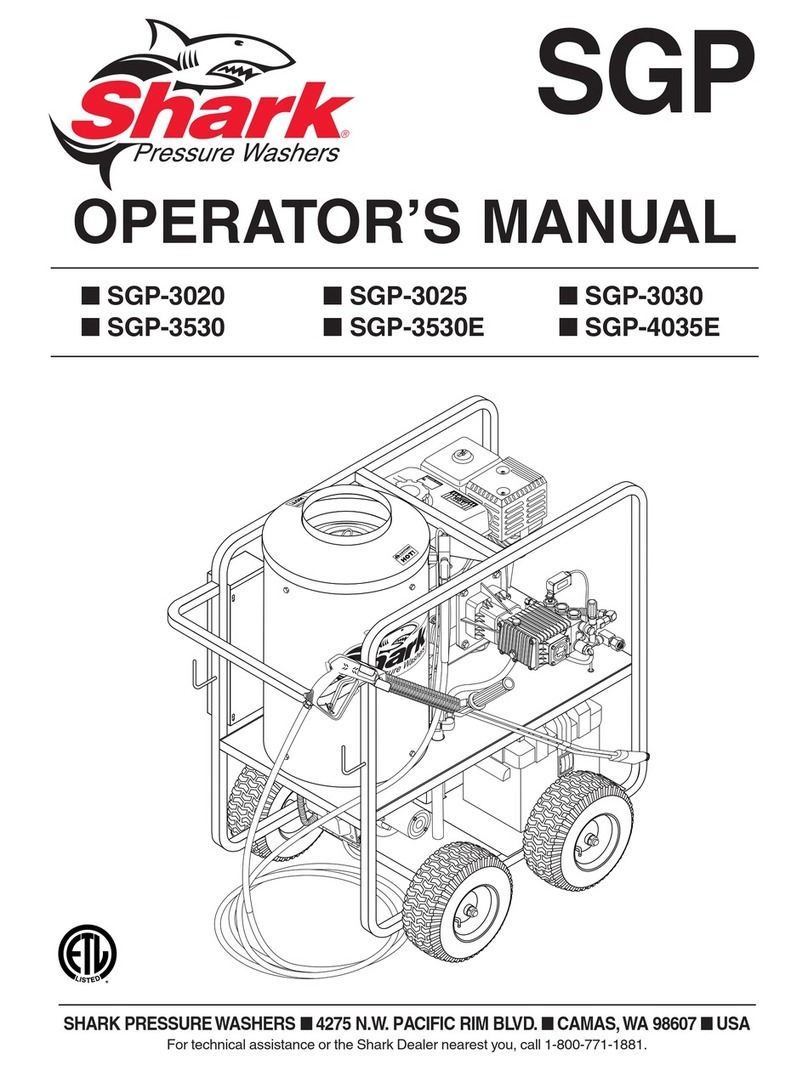

SHARK SSG • 97-6134 • REV. 7/05a

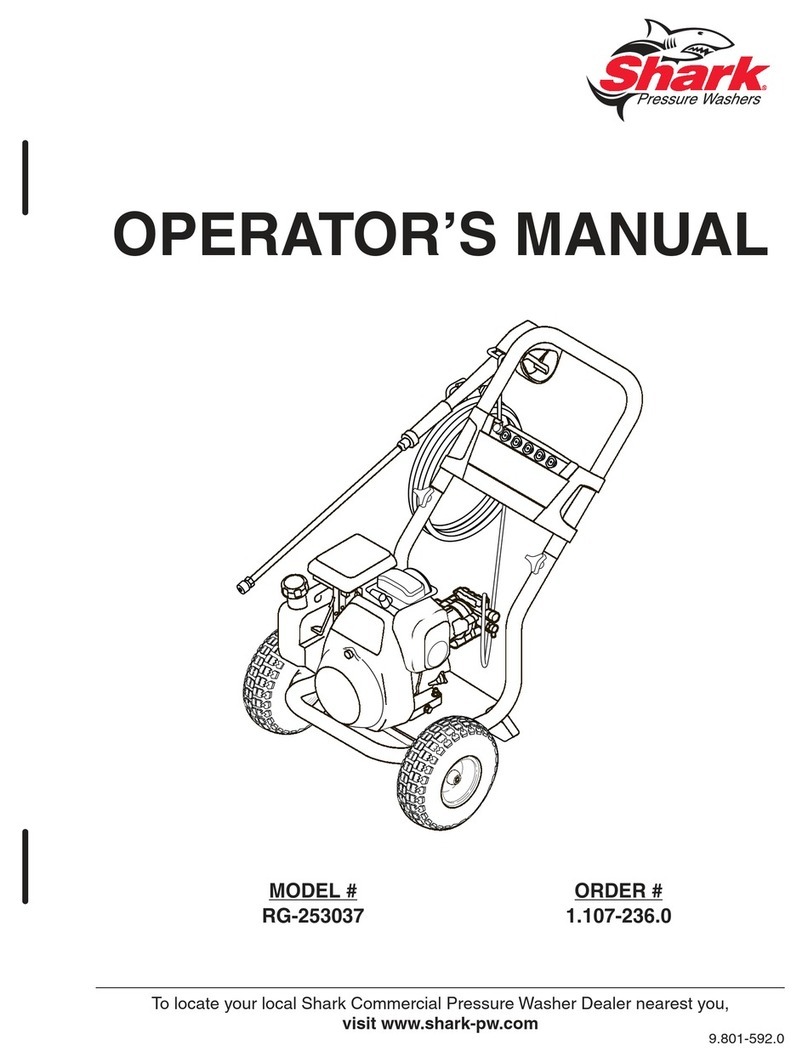

OPERATOR’S MANUAL PRESSURE WASHER

4

Thankyoufor purchasing our pressure washer.

Allinformationinthismanualisbasedonthelatestprod-

uct information available at the time of printing.

We reserves the right to make changes at any time

withoutincurringanyobligation.

Owner/User Responsibility:

Theownerand/orusermusthaveanunderstandingof

themanufacturer’soperating instructionsandwarnings

before usingthis pressurewasher.Warning information

shouldbeemphasizedandunderstood.Iftheoperator

is not fluent in English, the manufacturer’s instructions

and warnings shall be read to and discussed with the

operator in the operator’s native language by the pur-

chaser/owner, making sure that the operator compre-

hends its contents.

Owner and/or user must study and maintain for future

referencethemanufacturers’instructions.

This manual should be considered a permanent

part of the machine and should remain with it if

machine is resold.

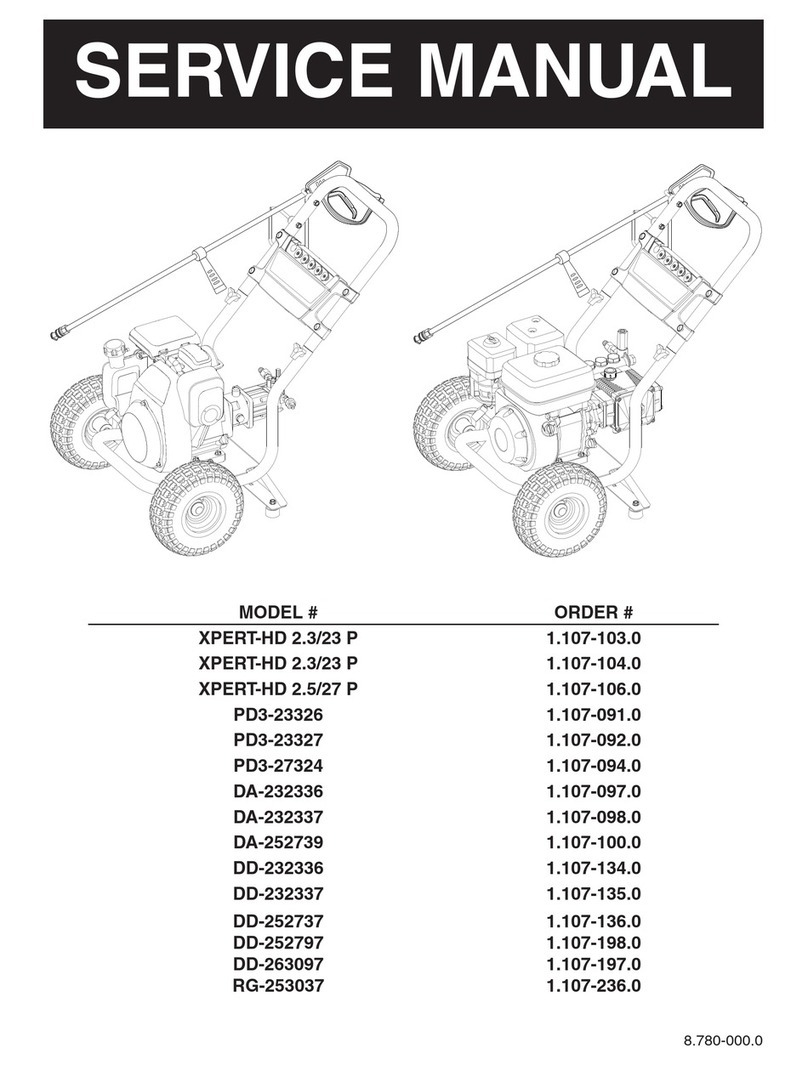

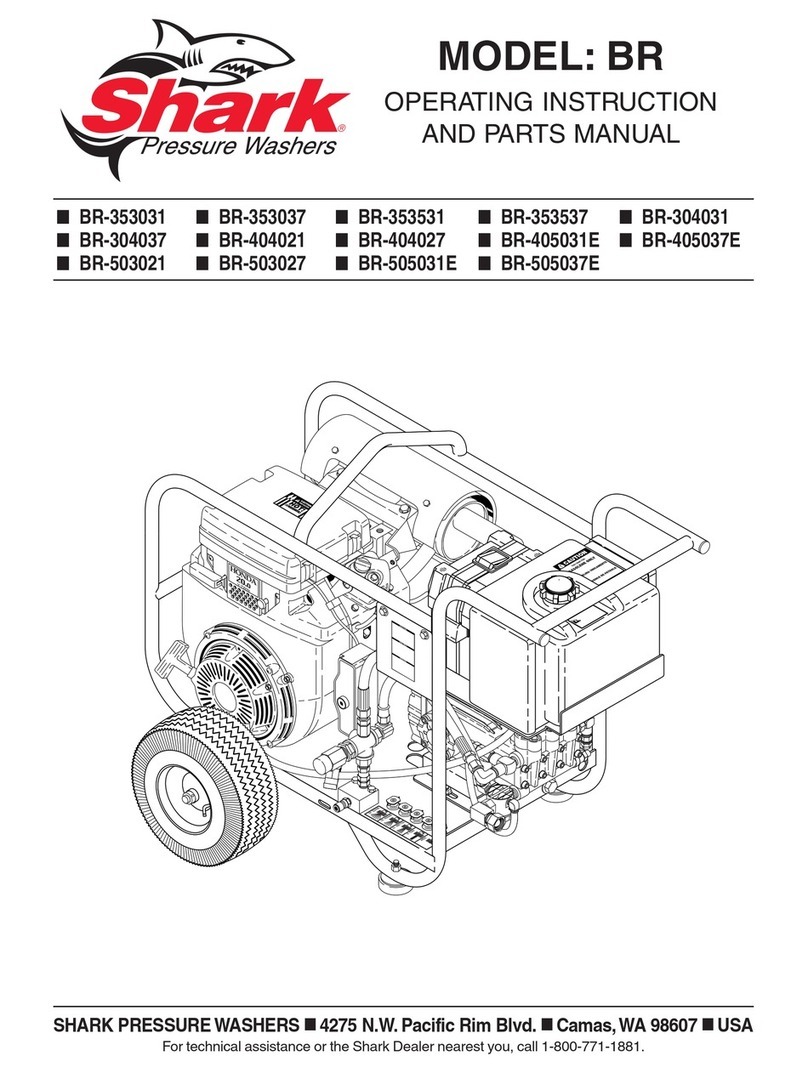

When ordering parts, please specify model and

serial number.

IMPORTANT SAFETY

INFORMATION

WARNING: When using this product basic precau-

tions should always be followed, including the

following: CAUTION:To reduce the risk of

injury, read operating instruc-

tions carefully before using.

1. Readtheowner’smanualthor-

oughly. Failure to follow in-

structionscouldcauseamal-

function of the machine and

resultindeath,seriousbodily

injuryand/orpropertydamage.

2. Knowhowtostopthemachineand bleedpressures

quickly. Be thoroughly familiar with the controls.

3. Stay alert — watch what you are doing.

4. Allinstallations must complywithlocalcodes. Con-

tact your electrician, plumber, utility company or

the selling distributor for specific details.

WARNING:Risk ofasphyxiation.

Use this product outdoors only.

5. Avoid installing machines in

small areas or near exhaust

fans. Exhaust contains poi-

sonouscarbonmonoxidegas;

exposure may cause loss of

consciousnessandmaylead

to death. It also contains

chemicals known in certain

quantities, to cause cancer, birth defects, or other

reproductiveharm.

WARNING: Flammable liquids

can create fumes which can ig-

nite,causingpropertydamage or

severe injury.

CAUTION:Riskoffire.Donotadd

fuel when machine is operating.

6. Allowenginetocoolfor 2min-

utes before refueling. If any

fuel is spilled, make sure the

areaisdrybefore testing the spark plug or starting

theengine.(Fire and/or explosion may occurifthis

is not done.)

Gasolineengines on mobileorportableequipment

shallberefueled:

(a) outdoors;

(b) with the engine on the equipmentstopped;

(c ) with no source of ignition within 10 feet of the

dispensingpoint; and

(d) with an allowance made for expansion of the

fuel should the equipment be exposed to a

higherambient temperature.

Inan overfillingsituation,additionalprecautionsare

necessary to ensure that the situation is handled in a

safemanner.

WARNING: Risk of explosion – do not spray flam-

mable liquids.

7. Do not place machine near flammable objects as

the engine is hot.

WARNING:Riskofinjectionorse-

vere injury to persons - Keep

clear of nozzle - Do not touch or

direct discharge stream at per-

sons.This machine isto be used

only by trained operators.

CAUTION: Hot discharge fluid.

Donot touch ordirect discharge

stream at persons.

WARNING

RISK OF

ASPHYXIATION.

USE THIS PRODUCT

ONLY IN A WELL

VENTILATED AREA.

WARNING

HIGH PRESSURE

STREAM CAN

PIERCE SKIN AND

TISSUES.

RISK OF EXPLOSION:

DO NOT USE WITH

FLAMMABLE

LIQUIDS.

WARNING

WARNING

READ OPERATOR’S

MANUAL

THOROUGHLY

PRIORTO USE.

CAUTION

INTRODUCTION AND IMPORTANT SAFETY INFORMATION