SHARP

SERVICE

MANUAL

ATSM881115RCS

GF-777H

GF-777E

In

the

interests

of

user-safety

the

set

should

be

restored

to

its

original

condition

and

only

parts

identical

to

those

specified

be

used.

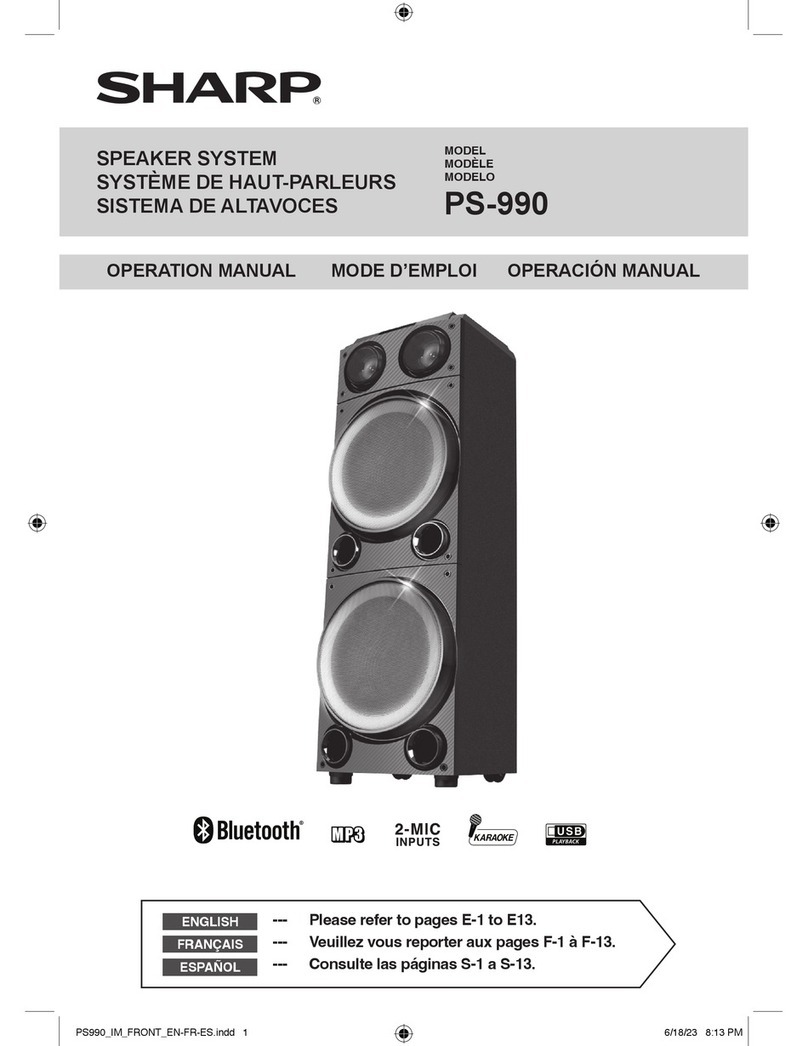

PHOTO:

GF-777H

FEATURES

Multi-Amp

3-Way

6-Speaker

System

Massive

90W

PMPO

Dynamic

Super

Woofer

Sound

16cm

(6%"")

Woofer

with

Rigid

Speaker

Ring

Horn

Tweeter

for

Clear,

Crisp

Highs

Two

Decks

Side

by

Side,

for

Versatile

Record/Playback

Soft-Touch

Cassette

Controls

Brilliant

Metal

Tape

Sound

APLD

(Auto

Program

Locate

Device)

Sharp Super

Noise

Reduction

System

INDEX

TO

CONTENTS

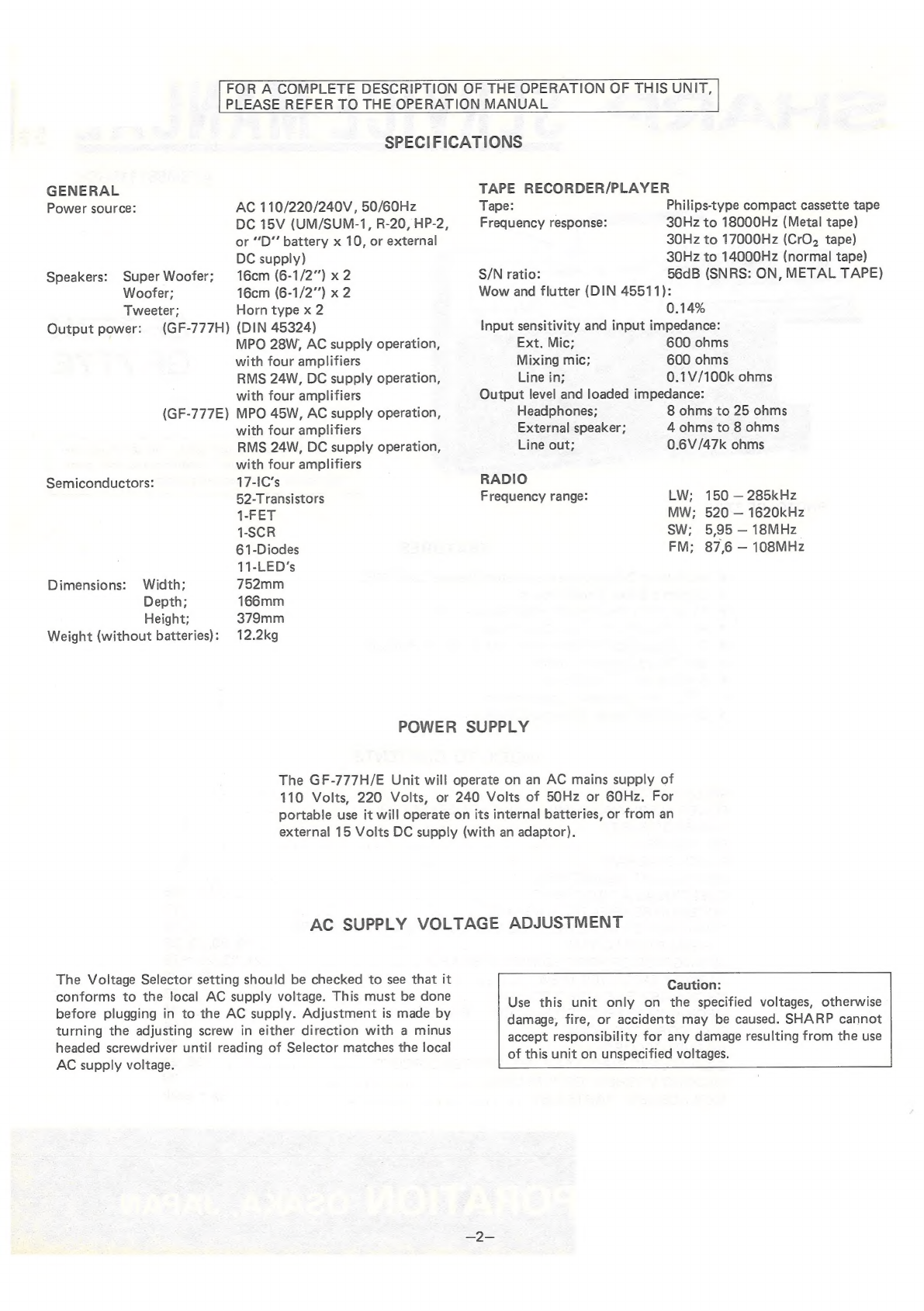

SPECIFIGATIONS,

qos

st

oe

cypress

EB

epee

coals

«ARR

6

gstet

R

amepegs

Cee

eee

see

eee

2

POWER

SUPPLY/AG-SUPPLY.

VOLTAGE.SELECTOR,

wo:.:0.00

ctecesegure

cence

w

canes

2

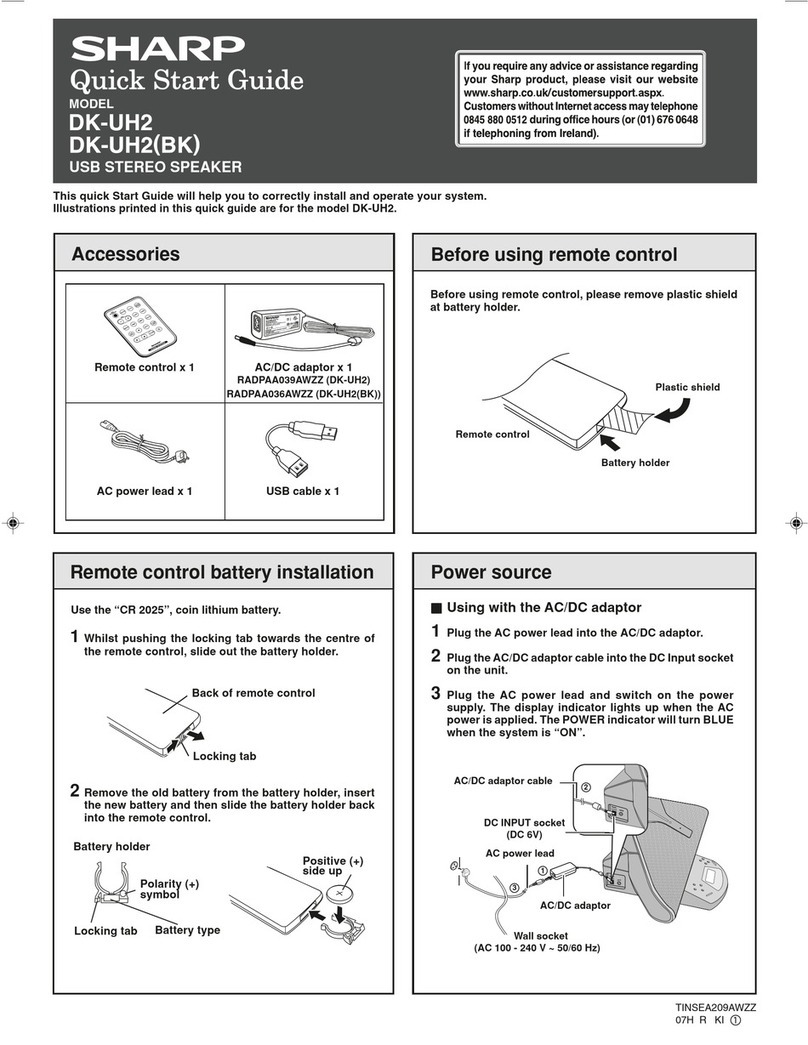

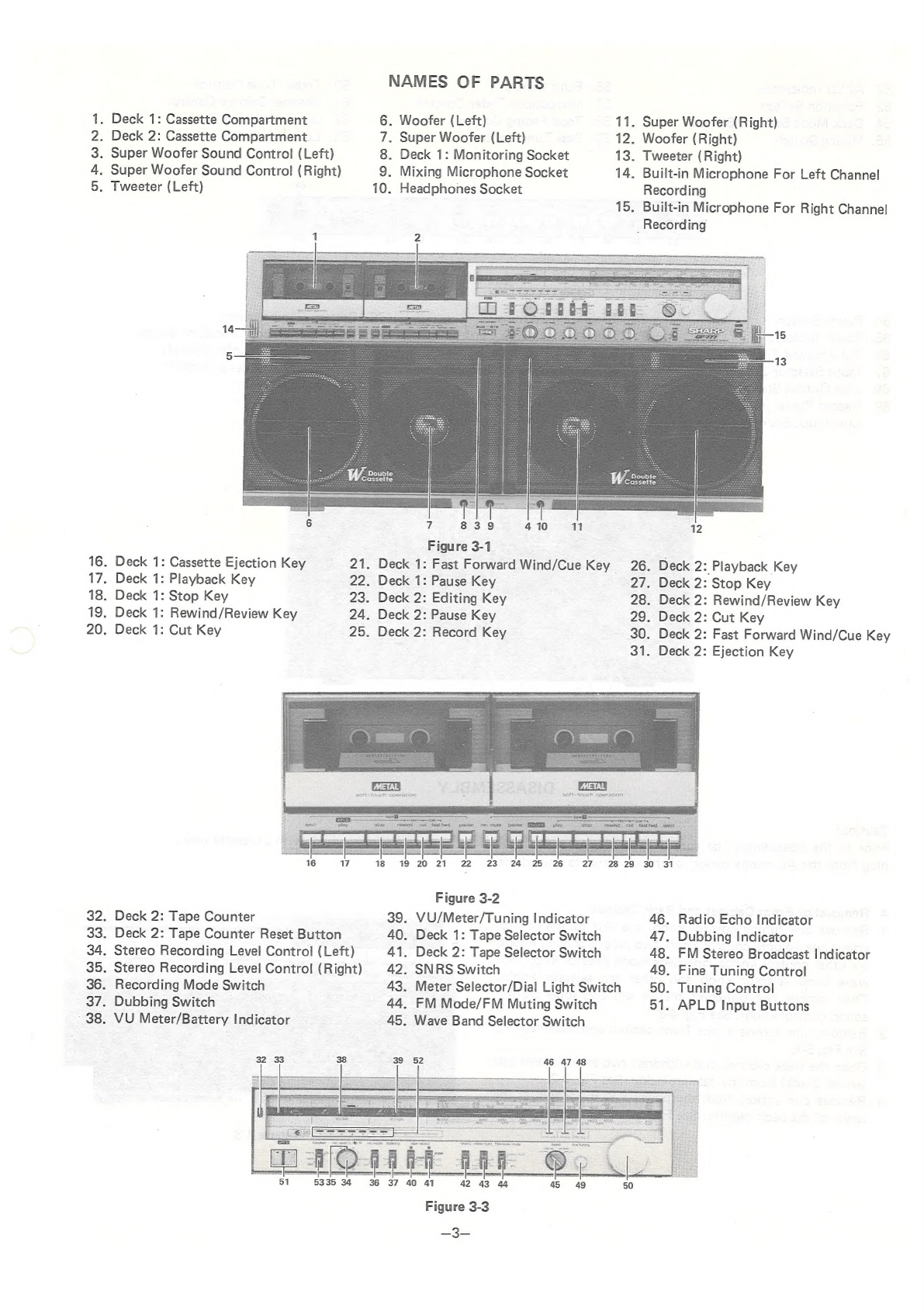

NAMES

OF

PARTS

a

isdseercveSpeiocoyeptasicss)

oy

tyecaj

can

Rhee

dceelshces

Se

Spneysbaqnpe

wien

decd

Spader

3,4

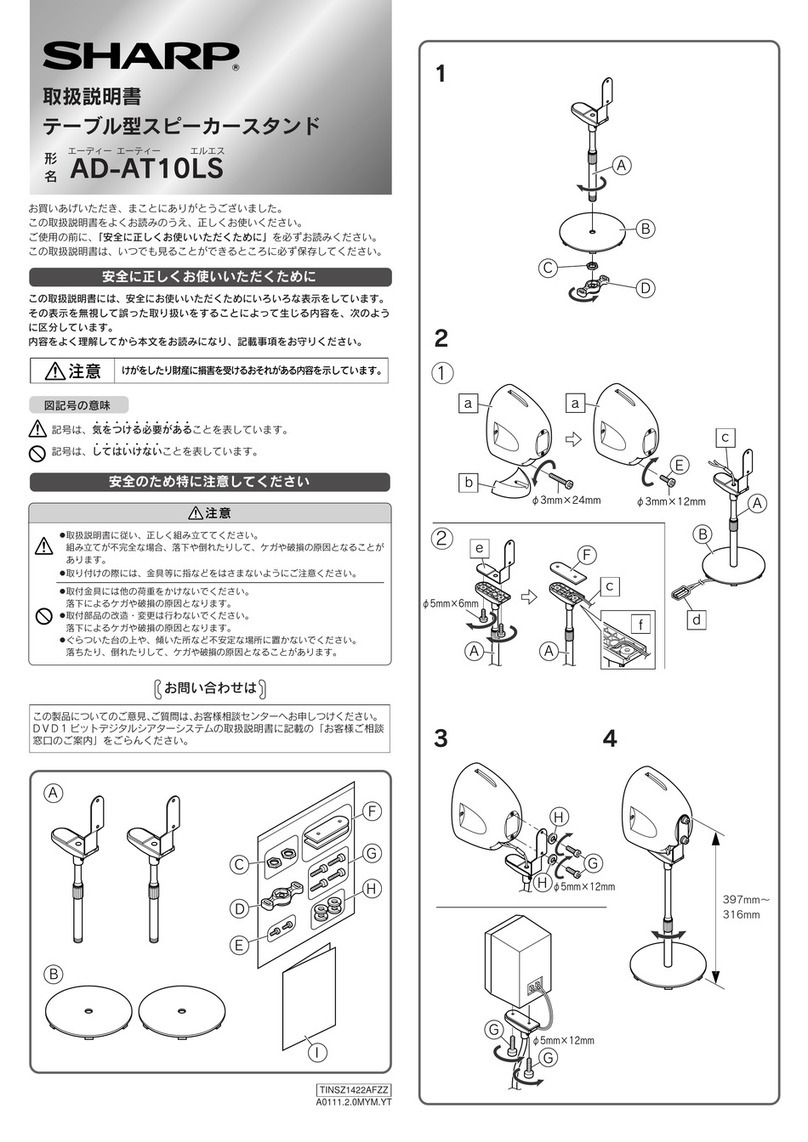

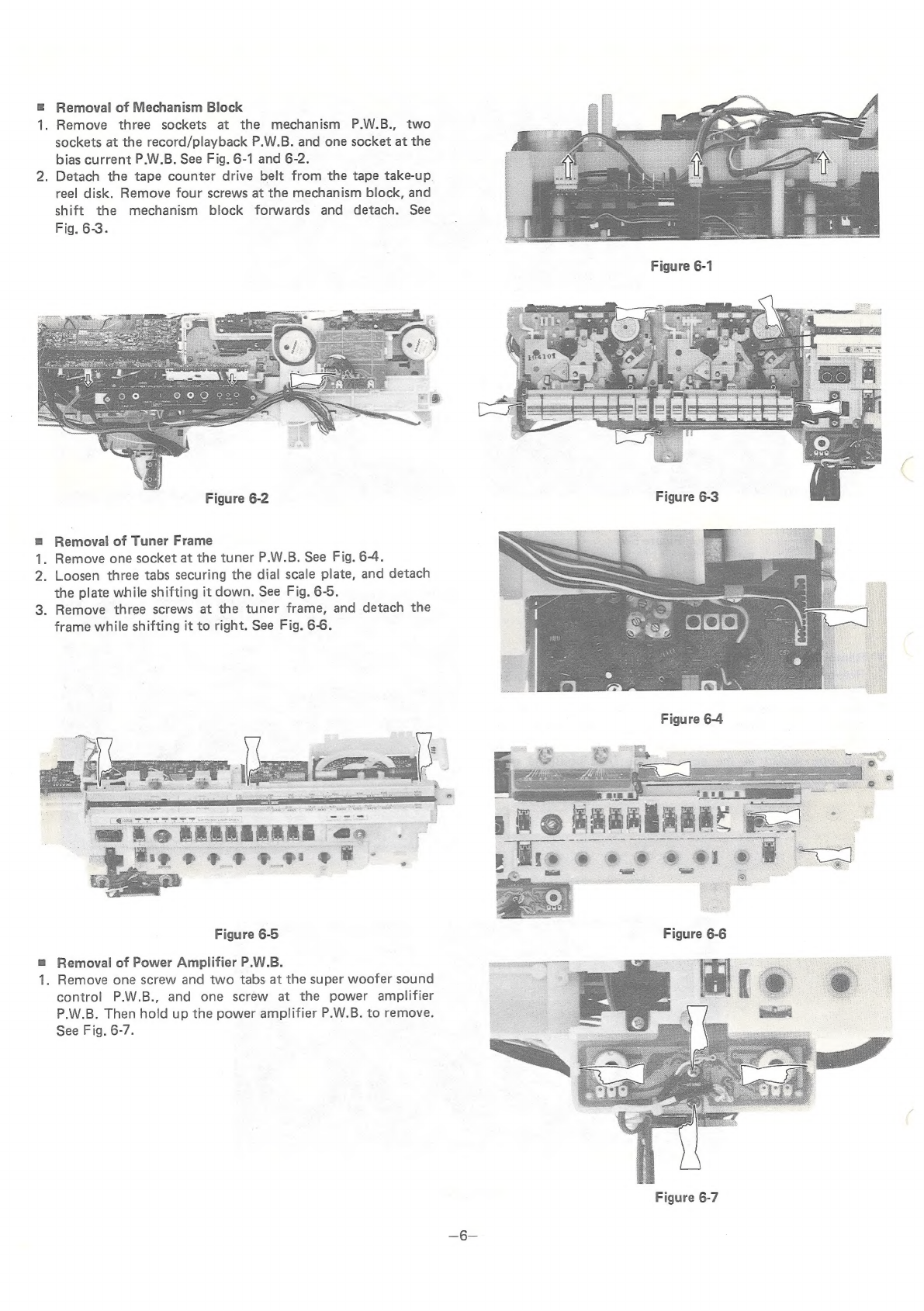

DISASSEMBLY

........

1G

Dien

Ot

Bmaeta

Kae

Cm

oeghs

se

We

Te

Dee

elame

ee

4~7

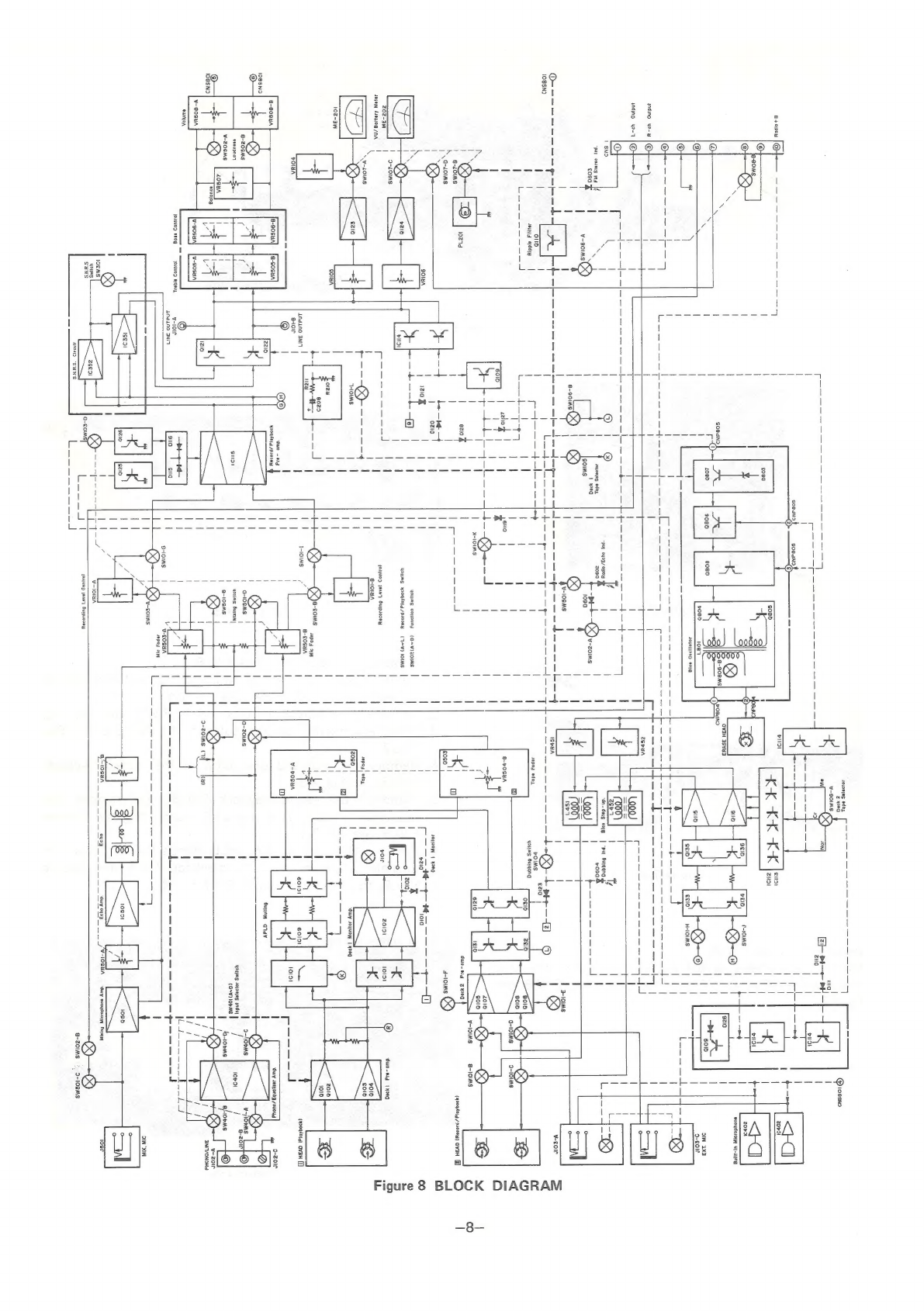

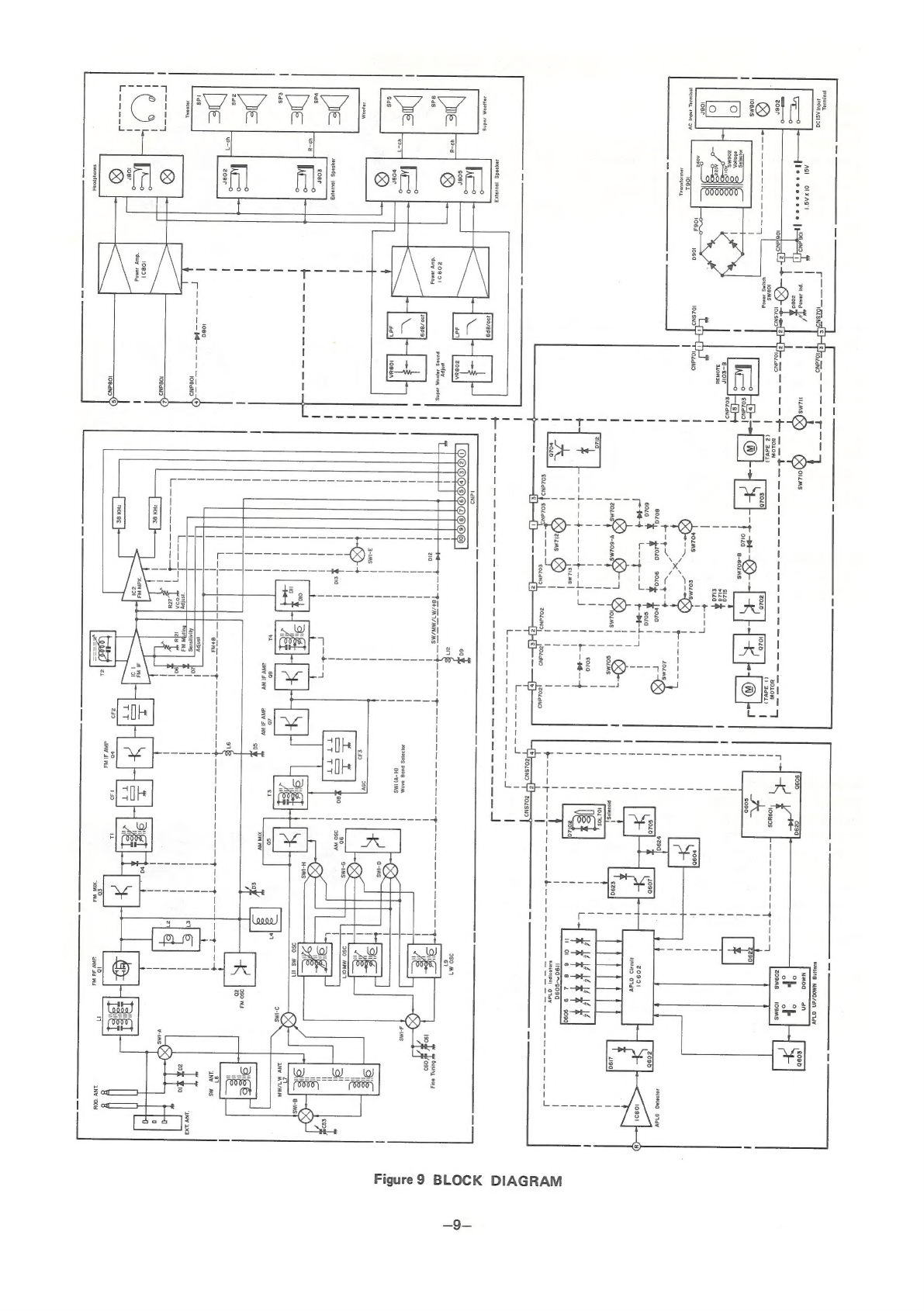

BLOCK.

DIAGRAM.

a

c.cccseccsberamesremeannn

cewenceuot

ee

weuaseoaguines

8,9

MECHANICAL.

ADJUSTMENT

sacncacce

cia

caae

cee

cane

e

cn

deen

ene

nee

ns

10

ELECTRICAL

ADJUSTMENT

oc

cccacccsedandaden

ines

wee

eneeeedaae

a

11

~16

NOTES

ON

SCHEMATIC:

DIAGRAM,

2.

ooo:

20s

ciuiaeeanae

cameee

maamerdmanc

aware

17

SERVICING

OF

LEG-LESS

TYPE

RESISTORS

AND

CAPACITORS

.........

17,18

SCHEMATIC

DIAGRAM)

«.c5sc0ica.eeswevis

vieeee

ee

Getions

ees

19,

20,

23,

24

WIRING

SIDE

OF

PRINTED

WIRING

BOARD

..................

21,22,25

~29

CABINET

EXPLODED

VIEW

ca.

.000

0

0tihate

teener.

Sasserln.

me

Laaosio

cael

30

~

32

MECHANISM

EXPLODED:

TOP

VIEW

...

..e¢cin

oc.

teu

aide

wagation

«.aeum

Dee

ds

33

MECHANISM

EXPLODED

BUTTOM

VIEW

*.

aiiceccs

deaiwen

Oo

setae

se

aarties

34

DIAL

CORDS

TRINGING

ic

ajsccise

tes

a:

0

se

a:

PROMS

cin,

SEES

AOR,

IE

ses

Ole

CNS

35

AG

SUPPLY:

CORID)

aco:

cctnsy-r

steps:

appeal

oa wo

OOS:

AAS

PENNS

wei".

te

oaibecs

lta

35

EQUIVALENT

CIRCUIT

OF

INTEGRATED

CIRCUIT

....................

36,

37

PACKING

METHOD

(GE-777E

Only)

ose:

ccniseewennees

snceeeeobe

wd

ee:

oak

38

REPLACEMENT

PARTS:

LIST

weiss

nace

sescyey

eect

sa

sea

oaunate

emi

erage

os

win

39

~

Back

SHARP

CORPORATION

Osaka,

JAPAN

GF-777H