Sharp MX-M266N User manual

Other Sharp All In One Printer manuals

Sharp

Sharp MX-B557F User manual

Sharp

Sharp MX-2010U User manual

Sharp

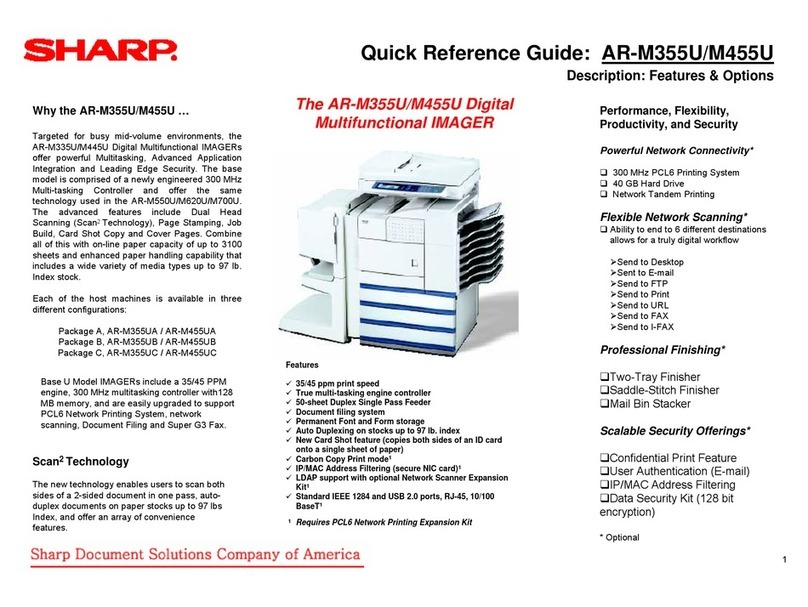

Sharp AR-M355U User manual

Sharp

Sharp AR-168N User manual

Sharp

Sharp AL-2021 Guide

Sharp

Sharp MX-M283 User manual

Sharp

Sharp AR-BC260 User manual

Sharp

Sharp Laser Printer User manual

Sharp

Sharp MX 5500N - Color Laser - Copier User manual

Sharp

Sharp FO-2080 Setup guide

Sharp

Sharp MX-M264U N User manual

Sharp

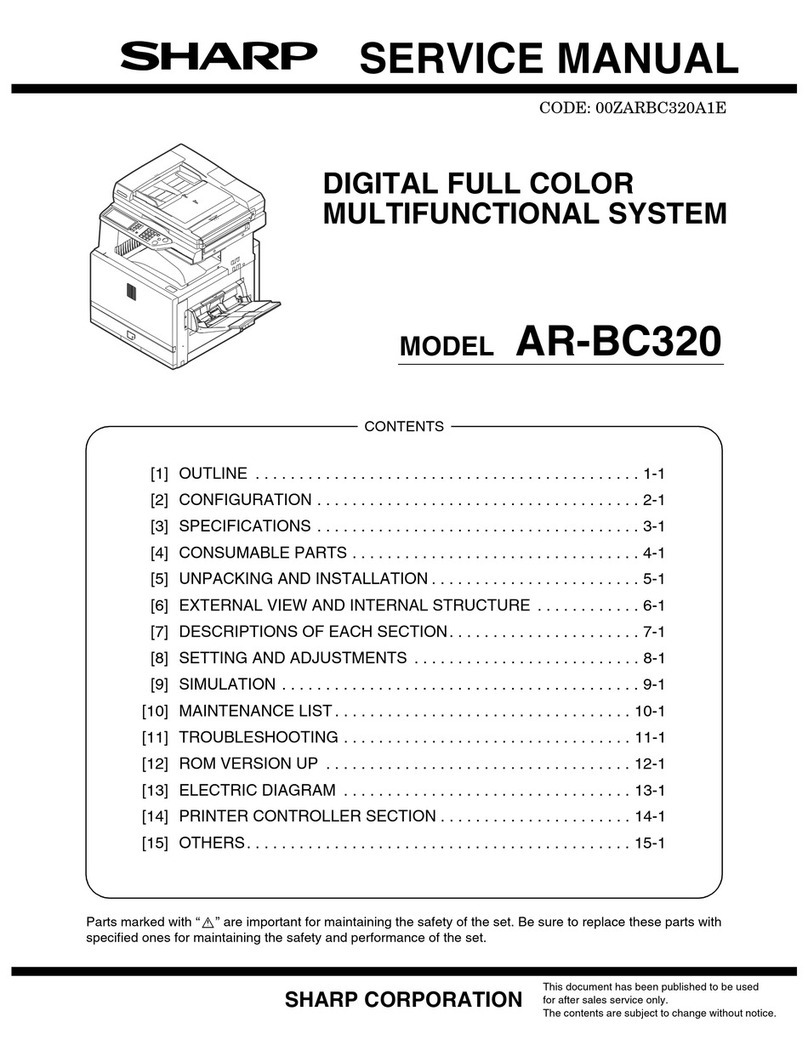

Sharp AR-BC320 User manual

Sharp

Sharp MX-M316NV User manual

Sharp

Sharp MX-B402 User manual

Sharp

Sharp AR-5623N User manual

Sharp

Sharp MX-B381 User manual

Sharp

Sharp MX-1810U User manual

Sharp

Sharp ARM207E - B/W Laser - All-in-One User manual

Sharp

Sharp MX-2610N User manual

Sharp

Sharp MX-5112 User manual