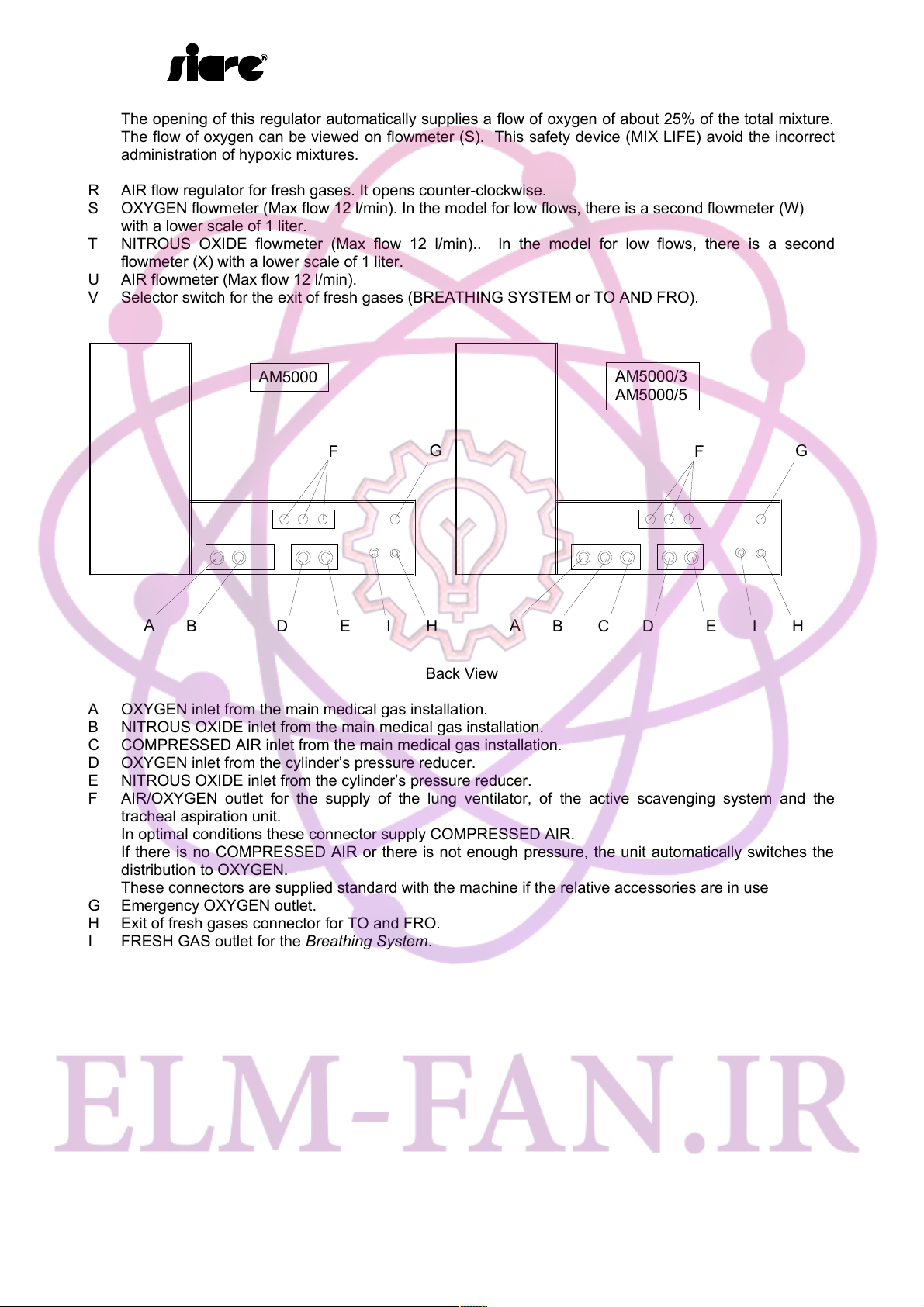

AM5000 – AM5000/3 – AM5000/5

Service Manual

The flowmeters should be handled with care, and should be wrapped in the paper in which

they were shipped , not with nylon.

Do not rube them with your hands, fabric or paper.

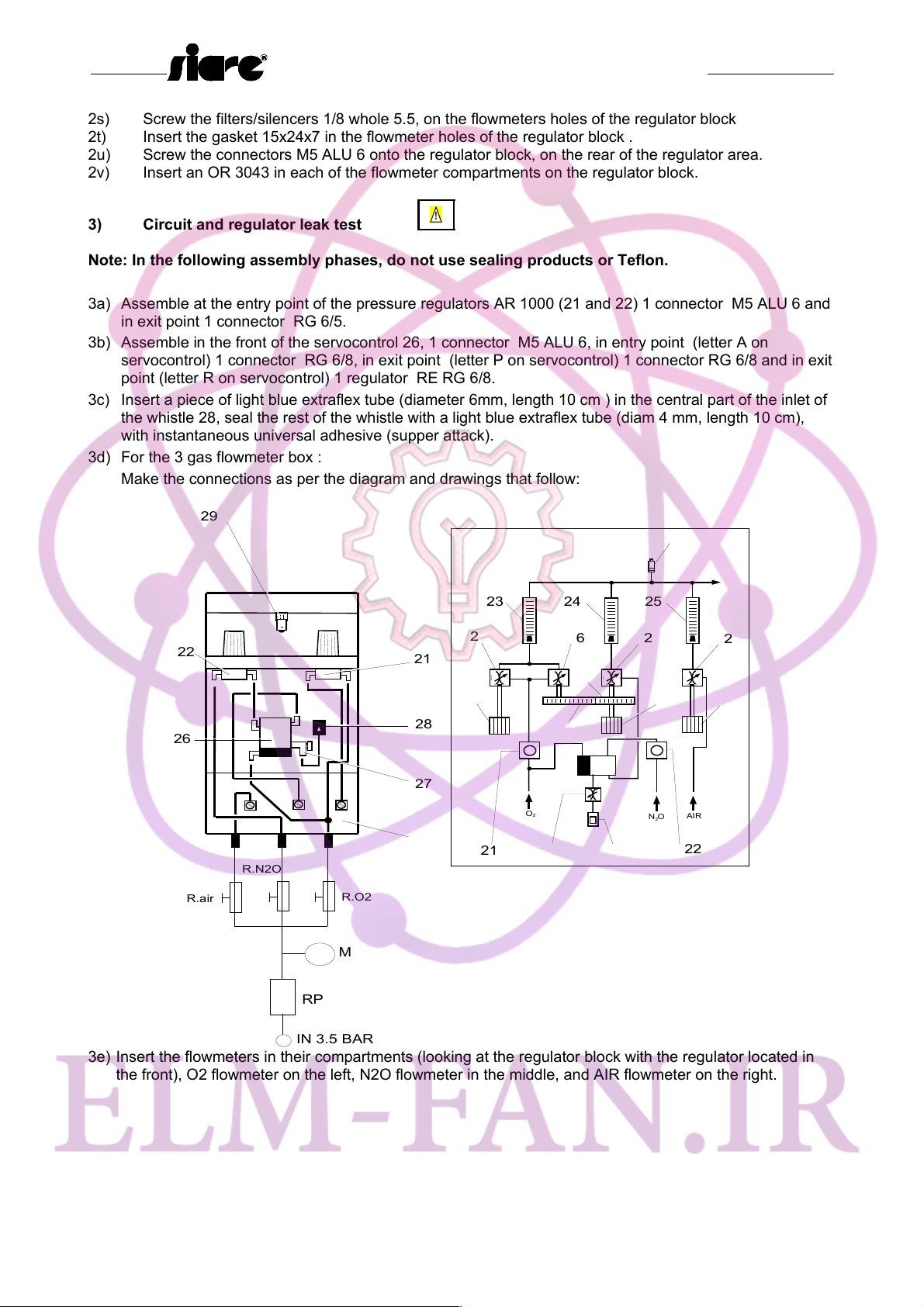

3f) All the tarring and flowmeter check hould be done with compre ed air at 3.5 bar.

3g) With the flow regulator clo ed, regulate the pre ure of the oxygen (21) at 2 bar and that of the nitrou

oxide (22) at 1.4 bar. In ert and remove the compre ed air upply 3 time o that the reducer are

tabilized, if nece ary correct the regulation.

3h) The leak te t hould be checked in two point :

1) - down from the valve (2, 6) in order to check the proper that there are not leak in the clo ure of

the valve .

2) - up from the valve (2, 6) in order to check the proper that there are not leak in the pneumatic

circuit.

1) Verify that the leak of each valve connecting the flowmeter corre ponding to a low flow gauger. The

mea ured leak hould not be higher than 20 ml/min. for the O2, N2O, Air.

The lack of ignificant leak hould be guaranteed without forcing the regulator.

If there i a ignificant leak it can be due to two factor

-a manufacturing defect that affect the hold of the pin (thi i the mo t probable cau e).

In thi ca e it i nece ary to repeat the preparation for operation of the regulator. If after two trie the

hold of the group BODY- PIN (2-4 or 6-7) it hould be replaced

- manufacturing defect that affect the hold of one of the o-ring (check that their urface i not damaged

during the a embly due to a re idual depo it)

2) Alway with the clo ed flow regulator clo e the air upply up from the control gauge (M) and verify

that the pre ure doe not go lower than 0.5 bar in 1 minute for all the 3 ga line at the ame time.

If the decrea e in pre ure i higher, there i a leak in the pneumatic circuit.

Verify the proper connection of the tube and connector, and if the leak continue u e the leak te ter

with bubble in the point of connection of the connector and on the pre ure reducer .

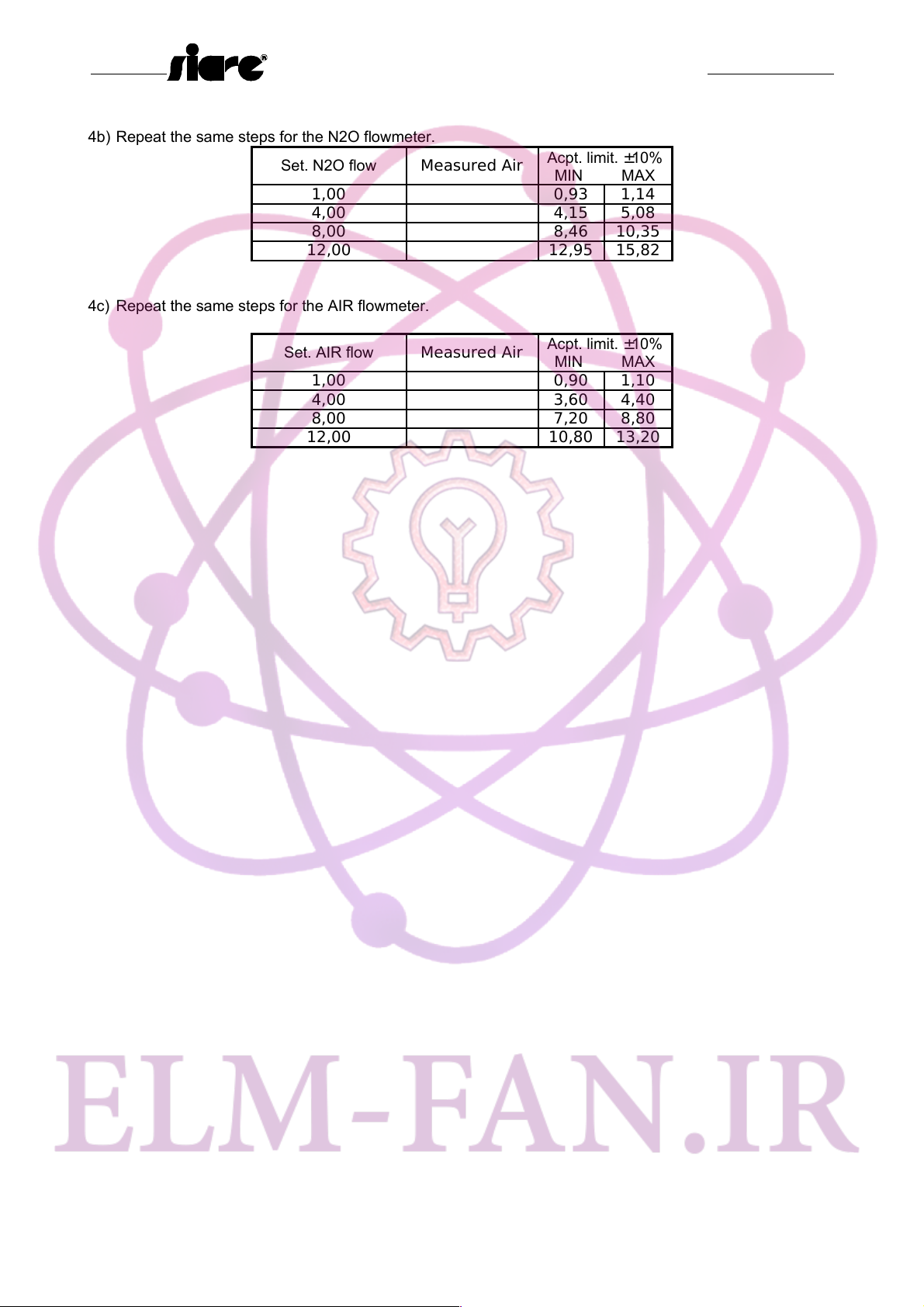

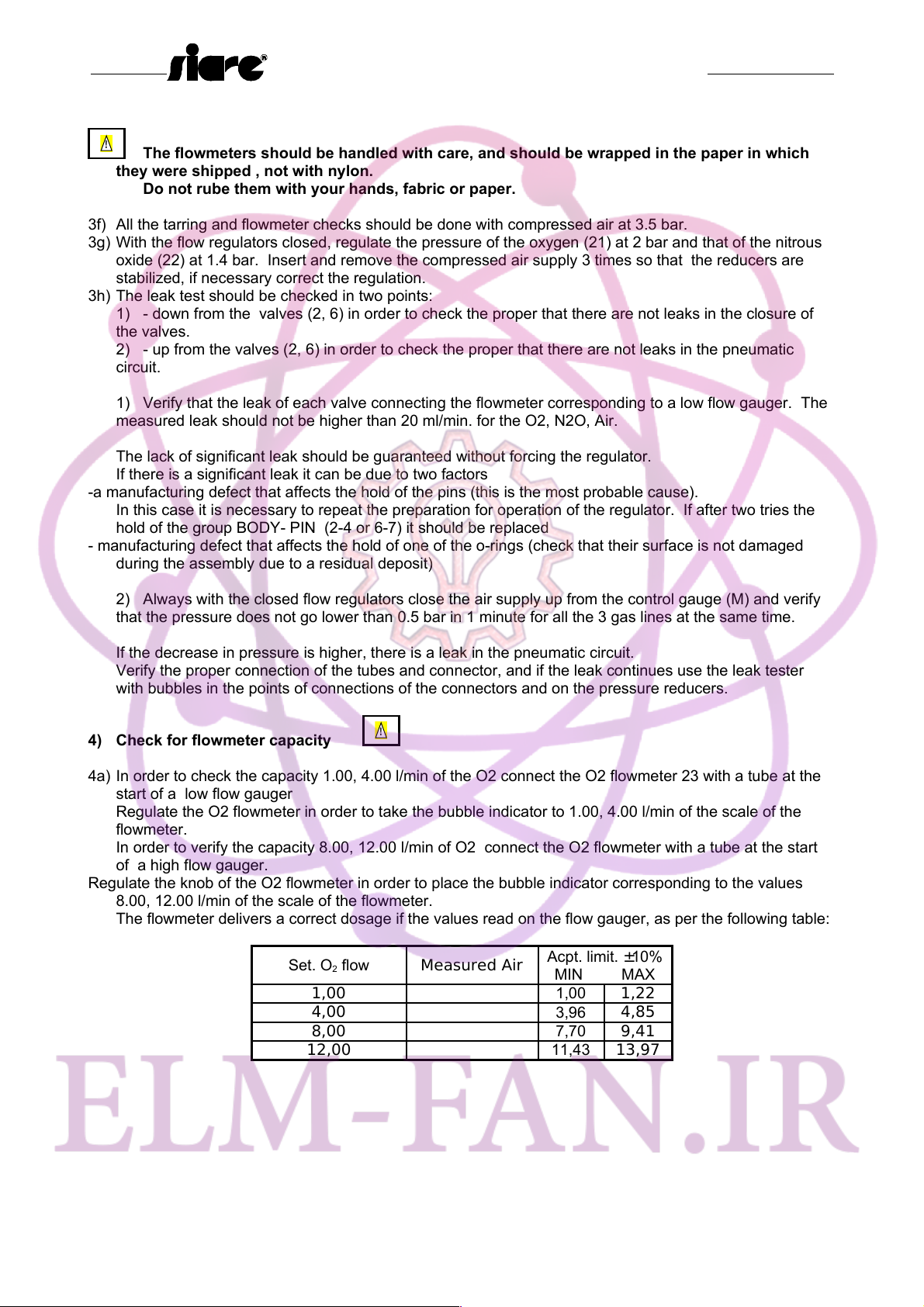

4) Check for flowmeter capacity

4a) In order to check the capacity 1.00, 4.00 l/min of the O2 connect the O2 flowmeter 23 with a tube at the

tart of a low flow gauger

Regulate the O2 flowmeter in order to take the bubble indicator to 1.00, 4.00 l/min of the cale of the

flowmeter.

In order to verify the capacity 8.00, 12.00 l/min of O2 connect the O2 flowmeter with a tube at the tart

of a high flow gauger.

Regulate the knob of the O2 flowmeter in order to place the bubble indicator corre ponding to the value

8.00, 12.00 l/min of the cale of the flowmeter.

The flowmeter deliver a correct do age if the value read on the flow gauger, a per the following table:

Set. O2 flow Me sured Air Acpt. limit. ±10%

MIN MAX

1,00 1,00 1,22

4,00 3,96 4,85

8,00 7,70 9,41

12,00 11,43 13,97

P.N.: DU5506130 Page 17 of 34 Rev.: 3.0

دﯾﯾﺎﻣرﻓ ﮫﻌﺟارﻣ.WWW.ELM-FAN.IRتﯾﺎﺳ ﮫﺑ رﺗﺷﯾﺑ دراوﻣ دوﻠﻧاد یارﺑ

To download more items, go to ELM-FAN.IR