Showa Denko Shodex Asahipak GF-HQ Series User manual

This manual suits for next models

12

Table of contents

Other Showa Denko Laboratory Equipment manuals

Showa Denko

Showa Denko Shodex RSpak NN-814 User manual

Showa Denko

Showa Denko Shodex RSpak DS-413 User manual

Showa Denko

Showa Denko Shodex Asahipak NH2P-50 10E User manual

Showa Denko

Showa Denko Shodex IC YS-50 User manual

Showa Denko

Showa Denko Shodex IEC CM-825 User manual

Showa Denko

Showa Denko Shodex PROTEIN LS-G 4J User manual

Showa Denko

Showa Denko Shodex GPC LF-804 User manual

Showa Denko

Showa Denko Shodex IC SI-50 4E User manual

Showa Denko

Showa Denko Shodex GPC LF-404 User manual

Showa Denko

Showa Denko Shodex IC Y-521 User manual

Showa Denko

Showa Denko Shodex SUGAR SP0810 8C User manual

Showa Denko

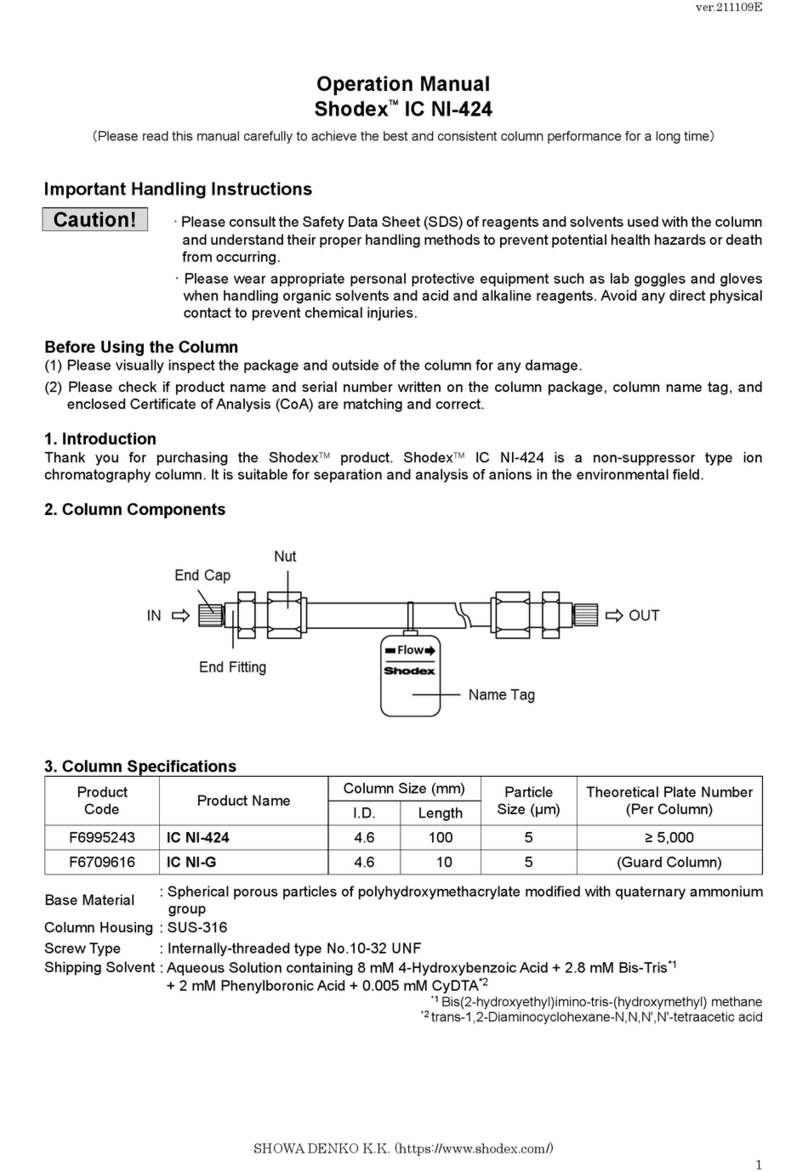

Showa Denko Shodex IC NI-424 User manual

Showa Denko

Showa Denko Shodex RI-101 Installation and user guide

Showa Denko

Showa Denko Shodex GPC KD-800 Series User manual

Showa Denko

Showa Denko Shodex Asahipak GS-HQ Series User manual

Showa Denko

Showa Denko Shodex RSpak DM-614 User manual

Showa Denko

Showa Denko Shodex RSpak JJ-50 2D User manual

Showa Denko

Showa Denko Shodex C18U 2B User manual

Showa Denko

Showa Denko Shodex GPC LF-604 User manual

Showa Denko

Showa Denko Shodex ORpak CDBS-453 User manual

Popular Laboratory Equipment manuals by other brands

Thermo Scientific

Thermo Scientific BF51731 Installation and operational manual

Optika Italy

Optika Italy B-150D Series instruction manual

Labnet

Labnet MultiGene Mini Operation manual

Reichert

Reichert Lensometer LensChek Plus user guide

WPI

WPI NANOLITER2020 instruction manual

Fisher Scientific

Fisher Scientific accuSpin 1R Service manual

Tuttnauer

Tuttnauer 1730E Operation & maintenance manual

NEW BRUNSWICK SCIENTIFIC

NEW BRUNSWICK SCIENTIFIC innova 4340 Guide to operations

Proton

Proton XQ30 manual

Agilent Technologies

Agilent Technologies Varian 3800 GC operating instructions

Thermo Scientific

Thermo Scientific Revco Installation and operation

Thermo Scientific

Thermo Scientific Orion 960 Addendum