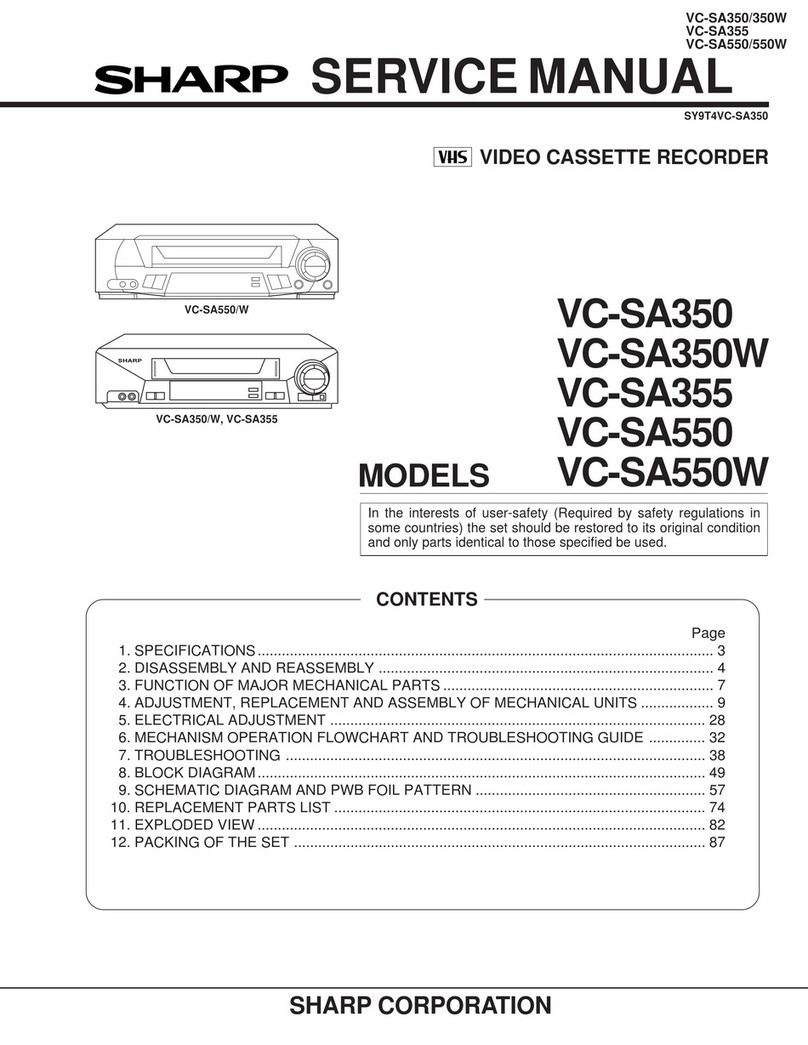

VC-90ET

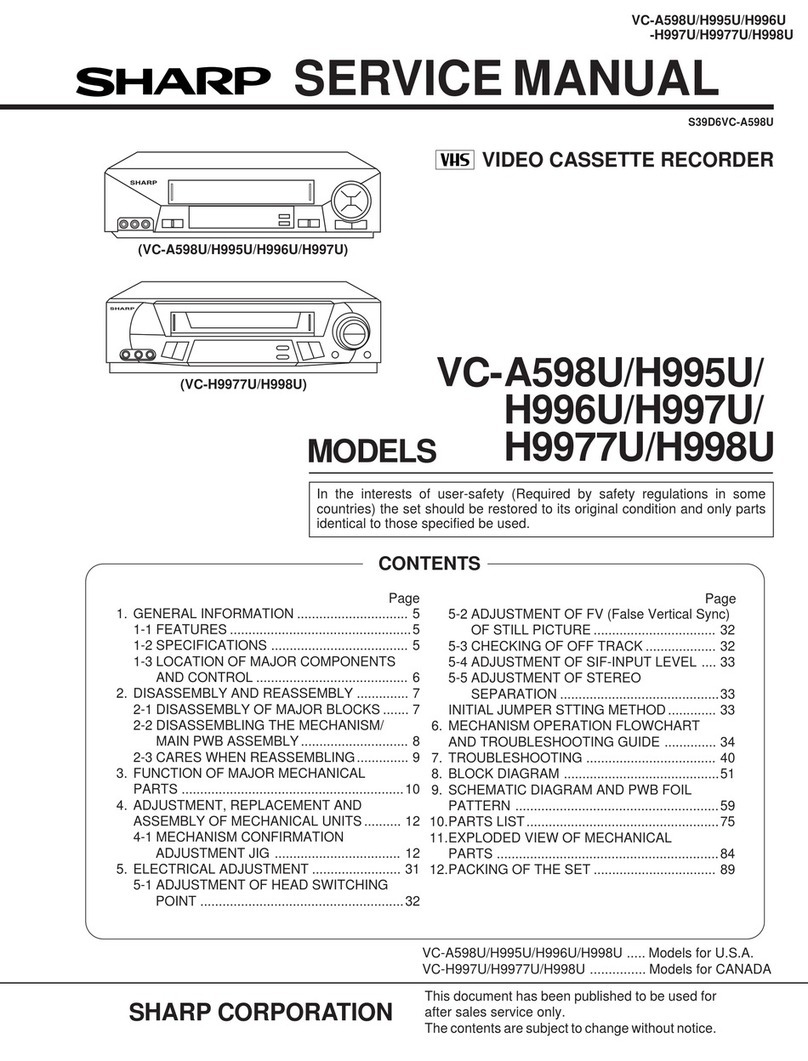

SHARP

SERVICE

MANUAL

VIDEO

CASSETTE

RECORDER

move.

VC-90ET

In

the

interests

of

user-safety

(Required

by

safety

regulations

in

some

countries)

the

set

should

be

restored

to

its

original

condition

and

only

parts

identical

to

those

specified

should

be

used.

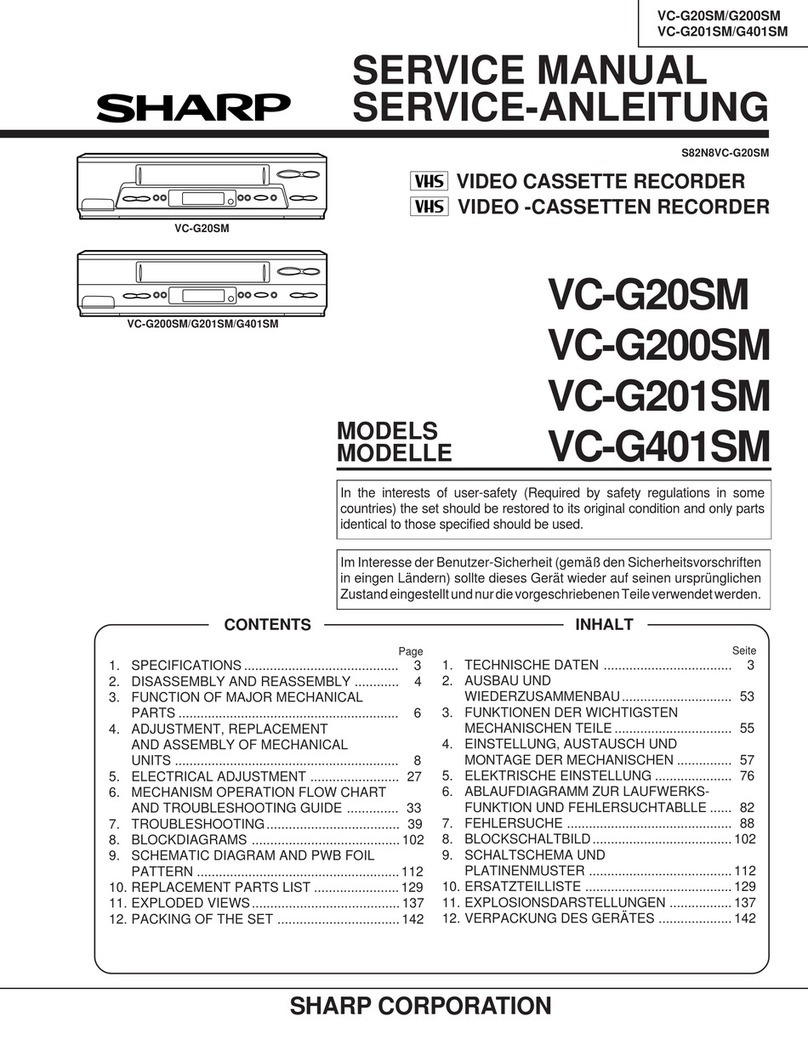

CONTENTS

SPECIFICATIONS.

........csccssecsecssecsseccenececssesensasnsssscneceeensaneasesssseanesacasonscsssussssaeeesanseeen

seers

DISASSEMBLY

AND

REASSEMBLY...........ccssesscsscsecsscrececeeneesneeseeserseeseserscsvenseeseneeesenenaes

FUNCTION

OF

MAJOR

MECHANICAL

ADJUSTMENT,

REPLACEMENT

AND

ASSEMBLY

OF

MECHANICAL

UNITS

.0.......ccssescsssessssecscssencensseresenneceessnesessoeecscesoneseesnssesenseaseensnsen

ses

ADJUSTMENT

OF

ELECTRICAL

CIRCUITRY

........ecsccsscessetscesceseceessessessscsncneseseceeseeeersteesseseeeseseqaaseenecseesscersssenenocecensasenaerees

TROUBLESHOOTING

GUIDE

BLOCK

DIAGRAM

WAVE

FORMS

..........sccsccccecsereesssessesnseceeseeasensssennecenssnscenecesnsceeseosecensosessassesaaraeesssnenereenans

SCHEMATIC

DIAGRAMS

WIRING

SIDE

PWBS

...........ccecccsceressecsssseesscsecssecnsenesenaeseeceanenserssceasnsesersnecausansaaceesseenaee

REPLACEMENT

ELECTRICAL

PARTS

LIST

uu...

esccsecssscsessccncseercesecsersccceesssescsusesceecesaeereceesssssensaeecsseeresessseesagesnsrssessesasnne

EXPLODED

VIEWS.

......ccececcecsceesscccsssensssecesersssseesseesesnaaeaenersoneassssensnestocsretenssenersensneesssentes

PACKING

OF

THE

SET

PPPPTPSTITITTITirrrrrrrrrrrietee

rier

PPPTITTTISTTITITITTTT

TTT)

SS

SS SS

SS

eS

SHARP

CORPORATION