– 6 –

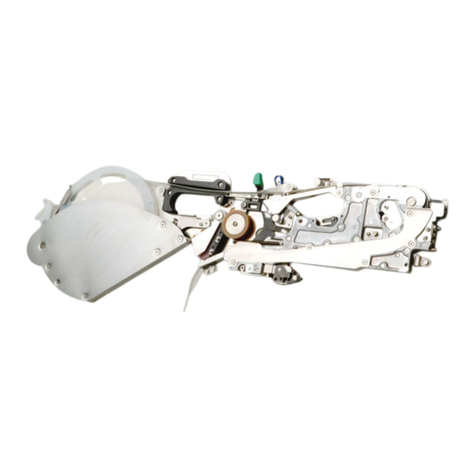

3-2. Connecting the device to the solenoid valve and the electrical control box

1)

Loosen setscrew ❷in end block ❶, and draw

out end block ❶in the direction A.

2)

Insert solenoid valve ❸into the position as

shown in the gure.

3)

Insert end block ❶into rail ❹, and tighten set-

screw ❷while contacting the end block closely

to the solenoid valve.

* Underside of the table, as viewed from the front

❶

❷

❹

❸

❺

When tightening setscrew

❷

, care should

be taken so that there will be no clearance

among the solenoid valve and other compo-

nents since air leakage will be caused if so-

lenoid valve and other components are not

closely set. Be sure to insert three bushings

❺

into solenoid valve

❸

.

A

connector(10P)

:

HK063610100 1 piece

solenoid valve cables asm.:

40190157 2 pieces

4)

Connect two solenoid valve cables (40190157)

that are packed together with the device to the

connectors (HK063610100).

5)

Connect the solenoid valve cable

asm. to the connectors.

Insert the red cable to the 7P and

9P of the connector.

Insert the black cable into the 8P

and 10P of the connector.

Insert the cables into the connec-

tors in such a way that the pin

contact projections are caught on

the connector claws.

コネクタ爪

(コネクタ側面)

ピンコンタクト突起

Projection of the

pin contact

Side face of the

connector

Claw of the connector

DANGER :

1. To avoid electrical shock hazards, turn OFF the power and open the control box cover after about

ve minutes have passed.

2. Be sure to turn OFF the power switch rst. Then, open the control box cover and carry out the

work.