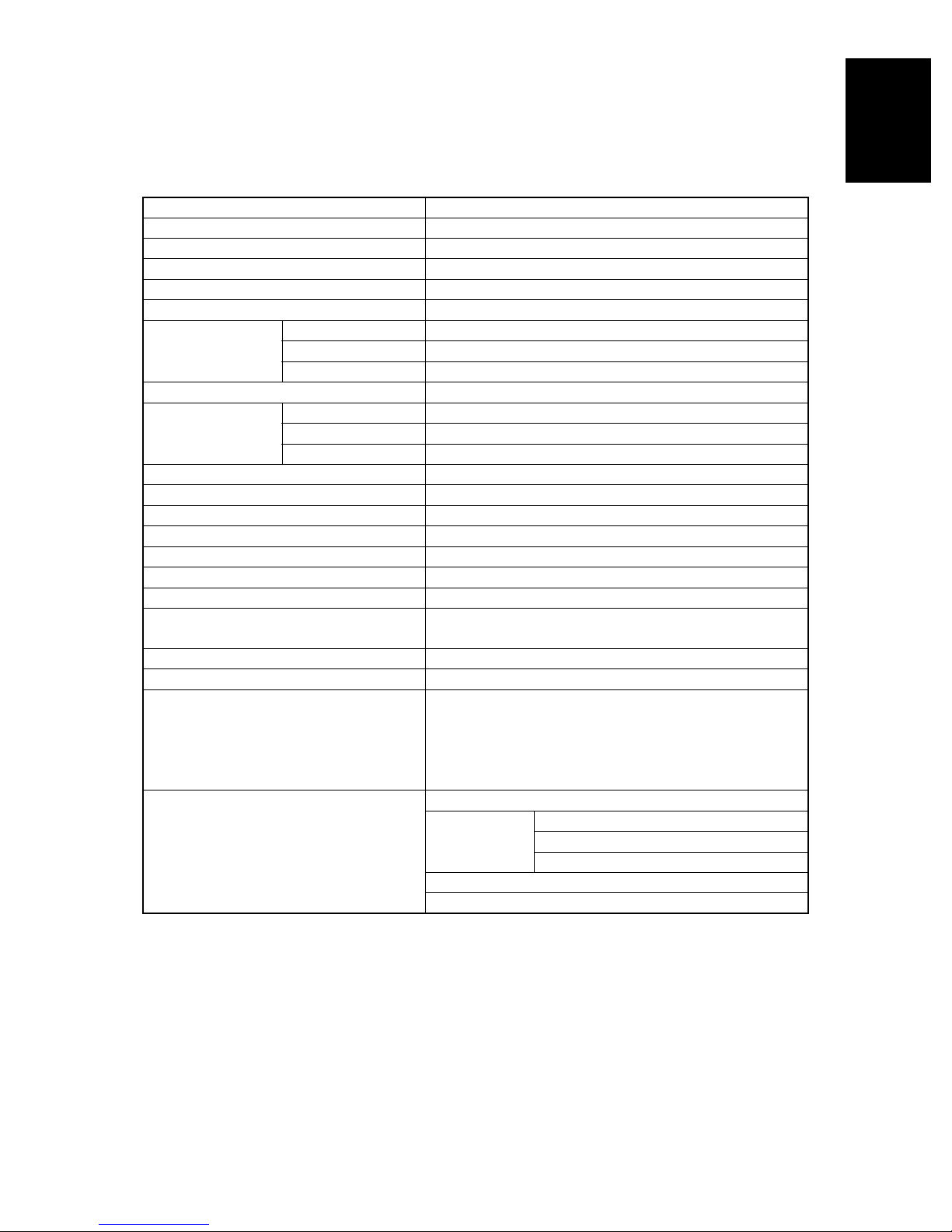

II AR-651/810 CONTENTS

3. 9. 2. Setting of fuser roller temperature ............................................................................. 3-36

3. 9. 3. Adjustment of fuser inlet guide ................................................................................. 3-36

3. 9. 4. High-fusing mode ...................................................................................................... 3-37

3. 10 Adjustment of Exit/Reversal Unit ...........................................................................................3-38

3. 10. 1. Adjustment of sideways deviation at reverse discharging ......................................... 3-38

3. 11. Adjustmet of Reversing Automatic Document Feeder ............................................................ 3-39

3. 11. 1. Installing of the RADF unit ........................................................................................ 3-39

3. 11. 2. Skew adjustment ...................................................................................................... 3-40

3. 11. 3. Adjustment of solenoid ............................................................................................. 3-41

3. 11. 4. Adjustment of RADF open/close switch .................................................................... 3-42

3. 11. 5. Adjustment of RADF height ...................................................................................... 3-42

4. PREVENTIVE MAINTENANCE (PM) ......................................................................................... 4-1

4. 1. PM Support Mode .................................................................................................................. 4-1

4. 1. 1. General description ................................................................................................... 4-1

4. 1. 2. Operational flow and operational screen .................................................................... 4-1

4. 2. General Descriptions for PM procedure .................................................................................. 4-5

4. 3. Operational Items in Overhauling ........................................................................................... 4-5

4. 4. Preventive Maintenance Checklist ......................................................................................... 4-5

4. 5. PM Kit ................................................................................................................................... 4-19

4. 6. Jig List ................................................................................................................................... 4-20

4. 7. Precautions for Storing and Handling Supplies ....................................................................... 4-21

4. 7. 1. Precautions for storing supplies ................................................................................ 4-21

4. 7. 2. Checking and cleaning of OPC drum ........................................................................ 4-21

4. 7. 3. Checking and cleaning of drum cleaning blade and transfer belt cleaning blade ............. 4-22

4. 7. 4. Handling of drum cleaning brush and transfer belt cleaning brush ............................. 4-23

4. 7. 5. Handling of transfer belt ............................................................................................ 4-23

4. 7. 6. Checking and cleaning of fuser roller and pressure roller........................................... 4-23

4. 7. 7. Checking and replacing of cleaning web and cleaning rollers (felt, metal) .................. 4-24

4. 8. Replacement of maintenance parts ........................................................................................ 4-25

4. 8. 1. DRUM UNIT .............................................................................................................. 4-25

4. 8. 2. DEVELOPER UNIT .................................................................................................. 4-30

4. 8. 3. FUSER UNIT ............................................................................................................ 4-34

5. TROUBLESHOOTING ................................................................................................................ 5-1

5.1 Diagnosis and Prescription for Each Error Code and Phenomenum ....................................... 5-1

5.1.1 Paper transport jam .................................................................................................. 5-1

5.1.2 Paper misfeeding ...................................................................................................... 5-14

5.1.3 Cover open jam ........................................................................................................ 5-21

5.1.4 Jams at eit/reverse section and other transport jams ............................................... 5-24

5.1.5 Original jam in RADF ................................................................................................ 5-33

5.1.6 Paper jam in finisher ................................................................................................. 5-37