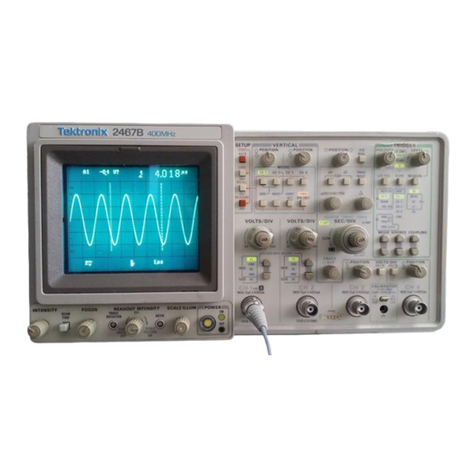

Tektronix 067-1039-00 User manual

Other Tektronix Laboratory Equipment manuals

Tektronix

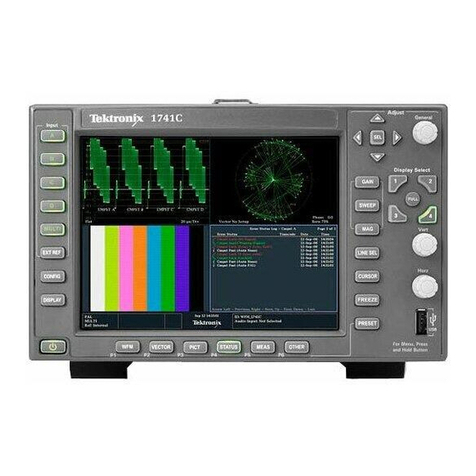

Tektronix 1741C Installation and maintenance instructions

Tektronix

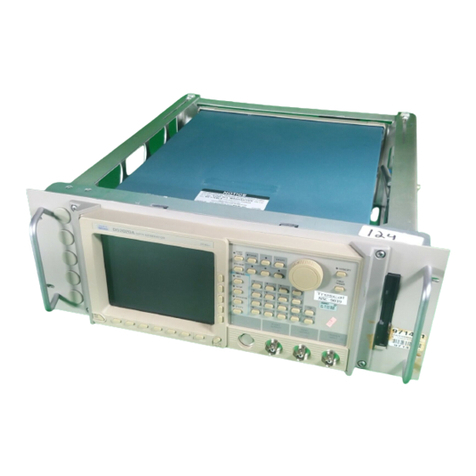

Tektronix 7B71 User manual

Tektronix

Tektronix P7708 User manual

Tektronix

Tektronix 2706 User manual

Tektronix

Tektronix RFA300A User manual

Tektronix

Tektronix TLA7PG2 User manual

Tektronix

Tektronix TSG130A User manual

Tektronix

Tektronix WVR5200 Series Use and care manual

Tektronix

Tektronix IntelliFrame VX1410 User manual

Tektronix

Tektronix P7350SMA User manual

Tektronix

Tektronix Option 10 User manual

Tektronix

Tektronix AWG4162 Use and care manual

Tektronix

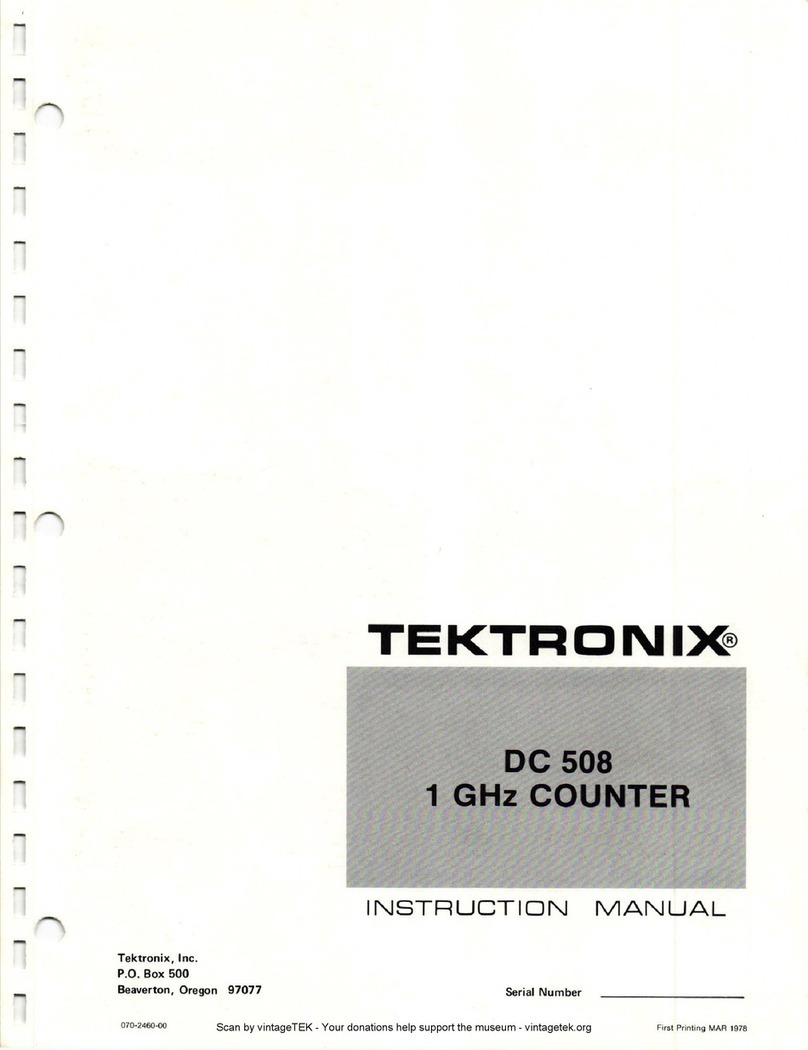

Tektronix DC508 User manual

Tektronix

Tektronix WFM5200 series Use and care manual

Tektronix

Tektronix Keithley 2380-500-30 Installation and operation manual

Tektronix

Tektronix Sony 370A User manual

Tektronix

Tektronix 1741C User manual

Tektronix

Tektronix Keithley SourceMeter 2450 User manual

Tektronix

Tektronix DG2020A User manual

Tektronix

Tektronix 7B71 User manual

Popular Laboratory Equipment manuals by other brands

Belden

Belden HIRSCHMANN RPI-P1-4PoE installation manual

Koehler

Koehler K1223 Series Operation and instruction manual

Globe Scientific

Globe Scientific GCM-12 quick start guide

Getinge

Getinge 86 SERIES Technical manual

CORNING

CORNING Everon 6000 user manual

Biocomp

Biocomp GRADIENT MASTER 108 operating manual