P/N 8100, Page 4 of6

NOTICE! THE DISPLAY DOES NOT CONVERT

DIMENSIONS FROM INCH TO METRIC!

The DRO reads rotary handwheel movement and

converts it to a linear dimension based on a formula

assuming a certain leadscrew thread pitch. The DRO

must be set to agree with the leadscrews installed on

your machine to provide accurate measurements.

The only difference between the inch and metric packages

is the number of divisions engraved into the handwheels.

The electronics package is the same for either and can be

set to read in either measurement system depending on the

leadscrews of the machine on which it is installed.

Setting the backlash compensation values

To set backlash compensation for each axis, you must

first measure to determine what the backlash is. Use a dial

indicator to determine how far the handwheel on each axis

rotates before the table starts to move. (If this amount is

excessive, see your instruction manual for instructions

on setting backlash. It should ideally be in the .003" to

.005" range.) Once the amount is determined, the backlash

is compensated for by setting it into the display unit’s

memory.

To set the measurement system to correspond to your

machine's leadscrews, complete the following steps for

each axis:

1. Turn the handwheel for each axis one full turn

clockwise. This assures that the software starts the

backlash compensation at the proper initial point.

2. Hold down the “Power” button for longer than a

second until the display changes.

3. Now you can set in the backlash for each axis by

pushing the button for that axis. Each time the button

is depressed, .0005" (or .01 mm on metric units) is

added to the reading. Set in the amount of backlash

you measured previously for each axis. Amounts

up to .015" (.50 mm) can be set. (Note: You cannot

cycle backwards to a lower number. If you go past

your desired setting you must continue pushing the

button until the reading passes .015" or .50 mm and

returns to zero. Then start over.)

4. Once the backlash for all three axes is set, briefly

push the “Power” button again to return the display

to its normal reading. The backlash setting can be

checked or changed at any time by holding the

power button until the display changes. The amount

can then be reset as described in instruction number

3 above. Once set, backlash settings are held in a

special memory chip even if the unit is turned off and

unplugged. They remain until you change them.

Adjusting the Z-axis handwheel screw

To adjust tension on the screw, first remove all Z-axis

backlash in the conventional manner by lifting the motor/

speed control unit by hand while tightening the handwheel

set screw on a “fresh” quadrant of the leadscrew to avoid

picking up any previous indentations. Once adjusted, tighten

the center screw* only until it is “finger tight”. Use a very

small amount of Loc-tite® on the end of the screw to keep it

in place. (Do not coat the threads or the screw may become

impossible to remove.) Overtightening the screw will cause

the handwheel to become hard to turn. The purpose of the

screw is not to adjust backlash, but rather to keep it from

increasing once it is properly adjusted. Do not try to use

the screw to pull out additional backlash. The small 5-40

threads are not strong enough for this task.

*Note: If installing the Z-axis DRO handwheel on an older

machine that does not have a 5-40 hole in the end of the

leadscrew this screw is not used.

A few more tips

When in use, shield the unit from chips so they don't

accumulate around the telephone jack connections on

the side. Do not use an air hose to clean the unit.

A metal stand is included with your DRO so you can stand

the unit up on your workbench. This makes it easier to

read while you work. If you wish to secure the box to the

stand, a piece of double-sided foam tape or hook-and-loop

(Velcro®) tape are good methods.

Reversing the direction of the reading on the X-axis

The X-axis readout is designed to read negative numbers

when the handwheel is turned in the clockwise direction

and positive when turned counter-clockwise. Should you

wish to change your readout so that it uses a standard x-

y plot, you can do so by switching two of the four wires

coming from the encoder for the X-axis.

To do so, unplug the X-axis cable from the readout box.

Remove the four screws that secure the lower housing to

the upper housing and then remove the encoder halves from

the handwheel. On the bottom of the half with the encoder

is a cover plate secured by three screws. Remove these

screws and the cover plate. This will expose the soldered

connections for the four wires coming from the encoder.

To reverse the direction of the readout, unsolder the green

and black wires. Reverse their position and re-solder to

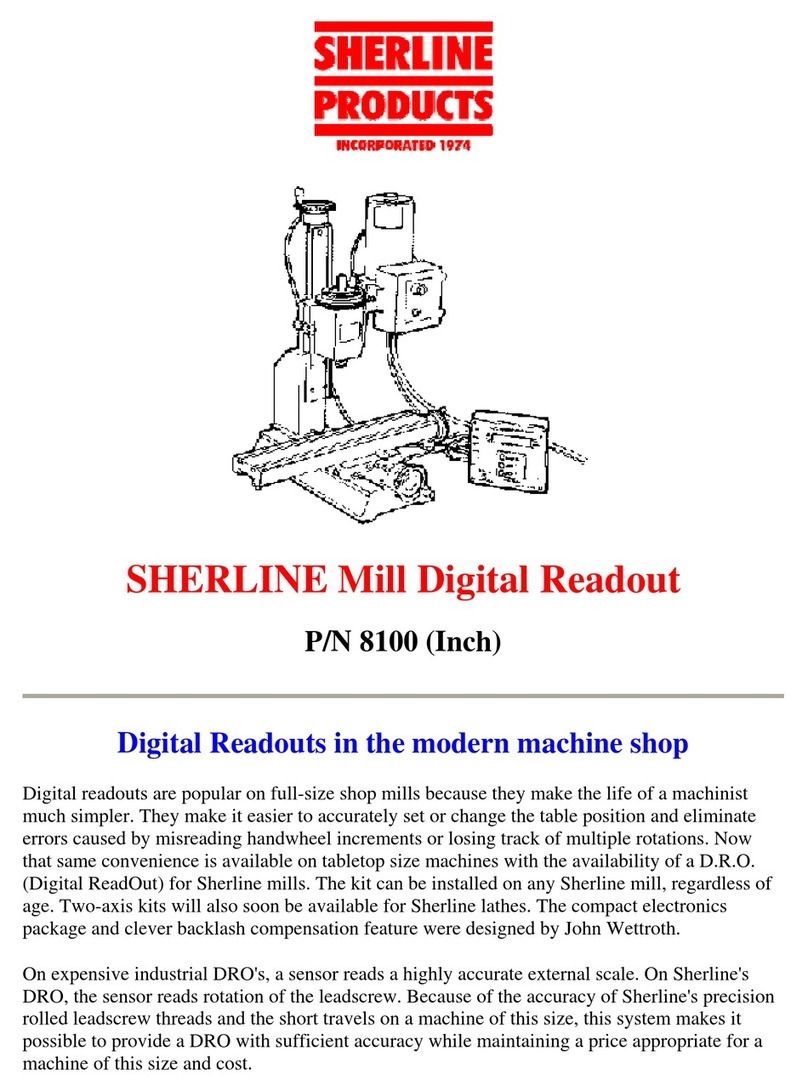

the encoder leads. Reinstall in reverse order. The diagram

below shows the factory locations of the wires before the

swap is made.

Figure 8—The drawing on the left shows the encoder hous-

ing and wires coming from the plug. The diagram to the

right shows a schematic of where each wire is connected.

Swapping the black and green wires will change the + and

– directions of the readout.