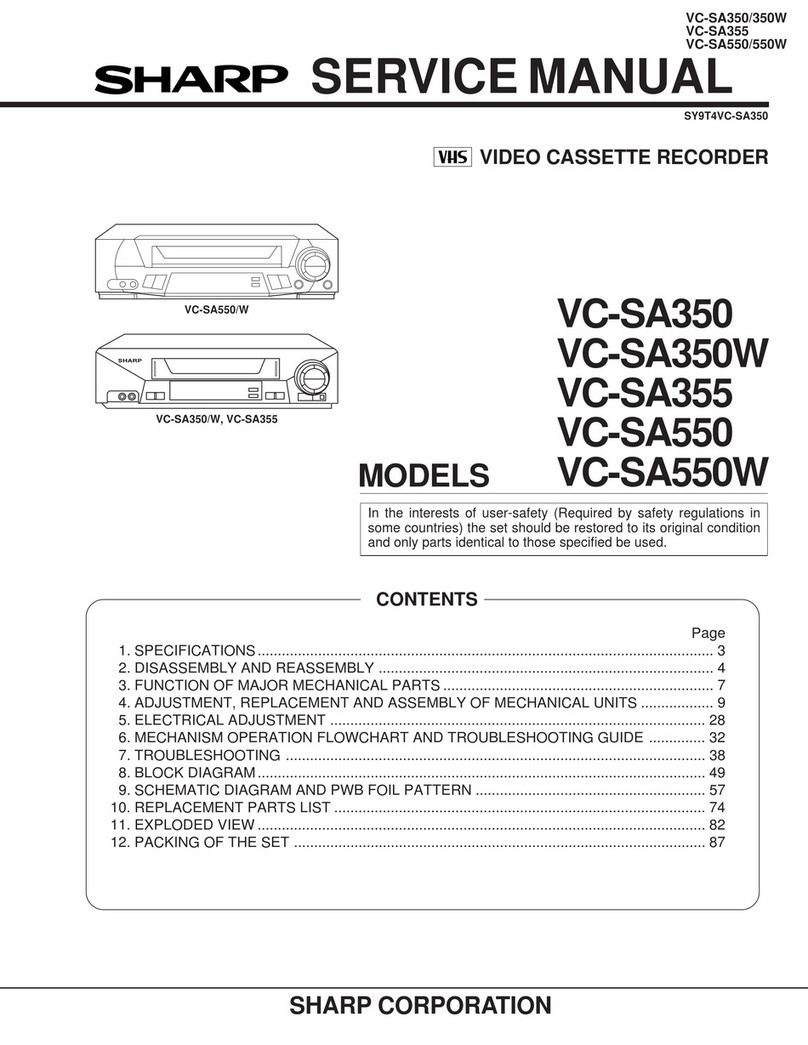

3

VC-S101U

entrelarésistance.InverserlaficheCA(uneficheintermédiaire

non polarisée doit être utilisée à seule fin de faire ces

vérifications.) sur l’appareil et répéter les mesures de tension

CA pour chaque piéce métallique exposée. Toute lecture de

0,45 Vrms (ceci correspond à 0,3 mArms CA) ou plus est

excessive et signale un danger de choc qui doit être corrigé

avant de rendre le magnétoscope à son utilisateur.

NOTES DE SERVICE IMPORTANTES

ATTENTION: POUR REDUIRE LES RESQUES D'IN-

CENDIE OU DE CHOC ELECTRIQUE,

NE PAS EXPOSER CET APPAREIL A

LA PLUIE OU A L'HUMIDITE.

AVANT DE RENDRE LE MAGNETOSCOPE

Avant de rendre le magnétoscope à l’utilisateur, effectuer les

vérifications de sécurité suivantes.

1. Vérifiertoutes les gaines de fil pourêtre sûr que les fils nesont

paspincés ou que le matériel n’est pas coincé entre le châssis

et les autres pièces métalliques dans le magnétoscope.

2. Vérifiertouslesdispositifsdeprotectiontelsquelesboutonsde

commande non métalliques, les matériaux d’isolement, le dos

ducoffret,lescouverclesdecompartimentetajustementoules

boucliers,lesréseauxderésistance/condensateurd’isolement,

Ies isolateurs mécaniques, etc.

3. Pourêtresûrqu’iln’yaaucunrisquedechocélectrique,vérifier

le courant de fuite de la maniére suivante.

●Brancher le cordon d’alimentation secteur directement dans

une prise de courant de 120 volts. (Ne pas utiliser de

transformateur d’isolement pour cet essai).

●Utiliser deux fils à pinces et connecter une résistance de 10

watts 1,5 kohm en parallèle avec un condensateur de 0,15 µF

ensérieavecdespiècesducoffretmétalliqueexposéesetune

masse de terre connue telle qu’un tuyau ou un conduit d’eau.

●Utiliser un VTVM ou VOM avec une sensibilité de 1000 ohms

par volt ou plus ou mesurer la chute de tension CA entre la

résistance (voir diagramme).

●Déposer la connexion de la résistance à toutes les pièces

métalliques exposées ayant un parcours de retour au châssis

(connexionsd’antenne,coffretmétallique,tétesdevis,boutons

etarbresdecommande,etc.)etmesurerlachutedetensionCA

RISQUE DE CHOC ELECTRIQUE

NE PAS OUVRIR

ATTENTION

Ce symbole avertit l'utilisateur que des instructions

importantesrelativesàl'utilisationetàl'entretiensetrouvent

dans le manuel accompagnant l'appareil.

ATTENTION: AFINDEREDUIRELESRISQUESDECHOCELECTRI-

QUE, NE PAS RETIRER LE COUVERCLE, AUCUN

ORGANE INTERNE NE PEUT ETRE REPARE PAR

L'UTILISATEUR. CONFIER L'APPAREIL A UN

DEPANNEUR QUALIFIE.

Ce symbole signale à l'utilisateur la présence d'une

tensionnonisoléeàl'intérieurdel'appareilquipeutêtrela

cause de secousses électriques dangereuses.

PRECAUTION:

Cette marque indique le fusible à action in stantansée.

Pourla protection continue contre le risqued'incendie,ne

remplacer que par le fusible type F901 (3A, 125V).

0,15 µF

SONDE D'ESSAI

VERS PIECES

METALLIQUES

EXPOSEES

VTVM

ECHELLE CA

1.5 KOHMS

10W

CANNECTER A

UNE MASSE DE

TERRE CONNUE

3A 125V