Delta OHM HD50R-MB User manual

The quality level of our instruments is the result of the constant development of the

product. This may produce some differences between the information written in this

manual and the instrument you have purchased. We cannot completely exclude the

possibility of errors in the manual, for which we apologize.

The data, images and descriptions included in this manual cannot be legally asserted.

We reserve the right to make changes and corrections with no prior notice.

HD50R-MB

Ethernet Data Logger

ENGLISH

REV. 1.0

20/07/2018

HD50 - 2 - V1.0

TABLE OF CONTENTS

1INTRODUCTION.................................................................................................... 3

2DESCRIPTION....................................................................................................... 4

3CONNECTIONS...................................................................................................... 5

4SOFTWARE ........................................................................................................... 8

5MODBUS ............................................................................................................... 9

6TECHNICAL CHARACTERISTICS .......................................................................... 14

7INSTRUMENT STORAGE ...................................................................................... 15

8SAFETY INSTRUCTIONS...................................................................................... 15

9ORDERING CODES .............................................................................................. 16

HD50 - 3 - V1.0

1INTRODUCTION

The HD50R-MB data logger allows several physical quantities to be monitored in a

large variety of application fields.

To the “Master” RS485 MODBUS-RTU input you can connect a network of sensors for

measuring, for example, temperature, humidity, atmospheric pressure, solar radiation,

wind speed and direction (e.g. an anemometer of the HD52.3D… series can be con-

nected), etc.

As an alternative to the Modbus-RTU protocol, a proprietary protocol can be used to

connect the HD2003 anemometer.

A voltage-free contact input allows connecting a rain gauge with contact output. Rain

gauges with contact output either normally closed or normally open can be connected.

A measurement compensation curve as a function of the rainfall rate can be config-

ured. The data logger calculates the rainfall rate in mm/h (by referring the rainfall

quantity in the last five minutes to an hourly value) and the rainfall quantity in the

last day.

The data logger can be connected to an Ethernet local network and allows the simul-

taneous operation of two communication protocols: proprietary and Modbus TCP/IP.

The data logger manages up to 10 “TCP/IP Client” simultaneously. If the local network

is connected to Internet, the data can be regularly sent to an FTP address, to the

Cloud and via e-mail.

For each detected quantity, two alarm thresholds can be set by the user. Exceeding a

threshold is signaled acoustically, by means of the internal buzzer, and remotely, by

sending alarm e-mails. An alarm hysteresis and a delay in the generation of the alarm

can be configured for each detected quantity.

The PC software HD35AP-S allows configuring the data logger, viewing the real time

measurements, downloading and viewing the data into a database. The HD35AP-S

software allows connecting one data logger at a time. If there are several data loggers

in the local network, the PC software HDServer1 allows detecting automatically all the

data loggers connected to the network and connecting simultaneously to all the data

loggers; it also allows entering the data received by the data loggers into a database,

viewing the data in the database and configuring the main measurement parameters

of the devices (alarms, logging interval, …). The HD35AP-CFR21 software option

(available with both HD35AP-S and HDServer1) allows the protection of recorded data

and configuration in response to FDA 21 CFR part 11 recommendations.

35 mm DIN rail installation.

7…30 Vdc external power supply.

HD50 - 4 - V1.0

2DESCRIPTION

MINI

USB B

NORMAL

NET RST

1

2

3

CLOSE

OPEN

RT

PWR

L2

1

3

7

2

9

8

4 5

6

1. Push-button and short-jumper for restoring the factory LAN configuration.

2. Input for contact rain gauge.

3. Red POWER LED: indicates the presence of the external power supply.

4. Power supply input.

5. RS485 line termination.

6. Input for RS485 Modbus-RTU sensors.

7. RJ45 connector for Ethernet connection.

8. Mini-USB connector.

9. Bicolor NETWORK LED: indicates the status of the connection to the LAN (blinks

green when the unit is in normal operation mode; blinks red to signal problems

in LAN connection).

HD50 - 5 - V1.0

3CONNECTIONS

POWER SUPPLY

CLOSE

OPEN

RT

PWR

V+

7...30 Vdc

V-

RS485 MODBUS-RTU CONNECTION

Thanks to RS485 connection, several sensors can be connected in a multi-point net-

work. The instruments are connected in sequence by means of a shielded cable with

twisted pair wires for signals and a third wire for the ground.

The RS485 ground is isolated from the power supply.

DATA+

DATA-

GND

220Ω ShieldShield

Lmax = 1200m

CLOSE

OPEN

RT

PWR

DATA- DATA+

GND

Line terminations must be placed at the ends of the network. If the instrument is at

one end of the line, insert the termination placing the short jumper next to the RS485

connector between the “RT” and “CLOSE” indications. Otherwise, remove the termina-

tion placing the short jumper between the “RT” and “OPEN” indications.

The cable shield must be connected to both ends of the line.

The cable maximum length depends on the transmission speed and on the cable char-

acteristics. Typically, the maximum length is 1200 m. The data line must be kept se-

parated from any power lines to avoid interferences to the transmitted signal.

Each sensor in the RS485 network is univocally identified by an address ranging within

1 and 247. No more than one sensor with the same address can be present in

the network.

Sensor with RS485

MODBUS-RTU output

Termination

Sensor with RS485

MODBUS-RTU output

HD50 - 6 - V1.0

RAIN GAUGE CONNECTION

MINI

USB B

NORMAL

NET RST

1

2

3

L2

USB CONNECTION

The data logger can be connected to a PC via the mini-USB connector and the CP23

cable.

USB connection doesn’t require the installation of drivers: when the data logger is

connected to a PC, Windows® operating system automatically recognizes the instru-

ment as an HID device (Human Interface Device) and uses the drivers already in-

cluded in the operating system.

ETHERNET CONNECTION

Connect the RJ45 connector of the data logger to a socket of the local network via a

standard Ethernet cable.

The data logger is preset to get a dynamic IP address from the network DHCP server.

The IP address can be displayed and changed by connecting the data logger to a PC via

USB and using the HD35AP-S application software. A static IP address can also be set.

The IP address can also be displayed by connecting the data logger to a PC via Ethernet

and using the HDServer1 software, which can automatically detect the data loggers

connected to the network.

Thanks to the availability of two TCP/IP ports, each of which can operate with proprie-

tary (for the connection with HD35AP-S software) or MODBUS TCP/IP protocol, and

ten sockets (in total, to be divided between the two ports), the data logger allows the

Rain gauge contact

HD50 - 7 - V1.0

simultaneous operation of two communication protocols (proprietary and Modbus

TCP/IP) and manages up to 10 “TCP/IP Client” simultaneously. The default setting of

the ports is the following:

•Port number = 5100 for proprietary protocol (8 sockets)

•Port number = 502 for Modbus TCP/IP protocol (2 sockets)

The Ethernet settings can be changed with the HD35AP-S software. It is possible to

restore the factory parameters by placing the short jumper next to the NET RST

push-button between the “2” and “3” indications and then pressing the NET RST

push-button. After the reset, replace the short jumper between the “2” and “1 (NOR-

MAL)” indications.

If the local network is connected to Internet, the data can be regularly sent to an FTP

address, to the Cloud and via e-mail (as attachments).

Note: if the communication with the Cloud is used, the maximum number of “clients”

with proprietary or MODBUS TCP/IP protocol is nine.

HD50 - 8 - V1.0

4SOFTWARE

The parameters of the instrument (logging parameters, alarm thresholds, quantities

to be acquired, network settings, etc.) can be configured by connecting the instru-

ment to the PC via USB or Ethernet local network and using the HD35AP-S applica-

tion software (see the instructions of the software).

Some basic parameters (alarms, logging interval, user code, …) can also be set with

the HDServer1 application software.

To download the data in a database, the HD35AP-S (it allows connecting one data log-

ger at a time) or HDServer1 (it allows connecting several data loggers simultaneously)

application software and the MySQL database management system (included in the

application softwares packages) must be installed.

HD35AP-CFR21 SOFTWARE OPTION

The HD35AP-CFR21 option allows, in addition to the features of the basic software

(both HD35AP-S and HDServer1), the protection of recorded data and instrument con-

figuration in response to FDA 21 CFR part 11 recommendations. In particular be-

come available:

•The traceability of activities (Audit Trail) performed with the software; for exam-

ple, which users connected and what changes were possibly made to the configu-

ration of the instrument.

•The management of users access for the instrument configuration and viewing of

data in the database. Each user can be assigned a different password for using the

software. There are also three levels of access (Administrator, Super-user and stan-

dard User); for each level, the allowed operations can be defined.

The HD35AP-CFR21 option works with USB hardware key to be connected to any PC con-

nected to the same local network of the PC in which the basic software is installed.

HD50 - 9 - V1.0

5MODBUS

The device general information can be read through the function code 0x2B/0x0E:

•Manufacturer (Delta OHM)

•Model

•Firmware version

The list of MODBUS registers is shown below. Depending on the connected sensors,

some of the registers could not be significant for the system.

The following conventions have been used in the tables:

oType: b= bit, B= 8 bits (Byte), W= 16 bits without sign (Word), SW = 16 bits

with sign

o(x10) = decimal value expressed as an integer (e.g., if the content of the register

is 184, the value is to be intended as 18,4).

o(x100) = centesimal value expressed as an integer (e.g., if the content of the reg-

ister is 500, the value is to be intended as 5,00).

The commands for requesting units of measurement return an index according to the

correspondence indicated in the table below:

Indexes of the units of measurement

Index Unit of

meas. Index Unit of

meas. Index Unit of

meas. Index Unit of

meas. Index Unit of

meas.

0 °C 13 inchHg 26 J/m239 inch 52 l/min

1 °F 14 inchH2O 27 µJ/cm240 counts 53 gallon/min

2 %UR 15 kgf/cm228 V 41 mm/h 54 m3/min

3 g/m316 PSI 29 mV 42 inch/h 55 m3/h

4 g/kg 17 m/s 30 mA 43 counts/h 56 µmol/(m2s)

5 mbar 18 km/h 31 ppm 44 mW/m257 mm/day

6 bar 19 ft/s 32 Hz 45 m 58 kV

7 Pa 20 mph 33 % 46 s 59 A

8 hPa 21 knot 34 degrees

47 µW/lumen 60 kA

9 kPa 22 W/m235 lux 48 dB

10 atm 23 µW/cm236 m2/s 49 dBA

11 mmHg 24 Wh/m237 g

(*) 50 kWh

12 mmH2O 25 kWh/m238 mm 51 l/s 255 Not

defined

(*) Gravity acceleration

Discrete Inputs - Read-only parameters

Address Type Discrete Input description

7 b If 1, at least a quantity is in alarm.

Coils - Read/Write parameters

Address Type Coil description

1 b Logging status: 0=active, 1=inactive

2 b Logging mode: 0=non cyclic, 1=cyclic

3 b Set 1 to delete the device logging memory. Bit zeroing is automatic.

4 b Buzzer activation in case of measurement alarm: 0=no, 1=yes

HD50 - 10 - V1.0

Address Type Coil description

9 b

Protection of configuration with password: 0=no, 1=yes

Changing the parameter requires the Administrator password (see Holding

Register 10036).

Input Registers - Read-only parameters

Address Type Input Register description

Measured values and status of measurement alarms

0 SW TEMPERATURE in the set measurement unit (x10).

1 B

Alarm for temperature:

0=OFF, 1= lower threshold alarm, 2= higher threshold alarm

2 SW RELATIVE HUMIDITY in % (x10).

3 B

Relative humidity alarm:

0=OFF, 1=lower threshold alarm, 2=higher threshold alarm.

4 SW DEW POINT in the set measurement unit (x10).

5 B

Dew Point alarm:

0=OFF, 1=lower threshold alarm, 2=higher threshold alarm.

6 SW PARTIAL VAPOR PRESSURE in hPa (x100).

7 B

Partial vapor pressure alarm:

0=OFF, 1=lower threshold alarm, 2=higher threshold alarm.

8 SW MIXING RATIO in g/Kg (x10).

9 B

Mixing ratio alarm:

0=OFF, 1=lower threshold alarm, 2=higher threshold alarm.

10 SW ABSOLUTE HUMIDITY in g/m3(x10).

11 B

Absolute humidity alarm:

0=OFF, 1=lower threshold alarm, 2=higher threshold alarm.

12 SW WET BULB TEMPERATURE in the set measurement unit (x10).

13 B

Wet bulb temperature alarm:

0=OFF, 1=lower threshold alarm, 2=higher threshold alarm.

18 SW SOLAR RADIATION in W/m2.

19 B

Alarm for solar radiation:

0=OFF, 1=lower threshold alarm, 2=higher threshold alarm.

20 SW ILLUMINANCE in lux.

21 B

Illuminance alarm:

0=OFF, 1=lower threshold alarm, 2=higher threshold alarm.

24 SW

ATMOSPHERIC PRESSURE in the set measurement unit (the multiplier de-

pends on the set unit).

25 B

Atmospheric pressure alarm:

0=OFF, 1=lower threshold alarm, 2=higher threshold alarm.

30 SW DAILY SOLAR RADIATION in Wh/m2.

31 B

Alarm for daily solar radiation:

0=OFF, 1=lower threshold alarm, 2=higher threshold alarm.

32 SW CO2in ppm.

33 B

CO2 alarm:

0=OFF, 1=lower threshold alarm, 2=higher threshold alarm.

86 SW RAIN RATE in counts/h.

87 B

Rain rate alarm:

0=OFF, 1=lower threshold alarm, 2=higher threshold alarm.

88 SW DAILY RAIN in counts.

89 B

Daily rain alarm:

0=OFF, 1=lower threshold alarm, 2=higher threshold alarm.

HD50 - 11 - V1.0

Address Type Input Register description

92 SW WIND SPEED (HD52.3D anemometer) in m/s (x100).

93 B

Wind speed (HD52.3D anemometer) alarm:

0=OFF, 1=lower threshold alarm, 2=higher threshold alarm.

94 SW WIND DIRECTION (HD52.3D anemometer) in degrees (x10).

95 B

Wind direction (HD52.3D anemometer) alarm:

0=OFF, 1=lower threshold alarm, 2=higher threshold alarm.

118 SW AIR SPEED (HD404…SR transmitter) in m/s (x100).

119 B

Air speed (HD404…SR transmitter) alarm:

0=OFF, 1=lower threshold alarm, 2=higher threshold alarm.

122 SW RAINFALL QUANTITY IN THE LAST HOUR in counts.

123 B

Alarm for rainfall quantity in the last hour:

0=OFF, 1=lower threshold alarm, 2=higher threshold alarm.

Measurement units and resolution

5000 W TEMPERATURE unit of measurement: 0=°C, 1=°F.

5004 W DEW POINT unit of measurement: 0=°C, 1=°F.

5012 W WET BULB TEMPERATURE unit of measurement: 0=°C, 1=°F.

5021 SW ILLUMINANCE resolution: -2=100, -1=10, 0=1

5024 W ATMOSPHERIC PRESSURE unit of measurement: see the table of indexes

5025 SW

ATMOSPHERIC PRESSURE resolution:

…, -2=100, -1=10, 0=1, 1=0.1, 2=0.01, …

5052 W WIND SPEED measurement unit: see TAB 12.1

5053 SW

WIND SPEED resolution:

…, -2=100, -1=10, 0=1, 1=0.1, 2=0.01, …

General information

10000 W Year of last measurement.

10001 W Month of last measurement.

10002 W Day of last measurement.

10003 W Hour of last measurement.

10004 W Minutes of last measurement.

10005 W Seconds of last measurement.

10013 W

Password level for the current connection:

0=no password, 1=user level, 2= administrator level

Holding Registers - Read/Write parameters

Address Type Holding Register description

Measurement alarm thresholds

0 SW TEMPERATURE lower alarm threshold in the set measurement unit (x10).

1 SW Temperature higher alarm threshold in the set measurement unit (x10).

2 SW RH lower alarm threshold in % (x10).

3 SW RH higher alarm threshold in % (x10).

4 SW DEW POINT lower alarm threshold in the set measurement unit (x10).

5 SW Dew point higher alarm threshold in the set measurement unit (x10).

6 SW PARTIAL VAPOR PRESSURE lower alarm threshold in hPa (x100).

7 SW Partial vapor pressure higher alarm threshold in hPa (x100).

8 SW MIXING RATIO lower alarm threshold in g/Kg (x10).

9 SW Mixing ratio higher alarm threshold in g/Kg (x10).

10 SW ABSOLUTE HUMIDITY lower alarm threshold in g/m3(x10).

11 SW Absolute humidity higher alarm threshold in g/m3(x10).

HD50 - 12 - V1.0

Address Type Holding Register description

12 SW

WET BULB TEMPERATURE lower alarm threshold in the set measurement unit

(x10).

13 SW

Wet bulb temperature higher alarm threshold in the set measurement unit

(x10).

18 SW Lower alarm threshold for SOLAR RADIATION in W/m2.

19 SW Higher alarm threshold for solar radiation in W/m2.

20 SW ILLUMINANCE lower alarm threshold in lux.

21 SW Illuminance higher alarm threshold in lux

24 SW

ATMOSPHERIC PRESSURE lower alarm threshold in the set measurement unit

(the multiplier depends on the set unit).

25 SW

Atmospheric pressure higher alarm threshold in the set measurement unit

(the multiplier depends on the set unit).

30 SW Lower alarm threshold for DAILY SOLAR RADIATION in Wh/m2.

31 SW Higher alarm threshold for daily solar radiation in Wh/m2.

32 SW CO2lower alarm threshold in ppm.

33 SW CO2higher alarm threshold in ppm.

86 SW RAIN RATE lower alarm threshold in counts/h.

87 SW

Rain rate higher alarm threshold in counts/h.

88 SW DAILY RAIN lower alarm threshold in counts.

89 SW

Daily rain higher alarm threshold in counts.

92 SW

WIND SPEED (ultrasonic anemometer) lower alarm threshold in m/s

(x100).

93 SW

Wind speed (ultrasonic anemometer) higher alarm threshold in m/s

(x100).

94 SW

WIND DIRECTION (ultrasonic anemometer) lower alarm threshold in de-

grees (x10).

95 SW

Wind direction (ultrasonic anemometer) higher alarm threshold in degrees

(x10).

118 SW AIR SPEED (HD404…SR transmitter) lower alarm threshold in m/s (x100).

119 SW

Air speed (HD404…SR transmitter) higher alarm threshold in m/s (x100).

122 SW Lower alarm threshold for RAINFALL QUANTITY IN THE LAST HOUR in counts.

123 SW

Higher alarm threshold for rainfall quantity in the last hour in counts.

General information

da 10000

a 10019 B User code with ASCII codification.

Acceptable values are in the set {32,…,126}.

10020 W Current year

10021 W Current month

10022 W Current day

10023 W Current hour

10024 W Current minute

10025 W Current second

10026 W

Measurement interval: 0=1s, 1=2s, 2=5s, 3=10s, 4=15s, 5=30s, 6=1min,

7=2min, 8=5min, 9=10min, 10=15min, 11=30min, 12=1h

10027 W

Logging interval: 0=1s, 1=2s, 2=5s, 3=10s, 4=15s, 5=30s, 6=1min, 7=2min,

8=5min, 9=10min, 10=15min, 11=30min, 12=1h

10036 W

Password to be supplied to enable configuration change commands. The

reading provides the fixed value 32768.

da 10037

a 10046 B Device group with ASCII codification.

Acceptable values are in the set {32,…,126}.

HD50 - 13 - V1.0

Address Type Holding Register description

da 20000

a 20011 B User code with ASCII codification of measurement #1.

da 20012

a 20023 B User code with ASCII codification of measurement #2.

da 20024

a 20035 B User code with ASCII codification of measurement #3.

da 20036

a 20047 B User code with ASCII codification of measurement #4.

da 20048

a 20059 B User code with ASCII codification of measurement #5.

da 20060

a 20071 B User code with ASCII codification of measurement #6.

da 20072

a 20083 B User code with ASCII codification of measurement #7.

da 20084

a 20095 B User code with ASCII codification of measurement #8.

da 20096

a 20107 B User code with ASCII codification of measurement #9.

da 20108

a 20119 B User code with ASCII codification of measurement #10.

da 20120

a 20131 B User code with ASCII codification of measurement #11.

da 20132

a 20143 B User code with ASCII codification of measurement #12.

HD50 - 14 - V1.0

6TECHNICAL CHARACTERISTICS

Measuring interval 1, 2, 5, 10, 15, 30 s / 1, 2, 5, 10, 15, 30, 60 min

(Note: the minimum interval may be greater than 1 s if the instrument

acquires several sensors)

Logging interval 1, 2, 5, 10, 15, 30 s / 1, 2, 5, 10, 15, 30, 60 min

(Note: the minimum interval may be greater than 1 s if the instrument

acquires several sensors)

Internal memory Circular management or stop logging if memory is full.

Number of storable samples from 259,000 a 890,500 depending

on the number of acquired quantities.

Interfaces ETHERNET (RJ45 connector) with proprietary TCP/IP or Modbus

TCP/IP protocol

USB (mini-USB connector)

Master RS485 Modbus-RTU (for acquiring the sensors)

Alarm Acoustic by means of the internal buzzer and sending of e-mails

Power supply External 7…30 Vdc

Consumption 40 mA @ 24 Vdc

LED indicators Power supply and LAN connection

Operating temperature/

humidity -10…+60 °C / 0…85 %RH non-condensing

Housing Plastic material

Weight 200 g approx.

Installation 35 mm DIN rail

Dimensions (mm)

The measurement characteristics depend on the sensors connected.

3 moduli DIN

HD50 - 15 - V1.0

7INSTRUMENT STORAGE

Conditions for storage of the instrument:

•Temperature: -20...+70 °C.

•Humidity: below 90 %RH no condensation.

•When storing, avoid places where:

•humidity is high;

•instrument is exposed to direct solar radiation;

•instrument is exposed to high temperature source;

•there are strong vibrations;

•there is vapor, salt and/or corrosive gas.

8SAFETY INSTRUCTIONS

General safety instructions

The instrument has been manufactured and tested in compliance with the safety stan-

dard EN61010-1:2010 “Safety requirements for electrical equipment for measurement,

control and laboratory use” and left the factory in a safe and secure technical condition.

The proper operation and the operational safety of the instrument can be ensured on-

ly if all the regular security measures are observed as well as the specific measures

described in this operating manual.

The proper operation and the operational safety of the instrument can be ensured on-

ly under the climatic conditions specified in this manual.

Do not use the instrument in places where there are:

•Rapid ambient temperature variations that may cause condensation.

•Corrosive or flammable gases.

•Direct vibrations, shocks to the instrument.

•High-intensity electromagnetic fields, static electricity.

If the instrument is moved from a cold environment to a hot one or vice versa, the

formation of condensation might cause problems to its operation. In this case you

need to wait for the instrument temperature to reach ambient temperature before op-

eration.

User obligations

The user of the instrument must make sure that the following regulations and direc-

tives related to the handling of hazardous materials are fulfilled:

•European directives on safety and health at work.

•National regulations on safety and health at work.

•Accident prevention regulations.

HD50 - 16 - V1.0

9ORDERING CODES

HD50R_MB Data logger with Master RS485 Modbus-RTU interface for acquiring

sensors with RS485 Modbus-RTU output. A proprietary protocol is also

available for connecting anemometers of the HD2003 series. A voltage-

free contact input allows connecting a tipping bucket rain gauge. USB

and Ethernet (proprietary TCP/IP or Modbus TCP/IP protocol) connec-

tion. Measurements are transmitted to an FTP address, to the Cloud and

via e-mail. Acoustic alarm with internal buzzer and sending of alarm e-

mails. External power supply 7…30 Vdc. 35 mm DIN rail installation.

HD35AP-S and HDServer1 softwares downloadable from Delta OHM

web site are included.

The probes and the CP23 USB cable have to be ordered separately.

The Ethernet cable is not included.

Accessories

HD35AP-CFR21 Software option that adds to the features of the basic software (both

HD35AP-S and HDServer1), the management of the data logging

system in accordance with the FDA 21 CFR part 11 recommenda-

tions. For Windows®operating systems.

CP23 Direct USB connection cable with mini-USB connector on the instru-

ment side and A type USB connector on the PC side. Cable length

1.5 m.

DELTA OHM metrology laboratories LAT N° 124 are ISO/IEC 17025 accredited by AC-

CREDIA for Temperature, Humidity, Pressure, Photometry / Radiometry, Acoustics and

Air Velocity. They can supply calibration certificates for the accredited quantities.

HD50 - 17 - V1.0

NOTES

HD50 - 18 - V1.0

NOTES

GUARANTEE

TERMS OF GUARANTEE

All DELTA OHM instruments are subject to accurate testing, and are guaranteed for 24 months from the

date of purchase. DELTA OHM will repair or replace free of charge the parts that, within the warranty

period, shall be deemed non efficient according to its own judgement. Complete replacement is excluded

and no damage claims are accepted. The DELTA OHM guarantee only covers instrument repair. The

guarantee is void in case of incidental breakage during transport, negligence, misuse, connection to a

different voltage than that required for the appliance by the operator. Finally, a product repaired or

tampered by unauthorized third parties is excluded from the guarantee. The instrument shall be returned

FREE OF SHIPMENT CHARGES to your dealer. The jurisdiction of Padua applies in any dispute.

The electrical and electronic equipment marked with this symbol cannot be disposed of in public

landfills. According to the Directive 2011/65/EU, the european users of electrical and electronic

equipment can return it to the dealer or manufacturer upon purchase of a new one. The illegal

disposal of electrical and electronic equipment is punished with an administrative fine.

This guarantee must be sent together with the instrument to our service centre.

IMPORTANT: Guarantee is valid only if coupon has been correctly filled in all details.

Instrument Code: HD50R-MB

Serial Number

RENEWALS

Date Date

Inspector Inspector

Date Date

Inspector Inspector

Date Date

Inspector Inspector

Table of contents

Other Delta OHM Data Logger manuals

Delta OHM

Delta OHM HD37B17D User manual

Delta OHM

Delta OHM DO2003 User manual

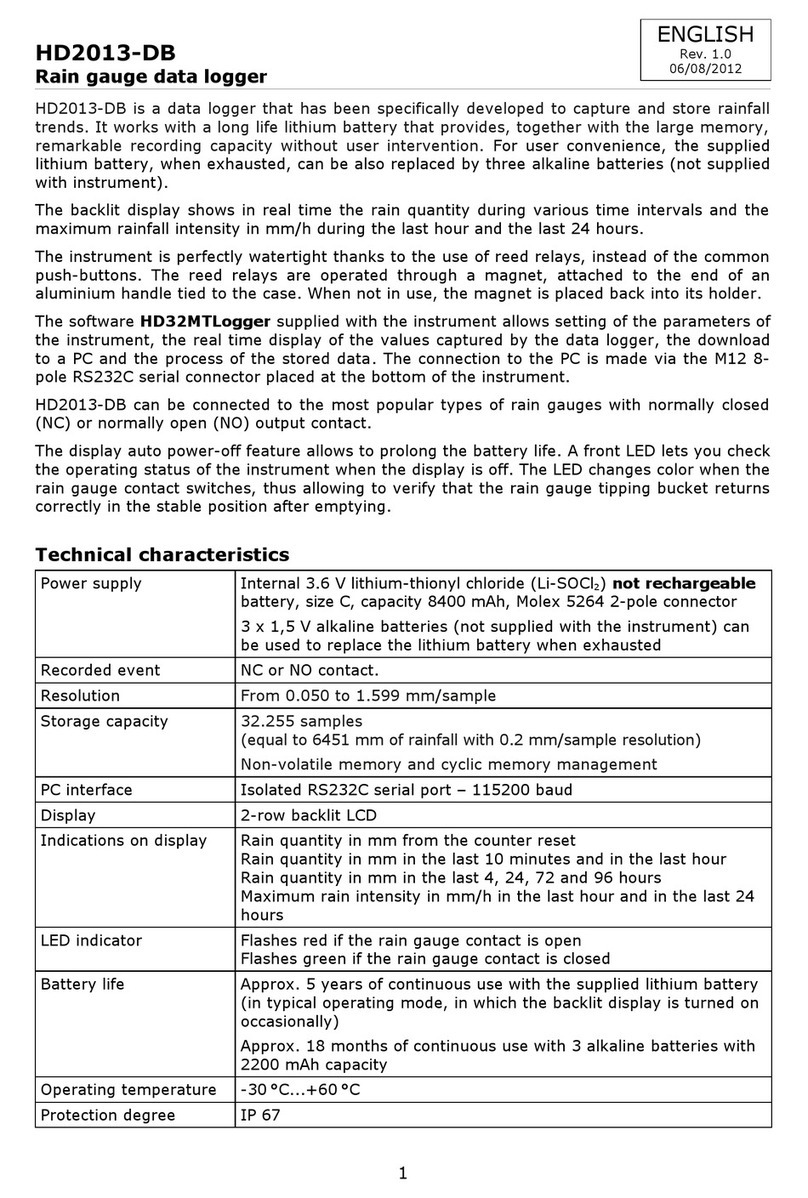

Delta OHM

Delta OHM HD2013-DB User manual

Delta OHM

Delta OHM HD50CR-AS User manual

Delta OHM

Delta OHM DO 9847K User manual

Delta OHM

Delta OHM HD33M-MB.2 User manual

Delta OHM

Delta OHM HD 2013 Series User manual

Delta OHM

Delta OHM HD32.7 User manual

Delta OHM

Delta OHM HD35 Series User manual

Delta OHM

Delta OHM HD32MT.3 User manual