This product is a class 1 laser product that complies with 21CFR 1040.10 and 1040.11 of the CDRH standard and IEC825. This means that this

machine does not produce hazardous laser radiation. The use of controls, adjustments or performance of procedures other than those specified

herein may result in hazardous radiation exposure.

This laser radiation is not a danger to the skin, but when an exact focusing of the laser beam is achieved on the eye’s retina, there is the danger of spot

damage to the retina.

The following cautions must be observed to avoid exposure of the laser beam to your eyes at the time of servicing.

1) When a problem in the laser optical unit has occurred, the whole optical unit must be exchanged as a unit, not as individual parts.

2) Do not look into the machine with the main switch turned on after removing the developer unit, toner cartridge, and drum cartridge.

3) Do not look into the laser beam exposure slit of the laser optical unit with the connector connected when removing and installing the optical

system.

4) The middle frame contains the safety interlock switch.

Do not defeat the safety interlock by inserting wedges or other items into the switch slot.

CAUTION

Warning!

This product is a class A product.

If it is operated in households, offices or similar surroundings, it can produce radio interferences at other

appliances, so that the user has to take adequate countermeasures.

CLASS 1 LASER PRODUCT

LASER KLASSE 1

LUOKAN 1 LASERLAITE

KLASS 1 LASERAPPARAT

VAROITUS!

LAITTEEN KÄYTTÄMINEN MUULLA KUIN TÄSSÄ

KÄYTTÖOHJEESSA MAINITULLA TAVALLA SAATTAA

ALTISTAA KÄYTTÄJÄN TURVALLISUUSLUOKAN 1

YLITTÄVÄLLE NÄKYMÄTTÖMÄLLE

LASERSÄTEILYLLE.

VARNING

OM APPARATEN ANVÄNDS PÅ ANNAT SÄTT ÄN I

DENNA BRUKSANVISNING SPECIFICERATS, KAN

ANVÄNDAREN UTSÄTTAS FÖR OSYNLIG

LASERSTRÅLNING, SOM ÖVERSKRIDER GRÄNSEN

FÖR LASERKLASS 1.

CAUTION

INVISIBLE LASER RADIATION,

WHEN OPEN AND INTERLOCKS DEFEATED. AVOID

EXPOSURE TO BEAM.

VORSICHT

UNSICHTBARE LASERSTRAHLUNG,

WENN ABDECKUNG GEÖFFNET UND

SICHERHEITSVERRIEGELUNG ÜBERBRÜCKT. NICHT

DEM STRAHL AUSSETZEN.

VARO !

AVATTAESSA JA SUOJALUKITUS OHITETTAESSA OLET

ALTTIINA NÄKYMÄTTÖMÄLLE LASERSÄTEILYLLE ÄLÄ

KATSO SÄTEESEEN.

ADVARSEL

USYNLIG LASERSTRÅLNING VED ÅBNING, NÅR

SIKKERHEDSBRYDERE ER UDE AF

FUNKTION. UNDGÅ UDSAETTELSE FOR

STRÅLNING.

VARNING !

OSYNLIG LASERSTRÅLNING NÄR DENNA DEL ÄR

ÖPPNAD OCH SPÄRREN ÄR URKOPPLAD. BETRAKTA EJ

STRÅLEN. – STRÅLEN ÄR FARLIG.

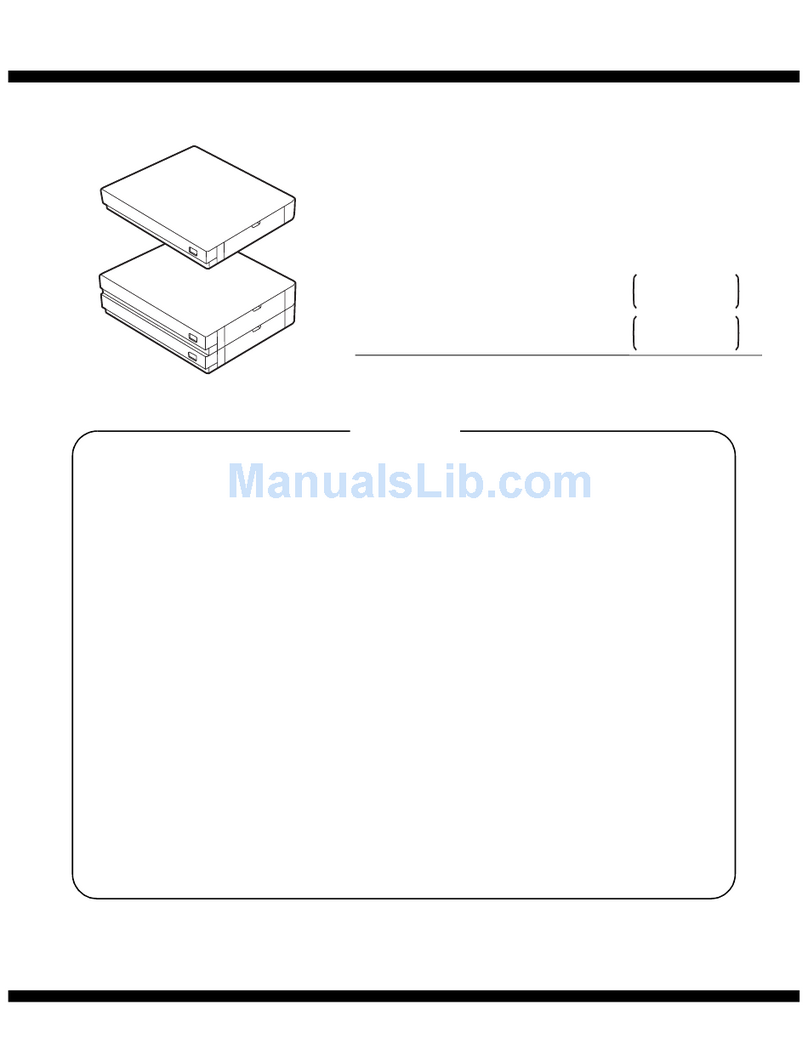

CLASS 1

LASER PRODUCT

LASER KLASSE 1

Disconnect the AC cord before servicing the unit.

LASER WAVE – LENGTH : 795 ± 15 mm

Pulse times : 0.481 ms/6 mm

Out put power : 5 mW

CAUTION

VORSICHT

ADVARSEL

ADVERSEL

VARNING

VARO!

INVISIBLE LASER RADIATION WHEN OPEN AND INTERLOCKS DEFEATED.

AVOID EXPOSURE TO BEAM.

UNSICHTBARELASERSTRAHLUNG, WENNABDECKUNG GEÖFFNETUND

SICHERHEITSVERRIEGELUNGÜBERBRÜCKT. NICHTDEM STRAHLAUSSETZEN.

USYNLIG LASERSTRÅLNING VED ÅBNING, NÅR SIKKERHEDSBRYDERE ER

UDE AF FUNKTION. UNDGÅ UDSAETTELSE FOR STRÅLNING.

USYNLIG LASERSTRÅLING NÅR DEKSEL ÅPNES OG SIKKERHEDSLÅS BRYTES.

UNNGÅ EKSPONERING FOR STRÅLEN.

OSYNLIG LASERSTRÅLNING NÄR DENNA DEL ÄR ÖPPNAD OCH SPÄRREN ÄR

URKOPPLAD. BETRAKTA EJ STRÅLEN. – STRÅLEN ÄR FARLIG.

AVATTAESSA JA SUOJALUKITUS OHITETTAESSA OLET ALTTIINA NÄKYMÄTTÖMÄLLE

LASERSÄTEILYLLE ÄLÄ KATSO SÄTEESEEN.

Laserstrahl