5

Contents

1. Model Page

1.1 Model ---------------------------------------------------------------------------------- 6

1.2 How to Read the Model Label --------------------------------------------------- 6

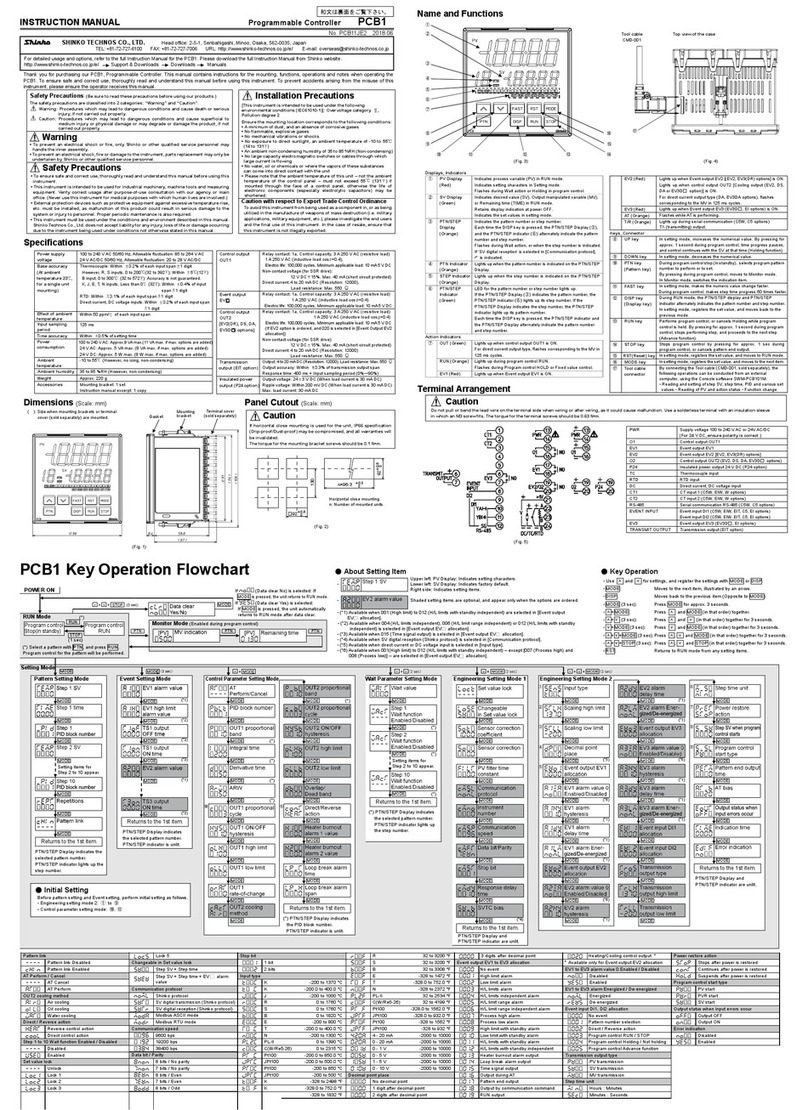

2. Name and Functions of Sections ----------------------------------------------- 7

3. Mounting to the Control Panel

3.1 Site Selection ---------------------------------------------------------------------- 8

3.2 External Dimensions (Scale: mm) --------------------------------------------- 8

3.3 Current Transformer (CT) Dimensions (Scale: mm) ---------------------- 8

3.4 Mounting to a DIN rail ------------------------------------------------------------- 9

4. Removal from a DIN rail ----------------------------------------------------------- 11

5. Wiring

5.1 Lead Wire Solderless Terminal -------------------------------------------------12

5.2 2ch Controller Spec --------------------------------------------------------------- 13

5.3 Timer Spec -------------------------------------------------------------------------- 13

5.4 Potentiometer Input Spec ------------------------------------------------------- 14

5.5 Wiring Example -------------------------------------------------------------------- 15

5.6 Wiring Example of Heater BurnoutAlarm (W, W3 option) -------------- 16

5.7 Wiring Example ofAlarm Output (AO option) ------------------------------ 17

5.8 Wiring Example of Heater Burnout Alarm (single-phase) +

Alarm Output (AW option) ------------------------------------------------------- 18

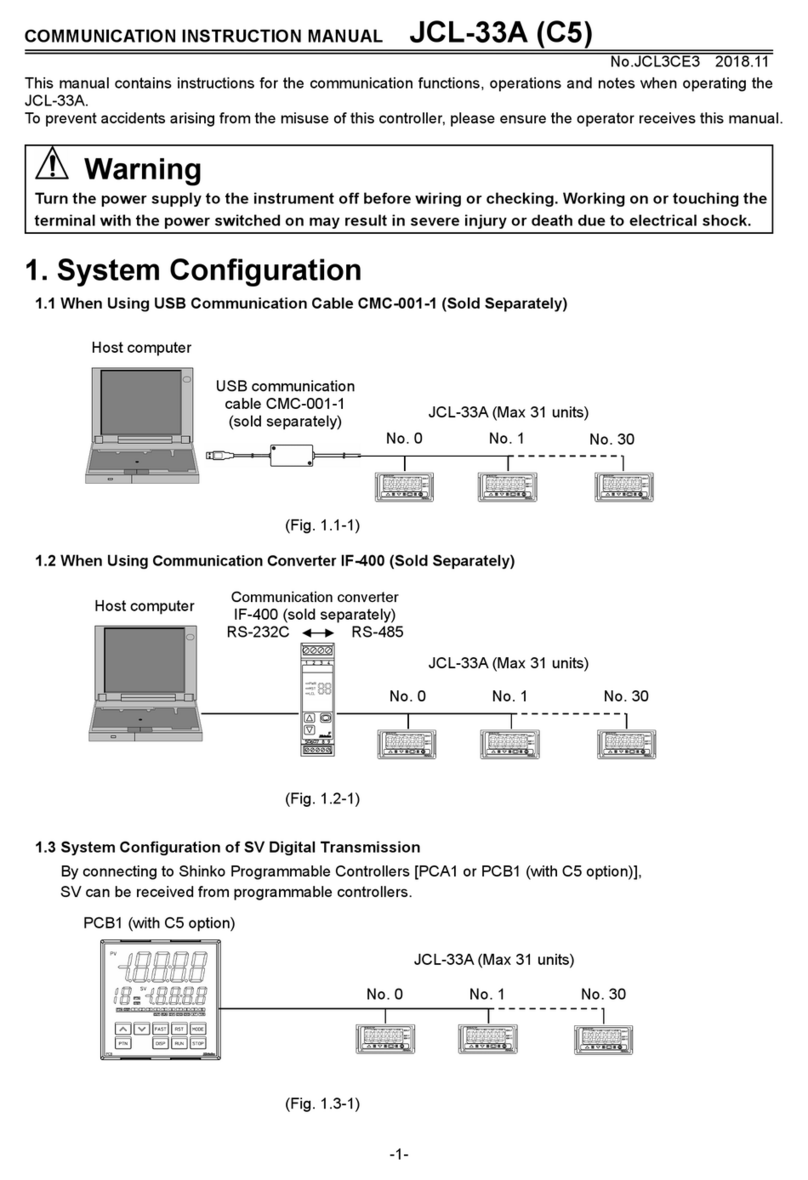

5.9 Wiring Example of Serial Communication (C5 option) ------------------- 19

6. Outline of Key Operation and Setting Groups

6.1 Outline of Key Operation -------------------------------------------------------- 20

6.2 Setting Groups --------------------------------------------------------------------- 20

6.3 Basic Operation Procedures --------------------------------------------------- 21

7. Key Operation Flowchart --------------------------------------------------------- 22

8. Setup

8.1 Turn the Power Supply to the WCL-13A ON ------------------------------- 24

8.2 CH1 Function Group ------------------------------------------------------------- 25

8.3 CH2 Function Group ------------------------------------------------------------- 30

8.4 Special Function Group --------------------------------------------------------- 34

9. Settings

9.1 SV Group ---------------------------------------------------------------------------- 39

9.2 CH1 Parameter Group ----------------------------------------------------------- 40

9.3 CH2 Parameter Group ----------------------------------------------------------- 43

10. Operation

10.1 Starting Operation --------------------------------------------------------------- 46

10.2 Switching PV/SV ----------------------------------------------------------------- 46

10.3 Indicating MV --------------------------------------------------------------------- 46

10.4 AT Perform/Cancel -------------------------------------------------------------- 46

10.5 Performing Cascade Control ------------------------------------------------- 47

11. Action explanation

11.1 CH1, CH2 OutputAction ------------------------------------------------------- 48

11.2 CH1, CH2 Output ON/OFF ControlAction -------------------------------- 48

11.3 CH1, CH2 Alarm Action -------------------------------------------------------- 49

11.4 Heating/Cooling Control Action ---------------------------------------------- 50

11.5 Heating/Cooling Control Action (When Setting Dead Band) ---------- 51

11.6 Heating/Cooling Control Action (When Setting Overlap Band) ----- 52

12. AT/Auto-reset of This Controller

12.1 AT (Auto-tuning) ----------------------------------------------------------------- 53

12.2 Auto-reset (Offset Correction) ----------------------------------------------- 53

13. Specifications

13.1 Standard Specifications ------------------------------------------------------- 54

13.2 Optional Specifications -------------------------------------------------------- 62

14. Troubleshooting

14.1 Indication -------------------------------------------------------------------------- 65

14.2 Key Operation -------------------------------------------------------------------- 66

14.3 Control ----------------------------------------------------------------------------- 66

15 Character Tables ------------------------------------------------------------------- 67