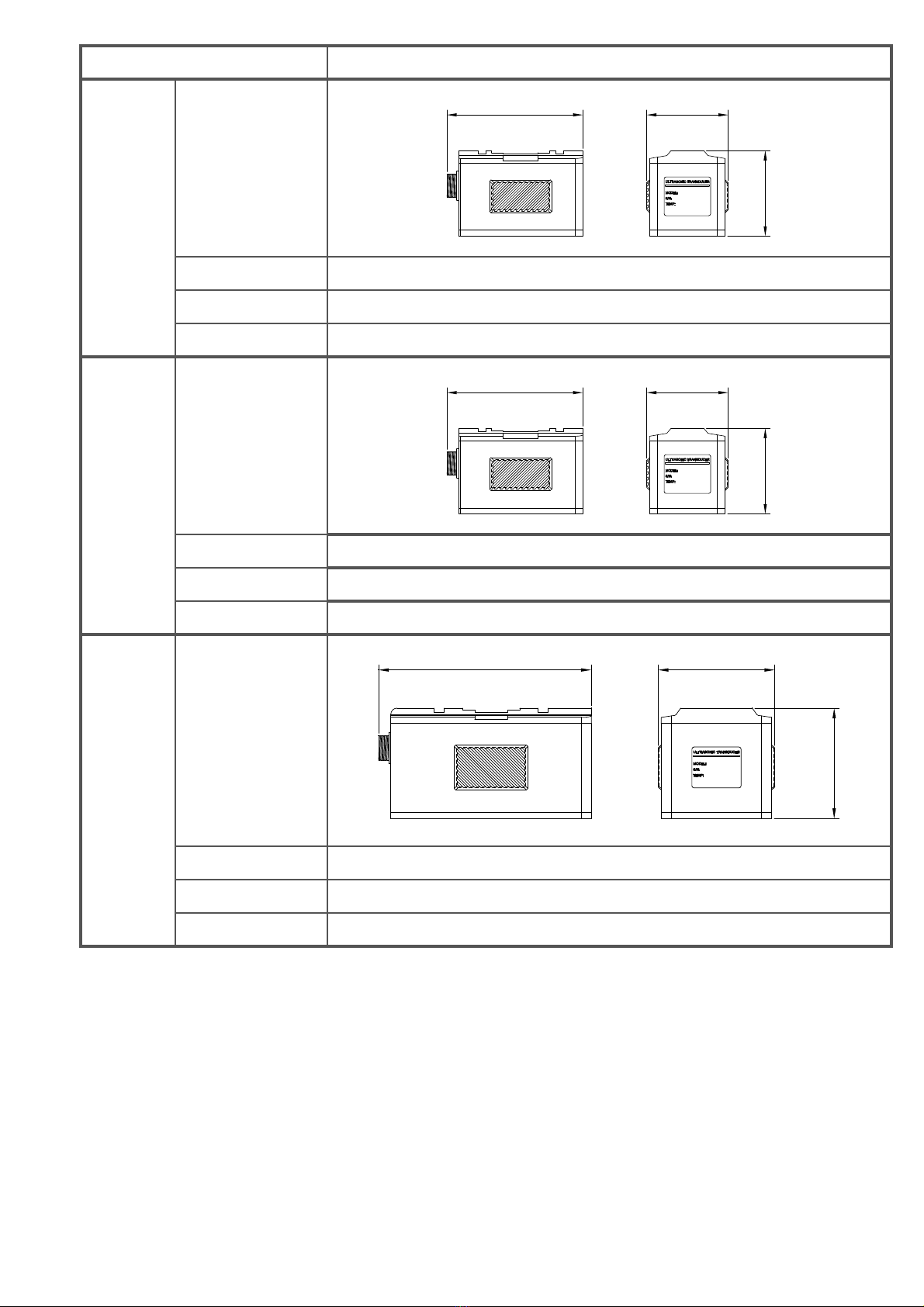

Transducer Model Features

TM-1

Dimensions

70 42

44

Pipe Ø range 50÷700mm (2” ÷ 28”)

Temperature -30 ÷ +90°C

Parameter 13 >STANDARD M1

TM-1H

Dimensions

70 42

44

Pipe Ø range 50÷700mm (2” ÷ 28”)

Temperature -30 ÷ +160°C

Parameter 13 >STANDARD M1

TL-1

Dimensions

104 57

54

Pipe Ø range 300÷4000mm (12” ÷ 160”)

Temperature -30 ÷ +90°C

Parameter 13 >STANDARD L1

Page 10 di 32 www.sgm-lektra.com

SGM-200H - dimensions

Transducer Model Features

HSNN

Dimensions

320 57

95

Pipe Ø range 20÷100mm

Temperature -40°C ÷ +90°C

Parameter 13 >STANDARD HS

HMNN

Dimensions

570 57

95

Pipe Ø range 50÷300mm

Temperature -40°C ÷ +90°C

Parameter 13 >STANDARD HM

HMEN

Dimensions

Pipe Ø range 50÷700mm

Temperature -40°C ÷ +90°C

Parameter 13 >STANDARD HM

Page 11 di 32

www.sgm-lektra.eu

SGM-200H - instrument parameters

5-INSTRUMENT PARAMETERS

5.1 PARAMETER TABLE

Basic

parameters

01 Pipe Circumference 02 Pipe Outside Diameter 03 Pipe Thickness

04 Pipe Inner Diameter 05 Pipe Material 06 Pipe Mat. Sound Speed

07 Internal Coat. Mat. 08 Coat. Sound Speed 09 Coating Thickness

10 Type of Liquid 11 Sound Speed In Liquid 12 Liquid Viscosity

13 Type of Transducer 14 Assembly of Transducer 15 Transd. Assemb. Distance

Flow Rate

16 Unit of Measure Sel. unit 17 Instan MisQ Unit 18 Totalis, Unit

19 Multi Total Fact. 20 Tot Net Totalis. 21 Positive Totalis.

22 Negative Totalis. 23 Totalis. Resetting 24 Port Low Cutoff

System

parameters

25 Zero Setting 26 Zero Setting 27 Zero Manual Sett.

28 Signal Muffling 29 Scale Factor 30 Products no.

31 Language 32 Interval Record 33 Date & Time Set

34 Curve Range Set 35 Not used 36 Not used

5.2 BASIC PARAMETERS

01 Outer circumference of the pipe.

02 Outside diameter of the pipe; from 0 to 18000mm.

03 Wall thickness of the pipe.

04 Inner diameter of the pipe.

05 Pipe material.

For non-standard materials, select “Other” and enter the sound speed in menu 06.

06 Sound speed in the pipe material; only for non-standard materials.

07 Inner liner material, select “None” for pipes without coating; for non-standard materials, select the “Other” and

enter the sound speed in menu 08.

08 Speed of sound in the coating; only for non-standard materials. 09 Thickness of the internal coating,

where provided.

10 Type of fluid; For non-standard fluids, select “Other” and enter the sound speed in menu 11.

11 Sound speed in the fluid; only for non-standard fluids.

12 Viscosity of the fluid; only for non-standard materials.

13 Transducer model.

14 Method for transducers installation.

15 Distance for installation transducer (automatically calculated by the meter).

Page 12 di 32 www.sgm-lektra.com

SGM-200H - description of main parameters

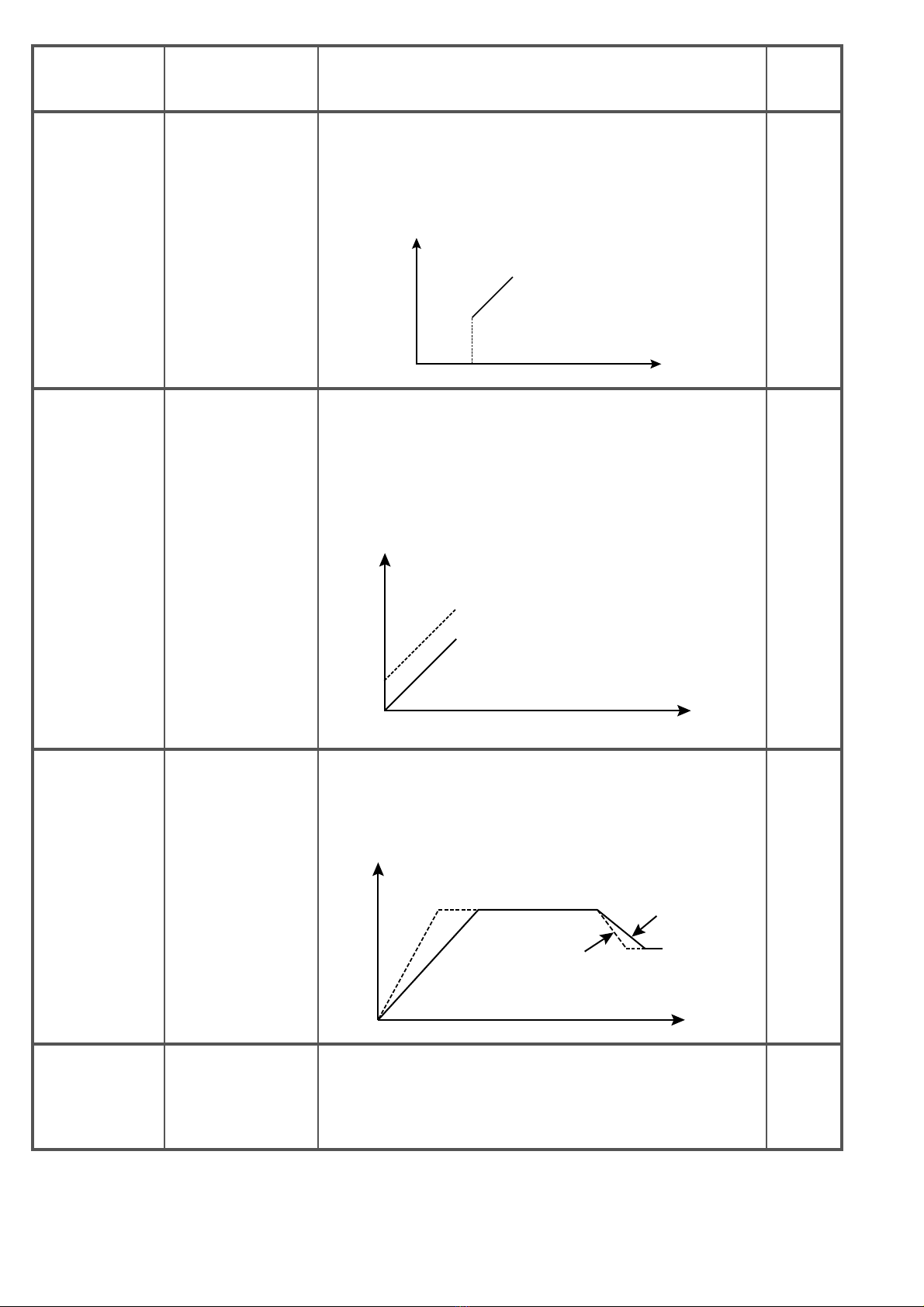

Name Display view Description Param.

Ø pipe

OUTSIDE

DIAMETER OF

PIPE

(Cross section of the pipe)

Outside diameter of

the pipe 02

Pipe thickness THICKNESS OF

THE PIPE

(Cross section of the pipe)

Thickness of the pipe 03

Pipe material MATERIAL OF THE

PIPE

CARBON STEEL; STAINLESS STEEL; CAST IRON; SWEET

IRON; COPPER; PVC-POLYVINYL CHLORIDE; ALUMINIUM;

FIBER CEMENT-AMI; VETROEPOXY FIBER; OTHER

MATERIALS

05

Inner coating

material

MATER. INTERNAL

COATING

NO INTERNAL COAT.; TAR. EPOXY; RUBBER; CONCRETE;

POLYPROPYLENE; POLYSTYRENE; POLYESTER;

PE-POLYETHYLENE; EBONITE-HARD RUBBER; TEFLON;

OTHER MATERIALS

07

Thickness of the

inner pipe coating

COATING

THICKNESS

(Cross section of the pipe)

Pipe inner coating

thickness 09

6-DESCRIPTION OF MAIN PARAMETERS

Page 13 di 32

www.sgm-lektra.eu

SGM-200H - description of main parameters

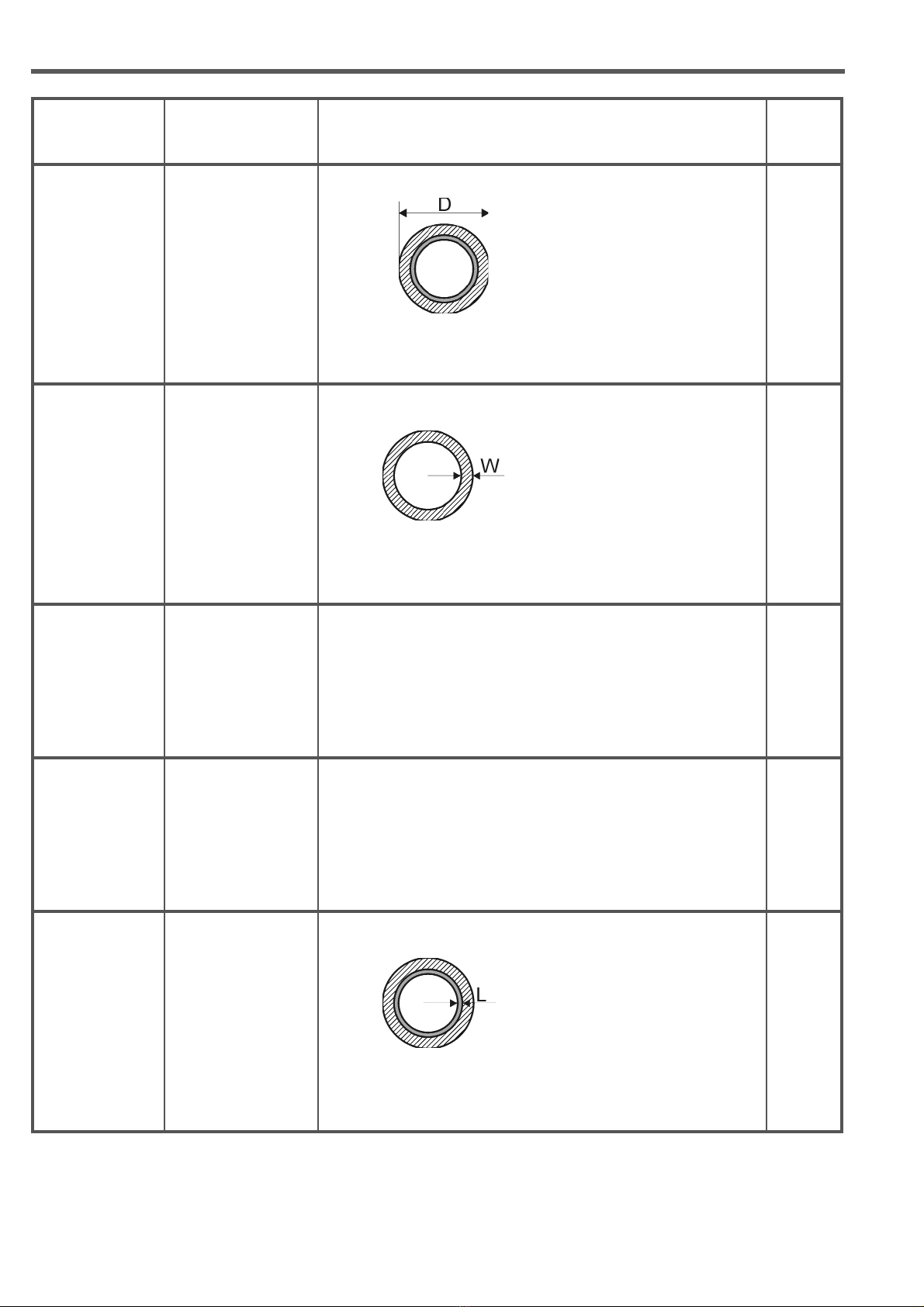

Name Display view Description Param.

Transducer

method of

assembly

INSTALLATION OF

TRANSDUCERS

Z mode The transducers can be

positioned on the pipe in 3

different modes: V; Z; N; W

and V.

The choice of installation

method depends on the

application conditions.

Methods of assembly

the most used are Vand Z.

14

V and W

mounting method

Transducer

installation

distance

TRANSDUCER

INSTALLATION

DISTANCE

Lout

Lout

The axial assembly

distance, Lout, is

automatically determined

based on the following data

previously

included: Ø pipe; pipe

thickness; pipe material;

internal coating, if any, with

thickness; transducer

installation method.

15

Instant flow rate

unit

Q INSTANT. UNIT

OF MEAS.

Unit of measurement associated with instantaneous flow

measurement.

It is possible to select 8 different units of measurement for the

volume: CUBIC METERS (m3); LITRES (l); US GALLONS(Gal);

UK GALLONS (IGL); MILLION US GALLONS; CUBIC FEET

(CF); OIL BARRELS (OB); UK OIL BARRELS (IB)

and 4 different units of measurement for time:

/SEC.; MIN.; /HRS; /DAY

17

Flow totalisers

unit of

measurement

TOTALISATI

ON UNIT

Unit of measurement associated with flow totalisers. It is

possible to select 8 different units of measurement: CUBIC

METERS (m3); LITRES (l); US GALLONS (Gal);

UK GALLONS (IGL); MILLION US GALLONS; CUBIC FEET

(CF); OIL BARRELS (OB); UK OIL BARRELS (IB)

18

Page 14 di 32 www.sgm-lektra.com

SGM-200H - description of main parameters

Name Display view Description Param.

Flow rate cutoff

value Port Low Cutoff

When the measured flow rate is lower than the cutoffvalue, the

displaywillshowtheinstantaneousflow rate measurement as a fixed0.

Range 0.000 ÷ 0.25m/s

Disp

l

aye

d

owrate

Actual

owrat

e

LV

24

Zero flow

calibration Zero Settings

When the fluid in the pipe is stationary, the flow rate value must

be 0. If it is not the case, it is necessary

to calibrate the Zero flow.

N.B. - Make sure that the fluid is perfectly still and that the pipe

is full

Displayed

owrate

Before setting

After setting

Actual

owrate

25

Integration

coefficient Signal damping

The integration coefficient defines the upward or downward

updating speed of the displayed flow measurement with respect

to the variation of the detected flow measurement.

Range: 0÷999 seconds

Flowrate

Actual

owrate

Displayed

owrate

Time

28

Correction

coefficient Scale Factor Coefficient for correction of measurement accuracy.

Range 0.5 ÷ 1.5% 29

Page 15 di 32

www.sgm-lektra.eu

SGM-200H - installation

7-INSTALLATION

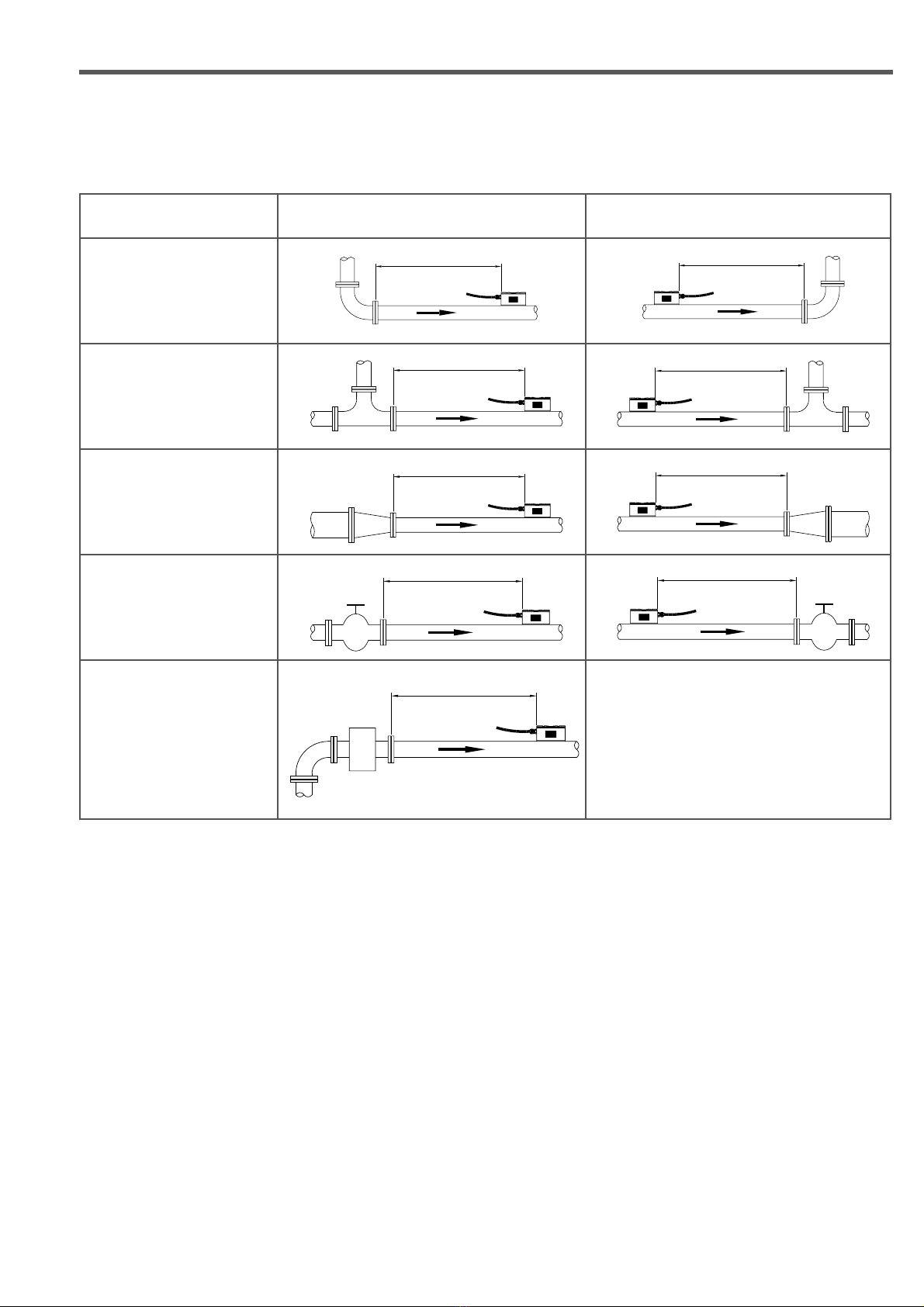

7.1 SELECTION OF MEASUREMENT POINT

The transducers must be installed on a section of pipe that allows to respect the minimum distance between the

element of resistance to flow, such as curves or extensions, and the measurement point.

See table below.

Flow resistance element Upstream side Downstream side

90° bend

15 x DN 5 x DN

T link

40 x DN 5 x DN

Adapters

18 x DN 5 x DN

Valves

40 x DN 5 x DN

Pumps

20 x DN

P

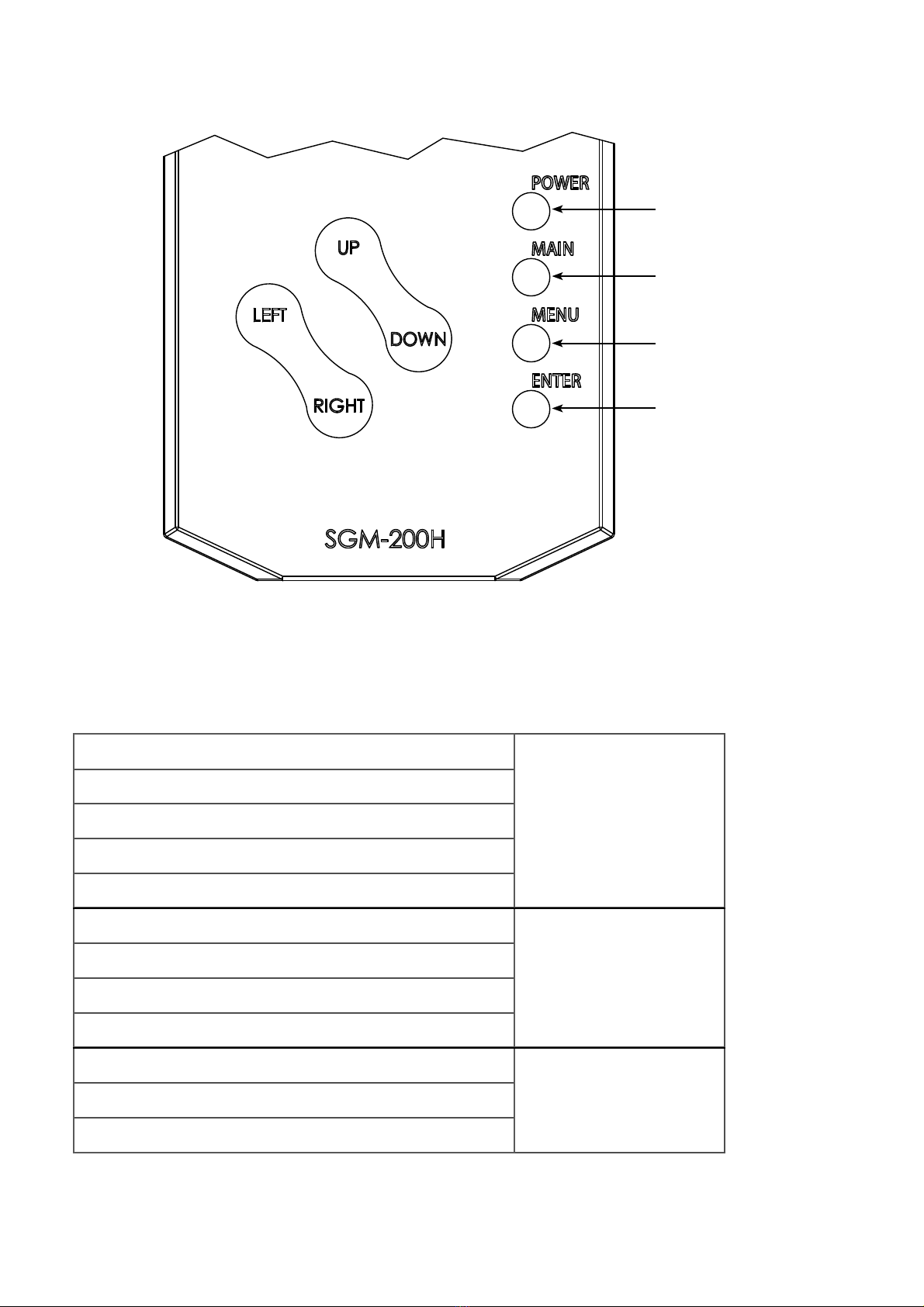

7.2 SETTING OF THE PARAMETERS IN THE INSTRUMENT

From the main page, press MENU to access the instrument menu; at the top right the letter "S" will appear on a blue

background.

Press ENTER to access the first page of the menu: PARAMETERS SET

With UP and DOWN it is possible to select the parameter within the page, with LEFT and RIGHT it is possible to move

to the previous/next page.

Once the parameter has been selected, by pressing ENTER the setting is accessed:

for multiple choice parameters, with the UP and DOWN keys it is possible to scroll through the available options and

choosing one with ENTER; for numeric fields, with UP and DOWN it is possible to increase/decrease the numeric

value of the selected digit, with LEFT and RIGHT it is possible to move to the adjacent digit.

Confirmation of the set value occurs by pressing ENTER. To exit the menu simply press MAIN.

Page 16 di 32 www.sgm-lektra.com

SGM-200H - installation

“UP” and “DOWN”: scroll

Parameter selection

“LEFT” or “RIGHT”: menu page change

“ENTER”: confirms the selection

“MENU”: cancels the modification of the parameter

“MAIN”: returns to the main screen

“ENTER”: confirms the selection and the number turns red

Numeric settings

“UP” or “DOWN”: increases or decreases the value of the digit

“LEFT” or “RIGHT”: selects the digit

“ENTER”: saves the parameter

“ENTER”: confirms the selection and the writing turns red

Option settings

"UP" or "DOWN": selects the parameter option

“ENTER”: saves the parameter

ON/OFF key

Main screen key

Cancel/annul key

Confirm key

UP KEY: Scroll up / Value increment. Flow rate curve display (in run mode).

DOWN KEY: Scroll down / Value decrease. Datalogger status display.

LEFT KEY: (LEFT + ENTER) data storage start (LEFT + MENU) data storage end.

Datalogger quick guide Menu selection / Menu page selection.

RIGHT KEY: SD memory status. Menu selection / Menu page selection.

7.3 KEYBOARD

Page 17 di 32

www.sgm-lektra.eu

SGM-200H - installation

7.4 SET THE LANGUAGE OF THE MENUS

Set the language in parameter 31.

7.5 SET DATE AND TIME

Set the date and time in parameter 33.

7.6 SET THE MEASURING SYSTEM

Set metric (mm) or British (in) system in parameter 16.

7.7 SET THE UNIT OF MEASUREMENT OF THE MEASUREMENT FLOW

Set the unit of measurement of the instantaneous flow rate to parameter 17.

7.8 SET THE UNIT OF MEASUREMENT OF THE TOTALISER

Set the unit of measurement of the totaliser in parameter 18.

7.10 ESSENTIAL SETTINGS FOR THE INSTALLATION OF THE TRANSDUCERS

• Set the value of the EXTERNAL diameter of the pipe in parameter 02; alternatively, the value of the pipe

circumference can be entered in parameter 01

• Set the pipe thickness value in parameter 03.

• Set the pipe material in parameter 05; if the material is not present in the options, select “Other” and set the

sound speed in the pipe material in parameter 06.

• Set the possible INTERNAL coating material of the pipe: if not present, choose NONE; if present but not foreseen

in the options, set the sound speed in the internal coating material in parameter 08.

• Set the thickness of the coating material, if present, in parameter 09.

• Set the type of fluid in parameter 10; if not present in the options, select “Other” and enter the sound speed in the

fluid in parameter 11 and the viscosity of the fluid in parameter 12.

• Set the transducer model in parameter 13.

• Set the assembling method of the transducers in parameter 14.

At this point, the instrument automatically provides the installation distance of the transducers in parameter 15.

7.9 SET THE "SCALE FACTOR" VALUE

The “scale factor” value to be set is shown on the calibration certificate of each pair of transducers supplied.

For setting, use parameter 29.

Page 18 di 32 www.sgm-lektra.com

SGM-200H - installation

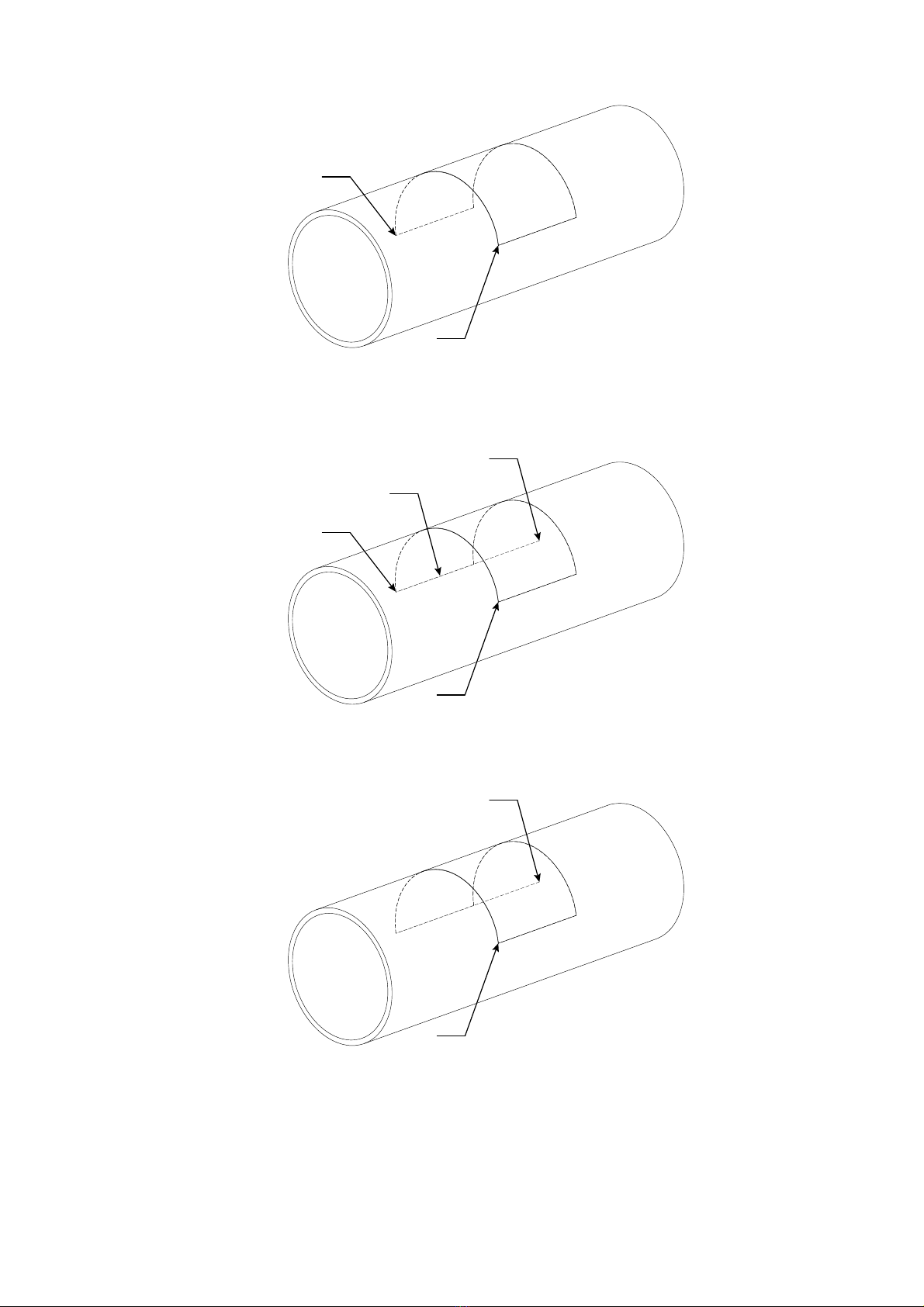

7.11 POSITIONING TYPE SELECTION

The selection of the type of positioning of the two transducers, Z-Mode, or V-Mode or W-Mode,

depends on the pipe DN involved in the measurement:

DN20÷50 - recommended installation W-Mode

DN50÷250 - recommended installation

V-Mode DN250÷4000 - recommended installation Z-Mode

7.12 PLACING THE POSITIONING

After entering the parameters relating to the pipe and the type of positioning of the transducers, the conversion unit

automatically calculates the axial mounting distance between the two transducers in parameter 15, TRANSD. ASSEMB.

DIST. The value of 15 is used to trace the exact position of the transducers on the pipe.

7.13 TRACKING TOOLS

To track the transducer positioning points on the pipe surface, simple tools are sufficient:

- a paper tape with a width of at least 50mm..

- a pencil or a fine-tipped marker

- a meter

7.14 TRACKING METHODS

7.14.1 Z-type positioning

To correctly position the transducers, proceed as follows:

1) Wrap the pipe with the paper tape, ensuring that the edges of the tape are perfectly overlapping each other.

Trace the circumference “C” on the pipe with the pencil or the fine-tipped marker and, at the same time,

trace the measurement point of the circumference on the paper tape.

C

2) Remove the paper tape and fold the part corresponding to the circumference in half. Place the paper tape

back on the pipe.

The intersection point, called "A", is the assembling position of one of the two transducers.

A

Page 19 di 32

www.sgm-lektra.eu

SGM-200H - installation

4) On the pipe, trace the straight line "D" from point "B" of length equal to the distance previously calculated and

displayed by the conversion unit in parameter 15 to obtain point "E".

D

A

B

E

5) Now the positions of both transducers have been obtained, points marked with the letter “A” and “E”.

A

E

3) Locate point “B” positioned 180° from point “A” using the ribbon folded in half.

A

B

Page 20 di 32 www.sgm-lektra.com

SGM-200H - installation

7.14.2 V or W type positioning

To correctly position the transducers, proceed as follows:

1) Determine a point called “A”, which will be the assembling position of one of the two transducers.

A

2) On the pipe, trace the straight line "S" parallel to the pipe from point "A" of length equal to the distance previously

calculated and displayed by the conversion unit in parameter 15 to obtain point "B".

A

B

Table of contents

Other SGM LEKTRA Measuring Instrument manuals