Page 7Shark DH3030HGB

To Start

DANGER: Do not point wand or trigger gun at your-

self or at any person. Bodily injury may result from

water under high pressure.

WARNING:Wear eye, ear, hand, foot and skin protec-

tion at all times while operating pressure washer.

IMPORTANT: The water must be turned on before

starting. Running the pump dry will cause damage

and void warranty.

IMPORTANT: Do not allow the machine to run with

trigger of the trigger gun released for more than

10 minutes at any one time or damage to pump may

occur.

1. Turn ON water supply.

2. Hold wand firmly, release trigger of trigger gun.

3. Turn engine ON/OFF switch to ON position.

4. Turnfuelshut-offvalvetoONposition(if soequipped).

Move choke lever to FULL CHOKE position, (choke

may not be needed on warm engine). Move throttle

lever to HALFTHROTTLE position.

5. Pulltheropestarterslowlyuntilresistanceisfelt, then

pull briskly.Do not allow the rope starter to snap back

against the engine. Return it gently to prevent dam-

age to the starter.

6. When the engine starts, move choke lever until

engine runs smoothly. Move throttle lever to FULL

THROTTLE position. When engine warms, move

choke lever to NO CHOKE position.

IMPORTANT:To allow for proper battery charging the

throttle control must be kept in the full throttle posi-

tion during operation.

NOTE: If engine fails to start, refer to Troubleshoot-

ing Guide in this manual.

7. Squeeze trigger of trigger gun and allow air to purge

from system.

8. If HOT water is desired, adjust the thermostat to the

proper temperature and turn burner switch ON. The

burnerwilllightimmediately withasmallpuffofsmoke.

You may need to initially adjust your burner for peak

performance.See Oil Burner section under Installa-

tion. If smoke continues, contact Customer Service

at 1-800-771-1881. When the trigger of the trigger

gun is released or when the thermostat temperature

setting is reached, the burner will automatically turn

off.

To Clean

DANGER: Do not place hands or fingers in front of

high pressure spray. Bodily injury may result.

1. Insert detergent inlet line into container of mixed

detergent. Squeeze the trigger of the trigger gun.

Opendetergentcontrolhandleonthe duallancewand,

2. Wash from the bottom to the top, using side to side

motions.This washes away heavy dirt and allows the

detergent to soak as you work toward the top.

3. Do not wash at a 90oangle to work (straight at it).

This will allow water to splash back at you and

reduces your cleaning power. Wash at a 30oto 60o

angle to the work.This will allow the water to splash

away from you and the water will wash the dirt away

faster and easier.

4. Use the full width of the spray pattern to wash in

a wide path. Overlap spray paths for complete

coverage.Wash from side to side, using slow, steady

motions.

5. The nozzle should be 12" to 24" from work, closer for

tough areas. Be careful on painted or delicate sur-

faces, the pressure may damage surface if nozzle is

too close.

6. Smallpartsshouldbewashedin a basketsothe pres-

sure does not push them away. Larger, lightweight

parts should be clamped down so the pressure does

not push them away.

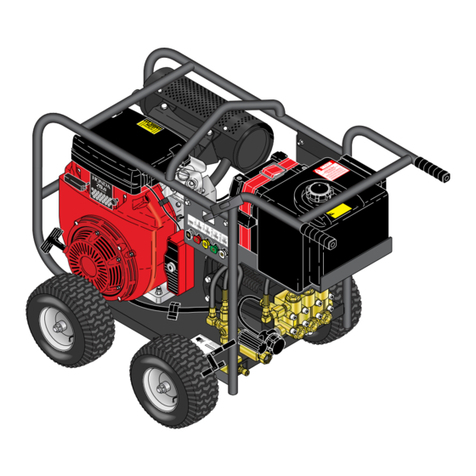

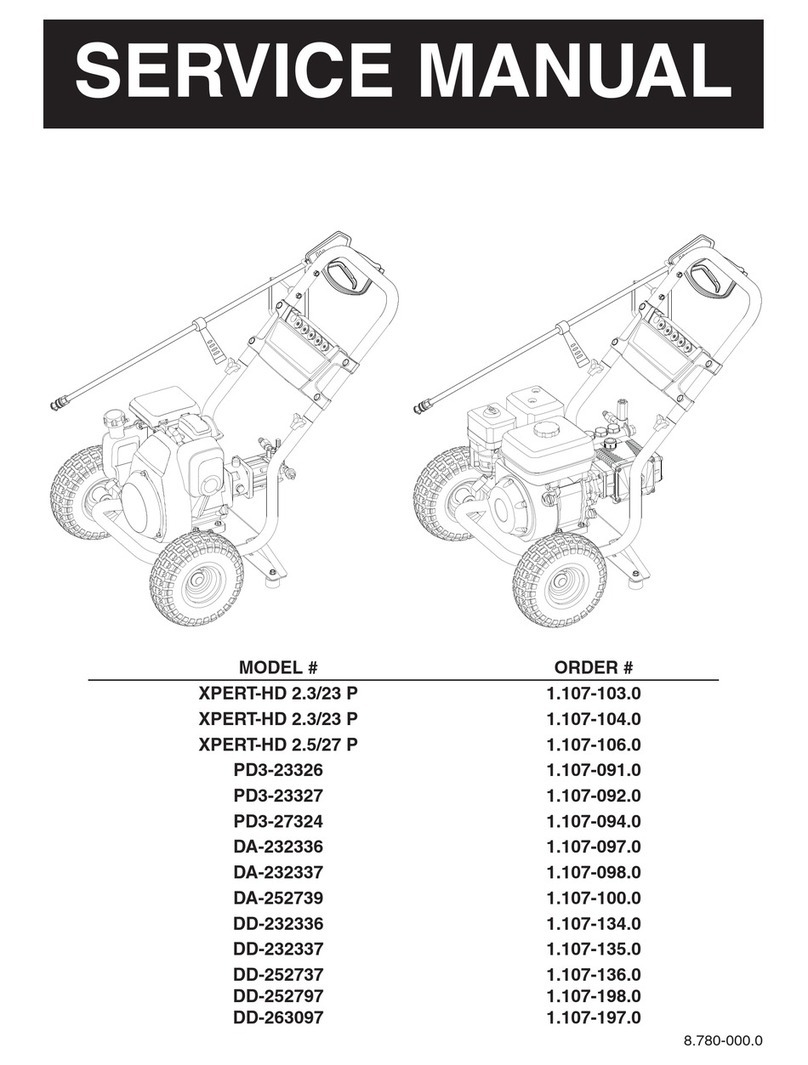

7. Close the detergent control handle on the dual lance

wand to permit high pressure rinse, refer to Figure 8.

Rinse from top to bottom to prevent detergent from

dripping onto rinsed area.

To Stop

1. Ifdetergentswereused,drawclearwaterthroughthe

detergent inlet line to purge detergent. Failure to do

so may clog detergent injector valve.

2. If burner was used, turn OFF burner switch and

allow pump to run cold water through coil for several

minutes.

3. Move throttle lever to idle position.

4 Turn engine ON/OFF switch to the OFF position.

5. Close fuel shut-off valve.

6. Turn water supply OFF.

7. Squeeze trigger of trigger gun to relieve system

pressure.

Figure 8 - Dual LanceWand Operation

refer to Figure 8. The output pressure is auto-

matically reduced for detergent application. Allow

detergent to reach end of wand before proceeding to

step 2.

DUAL LANCE WAND

OPEN CLOSE

DETERGENT CONTROL HANDLE