Shar

k

®

J

etters

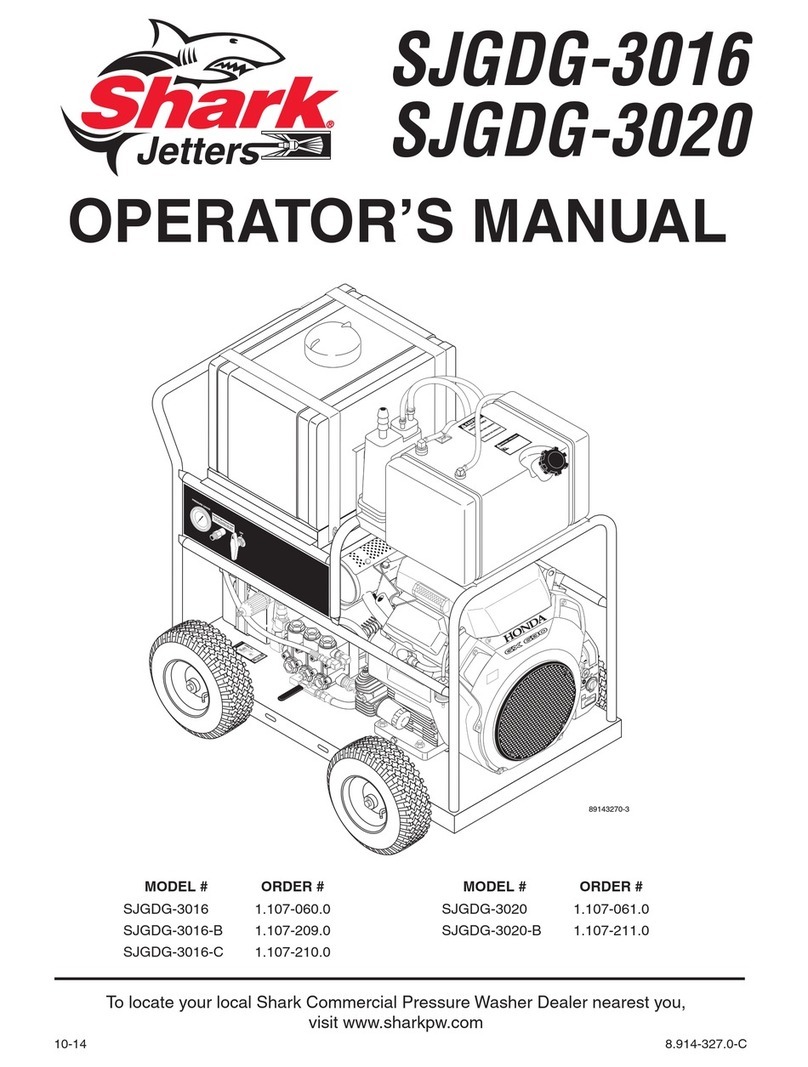

OPERATOR’S MANUAL 5

SJDDG-3011 • 8.914-324.0 • REV. 7/12

8. Never make adjustments on machine while it is in

operation.

9. Do not operate valve in the off position for extensive

periods of time as this may cause damage to the

pump.

10. The best insurance against an accident is precaution

and knowledge of the machine.

11. Shark will not be liable for any changes made to

our standard machines, or any components not

purchased from Shark.

12. Read engine safety instructions provided.

WARNING: Keep water spray

away from electric wiring or fatal

electric shock may result.

13. Never run pump dry.

14. Do not allow children to operate

the Shark®Jetter at any time.

15. Inlet water supply must be cold

and clean fresh water.

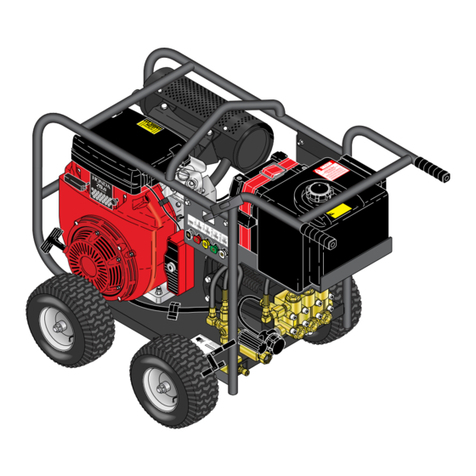

ASSEMBLY

Upon arrival, inspect the shipping crate for damages.

Uncrate and examine all parts. Note any damage to ma-

chine or components for claims against freight carrier.

The tires on the jets may be partially deflated for packing

and shipment. Reinflate tires to the pressure specified

on the side of the tire before using the machine.

Jets have antifreeze in the pump to protect it from freez-

ing conditions during shipment and storage. If machine

will be stored and operated in a cold climate, follow

Freeze Protection instructions on page 11.

PRE-OPERATION CHECK

Pump oil (SAE 30W non-detergent oil, General)

Coldcleanfreshwatersupply(6gpm•3/4"

(15.875mm)•20psi)

Hose, nozzle

Fuel (unleaded 86 or higher octane)

Engine oil (SAE 10W40)

SET-UP PROCEDURES

These machines are meant to be used at or near the

working area and under operator supervision. If machine

must be located out of sight of the operator, special

controls may be required for proper machine operation

and operator safety.

Locate the equipment on a solid level area with slopes

for drainage. Avoid areas where water can be sprayed

at machine.

Before using the jet, make sure there are no impurities

in the incoming water supply. Turn the water source on

for at least 15 seconds, to remove any possible debris in

the water before connecting hose to water inlet swivel.

The inlet screen located inside the filter should be

cleaned before each use. To clean the inlet screen,

unscrew cap beneath the filter, remove the screen and

rinse thoroughly with water. Then replace screen.

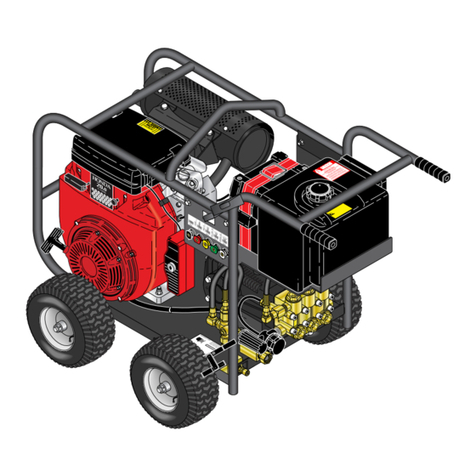

Connect one end of a garden hose (not included) to

the water faucet — water supply not to exceed 100 psi

(6.9 bar) and the other end to the water inlet of the jet

machine. (See component identification drawings on next

pages.)Useheavyduty3/4"hoseofnomorethan50ft.

(15m) in length. If run without an adequate water sup-

ply, the pump will cavitate. Cavitation causes the pump

to vibrate, causing damage to the pump. Note: Lack of

water supply can lead to seal damage, causing a loss of

pressure and will void the warranty to the pump.

Maximum temperature from the water source should

not exceed 140°F (60°C). Using water hotter than 140°F

(60°C) can cause damage to the pump and void the

warranty. If jet is being used to clear ice blockages, see

instructions on page 10.

Remove oil plug on top of pump and replace with dipstick

supplied. Fill engine with oil. Refer to engine manual for

quantity.

Hose Selection Guide

Select the proper hose diameter for the line to be

cleaned. When using new hose, run water through it to

clean it out before attaching the nozzle.

Hose Size (ID)* Pipe Size Typical Applications

3/8" or 5/16" 4"to8" Floordrains,septiclines

(9.925mm (102mm to 203mm) long runs

or 7.938mm)

1/4" 2"to4" Kitchen sinks, laundry

(6.35mm) (51mm to 102mm) drains, clean outs

1/8" 1-1/2"to2" Smalllines,bathroom

(3.175mm) (38mm to 51mm) sinks, tight bends

* Inside Diameter

When selecting hose size, consider that pressure is lost

as the water travels down the length of the hose. As the

length increases, the pressure decreases. In addition,

the smaller the diameter of the hose, the greater the

loss of pressure per foot will be. As an example, at 2

GPM (.13L/sec) a1/4"(6.350mm) hose will lose 180 lbs.

(12.4 bar) of pressure over 100 ft. (30.5m) of hose, yet

a3/8"(9.925mm) hose will only lose 25 lbs. (1.7 bar) of

pressure over the same length and at the same flow

rate.At4GPM,a3/8"hosewilllose90lbs.(6.2 bar) of

pressure over a 100 ft. (30.5m) length.The gauge reflects

pressure from the pump only, not pressure at the end

of the hose. It is important to select the largest possible

KEEP WATER SPRAY

AWAY FROM ELEC-

TRICAL WIRING.

WARNING