2. SPECIFICATIONS VM-13V1

-3-

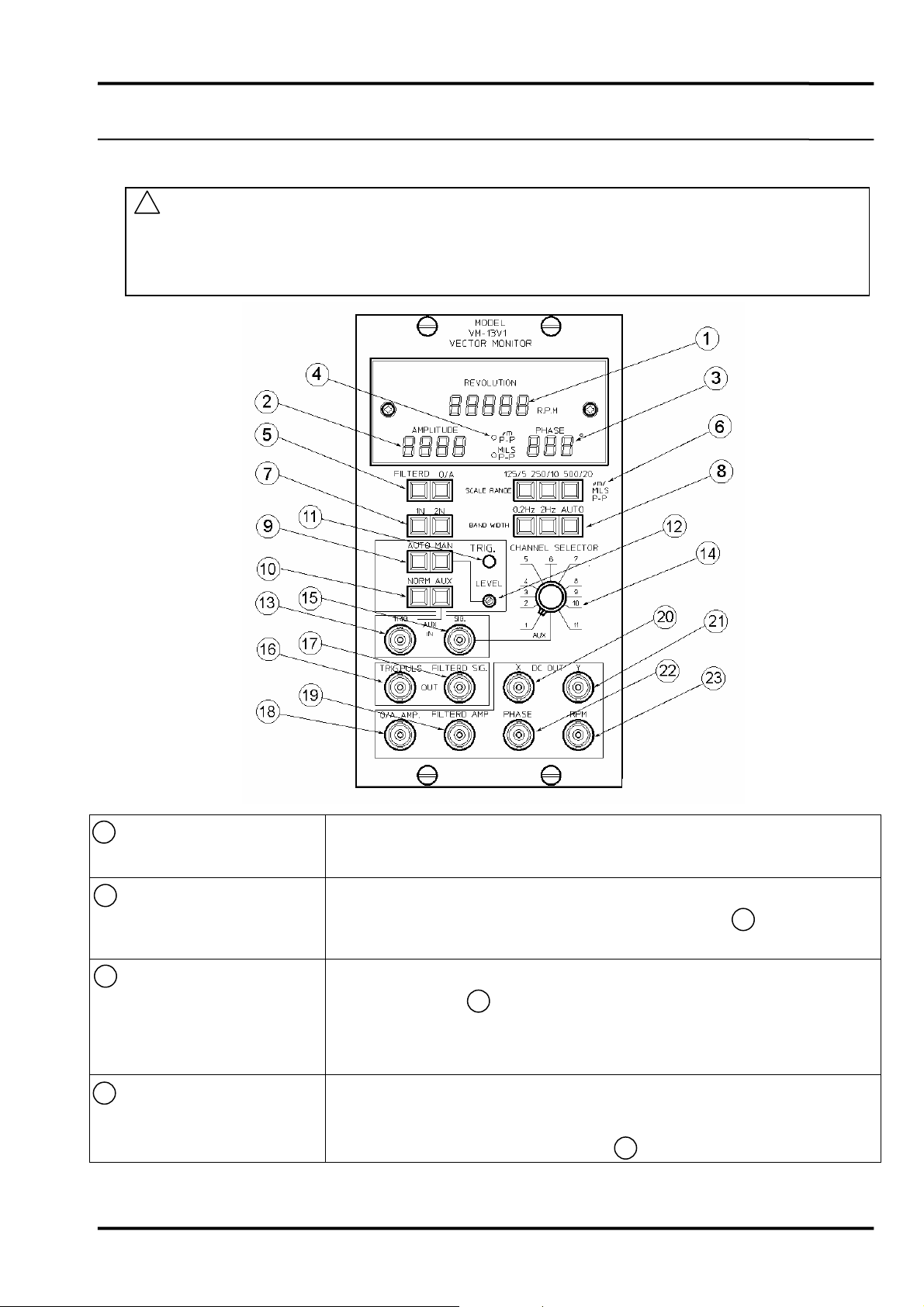

1. RPM RANGE 200 to 100,000rpm

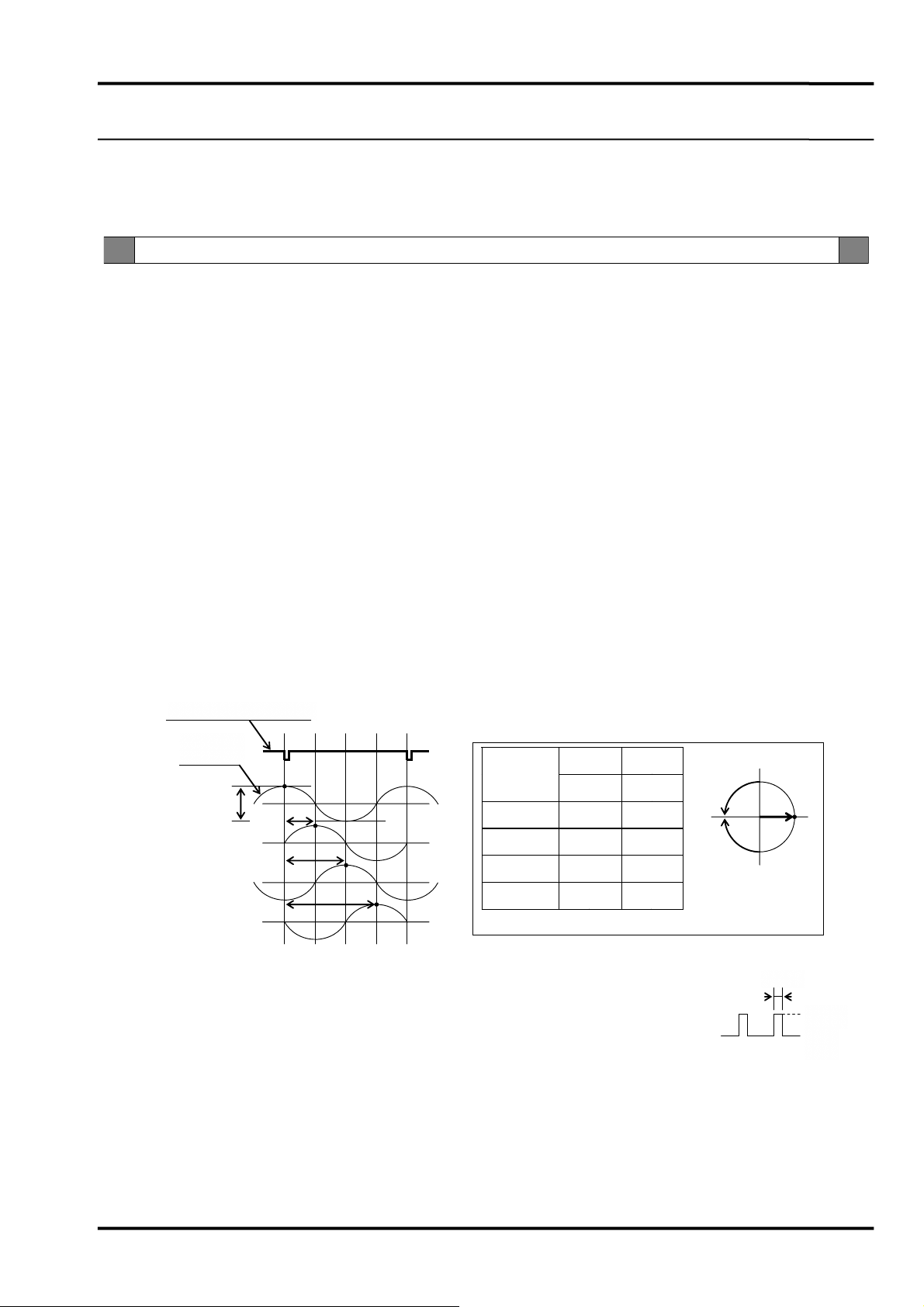

2. DISPLAY

1) RPM Readout : 5 digits LED(red), 200 to 99,999rpm

Accuracy : ±(0.003% of rdg.+1 digit) at 25°C

Resolution : 1rpm

2) AMPLITUDE Readout : 3 digits LED(red)

Full Scale Range : 500/250/125µm P-P

20.0/10.0/5.0mils P-P

Unit(µm or mils)selection:Selected by internal switch

Range selection:Selected by front panel switch

Accuracy : Overall ±3% of F.S. at 25°C

Filtered ±3% of F.S. at 25°C

Resolution : 1µm or 0.1mils

3) PHASE ANGLE Readout : 3 digits LED(red), 0 to 360°

Operating Range : 200 to 100,000rpm

Resolution : 1°

Accuracy : ±3° at at amplitude input>10% F.S. and 25°C

3. TRACKING FILTER

1) OPERATING FREQUENCY RANGE

200 to 100,000rpm(3.33 to 1,666Hz)

2) BAND WIDTH(BW) 0.2 or 2Hz(-3dB down)(selected by front panel switch)

3) BAND WIDTH SELECT MODE

AUTO or MANUAL(selected by front panel switch)

AUTO Mode : <1,000rpm=0.2Hz BW

>1,000rpm=2Hz BW

4) FILTER RESPONSE 0.2Hz BW=0.6rpm/s

2Hz BW=60rpm/s

5) ORDER RATIO 1×(1N) or 2×(2N)(selected by front panel switch)

7) DYNAMIC RANGE 60dB or more

4. INPUT SIGNAL

1) VIBRATION SIGNAL INPUT From displacement transducers or velocity transducers(selected by internal switch)

Input Impedance : 10kΩ(unbalance)

Input Sensitivity : Displacement transducer 2.5V/mm,4V/mm,5V/mm,8V/mm

(selected by internal switch)

Velocity transducer 2.5 to 40mV/mm/s

(internal potentiometer setting)

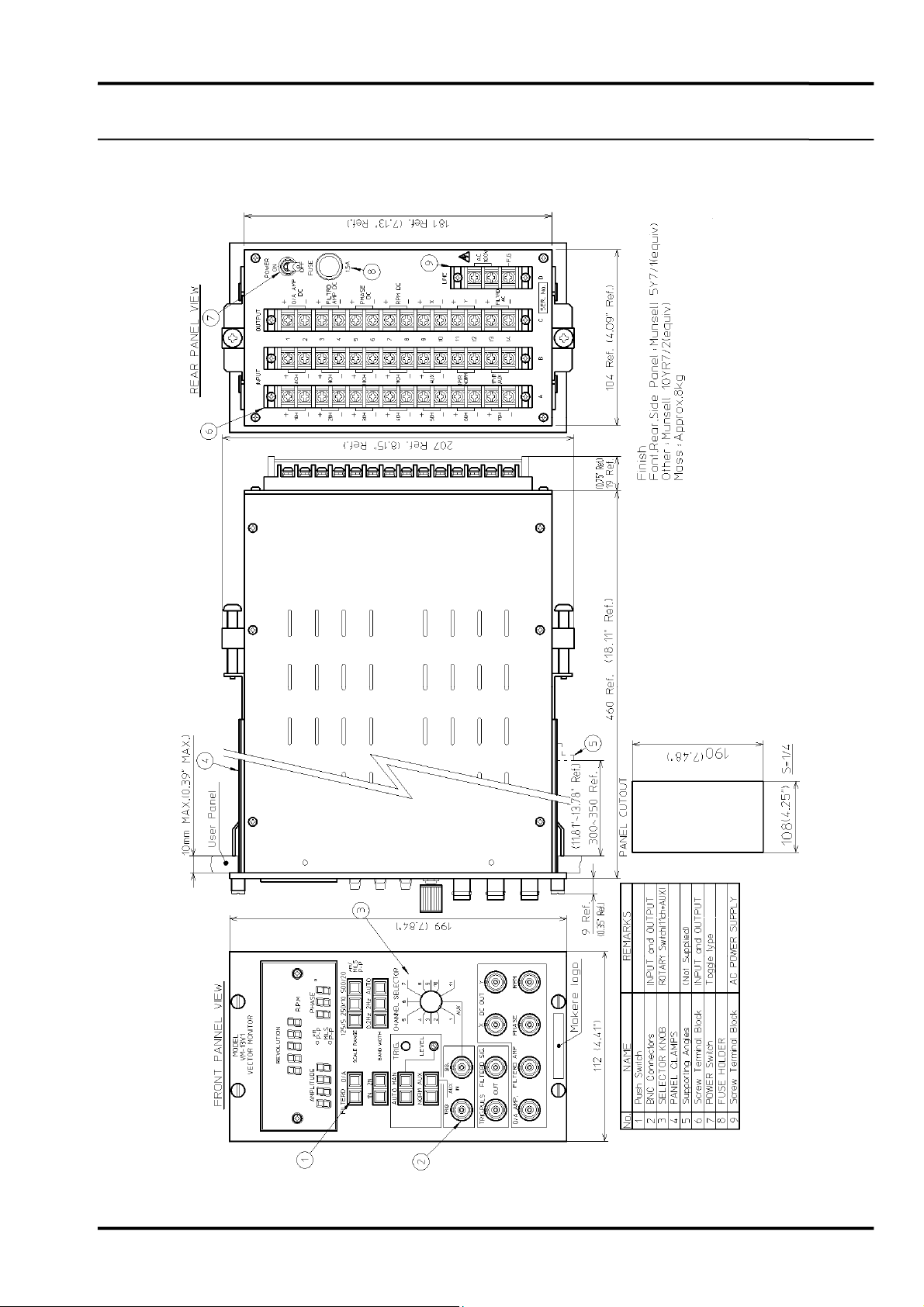

Input Channel : 1 to 11ch(rear panel screw terminal)

AUX ch(rear panel screw terminal and front panel BNC)

SPECIFICATIONS

GENERAL

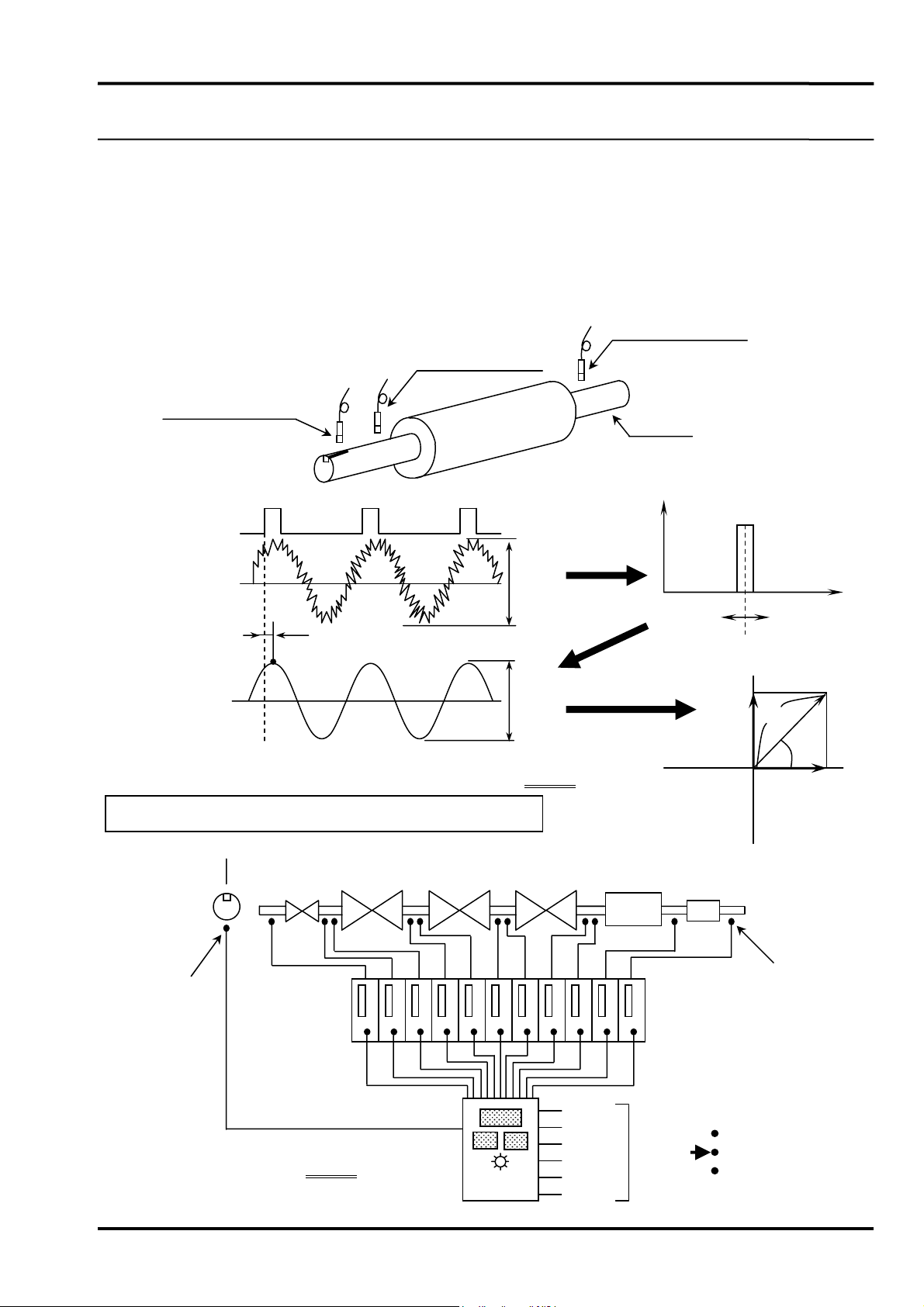

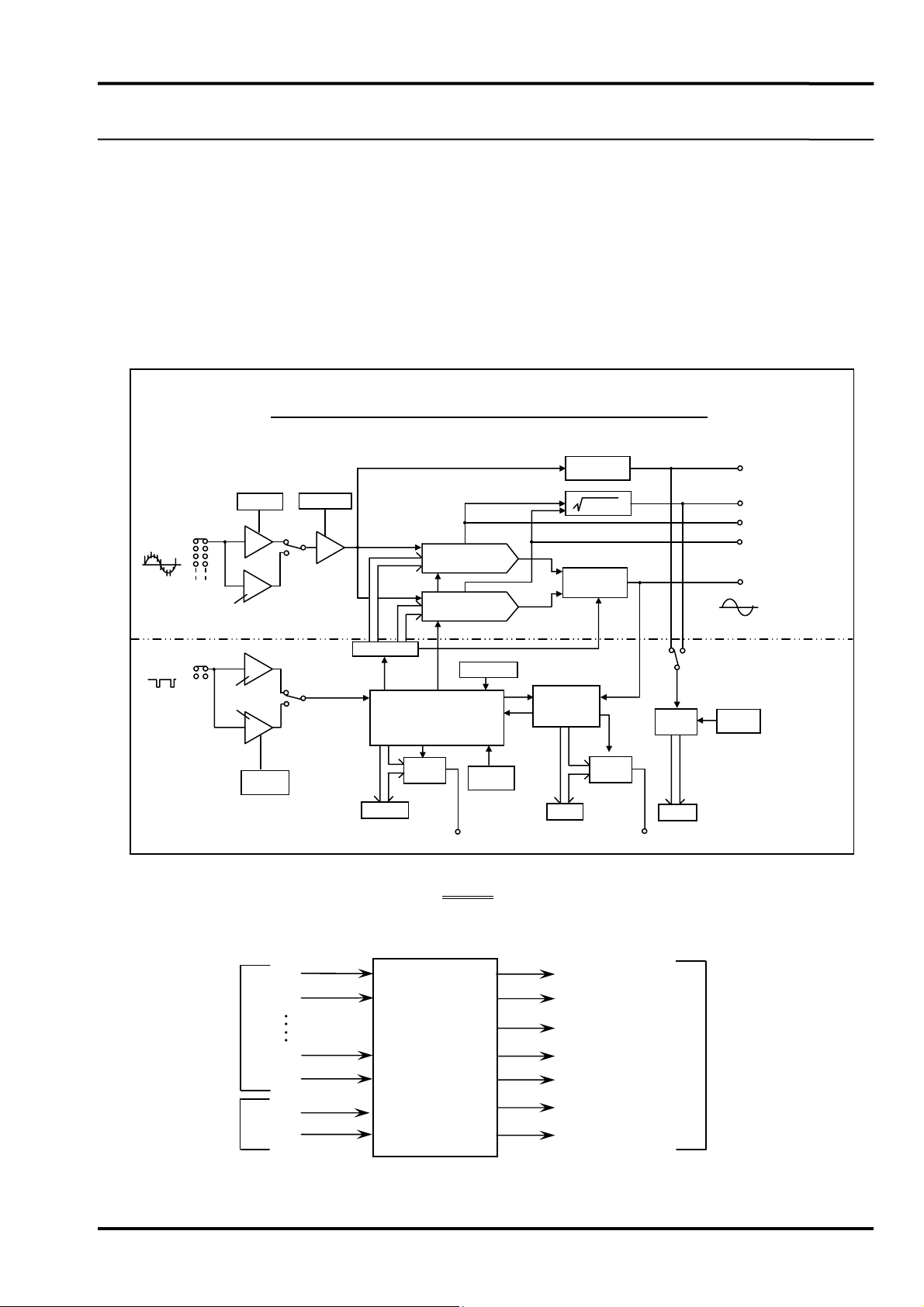

MODEL VM-13V1 VECTOR MONITOR accepts vibration transducer inputs (max.11 channels +AUX) and phase

reference signal (1 pulse per revolution). It provides a digital readout of selected vibration vector (amplitude and

phase angle) and machine speed (rpm), and recorder outputs.

VM-13V1

VECTOR

MONITOR DC Recorder Output

Filtered AC

Y(IMAGINARY)

X(REAL)

Phase Angle

Filtered Amplitude

Overall Amplitude

rpm

1

2

11

AUX

1 P/R

AUX

Vibration Signal Input

Phase Reference

Signal Input

……..

39335E1.5