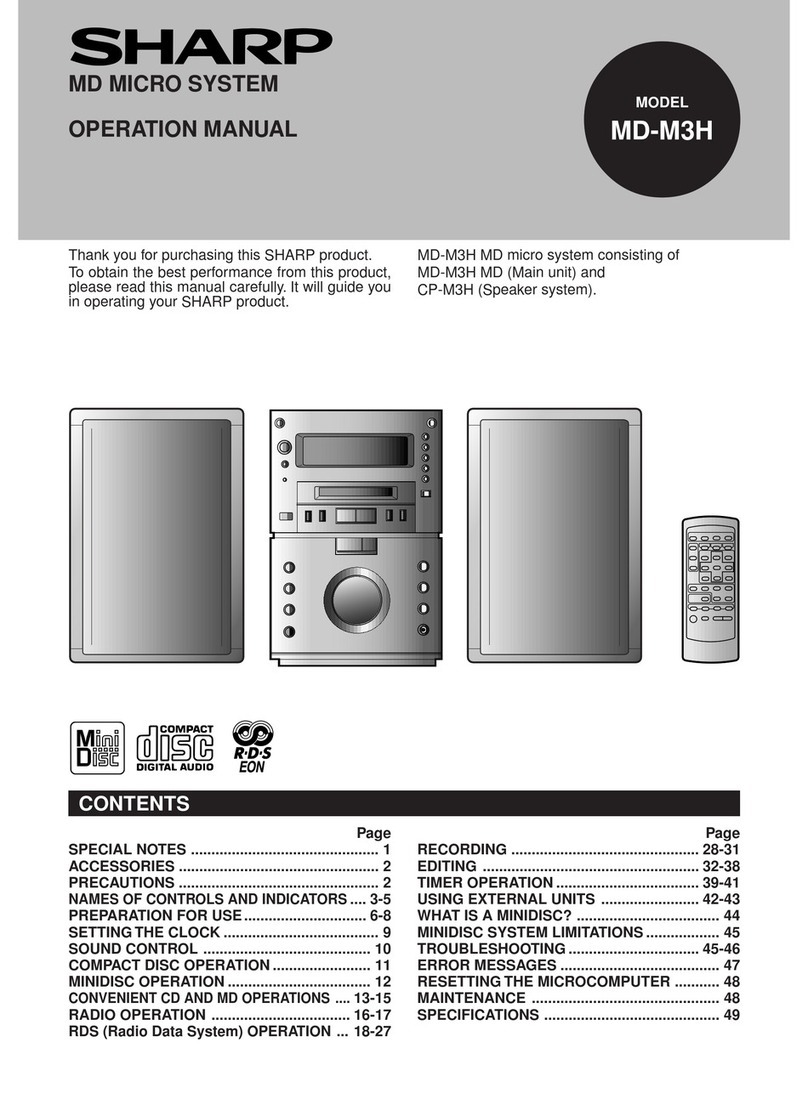

REMOVING

AND

REINSTALLING

THE MAIN PARTS

TAPE MECHANISM SECTION

Perform steps

1,

2, 3. 4, 5, 6, and 7 of the disassembly method

to remove the tape mechanism.

How to remove the main,

FF/rewind

belt (See

Fig. 13-1.)

1. Remove the

Mann

belt, (Al) x

1

PC.,

at the tape 2 side from

the motor pulley.

2.

Remove the main belt, (A2) x1 pc.,at the tape 1 side from the

motor pulley.

3. Remove the FF/Rewlnd belt, (A3) x

1

PC.,

from the tlywheel

of tape 2.

4.

Put on the belts in the reverse order of removal.

Note:

1.

When putiing on the belt, ascertain that the belt is not busted,

and clean

It.

How to remove the T2 motor (See Fig. 13-2.)

1.

Remove the screw,

(El)

x1

PC.,

and remove the motor fixture.

2. Remove the screws,

(82)

x2

PCS.,

and remove the motor.

How to remove the

Tl

motor (See Fig. 13-2.)

1.

Remove the screws, (83) x2 pcs.,and remove the motor

fc&re

2.

Remove the screws,

(84)

x3 pcs.,and remove the motor.

Note:

1.

When mounting the motor, pay attention to the motor bracket.

2. When the motor is removedShe belt comes off Put it on,

referrlng to the description of belt putting-on.

How to remove the flywheel of tape 1 side (See

Fig. 13-3.)

1.

Remove the drive belt.

2. Remove the washers,

(Cl),(C3)

and the stop wasper, (C2)

with a small precision screwdriver to extract the flywheel from

the chassis.

How to remove the flywheel of tape 2 side. (See

Fig. 1’3-2 and 13-3.)

1.

Remove the drive belt.

2.

Remove the screws, (83) x2

PCS.,

and remove the motor

fixture.

3.

Remove the stop washer, (C4) with a small precision screw-

driver to extract the flywheel from the chassis.

Note:

1.

When the stop washer

IS

deformed or damaged, replace it

with a new one.

Figure 13-l

Figure 13-2

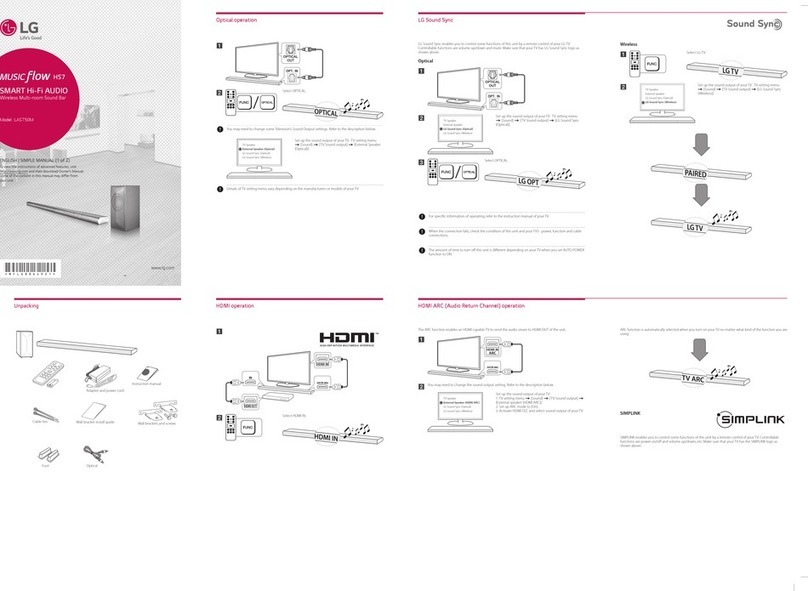

How to remove the pinch roller of tape 1 side

(See

Fig.l4-1.)

1. Remove the stop washer,

(Dl)

with a small precision

screwdriver, and remove the pinch roller.

How to remove the pinch roller of tape 2 side

(See Fig. 14-l.)

1. Carefully release the pinch roller hook in the

directIon

indicated by the arrow mark, and remove the pinch roller.

How to remove the playback head (See Fig.

14-2.)

1. Remove the screws, (El) x2

PCS.,

and remove the button

block.

2.

Remove the screws, (EZ),(E3), and remove the head.

How to remove the record/playback and

erase heads (See Fig. 14-2)

1. Remove the

screws,(E4).(E5),and

remove the

record/playback head.

2.

Removethescrews,

(E6)xZpcqandremovetheerase

head.

Be sure to apply screw lock after replacement of head and

azimuth adjustment.

Figure 14-1

Figure 14-2

Figure 13-3

-

13

-

14-